Staggered overlapping cotton baling method

A cotton, laminated technology, applied in the direction of packaging, transportation packaging, transportation and packaging, etc., to achieve the effect of tight connection, improved efficiency, and improved roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

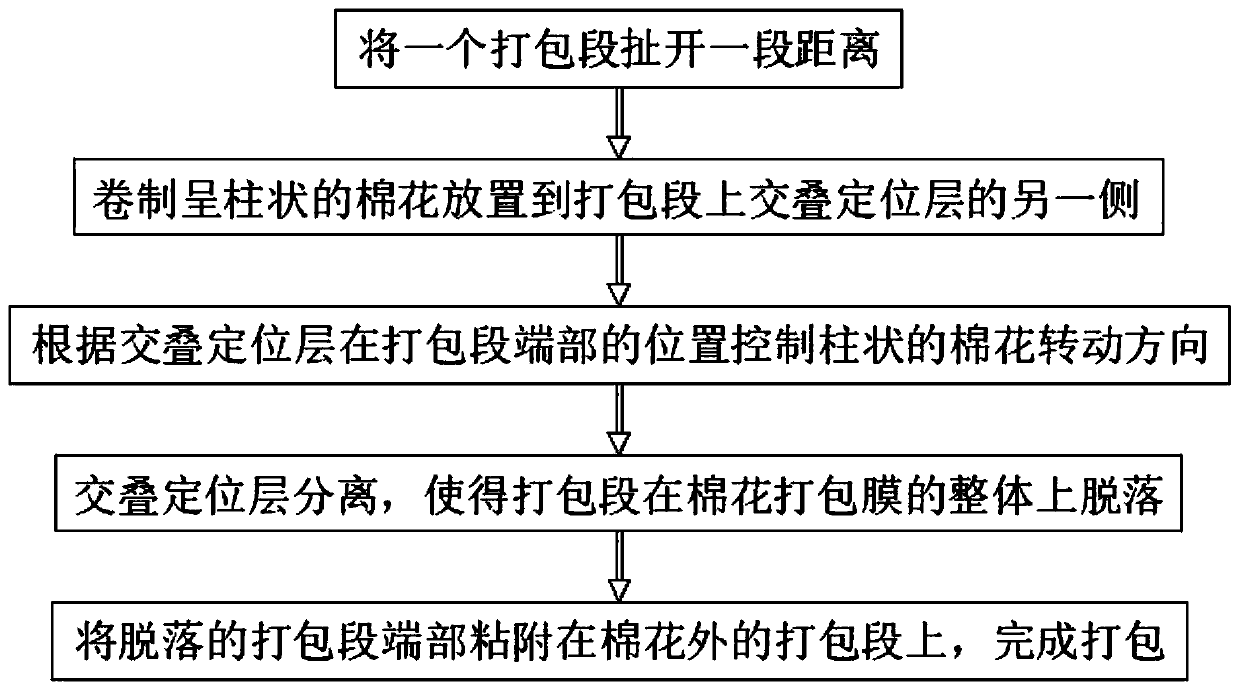

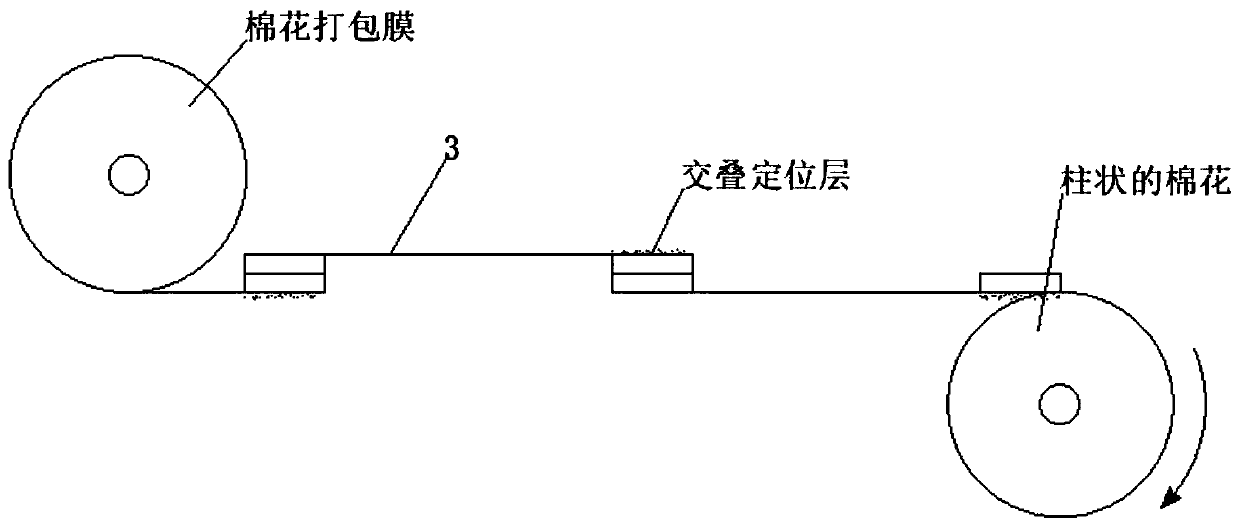

[0049] see figure 1 , a kind of misplaced stacked cotton packing method, comprises the following steps:

[0050] S1, first tear the end of the roll-shaped cotton packing film away from one end, that is, to tear off a packing section 3 for a certain distance;

[0051] S2. Place the rolled cotton in a columnar shape on the other side of the overlapping positioning layer on the packaging section 3;

[0052] S3. Observe the position of the partial structure of the overlapping positioning layer at the end of the packing section 3, and control the rotation direction of the columnar cotton according to the position;

[0053] S4, until a packing section 3 is completely wrapped on the outside of the columnar cotton, resist the roll-shaped cotton packing film and continue to rotate the columnar cotton until the overlapping positioning layer between the two packing sections 3 is separated. At this time, the columnar cotton The packaging section 3 of the cotton wrapping comes off on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com