Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Solve anti-corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

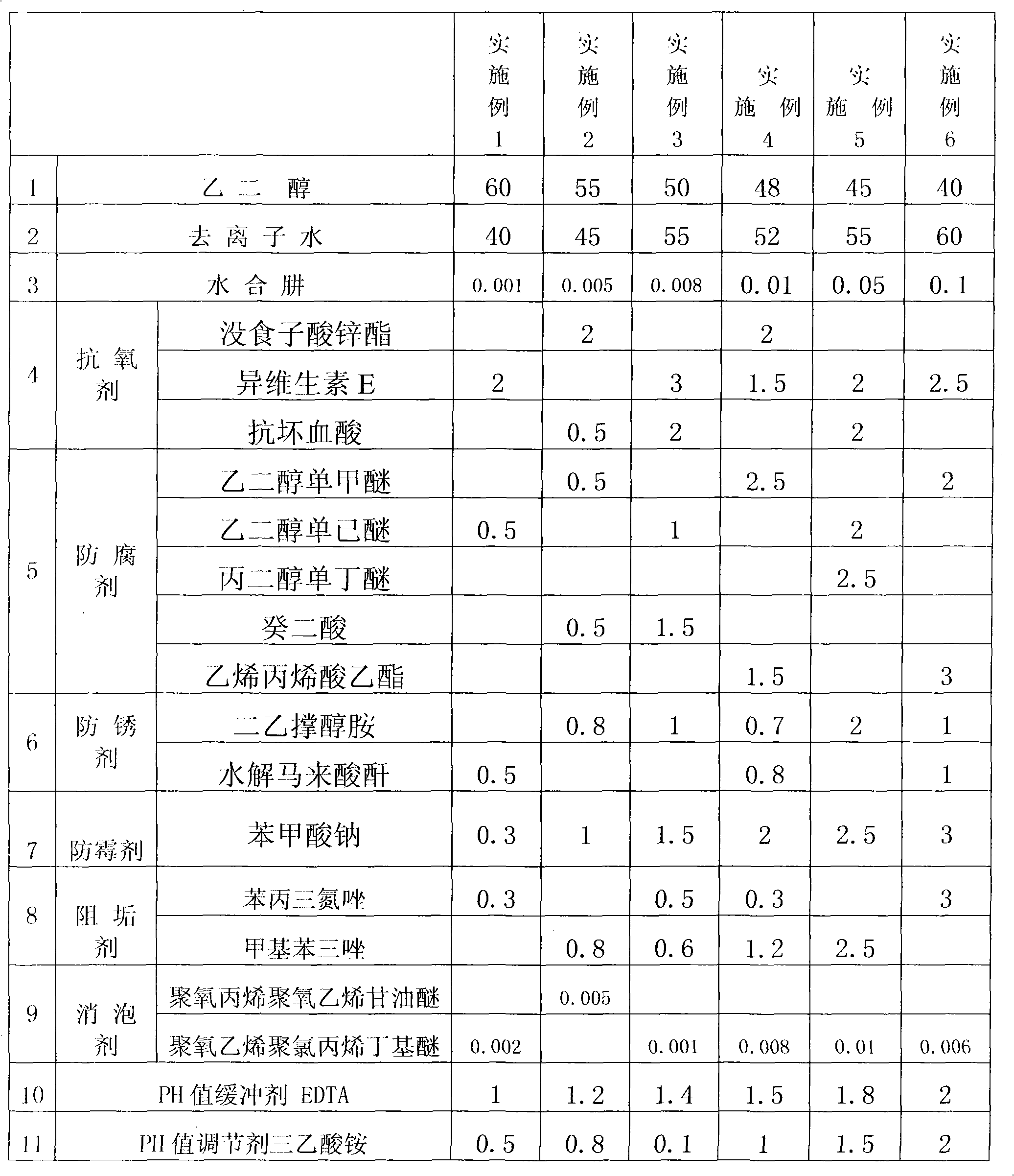

Organic anti-freeze cooling liquid and preparation method thereof

InactiveCN101914369AEliminate free oxygenPrevent oxidationHeat-exchange elementsNon toxicityAntioxidant

The invention discloses a cooling liquid for automobiles, and relates to an organic anti-freeze cooling liquid and a preparation method thereof. The cooling liquid is characterized by comprising 40 to 60 percent of glycol, 60 to 40 percent of de-ionized water and additives, wherein the additives comprise a reducing agent, an antioxidant, an antiseptic, a rust preventative, a mildew inhibitor, a scale inhibitor, a defoaming agent, a pH value buffer and a pH value regulator. The preparation method comprises the following steps of: 1, adding the de-ionized water and the reducing agent into a reactor A and heating the mixture to the boiling point; and 2, squeezing the liquid in the reactor A into a reactor B after the temperature reaches the normal temperature, and adding the glycol and the additives into the reactor B to prepare the anti-freeze cooling liquid. Due to the adoption of hydrazine hydrate in the invention, free oxygen in the de-ionized water is eliminated and the problem of corrosion resistance is solved well; the product meets the requirements on long-term effect, environmental protection, safety and non-toxicity; the cooling liquid has the advantage of low cost of the required raw materials; the preparation method has the advantages of simplicity, a few facilities and low energy consumption, wins warm praise from customers and has extremely high popularization and application value and broad market prospect.

