A pvc plastic pipe fitting cutter

A technology of plastic pipe fittings and cutters, which is applied in metal processing and other directions, can solve the problems of tired workers, slow cutting speed, labor-intensive and other problems, and achieve the effect of reducing operation difficulty, avoiding loss, and convenient taking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

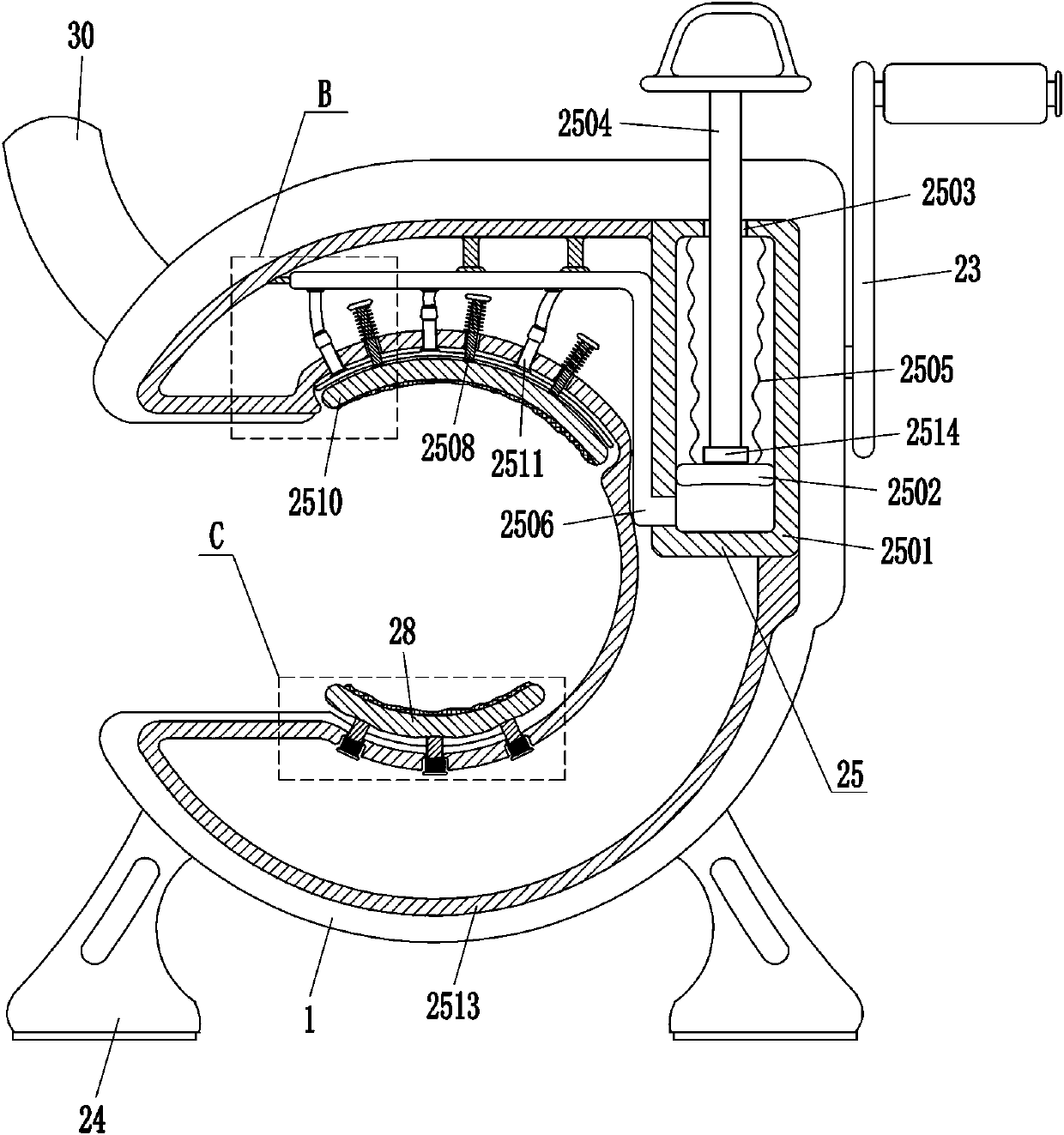

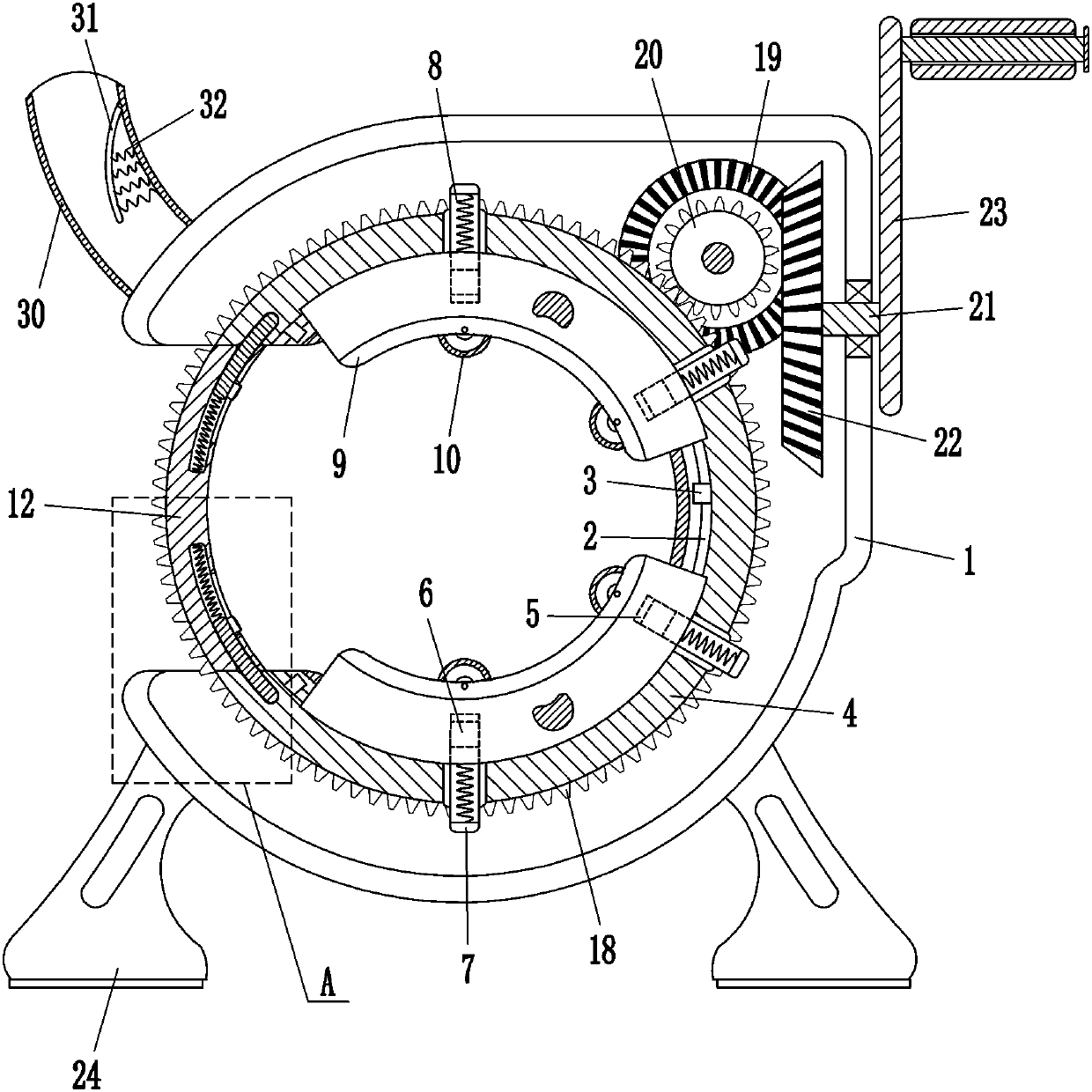

[0017] A PVC plastic pipe fitting cut-off device, such as Figure 1-3 As shown, it includes a large housing 1, a sliding block 3, an annular plate 4, a sliding rail 5, a sliding block 6, a block 7, a first spring 8, an arc block 9, a cutter 10, an arc plate 12, the first Two springs 14, arc-shaped block 15, shifting block 17, tooth block 18, small bevel gear 19, first gear 20, rotating shaft 21, large bevel gear 22, rocking rod 23 and supporting legs 24, the left and right sides of the bottom of the large housing 1 Both sides are fixedly connected with two supporting legs 24, and the large housing 1 is connected with the supporting legs 24 by means of bolts. The rear side of the large housing 1 is provided with a sliding groove 2, and the sliding groove 2 is of sliding type. There are multiple sliding blocks 3, the front side of the sliding block 3 is fixedly connected with the annular plate 4, the sliding block 3 is connected with the annular plate 4 by welding, and the front...

