Protective shell for cable laying

A cable laying and protective shell technology, applied in electrical components, mechanical equipment, springs/shock absorbers, etc., can solve problems such as corrosion, affecting the reliability of cable connections, and moisture in cable joints, achieving easy use, preventing jitter, and preventing Effects of loose cable connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

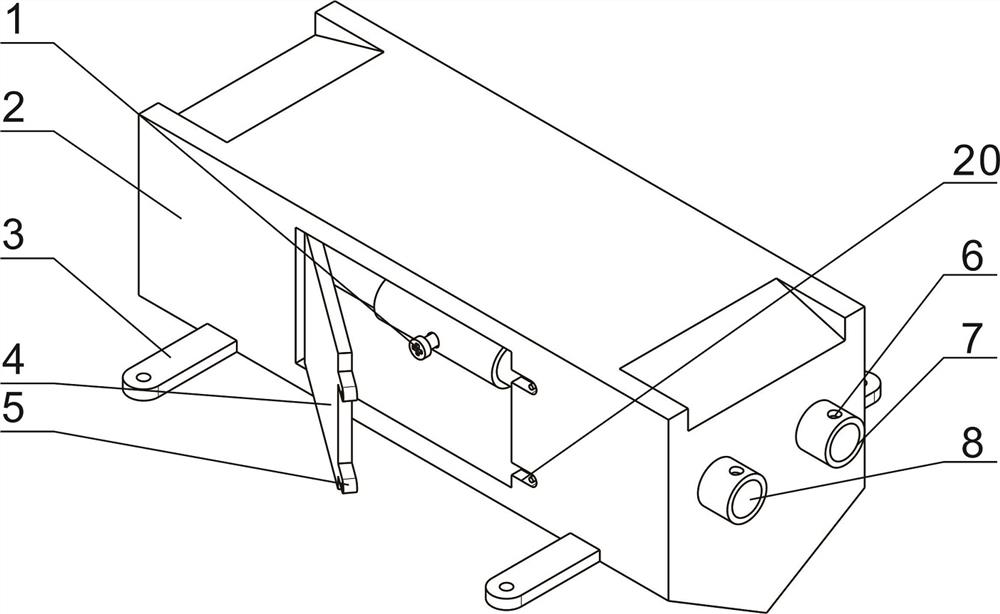

[0027] Embodiment 1, the above-mentioned protective case for cable laying, insert the cable into the first slot 7 during the laying process, connect the two separate cable heads, and use insulating tape for processing after the connection, after processing Slide the protective case and place the connection part of the cable in the first support sleeve in the support frame 10, fasten it by adjusting the bolt 1, close the sealing plate 4 after fastening, and fill in the sealing plate 4 along the connection seam after closing Put epoxy resin potting glue, after adjusting the final angle of the cable, pour epoxy resin sealant into the first slot 7, after sealing, insert the positioning column into the positioning frame 3 for final positioning to complete the operation.

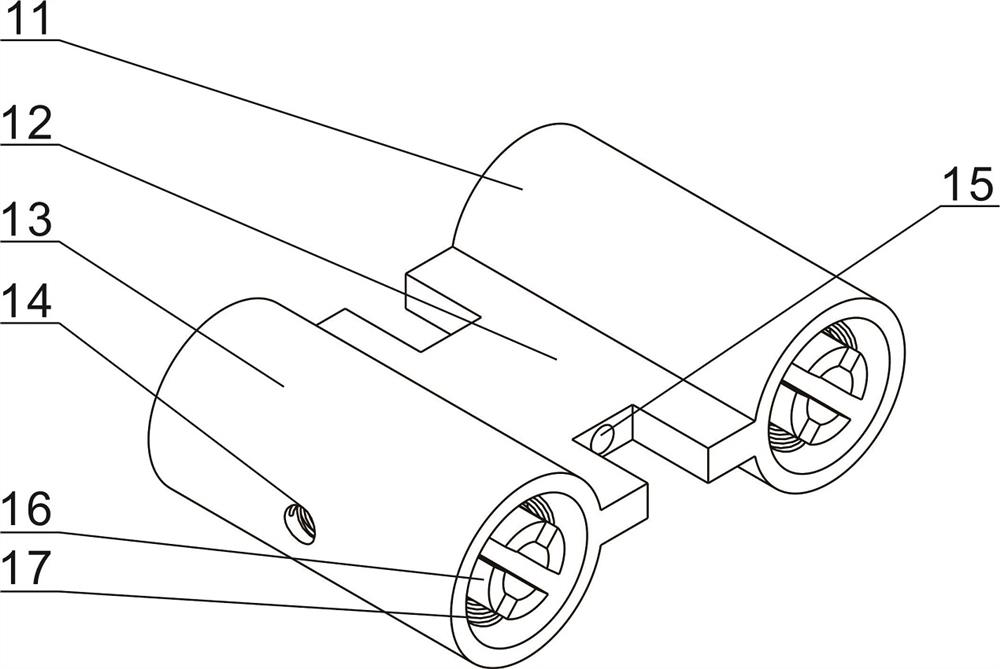

[0028] In addition, when two cables are operated at the same time, they can be inserted into the second slot 8. The operation process is the same as above. The second connection block 12 can separate the first supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com