Owner:吉化集团吉林市星云化工有限公司

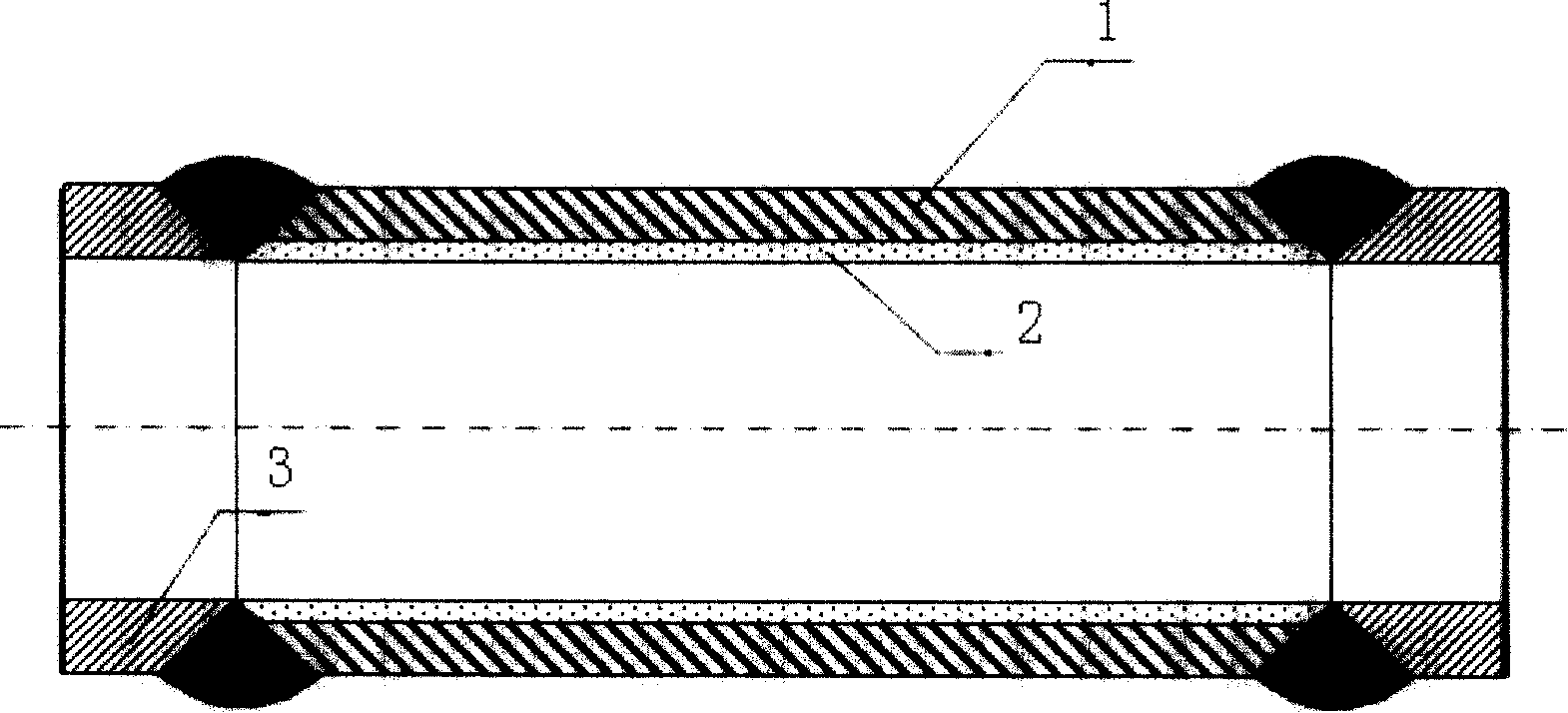

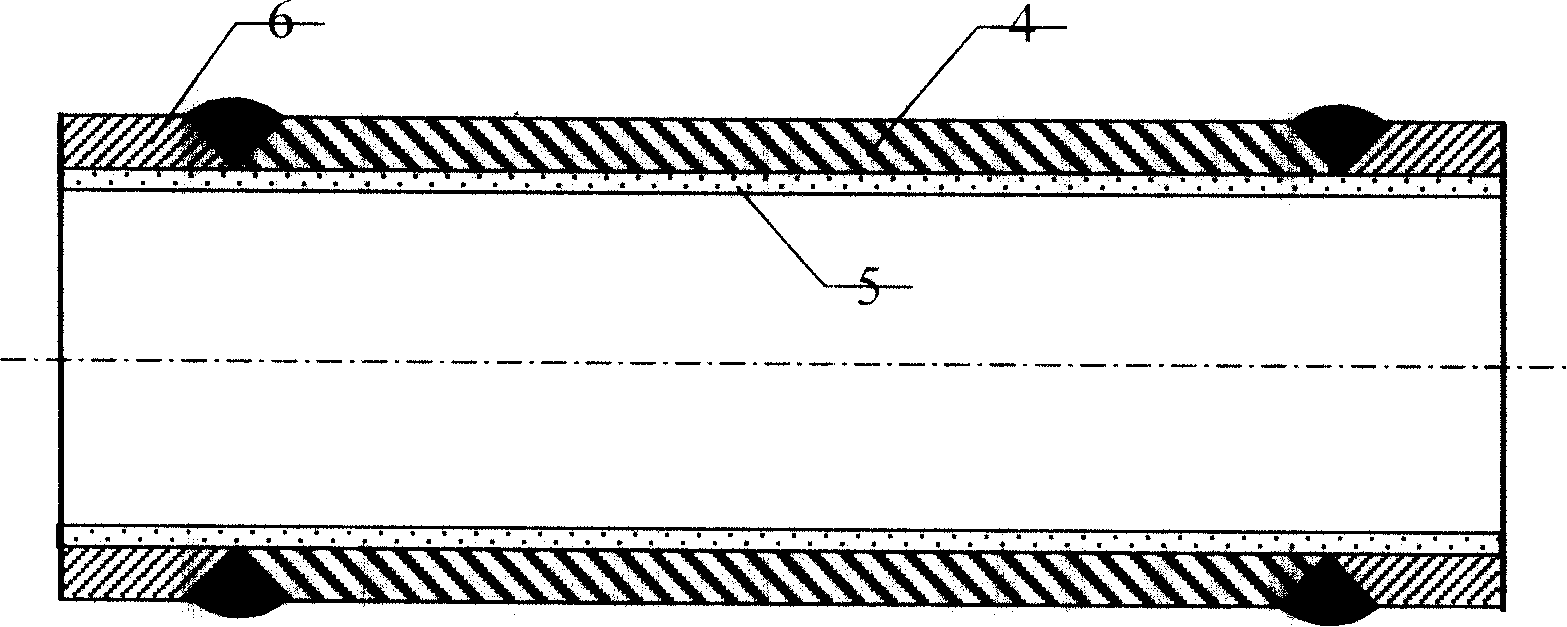

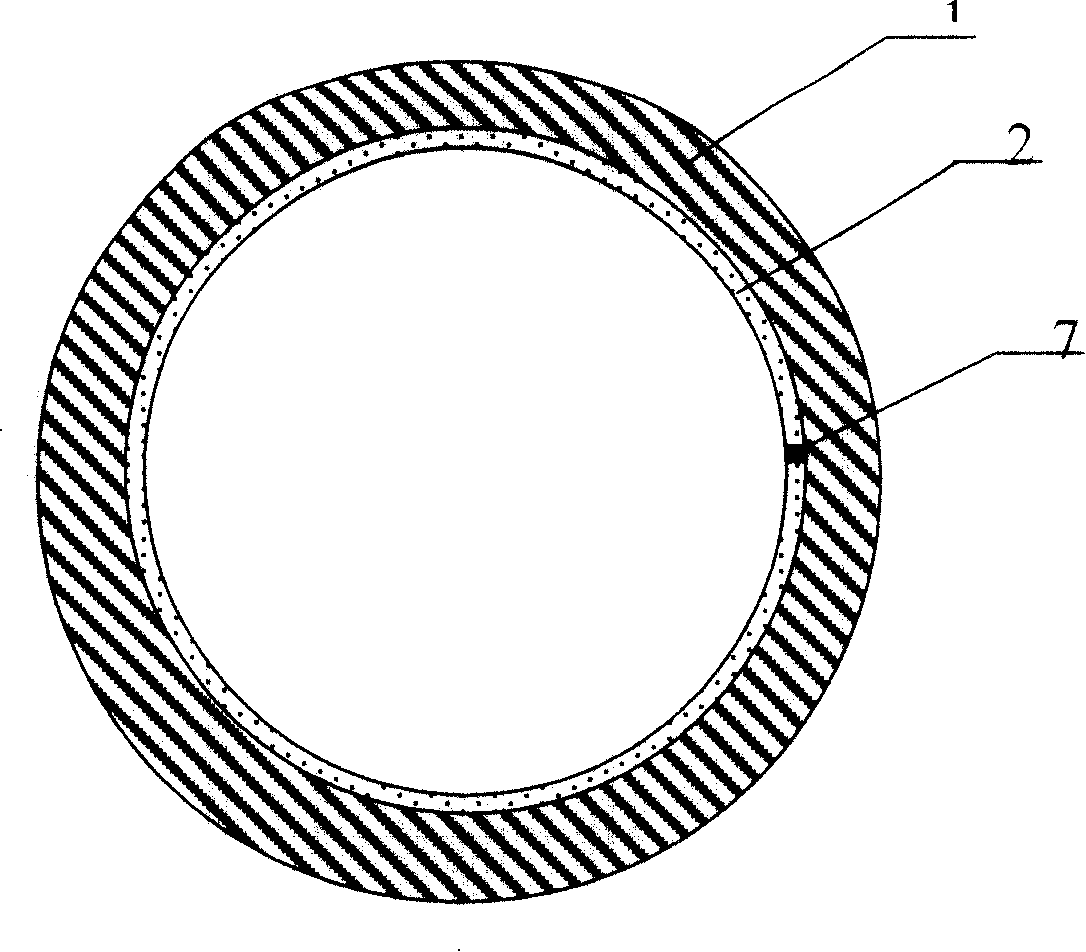

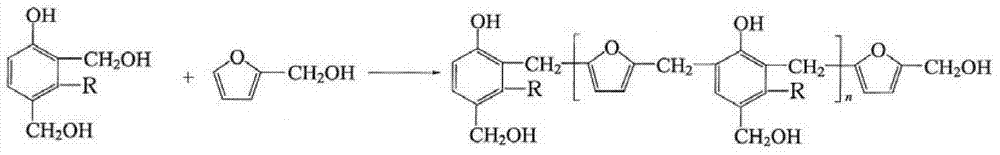

Inner lining anti-corrosion metallic composite pipeline with easy welded joint structure

InactiveCN101205994ASolve anti-corrosionImprove corrosion resistanceLayered productsCorrosion preventionChromium nickelNichrome

The invention relates to a compound tube with internal lining made of corrosion resistant metal, which has end parts and a liner tube made of corrosion resistant metal and an outer body tube made of carbon steel or low alloy steel. The corrosion resistant metal applied in the end parts and the liner tube is used for resisting medium corrosion, while the carbon steel or the low alloy steel applied in the body tube is used for ensuring mechanical strength. When two compound tubes are welded together, a continuous tube made of corrosion resistant metal is formed in the compound tube, thereby ensuring that the whole tube has the corrosion resistance property of the corrosion resistant metal. When the mechanical strength at the joint of the two compound tubes is relatively low, the mechanical strength can be reinforced by (1) improving the wall thickness of the tube joint, (2) applying fiber reinforced composite, or (3) applying clamper filling technology. The liner tube of the invention can be made of corrosion resistant metals like stainless steel, nickel-based alloy, high content nichrome, titanium alloy, etc. The compound tube provided by the invention has good corrosion resistance, easy processing and low cost.

