Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56 results about "Direct-buried cable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Direct-buried cable (DBC) is a kind of communications or transmissions electrical cable which is especially designed to be buried under the ground without any kind of extra covering, sheathing, or piping to protect it.

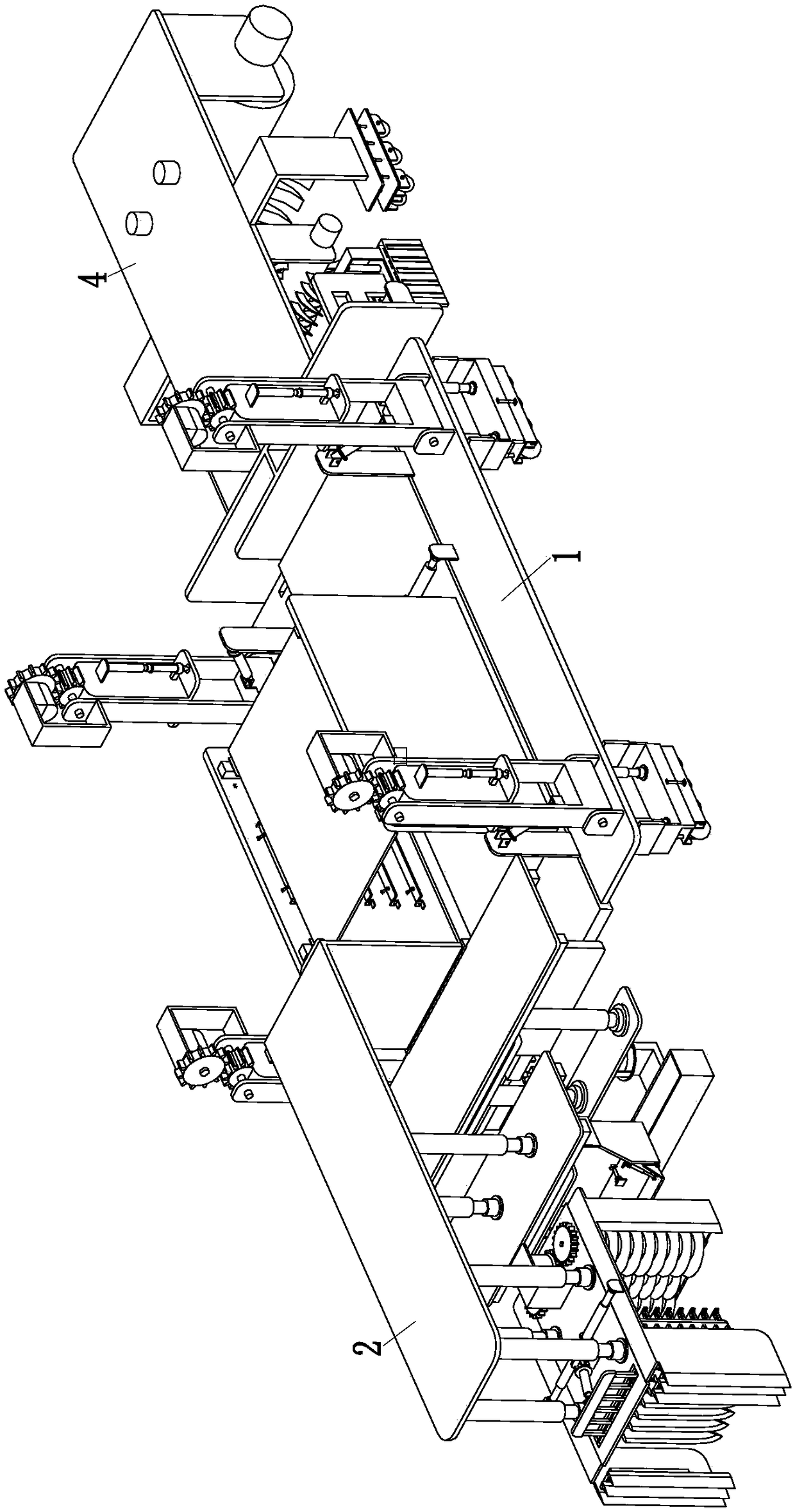

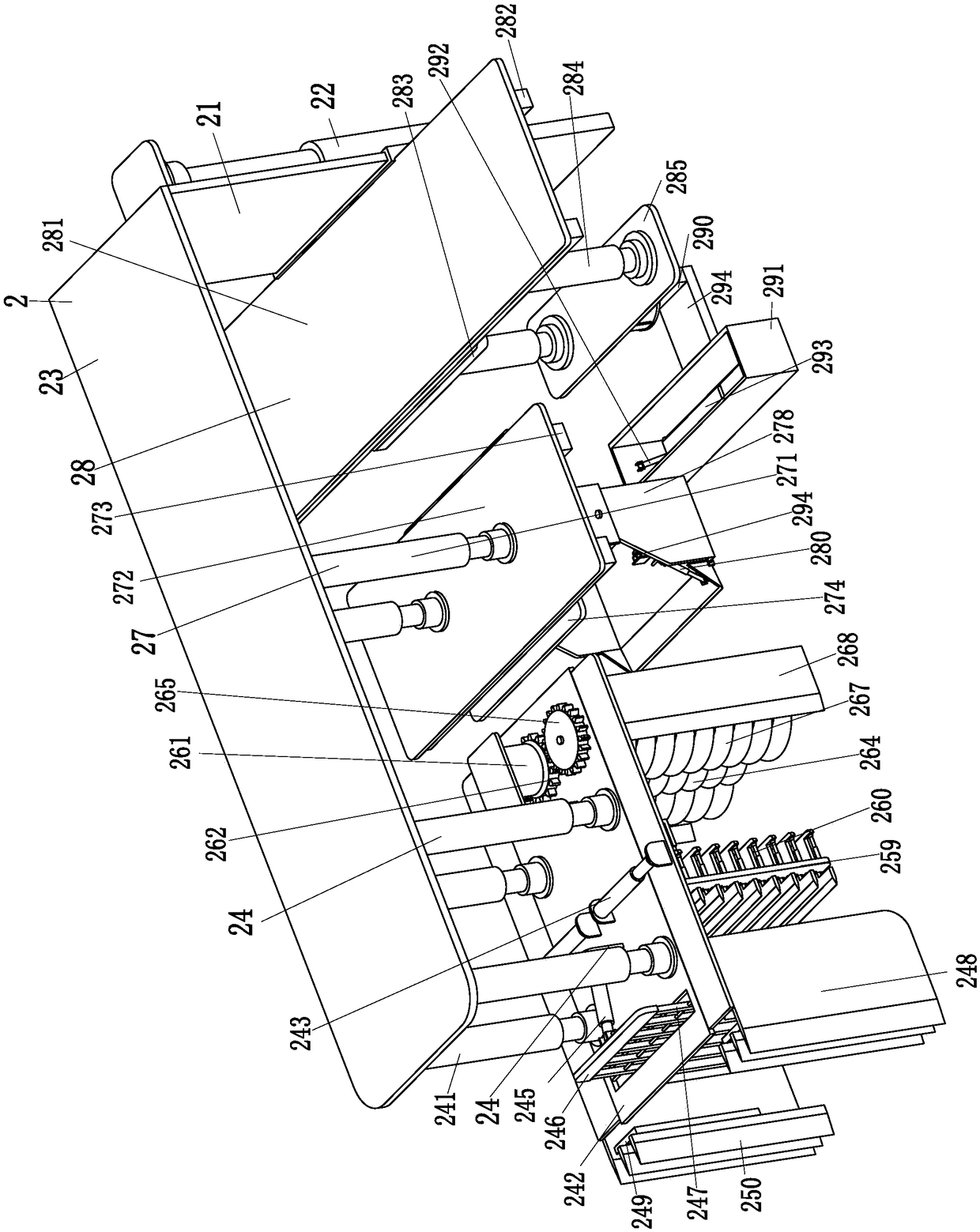

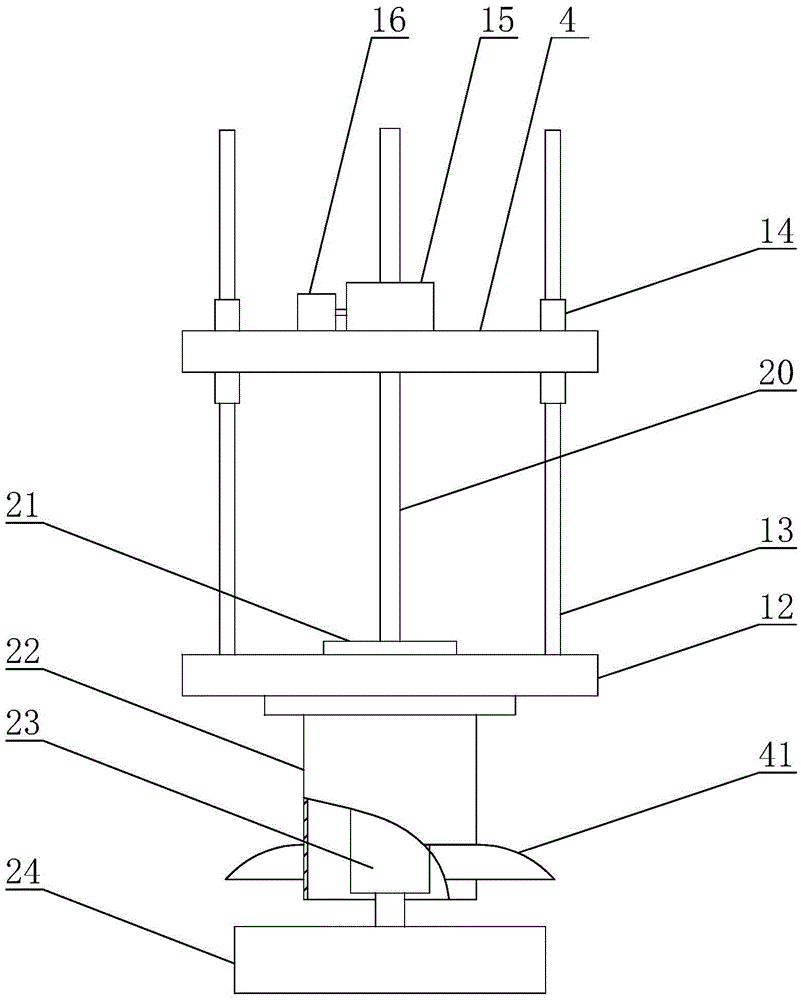

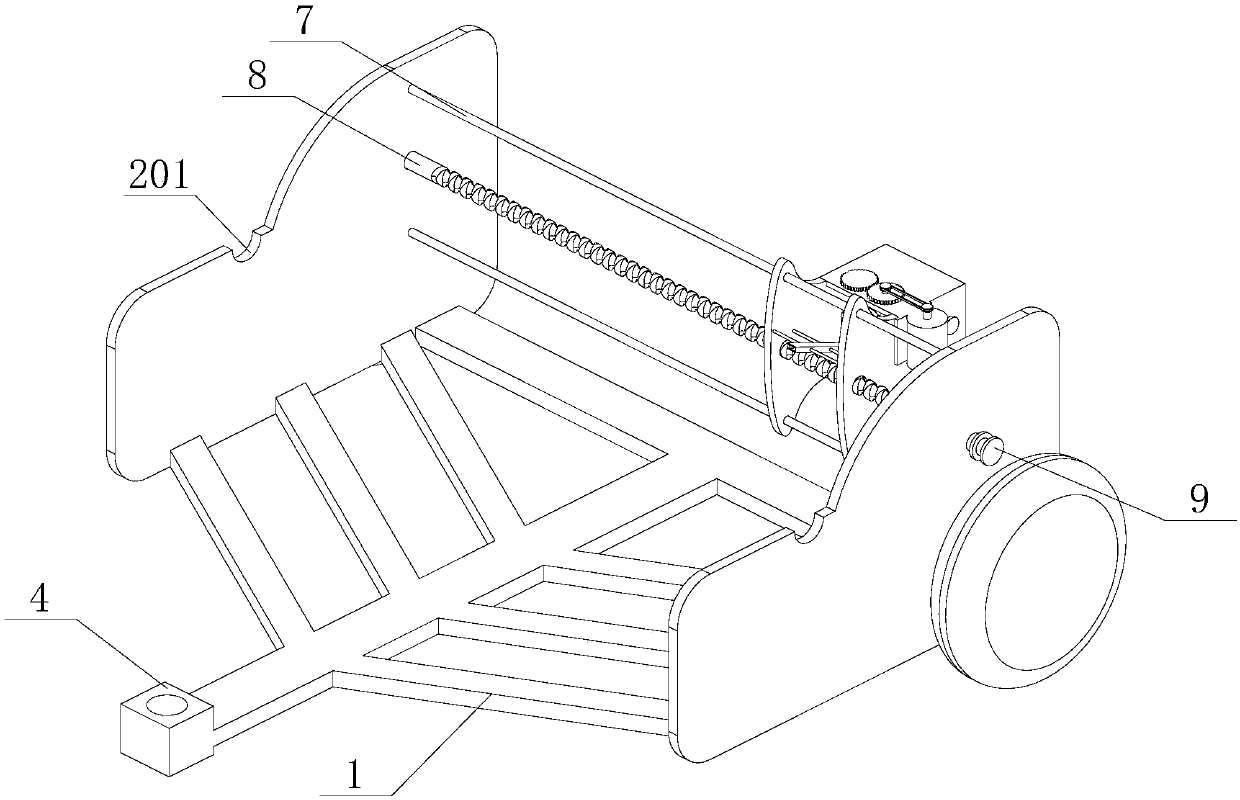

Buried cable laying device

InactiveCN105490217AReduce workloadImprove construction efficiencyApparatus for laying cablesHydraulic cylinderVehicle frame

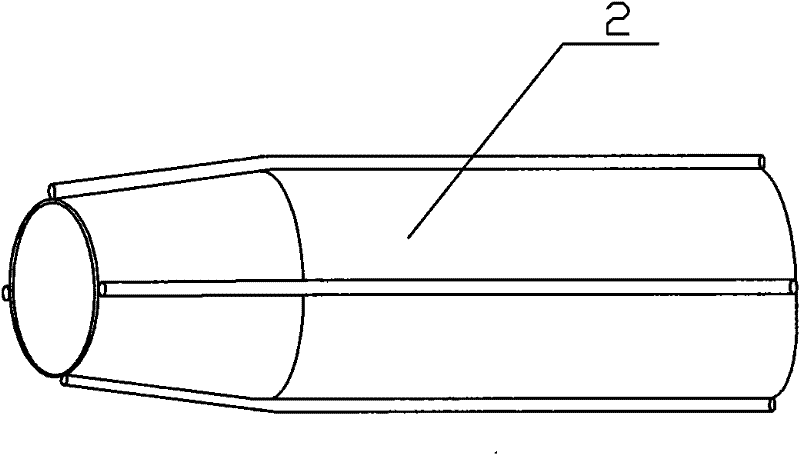

The invention discloses a buried cable laying device, and mainly relates to the technical field of electric power construction. The buried cable laying device comprises a vehicle frame, the vehicle frame