Embodiment 2

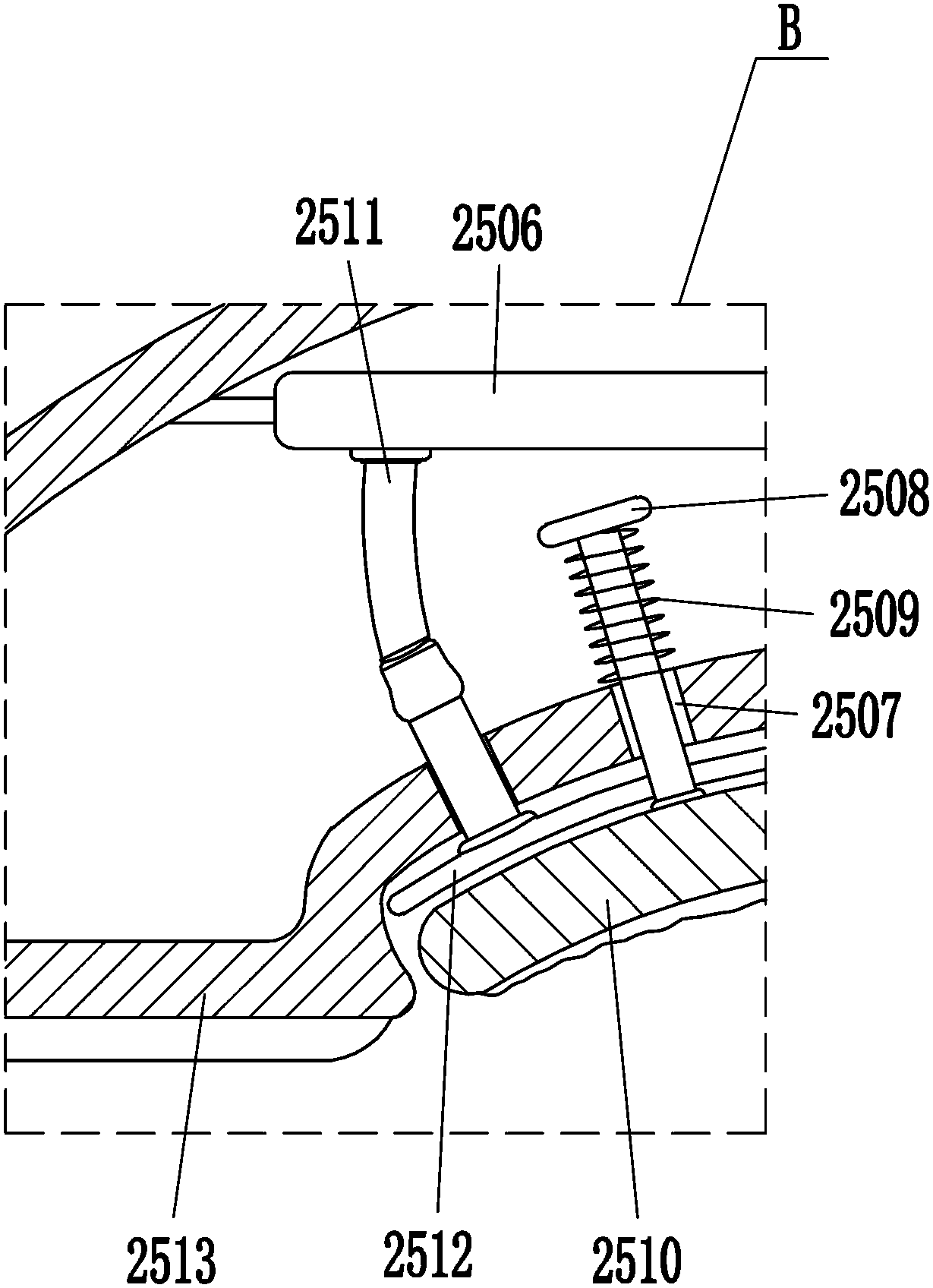

[0019] A PVC plastic pipe fitting cut-off device, such as Figure 1-4 As shown, it includes a large housing 1, a sliding block 3, an annular plate 4, a sliding rail 5, a sliding block 6, a block 7, a first spring 8, an arc block 9, a cutter 10, an arc plate 12, the first Two springs 14, arc-shaped block 15, shifting block 17, tooth block 18, small bevel gear 19, first gear 20, rotating shaft 21, large bevel gear 22, rocking rod 23 and supporting legs 24, the left and right sides of the bottom of the large housing 1 Both sides are fixedly connected with two supporting legs 24, and the rear side of the large housing 1 is provided with a sliding groove 2, and the sliding groove 2 is provided with a plurality of sliding blocks 3, and the front side of the sliding block 3 is fixed There is an annular plate 4, and the front side of the annular plate 4 is evenly spaced and bolted with four slide rails 5 that play a guiding role. The slide rail 5 is slidably provided with a slider 6, ...

Embodiment 3

[0022] A PVC plastic pipe fitting cut-off device, such as Figure 1-5 As shown, it includes a large housing 1, a sliding block 3, an annular plate 4, a sliding rail 5, a sliding block 6, a block 7, a first spring 8, an arc block 9, a cutter 10, an arc plate 12, the first Two springs 14, arc-shaped block 15, shifting block 17, tooth block 18, small bevel gear 19, first gear 20, rotating shaft 21, large bevel gear 22, rocking rod 23 and supporting legs 24, the left and right sides of the bottom of the large housing 1 Both sides are fixedly connected with two supporting legs 24, and the rear side of the large housing 1 is provided with a sliding groove 2, and the sliding groove 2 is provided with a plurality of sliding blocks 3, and the front side of the sliding block 3 is fixed There is an annular plate 4, and the front side of the annular plate 4 is evenly spaced and bolted with four slide rails 5 that play a guiding role. The slide rail 5 is slidably provided with a slider 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com