Owner:BEIJING SAFETECH PIPELINE

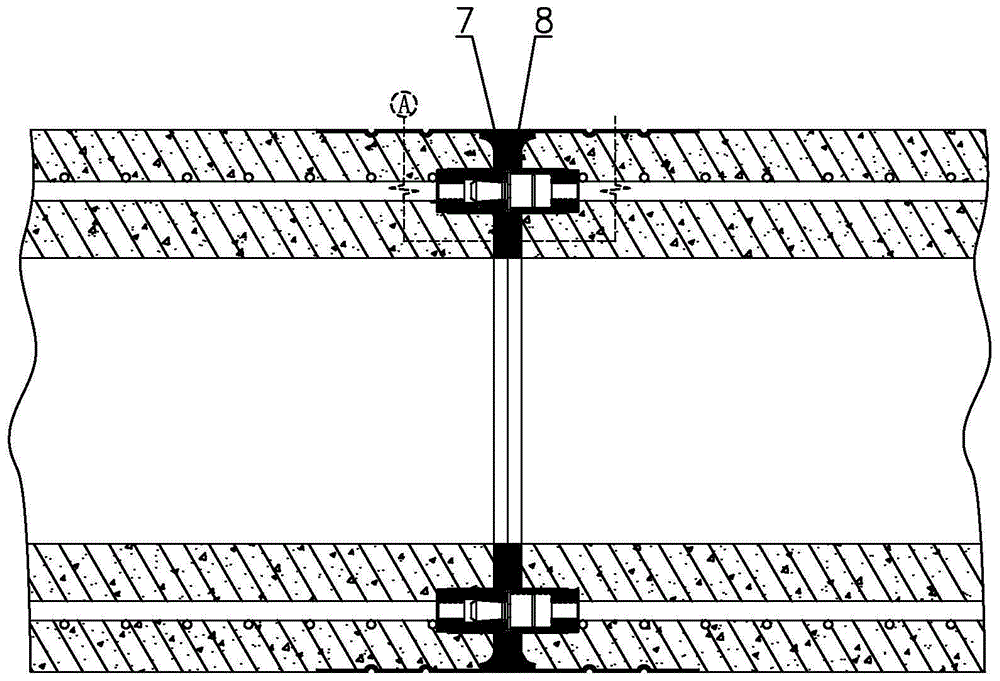

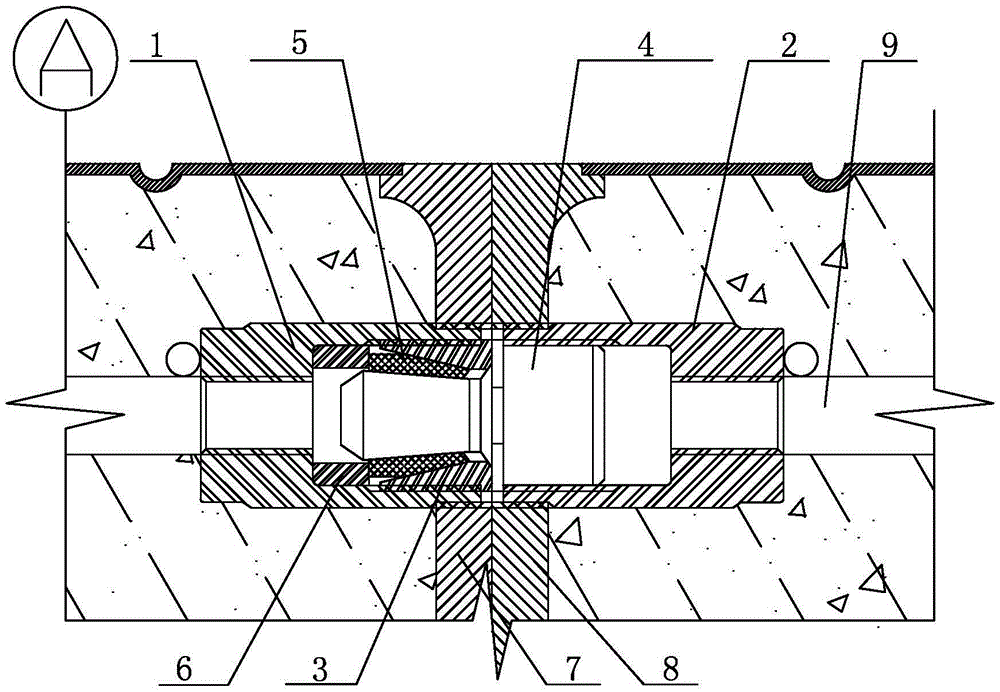

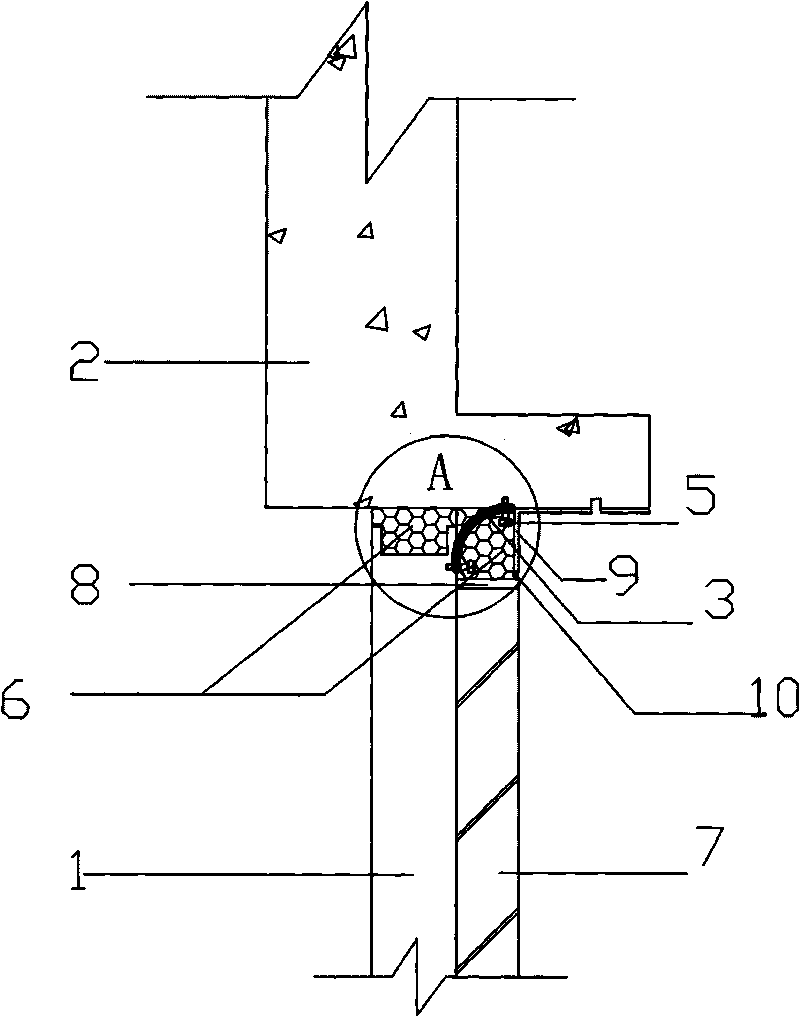

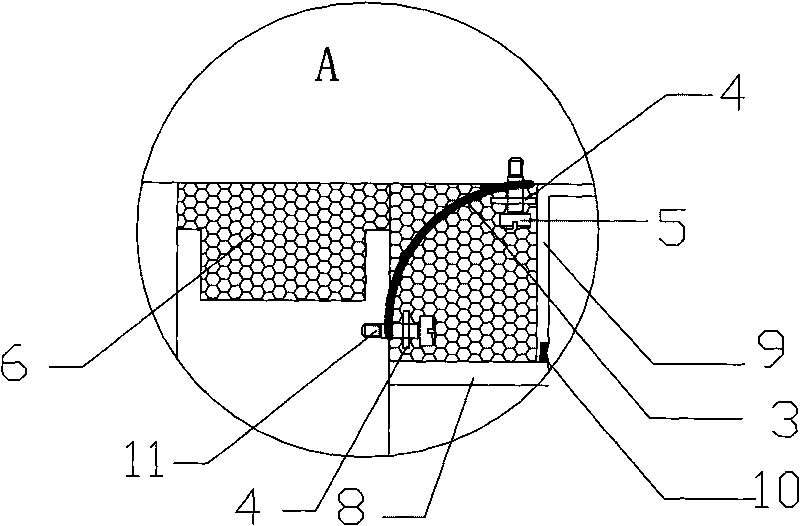

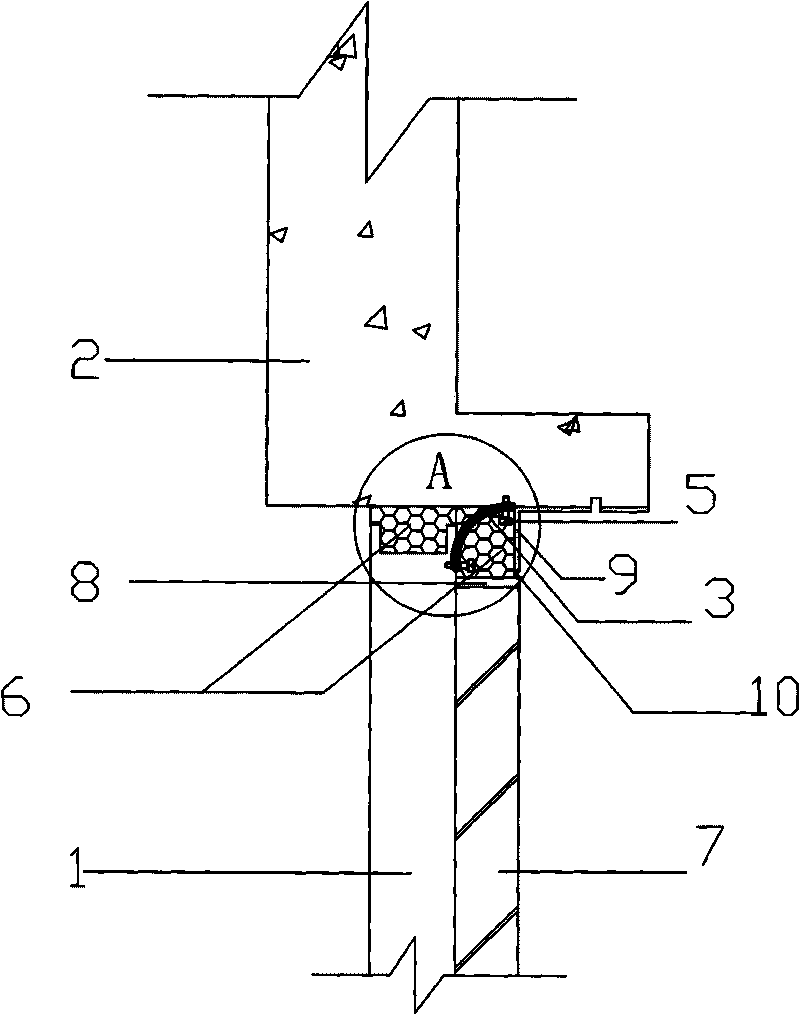

Uplift pile mixed connection structure

ActiveCN105756054AEfficient deliverySolve the problem of impact resistanceBulkheads/pilesAdhesiveStructural engineering

The invention discloses an uplift pile mixed connection structure which comprises a pile head protective sleeve I, a pile head protective sleeve II and a plug connector. The plug connector comprises a first sleeve-shaped fixed positioning sleeve and a second sleeve-shaped fixed positioning sleeve. A clamping piece is arranged in the first fixed positioning sleeve. A plug connection piece is arranged in the second fixed positioning sleeve. The plug connection piece can be inserted into the first fixed positioning sleeve and limited on the clamping piece, and therefore the first pile head protective sleeve and the second pile head protective sleeve can be fixedly connected in a butted mode. Both the first fixed positioning sleeve and the second fixed positioning sleeve are connected with main reinforcement bars and fixedly combined with the pile head protective sleeves through screws. When the uplift pile mixed connection structure is subjected to tensile force, the plug connector effectively connects the upper and lower main reinforcement bars, butt connection of the upper and lower main reinforcing bars on the same axis is achieved, inner stress is effectively transferred, meanwhile, the butted connection faces of the pile head protective sleeve I and the pile head protective sleeve II are in butted connection through a steel adhesive, the uplift resistance is further improved, and the purposes of impact resistance of a pile head end face and shear resistance and corrosion resistance of the connector are thoroughly achieved.

Owner:天海钢棒(张家港)有限公司

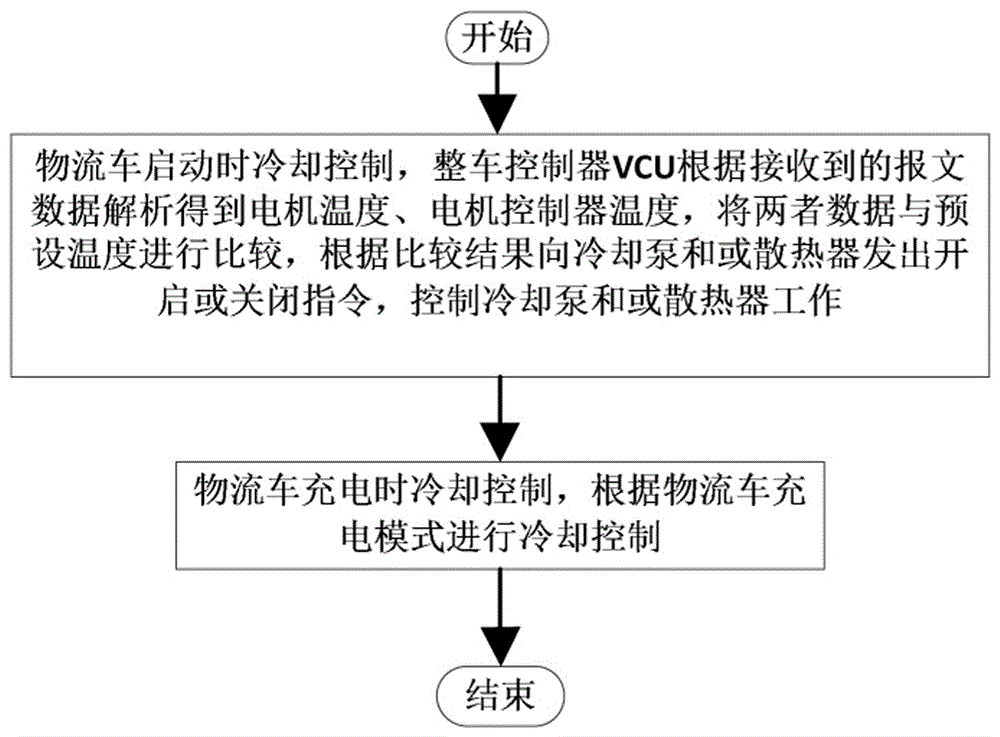

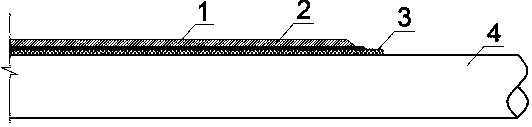

Cooling device of pure-electric logistics vehicle and control method of cooling device

PendingCN106608179AExtended service lifeEffective filteringSpeed controllerPropulsion coolingLogistics managementElectric machine

The invention relates to a cooling device of a pure-electric logistics vehicle and a control method of the cooling device. The cooling device comprises a cooling circuit, a cooling mechanism, a motor controller, a vehicle-mounted charger and a motor, wherein the cooling mechanism, the motor controller, the vehicle-mounted charger and the motor are respectively in signal connection with a vehicle controller unit (VCU); the cooling mechanism comprises a cooling pump, a cooling fluid filter, a radiator and a liquid storing tank which are connected in the cooling circuit in series; the cooling fluid filter adopts a straight-through type cooling fluid filter which communicates with the cooling circuit; cooling fluid for performing circulation to take away heat quantity in the cooling circuit is arranged in the liquid storing tank; and the cooling pump and the radiator are respectively in signal connection with the VCU. According to the cooling device disclosed by the invention, the cooling effect can be quickly and effectively achieved; the energy consumption is reduced; the cost is low; the cooling device is convenient to mount; the normal working of the cooling system is guaranteed; the situation that impurities enter the motor and the controller is avoided; the service life of the motor and the service life of the controller are prolonged; the response time is short and the response is timely; and the service life of the cooling pump and the service life of an electronic fan of the radiator are guaranteed.