is provided with a pay-off rack, the pay-off rack is provided with a plurality of spools, the top of a first support frame is provided with a hub, a support arm is provided with a guide frame, the vehicle frame is provided with a plurality of threading holes, a second support frame is provided with a tensioning rack, the bottom of the vehicle frame is provided with a rotation hydraulic cylinder, the rotation hydraulic cylinder is provided with a rotating arm, the rotating arm is provided with a U-shaped frame, the U-shaped frame is provided with rolling wheels, the vehicle frame is provided with a box body, the bottom of the box body is provided with a cloth-sand pipe, the bottom of the cloth-sand pipe is provided with a telescoping pipe, the lower part of the telescoping pipe is provided with a scraper frame, and the scraper frame is provided with a smoothing scraper. The beneficial effects of the buried cable laying device are that laying and sand filling of the buried cable can be accomplished, a lot of manpower resources can be saved, the workload of construction personnel can be reduced, and the construction efficiency can be improved.

Owner:JIYANG POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO

Automatic laying robot for direct-embedded communication cable

InactiveCN108049443AReduce labor intensityImprove work efficiencySoil-shifting machines/dredgersFoundation engineeringDirect-buried cableCement board

The invention relates to an automatic laying robot for direct-embedded communication cable. The automatic laying robot for direct-embedded communication cable comprises a travelling device, an earth cutting device and a grouting device. The earth cutting device is mounted at the front end of the travelling device. The grouting device is mounted on the travelling device. The automatic laying robotcan solve the problems that in the existing direct-embedded cable laying process, operators need to ditch and grout layers manually, during ditching, the operators need to use tools for ditching, later operation is affected due to uneven manual ditching, during laying-up, ditch bottoms need to be manually grouted and rolled, during grouting of side faces, cement boards need to be grouted and solidified by the operators outside and then conveyed to designated spots to be mounted, during advancing, existing equipment vehicles vibrate during travelling due to the steep land surface, the working progress is affected, the existing equipment vehicles is prone to vibrating when standing still in situ for operation due to the fact that no fixing device is arranged, lots of time is taken, the laborintensity is high, and the efficiency is low, and the functions of automatic ditching and laying-up for the direct-embedded cables can be achieved.