Owner:ZHENGZHOU BIKE NEW ENERGY AUTOMOBILE

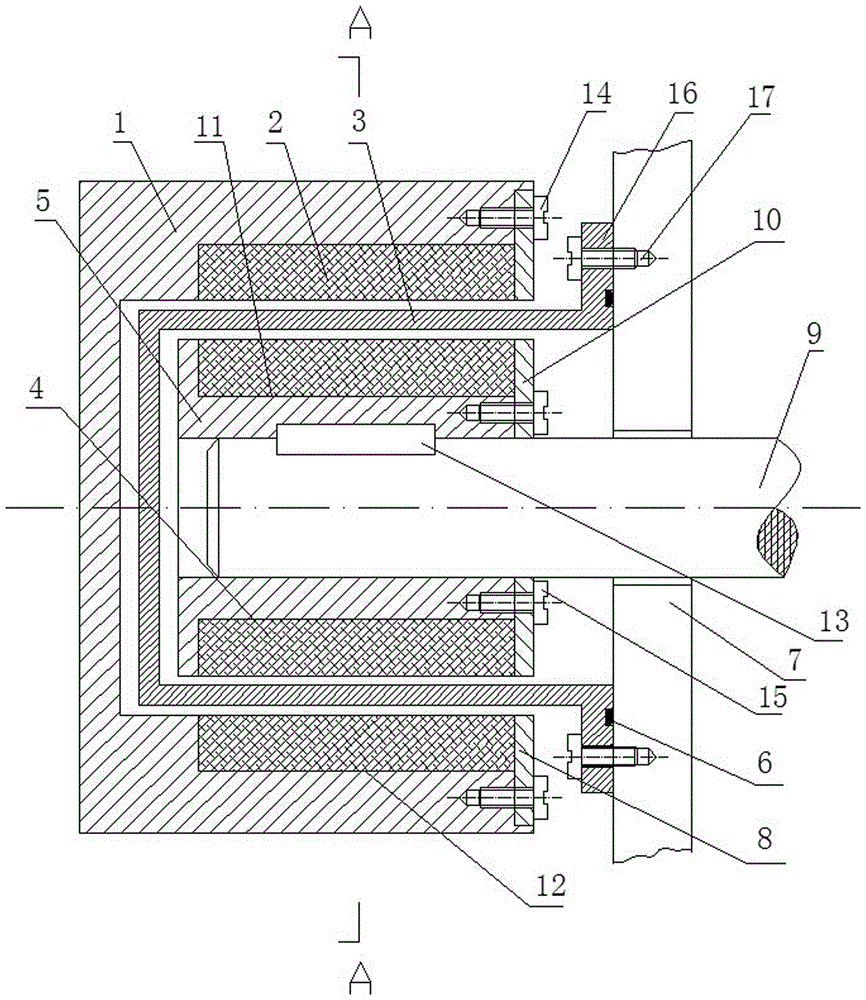

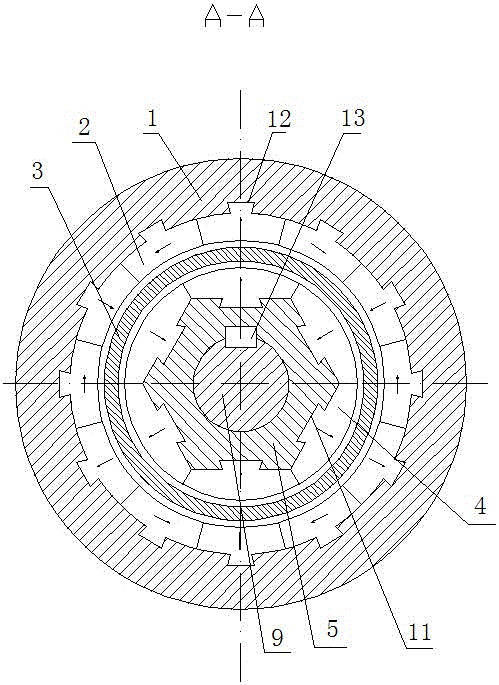

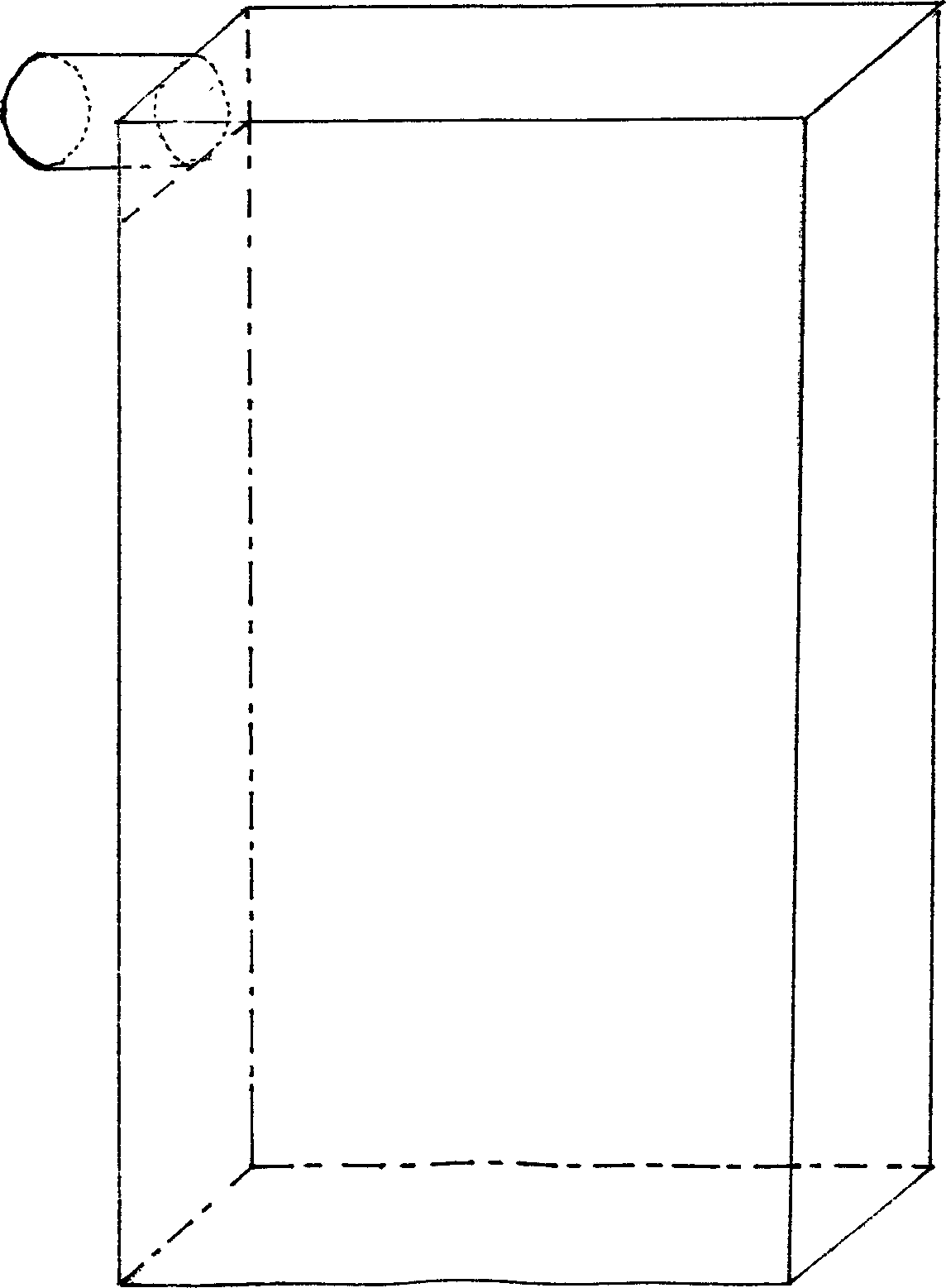

Inner closed type radial flux magnetic transmission mechanism for underwater direct-driven propeller

InactiveCN105703602AGuaranteed reliable operationAvoid overload damagePermanent-magnet clutches/brakesMechanical energy handlingRotor magnetsStructural engineering

The invention relates to an inner closed type radial flux magnetic transmission mechanism for an underwater direct-driven propeller. According to the inner closed type radial flux magnetic transmission mechanism for the underwater direct-driven propeller provided by the invention, the opening end of the inner circumference surface of an outer rotor iron core (1) is equipped with multiple dovetail slots II (12) along a radial direction; the multiple dovetail slots II (12) are evenly distributed along the inner circumference surface of the outer rotor iron core (1); a piece of outer rotor magnetic steel (2) is matched and fixed in each dovetail slot II (12); an inner rotor end plate (10) is annularly sleeved on the prime motor rotation shaft (9) of the propeller and is fixedly connected with the outer end of an inner rotor magnet yoke (5); an outer rotor end plate (8) is fixedly connected with the outer end of the outer rotor iron core (1); the opening end of an isolation sleeve (3) is equipped with a connection flange plate (16); and the connection flange plate (16) of the isolation sleeve (3) and a propeller end plate (7) are in sealed connection. The mechanism provided by the invention is applied in the underwater direct-driven propeller.

Owner:HARBIN INST OF TECH

Machining method used for thin-wall cavity type magnesium-lithium alloy part

The invention relates to a machining method used for a thin-wall cavity type magnesium-lithium alloy part. The machining method comprises at least the following steps that (1) bar blanking is conducted; (2) outer circle turning is conducted, and a deep hole is drilled and turned; (3) rough milling is conducted on the part shape, and a 2 mm unilateral allowance is reserved; (4) according to part requirements, the deep hole in the step (2) is numerically milled to form a mold cavity; (5) the part is subjected to heat treatment, firstly, the part is washed to be clean through gasoline and placed in air to be aired thoroughly, the effect that no cuttings are on the surface of the part is ensured, and after the part is heated to 90 DEG C and heat preservation is conducted for 3 h in a thermotank, air cooling is conducted to the room temperature; (6) half-finish-milling is conducted on the part surface; (7) subzero treatment is conducted on the part, small fragmental or pulverized cuttings on the part are cleared away before furnace charging, then the part is put into a refrigeration box to be subjected to heat preservation for 5-6 h in -195 DEG C liquid nitrogen, and air cooling is conducted to the room temperature; (8) finish-milling is conducted on the part surface according to the edge distance size requirement of the part surface; and (9) finishing is conducted. Through the machining method, safety and high-quality during machining of the thin-wall cavity type magnesium-lithium alloy part are achieved, and the anti-corrosion capacity is improved.

Owner:XIAN NORTH ELECTRO OPTIC TECH DEFENSE

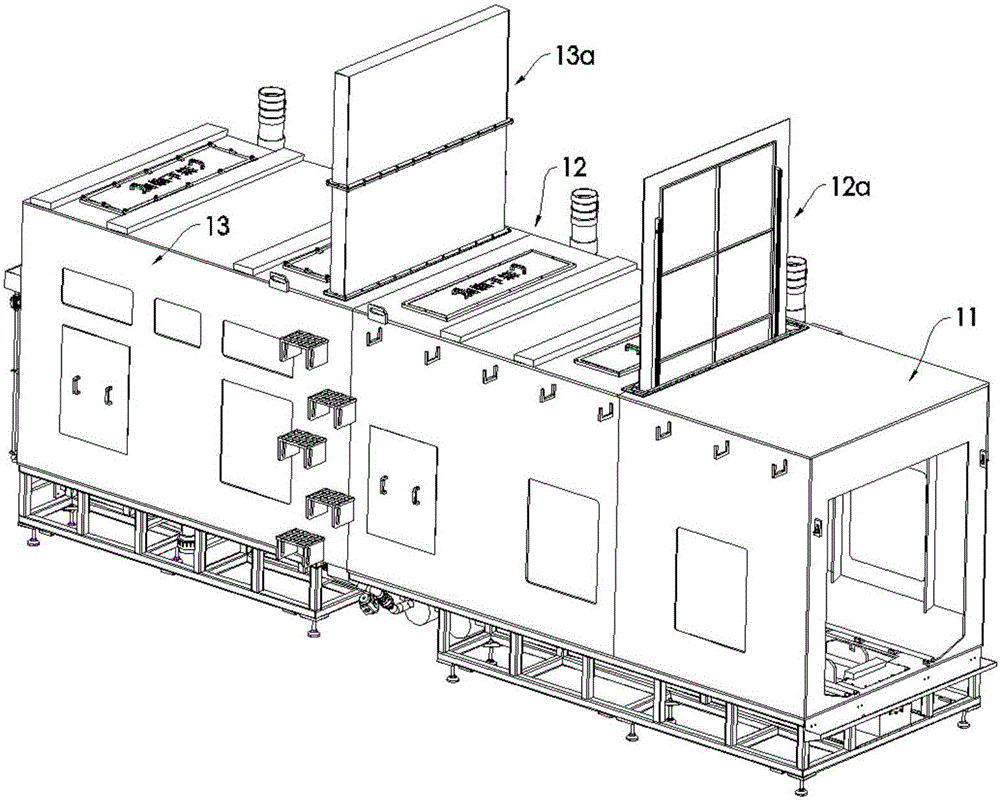

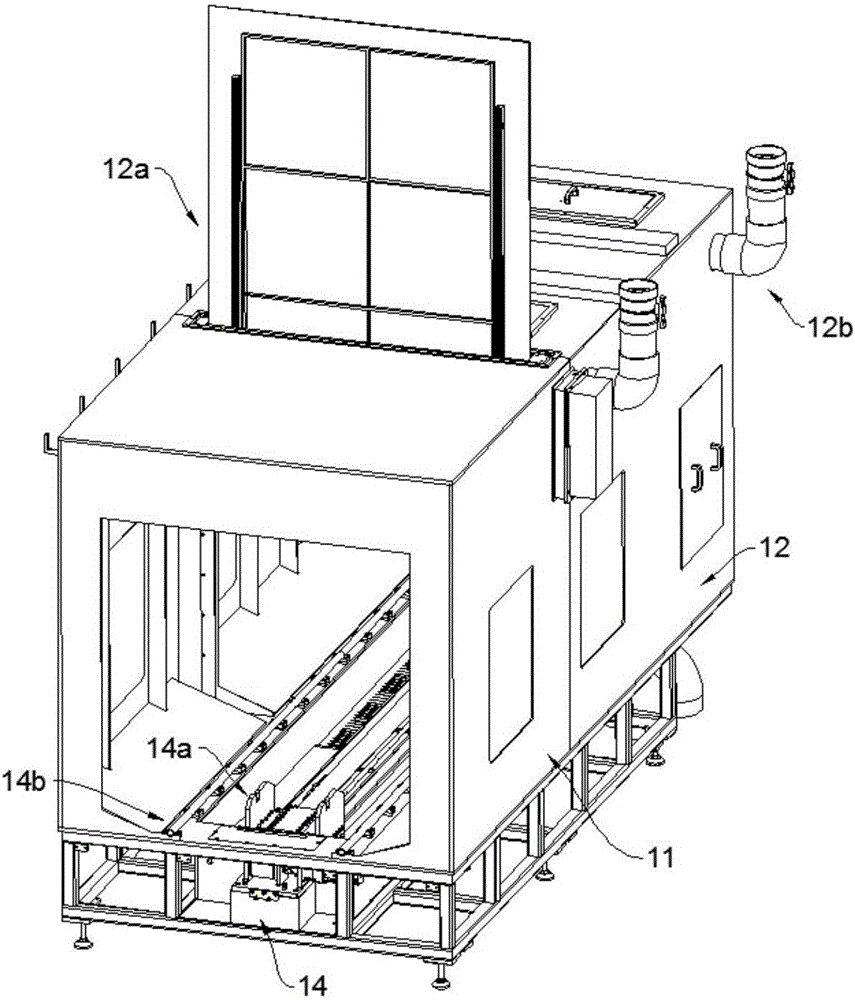

Top-jet type spray etching machine

A top-jet type spray etching machine comprises an etching machine body and a liquid medicine circulating system, wherein the etching machine body is mainly composed of a transition area, a cleaning area and an etching area, spraying devices are arranged on the cleaning area and the etching area respectively, synchronous belt conveying devices are arranged below the transition area and the cleaning area, a servo drive motor is arranged below the transition area, a slide rail penetrating through the transition area, the cleaning area and the etching area is arranged below the etching machine body, etching basket tools are placed on the slide rail, the synchronous belt conveying devices are connected and linked through push rods, and the liquid medicine circulating system is mainly composed of a DI water tank body, a chemical liquid medicine tank body, a heating tank, corresponding pipelines, corresponding valves and a circulating pump. In the glass panel etching process, the temperature, pressure, flow and the like of liquid medicine can be controlled in a full-automatic mode, double-sided waterfall etching is conducted on glass panel, no manual operation is needed in the whole working process, cleaning and etching are both completed automatically, and the etching precision and efficiency are remarkably improved.

Owner:CHENGDU IND INVESTMENT ELECTRONICS EQUIP

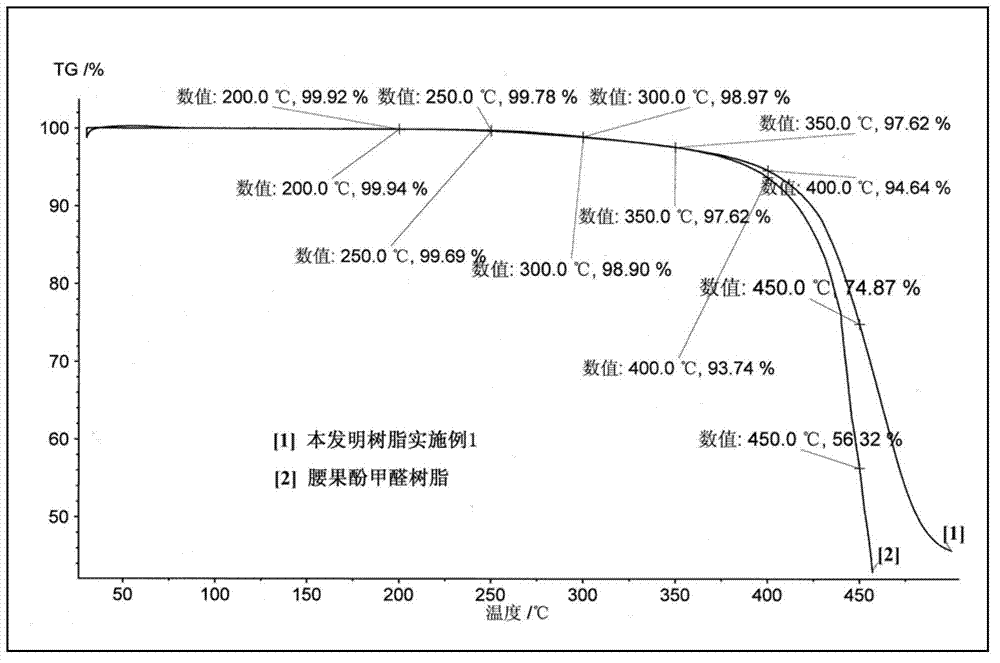

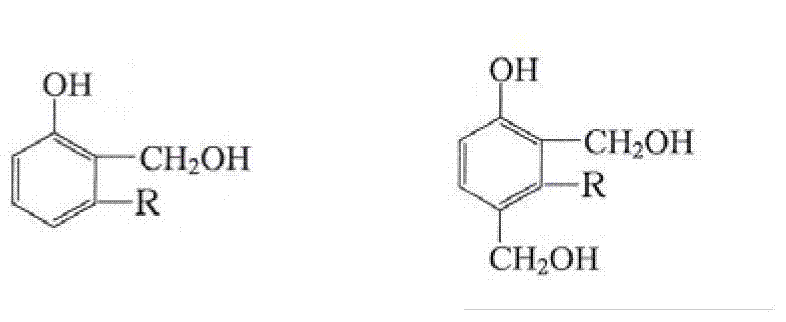

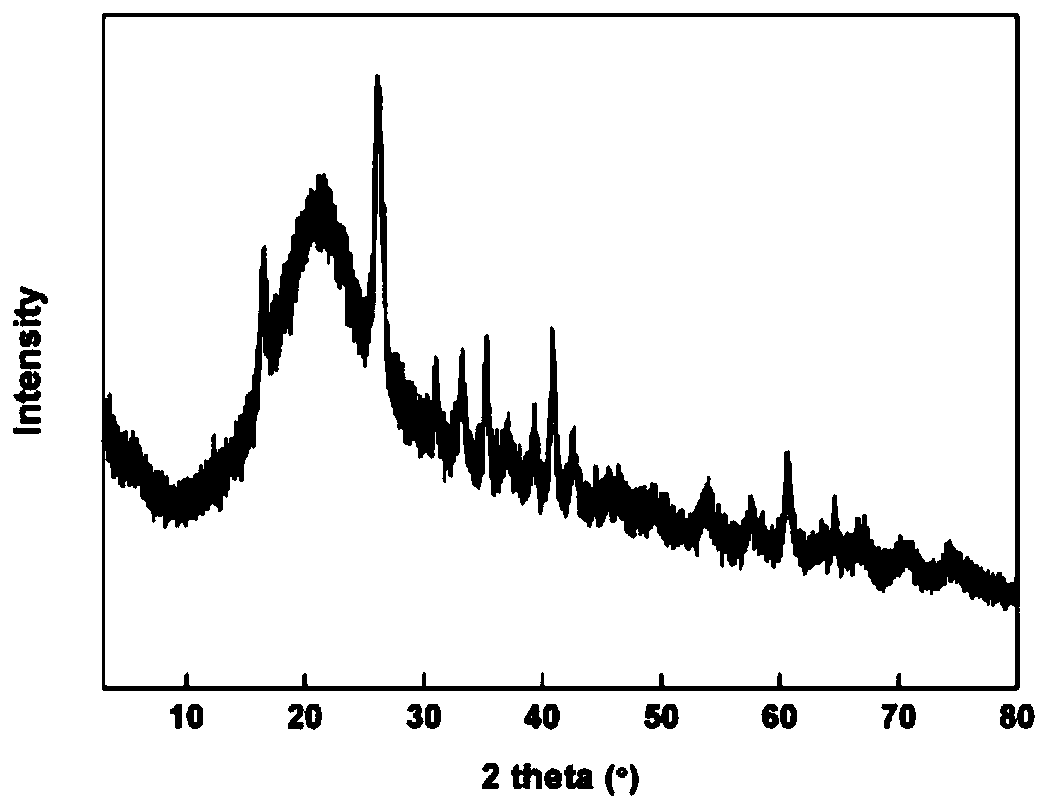

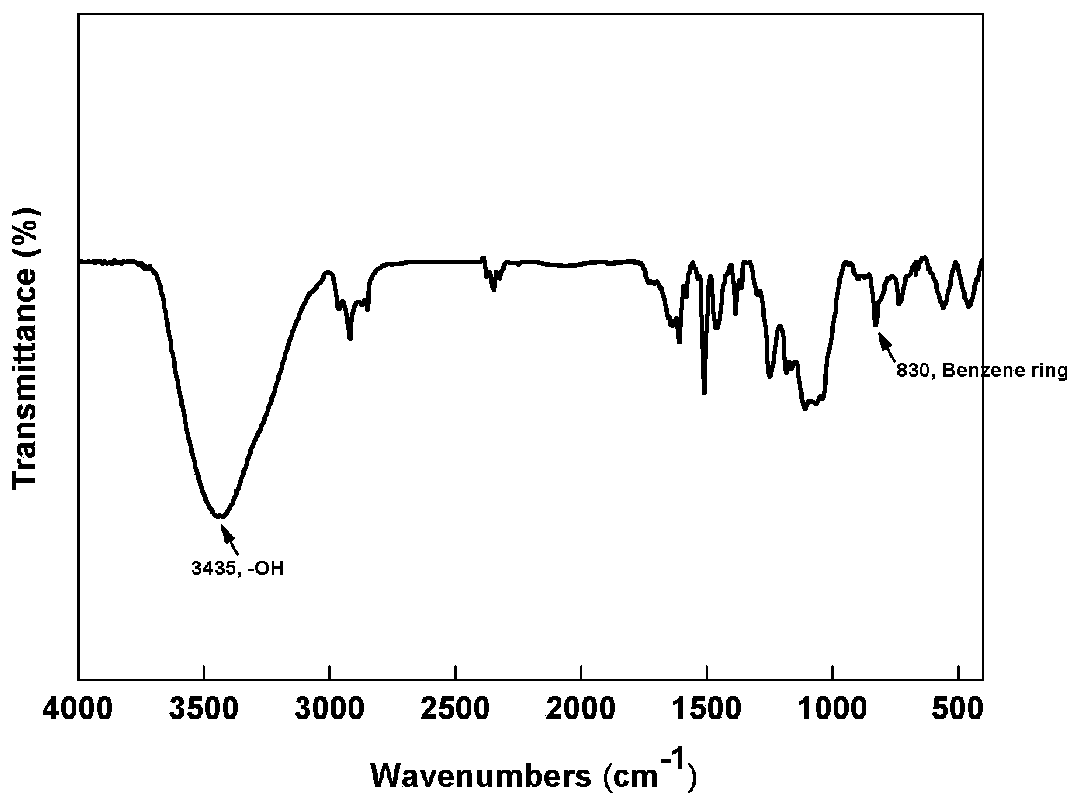

Preparation method of furan-modified cashew phenolic resin

ActiveCN103289035AImprove boiling water resistanceExcellent resistance to boiling waterHeat transfer tubeSeawater

The invention provides a preparation method of furan-modified cashew phenolic resin. The preparation method comprises the following steps of: selecting the following raw materials in parts by weight: 100-140 parts of cardanol, 32-54 parts of formaldehyde, 10-23 parts of furfuryl alcohol, 80-120 parts of dimethyl benzene and 8-10 parts of catalyst; adding the cardanol, the formaldehyde and the catalyst into a reaction kettle in proportion, reacting for 1 hour to 2 hours at 70 DEG C-80 DEG C; adding the furfuryl alcohol, and reacting for 1 hour to 2 hours at 90 DEG C-100 DEG C; adding the 80-120 parts of dimethyl benzene, heating up, separating the water by adopting an oil-water separating device until the temperature reaches 155 DEG C-160 DEG C, and performing heat preservation for 1 hour to 2 hours to obtain the furan-modified cashew phenolic resin. The preparation method of the furan-modified cashew phenolic resin has the beneficial effects of remarkably improving boiling water resistance and heat resistance of the resin, having a practical application meaning in corrosion resistance and scaling prevention of a distillation-process seawater desalting heat transfer tube as well as steam blowing resistance of a heat exchanger tube bundle of a petrifaction system, and being applicable to paint base preparation of industrial heavy-duty anticorrosive coating.

Owner:天津市中海科技有限公司

Composite anticorrosion coating process based on stainless steel material

InactiveCN108187993ASolve the problems of complex coating processing and high costSolve anti-corrosionPretreated surfacesCoatingsLine tubingSand blasting

The invention discloses a composite anticorrosion coating process based on a stainless steel material. The composite anticorrosion coating process comprises the following steps that a steel pipe subjected to surface purification treatment is conveyed into a rust removal machine through a pipe feeding platform to be subjected to totally-closed surface sand blasting rust removal, and a dual shot blasting and sand blasting process is adopted; high-pressure deionized water or reverse osmosis water is adopted for carrying out 100% surface flushing polarization on the surface of the steel pipe subjected to sand blasting, and an air knife is used for blow-drying; and the cleaned steel pipe is conveyed to a powder electrostatic spraying device to be sequentially coated with an epoxy resin FBE layer, a polypropylene adhesive AD layer and a polypropylene PP layer and finally is washed with water and cooled. According to the composite anticorrosion coating process, the anticorrosion aim of the stainless steel pipe in a conveying pipeline is achieved, and the service life of the pipeline is prolonged.

Owner:SHANGHAI HILONG ANTI CORROSION TECH ENG

Circulation system for controlling water level display and detecting scale accumulation separation based on multi-spot

ActiveCN102193563AEasy to controlRealize the display effectLevel controlLevel indicators by floatsElectricityTemperature control

The invention relates to a circulation system for controlling water level display and detecting scale accumulation separation based on multi-spot. The system is characterized in that: the upper part and the lower part of a multi-spot detection water level controller 8 at the side of a water tank 9 are communicated to form a loop and also communicated with a water inlet alarm device or a water charging electromagnetic valve 11, and a cooling circulation system 17 or a solar vacuum heat absorption circulation system 10 is communicated with the water tank 9 to independently form a circulation system; the water tank 9, a gauze filter 3, a multi-spot detection scale accumulation separating device 4, an electromagnetic valve 5, a water quantity control valve 6 and a pipeline pump 7 form an independent multi-spot detection scale accumulation separation circulation system, wherein the electromagnetic valve, the pipeline pump, the multi-spot detection water level controller, the multi-spot detection scale accumulation separation circulation system and a temperature control probe 14 are electrically connected with corresponding interfaces of a CPU (Central Processing Unit) processing system. The invention has the beneficial effects: the problem of anticorrosion of the current water level controllers is solved, impurities, such as scales and the like, in containers and circulation pipelines are separated, and multi-contact control and numerical value display control are also realized, thus the purposes of energy conservation and exhaust reduction are achieved.

Owner:杨昌地 +2

Surface anti-corrosive ventilating type nanomaterial industrial paper packing bag and its application

InactiveCN1594042AGuaranteed packaging effectEfficient separationFlexible coversWrappersSilica HydrateEngineering

This invention is about a packing bag for industrial paper, to be exact, this packing bag is made of nanophase materials and its surface is permeable but antiseptic. Inside the bag is plastered a layer of film in which some tiny holes are made from internal to external. The film is made of polythene, polypropylene and polythene or polypropylene containing silica hydrated. This invention has such following advantages: 1) better antisepsis, because the invention films a kind of high molecular material( high pressure polythene or polypropylene) onto the surface of a packing bag for average paper and forms into a new type of compound paper-packing material, it is a better and more effective solution to antisepsis; 2) that the bag has a good air delivery from inside to outside and excellent feasibility, so it improves the mechanic intensity of brown packing paper and waterproofing and damp proofing; 3) its film is even spilled.

Owner:天威英利

Method for anti-seepage construction between hidden frame glass window and building structure

InactiveCN101705777AControl leakage quality common faultsReduce maintenanceJoints tightening/coveringSealing arrangementsFoaming agentArchitectural engineering

The invention discloses a method for the anti-seepage construction between a hidden frame glass window and a building structure, which comprises the following steps: firstly, according to the separation distance and the shape of a structural surface at a joint seam of the outer side of a window frame and the building structure, cutting a waterproof sheet material made of ethylene propylene diene rubber; adhering the waterproof sheet material to the joint seam by using a waterproof paste, and then compacting and fixing the waterproof sheet material and the joint seam of the building structure and the window frame by using an aluminum strip; fully packing the gaps between the periphery of the window frame and the adjacent building structure by using a foaming agent; and mounting a piece of glass, then packing the foaming agent in the joint seam of an aluminum sleeve frame and an adjacent structure, closing up the joint seam on the outer side of the foaming agent by using a mortar, and finally sealing joint seam by using a weatherproof sealant. According to the method, the ethylene propylene diene rubber sheet material, the foaming agent and the weatherproof sealant form a three-path waterproof thin part node, so common quality problems of the seepage on the periphery of the window frame are effectively controlled; besides, the material can be recycled for reuse, and simultaneously the maintenance caused by the seepage is reduced during engineering use.

Owner:LONGXIN CONSTR GRP

Stopper rod for controlling liquid-state molten slag flow

ActiveCN105779672AGuaranteed cooling effectReduce wall temperatureRecycling and recovery technologiesCold airInsulation layer

The invention discloses a stopper rod for controlling a liquid-state molten slag flow. The stopper rod comprises a metal inner pipe, a metal outer pipe and a heat insulation layer; the metal inner pipe is sleeved with the metal outer pipe, and the metal inner pipe and the metal outer pipe are arranged in a spaced manner; the heat insulation layer is fixed to the outer wall of the metal outer pipe, a lower end opening of the metal inner pipe is communicated with the metal outer pipe, the lower end of the metal outer pipe is sealed, and a hot air outlet is formed in the upper end of the metal outer pipe; a cold air inlet is formed in the upper portion of the metal inner pipe; and according to the stopper rod, the metal inner pipe is sleeved with the metal outer pipe, and is connected with the metal outer pipe through connecting ribs, and hollow arrangement is formed. Cold air enters a center pipe from the cold air inlet, flows to the periphery from the bottom, and flows out of the position between the two pipes, and the cooling effect on the metal wall face is formed. The stopper rod can effectively resist slag corrosion, and is matched with a water opening to control the slag flow, and the stopper rod can be widely applied to precise control over the slag flow in a liquid-state molten slag sensible heat recovery system.

Owner:XI AN JIAOTONG UNIV

Container house built on marine floating type platform

InactiveCN106494586AImprove economic efficiencyStrong weather resistanceWaterborne vesselsFloating buildingsWeather resistanceSeawater

The invention discloses a container house built on a marine floating type platform. The container house structurally comprises a composite roof, a supporting frame, a thick top plate, an insulating layer, a composite wall body, thick side plates, a buoy, a cement and mortar combining layer, a keel, a window frame, a fireproof layer, a fiber board layer, a floor tile layer, a ceramic anti-corrosive panel and an enhanced material layer, wherein the ceramic anti-corrosive panel is arranged on the composite roof and the composite wall body, and the composite wall body is provided with the enhanced material layer. The container house disclosed by the invention has the advantages that the container house can be made into a water house, a water floating road, a yacht-marina buoyancy tank and the like in reservoirs of rivers, lakes and seas; the corrosion resistance and the weather resistance are high, and the service life is long and is 3 times of that of a steel buoy; due to the properties of corrosion resistance, freezing resistance, oxidation resistance and ultraviolet resistance of the enhanced material, the erosion from sea water, chemicals, agents, oil spots and aquatic creatures can be resisted, and a maintainable and replaceable floating body is designed in structure, so that the service life of the floating body can be prolonged; and the container house is of a regular hexagon in structure, is built triangularly by containers, and is high in stability and wind wave resistance.

Owner:TIANJIN GELINSEN TECH CO LTD

Anti-corrosion and heat-dissipation integrated coating of waterborne graphene/epoxy zinc-rich dispersion system and preparation method and application thereof

ActiveCN111534192AImprove anti-corrosion performanceGood dispersionAnti-corrosive paintsSpecial surfacesFirming agentMetallic materials

The invention provides an anti-corrosion and heat-dissipation integrated coating of a waterborne graphene / epoxy zinc-rich dispersion system and a preparation method and application thereof, and relates to the technical field of water-based coatings. The anti-corrosion and heat-dissipation integrated coating comprises the following components in parts by mass: 10 to 20 parts of waterborne epoxy zinc-rich resin, 0.5 to 1.5 parts of hydrophilic graphene, 0.5 to 1.5 parts of hydrophilic kaolin, 0.05 to 0.15 part of fumed silica, 7.2 to 12.5 parts of water, 1 to 3 parts of an antifoaming agent, 0.5to 1.5 parts of a leveling agent and 1 to 5 parts of a double-component waterborne epoxy zinc-rich curing agent. The anti-corrosion and heat-dissipation integrated coating provided by the invention has excellent anti-corrosion performance, the anti-corrosion problem of metal materials can be effectively solved, the raw materials of the anti-corrosion and heat-dissipation integrated coating provided by the invention are environment-friendly, and the prepared anti-corrosion and heat-dissipation integrated coating is low in VOC emission.

Owner:湖南库泠斯特科技有限公司

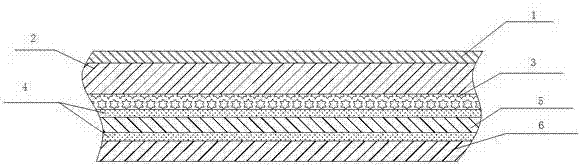

Imitation aluminum composite membrane

InactiveCN102371729AMaintain metallic lusterRetain glossMetal layered productsPolyvinyl chlorideMetallic materials

Owner:JIANGSU OBON PLASTIC

Single element multilayer infrared high-reflection film and preparation method thereof

ActiveCN110221368AImprove bindingImprove mechanical propertiesMirrorsVacuum evaporation coatingSingle elementRefractive index

The invention relates to a single element multilayer infrared high-reflection film and a preparation method thereof. The film structure consists of a substrate and a multilayer DLC film plated by a graphite target material, and the basic structure of the film system is as follows: S / (HL)xH / A, wherein S is a Si substrate, H is a DLC film with high refractive index, L is a DLC film with low refractive index, x is the number of cycles of H and L repeated plating, and A is air. The single element multilayer infrared high-reflection film provided by the invention effectively improves the mechanicalproperty, and has high chemical stability and wide application range; and meanwhile, the preparation method is simple and easy to implement, and meets the requirement of large-scale industrial production.

Owner:XIAN TECH UNIV

Imitated titanium processing process for magnesium alloy

InactiveCN101311313ASolve anti-corrosionImprove wear resistanceVacuum evaporation coatingSputtering coatingTitaniumMetal

The invention discloses a treatment process of magnesium alloy imitation titanium, the processing steps are as follows: first, the surface of the magnesium alloy is carried out pretreatment and cleaned; then, the clean surface of the magnesium alloy is painted with metal backing vanish as a base coat; then, the base coat is vacuum plated with stainless steel to lead the surface of the magnesium alloy to take on the metal luster similar to titanium. The metal luster similar to titanium is realized by the stainless steel vacuum plated on the surface of the magnesium alloy surface by the invention, which not only effectively solves the anti-corrosion problem of the magnesium alloy under thin coating condition but also reserves the metal texture and tactility of the magnesium alloy.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

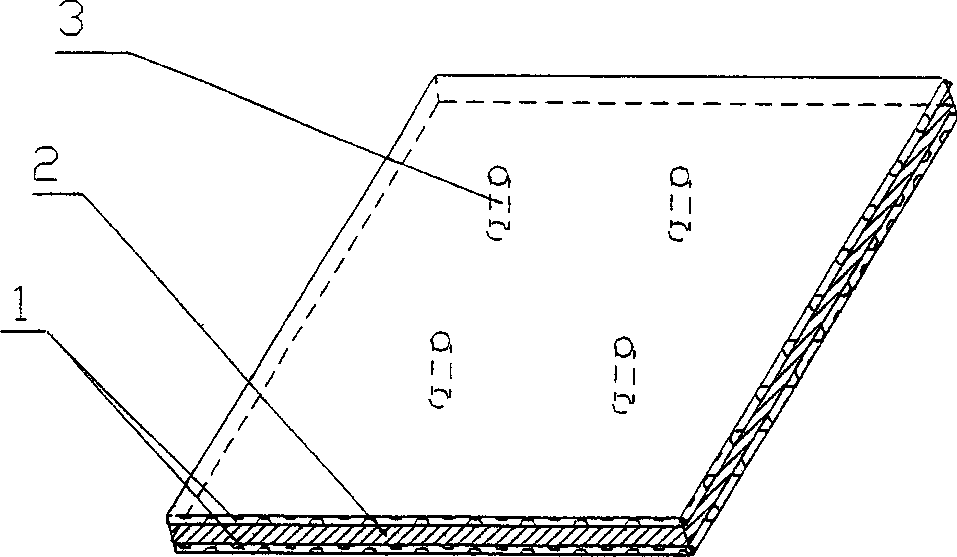

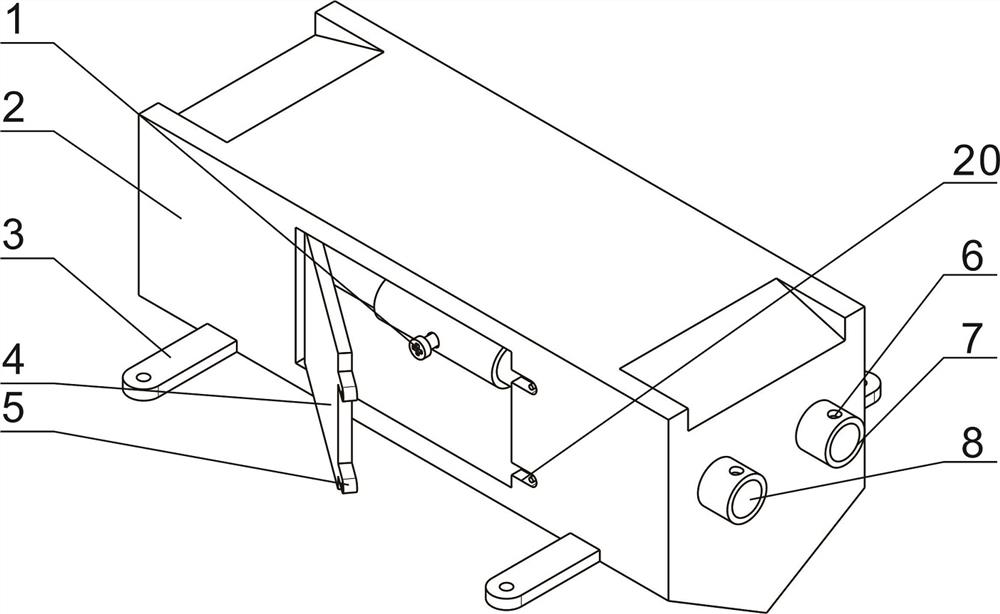

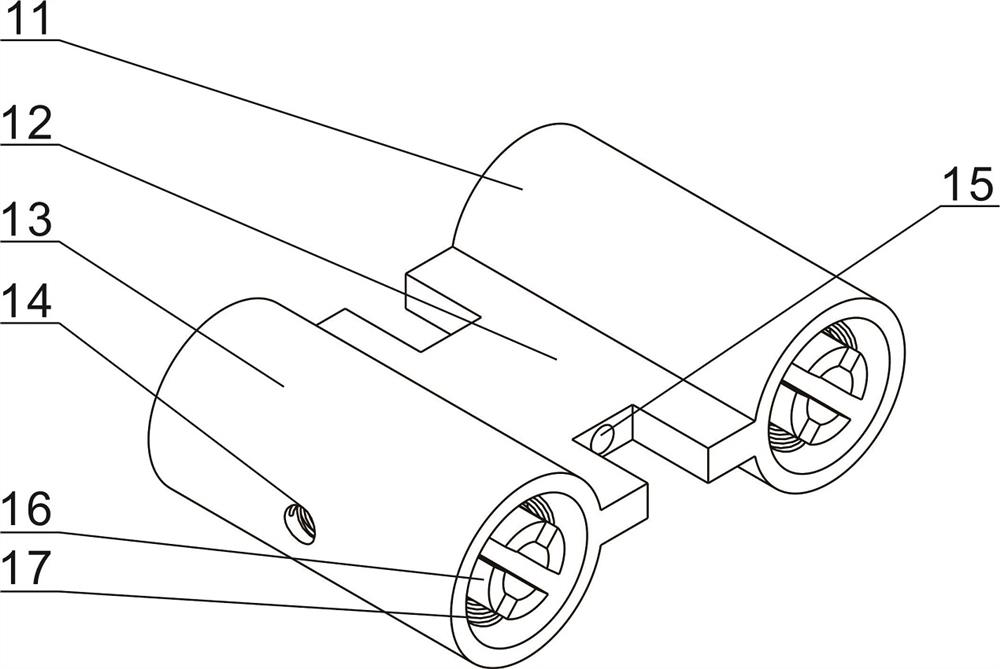

Powder room for suction coating in pipelines

InactiveCN107930942ALow costSolve anti-corrosionCleaning using gasesSpray boothsPowder SprayMaterials science

The invention discloses a powder room for suction coating in pipelines. The powder room comprises a room body, a powder bucket, a vacuum dust suction device and a clamping rotation device, wherein thepowder bucket is arranged on the room body and used for storing a powdery anticorrosion coating; the vacuum dust suction device is arranged on the room body and can be used for sucking out the anticorrosion coating in the powder bucket communicated with the vacuum dust suction device; the clamping rotation device is arranged on the room body; first suction coating channels are arranged on the clamping rotation device; clamping heads are also arranged on the clamping rotation device and used for clamping one ends of pipelines to ensure that one ends of the first suction coating channels are communicated with inner holes of the pipelines; and the other ends of the first suction coating channels are communicated with either of the powder bucket or the vacuum dust suction device through a switching device. The powder room disclosed by the invention has the advantages that a powder spraying gun is not needed in the working process; the powder room can be applied to various pipelines with different diameters; and therefore, the spraying cost is effectively reduced and the anticorrosion problem of inner walls of the pipelines is solved.

Owner:ZHONGSHAN JUNHE ELECTRO MECHANICAL APP

Environment-friendly sewage treatment equipment capable of being circularly utilized

InactiveCN108862780AAvoid corrosionSolve anti-corrosionWater/sewage treatment by irradiationSpecific water treatment objectivesActivated carbonSewage

The invention discloses environment-friendly sewage treatment equipment capable of being circularly utilized. The environment-friendly sewage treatment equipment comprises a No. 2 sedimentation tank and a purification groove, wherein a No. 1 sedimentation tank is arranged at one side of the No. 2 sedimentation tank; an electrolytic tank is arranged at the other side of the No. 2 sedimentation tank; a filtering screen is arranged on an inner surface of the No. 1 sedimentation tank; an activated carbon layer is arranged below the filtering screen; a pipeline is arranged at the other side of theNo. 1 sedimentation tank; a stirrer is arranged on the inner surface of the No. 2 sedimentation tank; a No. 2 waste dreg opening is formed below the No. 2 sedimentation tank. The environment-friendlysewage treatment equipment capable of being circularly utilized, disclosed by the invention, is provided with an anticorrosion coating, the filtering screen and a solar cell panel, and can be used forpreventing the pipeline from being corroded, so that the service life of the equipment is prolonged; the filtering screen also can detached to clean impurities, and electric energy produced by the solar cell panel can be used for carrying out electrolysis and deposition on sewage, so that energy saving and environment protection are realized; the equipment is applicable to different working conditions and brings a better application prospect.

Owner:单伟民

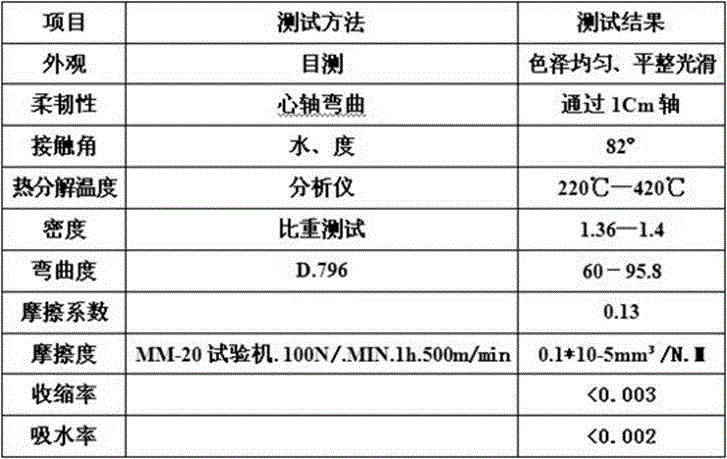

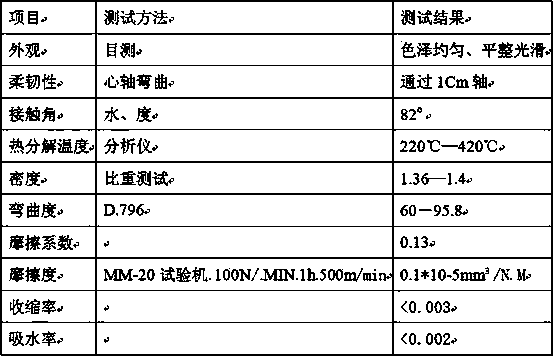

Composite material for high-performance foot pads, and preparation method thereof

The invention relates to the field of material manufacturing, and discloses a composite material for high-performance foot pads, and a preparation method thereof, wherein the raw materials comprise, by weight, 50-60 parts of a PVC resin SG-5, 50-60 parts of DOP, 0.5-1 part of stearic acid, 2-5 parts of toner, 30-40 parts of a filler, 7-12 parts of oxidized polyethylene wax, 2-6 parts of diantimonytrioxide, 10-18 parts of a plasticizer, 1-3 parts of a low-temperature-resistant modifier, and 15-20 parts of a JUST-5100 surface antifouling agent. The preparation method comprises: adding the raw materials into a twin-screw extruder, extruding, and granulating to prepare the composite material. According to the present invention, the added PVC raw material and the main auxiliary materials are treated by the technical means so as to meet the environmental protection standards, and the foot pad made by the process technology has advantages of wear resistance, corrosion resistance, fouling resistance, environmental protection and the like.

Owner:HIGHER TECH CO LTD

Waterproof and anticorrosive paint for helicopter and preparation method of waterproof and anticorrosive paint

InactiveCN108047895AImprove waterproof performanceImprove adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinPolytetrafluoroethylene

The invention discloses waterproof and anticorrosive paint for a helicopter. The waterproof and anticorrosive paint is prepared from components in parts by weight as follows: 36-45 parts of epoxy acrylic resin, 22-26 parts of isocyanate, 28-32 parts of n-butyl acetate, 16-25 parts of dibutyl benzoate, 21-27 parts of an organic solvent, 13-18 parts of polytetrafluoroethylene, 15-23 parts of polyethylene, 17-24 parts of neodymium fluoride, 13-22 parts of gadolinium fluoride, 15-19 parts of sodium oxide, 18-21 parts of triethanolamine,11-15 parts of titanium trioxide, 8-14 parts of a catalyst, 6-12 parts of filler and 22-34 parts of water. The paint has good waterproof performance, adhesive force and anti-corrosion property.

Owner:江苏东翼通用航空科技有限公司

Overhead insulation lead lightening protection wire breaking device

PendingCN108257744APrevent water ingressSolve anti-corrosionElectrically conductive connectionsInsulatorsElectrical conductorCorrosion

The invention discloses an overhead insulation lead lightening protection wire breaking device. The device comprises a cross arm, an insulator and an insulation lead, wherein the insulator is arrangedon the cross arm, the insulation lead is arranged on the insulator, the insulation lead is provided with two puncture type connecting fittings, the puncture type connecting fittings are respectivelyarranged on the insulation lead at two sides of the insulator, the insulation lead is connected in parallel with a bare conductor, and two ends of the bare conductor are connected in parallel with theinsulation lead through connecting with conductor connection portions of the puncture type connecting fittings. The device is advantaged in that one lead is connected in parallel with two ends of theinsulation lead taking the insulator as the center through utilizing the two puncture type connecting fittings, reconstruction cost is quite low, enforcement is convenient, the lightening protectionwire breaking effect is obvious, popularization and enforcement are facilitated, the device is convenient to mount, a sealing structure is further employed, the water can be prevented from entering the insulation lead, corrosion is prevented, and service life is longer.

Owner:STATE GRID CORP OF CHINA +1

Hydroxylated nano closed treatment liquid as well as preparation method and application thereof

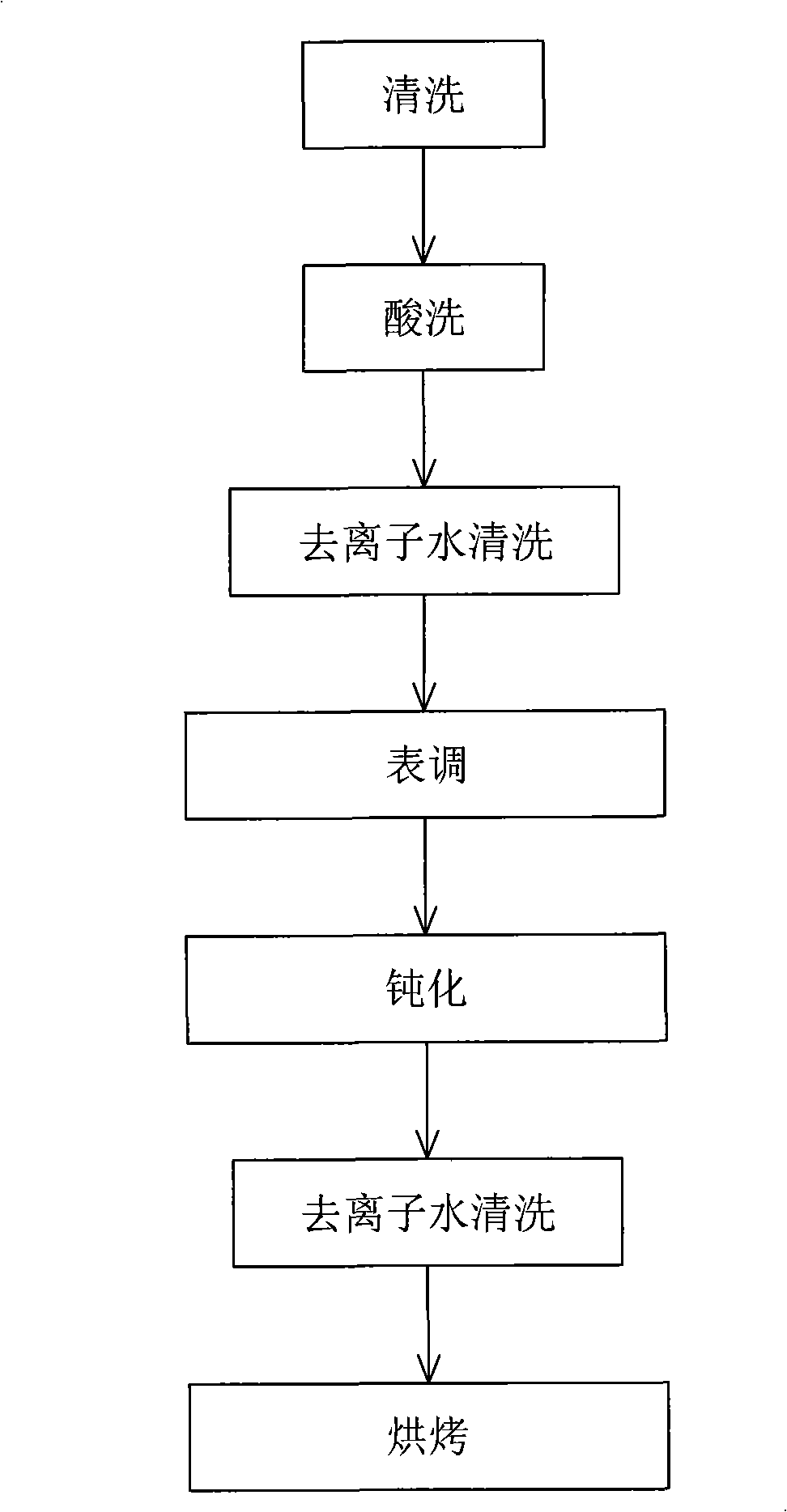

ActiveCN110777408AImprove corrosion resistanceSolve anti-corrosionMotor vehicle partCorrosion resistant

The invention relates to a hydroxylated nano closed treatment liquid as well as a preparation method and application thereof. The hydroxylated nano closed treatment liquid is prepared by mixing, according to a certain volume ratio, an inorganic basic component solution with the concentration being 5-30 wt%, a nanosol solution with the concentration being 3-20 wt%, a hydroxyl surfactant solution with the concentration being 0.1-5 wt% and an organic acid solution with the concentration being 10-40 wt%. According to the treatment liquid, between chemical nickel-plating and electroplating zinc-nickel plating layers, hydroxylated nano closed treatment is adopted, so that the corrosion resistance of the chemical nickel-plating layer, and the combined force with the subsequent zinc-nickel alloy plating layer are improved, and the percent of pass of electroplated products is improved to 98% or above from 70-80%. In the aspect of improving the corrosion resistance of automobile parts, the endurance in a salt-spray corrosion test is prolonged from the past 48 hours to 360 hours, and the corrosion resistance is greatly improved.

Owner:玛斯特(中山)汽车表面技术有限公司

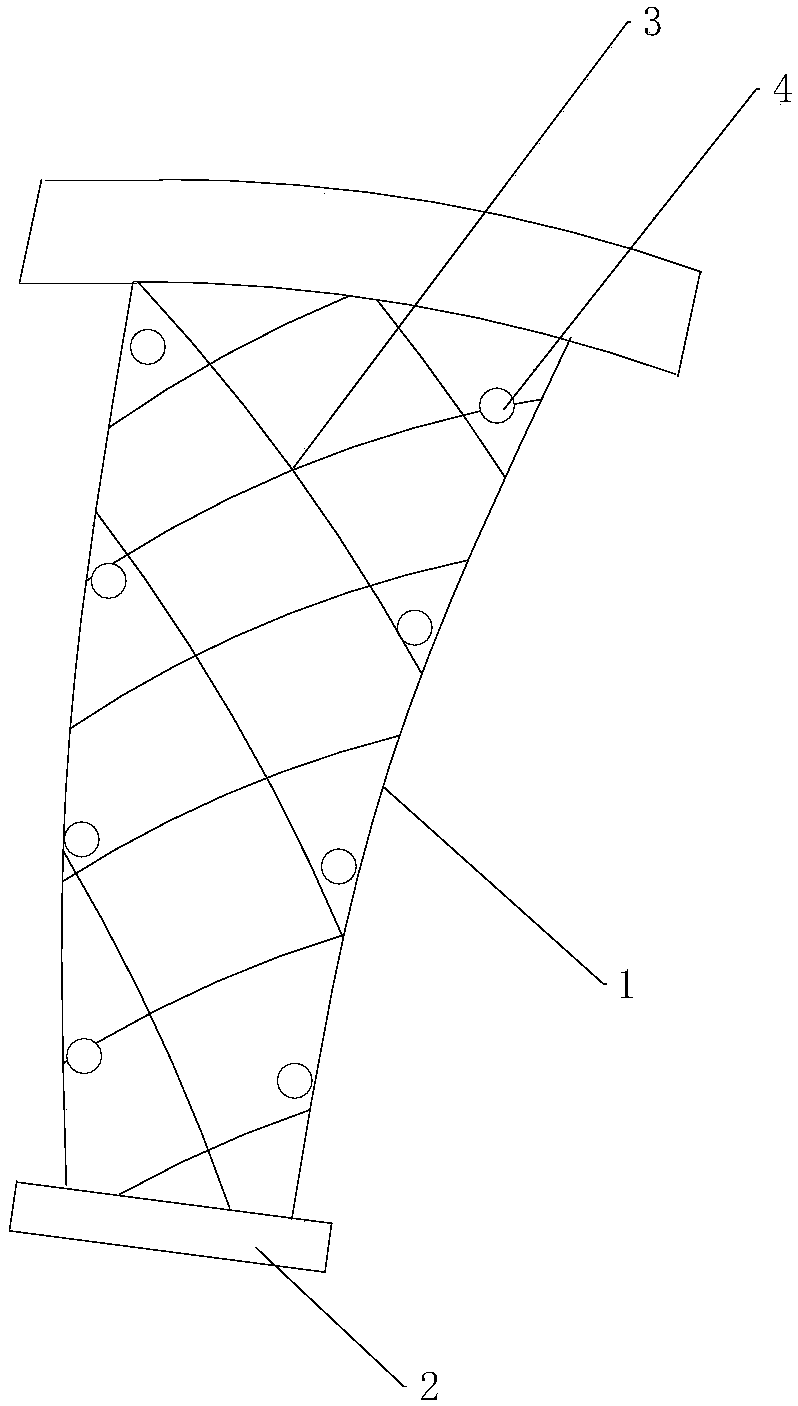

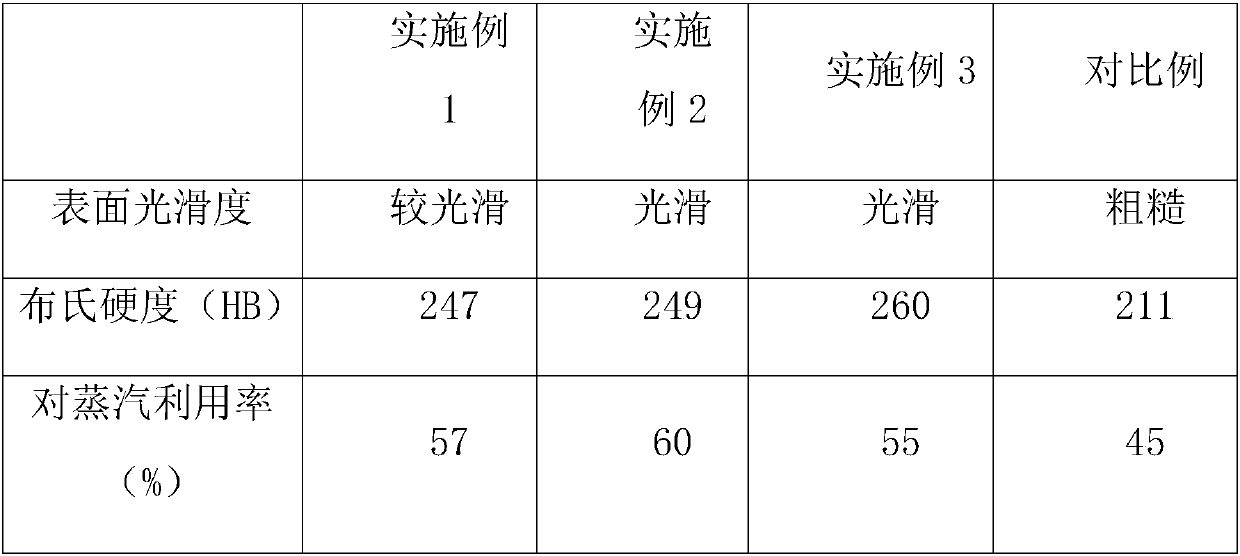

Antifouling titanium alloy turbine blade and preparation method thereof

InactiveCN107739969ASolve anti-corrosionPrevent failures such as breakageBlade accessoriesMachines/enginesSteam turbine bladeTitanium alloy

The invention discloses an antifouling titanium alloy turbine blade, and relates to the technical field of turbine blades. The antifouling titanium alloy turbine blade comprises a blade body and a blade root. The blade body comprises an inner arc face and an outer arc face, a rough face is arranged on the inner arc face, and the turbine blade is prepared from, by mass, 3.3% to 4.2% of C, 0.2% to 3.6% of Si, 0.2% to 1.1% of Mn, smaller than 0.1% of P, smaller than 0.05% of S, 0.2% to 3.0% of Ni, 0.35% to 0.38% of V, 0.02% to 0.04% of Mo, 0.04% to 0.6% of Ti, 0.05% to 0.3% of ZnO, 0.7% to 0.95%of Cu, 0.2% to 0.9% of TiN, 0.03% to 1.1% of TiAlN, 0.09% to 0.2% of CrN, not smaller than 0.3% of Cr and Co and the balance Fe.

Owner:南京赛达科技有限公司

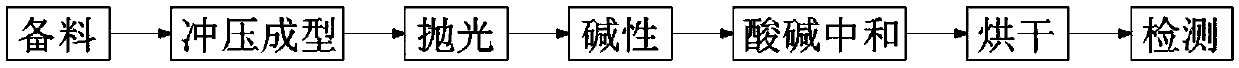

Production technology of lead frame with locating function

The invention discloses a production technology of a lead frame with a locating function. The production technology includes material preparation, punch forming, polishing, alkali washing, acid-base neutralization, drying and detection. Through a series of operation including material preparation, punch forming, polishing, alkali washing, acid-base neutralization, drying and detection, the lead frame with the excellent quality can be manufactured, oil stains and an active agent on the surface of the lead frame are eliminated, the smoothness of the lead frame is improved, the lead frame can beused with long action, through the action of an anticorrosive layer, the lead frame is effectively prevented from being corroded, the anti-corrosion property of the lead frame is improved, and the service life of the lead frame is greatly prolonged.

Owner:TAIZHOU YOURUN ELECTRONICS

Rapid cooling fluid for metal tube cutting surfaces and preparation method of rapid cooling fluid

The invention discloses a rapid cooling fluid for metal tube cutting surfaces and a preparation method of the rapid cooling fluid. The rapid cooling fluid is prepared from raw materials in parts by weight as follows: 150-200 parts of soybeans, 10-15 parts of a modified amine and polyamide mixture, 20-25 parts of titanium dioxide, 60-65 parts of polyether urethane, 10-13 parts of ammonium persulfate, 5-6 parts of acrylic acid, 5-6 parts of caustic soda, 5-6 parts of ammonium hydroxide, 6-9 parts of vinyl acetate, 8-11 parts of liquid low-molecular-weight polyamide, 30-40 parts of epoxy chloropropane, 40-50 parts of naphthenic base oil, 2-5 parts of an anti-wear agent, 5-10 parts of an anti-corrosion and anti-rust agent, 2-5 parts of a cleaning factor, 5-15 parts of propolis, 1-3 parts of metal deactivator and 8-12 parts of a m-cresol curing accelerator. The preparation method is simple, the adhesive and base oil in the cooling fluid are bonded in high-temperature welding positions, cracking is avoided, little equipment is used, energy consumption is low, the production cost is low, and the cooling fluid is very popular among clients, has very high popularization and application value and has bright market prospects.

Owner:安徽鹏远金属制品股份有限公司

Protective shell for cable laying

InactiveCN112103879AAffect connectionAvoid loose connectionsElectrical apparatusVibration suppression adjustmentsElectric cablesCorrosion prevention

The invention discloses a protective shell for cable laying, and relates to the technical field of cable laying equipment, the protective shell for cable laying comprises a shell body and a support frame, wherein the shell body is of a square structure, the bottom of the shell body is of a conical structure, the left and right sides of the shell body are respectively provided with two end faces, and the support frame is operated by arranging an open groove in the shell body. According to the invention, the supporting frame is arranged to prevent the shell from shaking to influence connection of cables, the sealing plates are arranged at the positions of the open grooves for sealing,and the sealing holes are formed in the first inserting groove and the second inserting groove for moisture prevention and corrosion prevention, and the limiting blocks and the springs are arranged on the supporting frame to achieve the purpose of shaking prevention; and an adjusting bolt is arranged to fasten the cable. The cable terminal protection shell is reasonable in structure, convenient to use and low in manufacturing cost and the like, can effectively prevent moisture and corrosion of the cableterminal and prevent cable connection loosening caused by shaking of the protection shell, and is suitable for various occasions and batch production.

Owner:国网河南省电力公司嵩县供电公司 +1

Polymer alloy composite cement water supply pipe and manufacture method thereof

The invention provides a polymer alloy composite cement water supply pipe which sequentially comprises a cement layer, a bonding layer, an interface compatible layer and an overflowing layer from outside to inside. The bonding layer adopts fibers to serve as polyamide modified epoxide resin composite materials of a reinforcing material, the overflowing layer is a resin modified polymer alloy material layer, and the interface compatible layer is a coupling reagent connecting the bonding layer and the overflowing layer. A manufacture method particularly comprises the following steps of prefabricating the cement layer, enabling the fibers to be soaked by liquid state polyamide modified epoxide resin, bonding the fiber on an inner wall of the cement layer, and solidifying for 4 hours at the temperature of 80-100 DEG C or conducting normal temperature solidification for 240 hours; spraying the liquid state polyamide modified epoxide resin on an inner surface of the bonding layer, evenly pasting resin modified polymer alloy material sheets of soaked by the liquid state coupling reagent, and solidifying for 4 hours at the temperature of 100 DEG C or conducting normal temperature solidification for 240 hours. The polymer alloy composite cement water supply pipe has performance such as corrosion resistance, aging resistance, impact resistance, zero poison, innocuity, zero pollution, wear resistance, high strength and the like.

Owner:宋广山 +1

Polymer alloy composite cement water supply pipe and manufacture method thereof

The invention provides a polymer alloy composite cement water supply pipe which sequentially comprises a cement layer, a bonding layer, an interface compatible layer and an overflowing layer from outside to inside. The bonding layer adopts fibers to serve as polyamide modified epoxide resin composite materials of a reinforcing material, the overflowing layer is a resin modified polymer alloy material layer, and the interface compatible layer is a coupling reagent connecting the bonding layer and the overflowing layer. A manufacture method particularly comprises the following steps of prefabricating the cement layer, enabling the fibers to be soaked by liquid state polyamide modified epoxide resin, bonding the fiber on an inner wall of the cement layer, and solidifying for 4 hours at the temperature of 80-100 DEG C or conducting normal temperature solidification for 240 hours; spraying the liquid state polyamide modified epoxide resin on an inner surface of the bonding layer, evenly pasting resin modified polymer alloy material sheets of soaked by the liquid state coupling reagent, and solidifying for 4 hours at the temperature of 100 DEG C or conducting normal temperature solidification for 240 hours. The polymer alloy composite cement water supply pipe has performance such as corrosion resistance, aging resistance, impact resistance, zero poison, innocuity, zero pollution, wear resistance, high strength and the like.

Owner:宋广山 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com