Owner:王炯炜

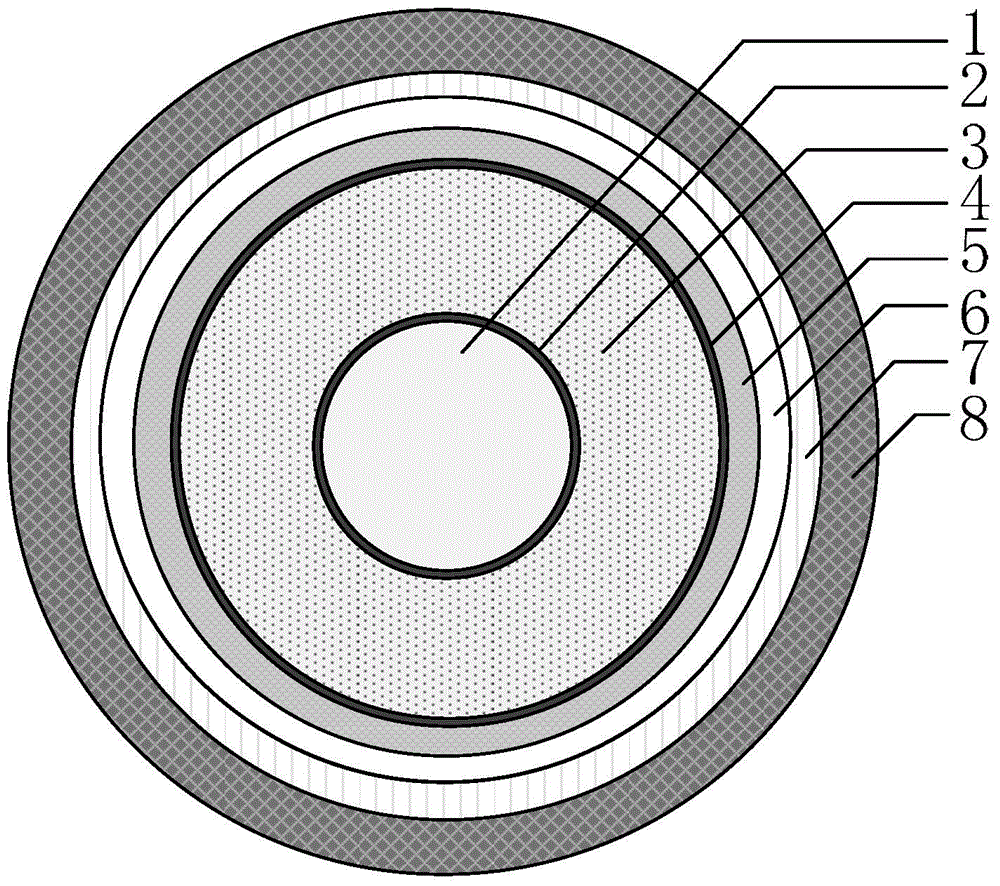

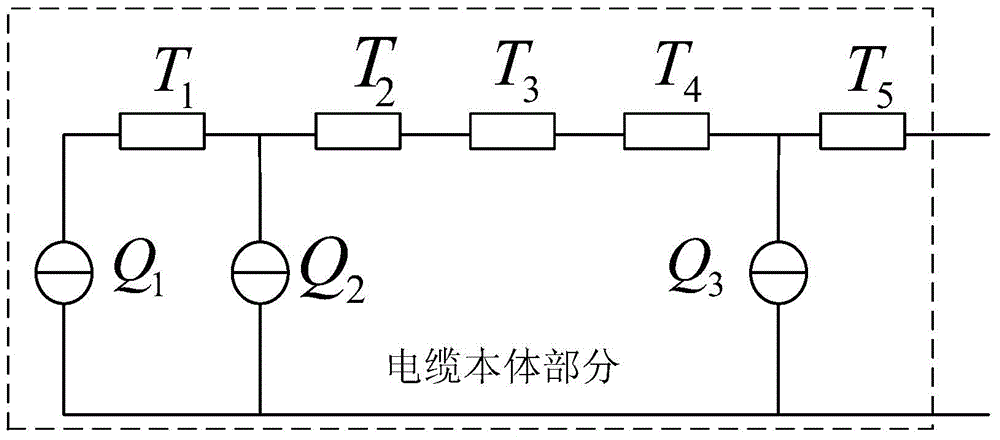

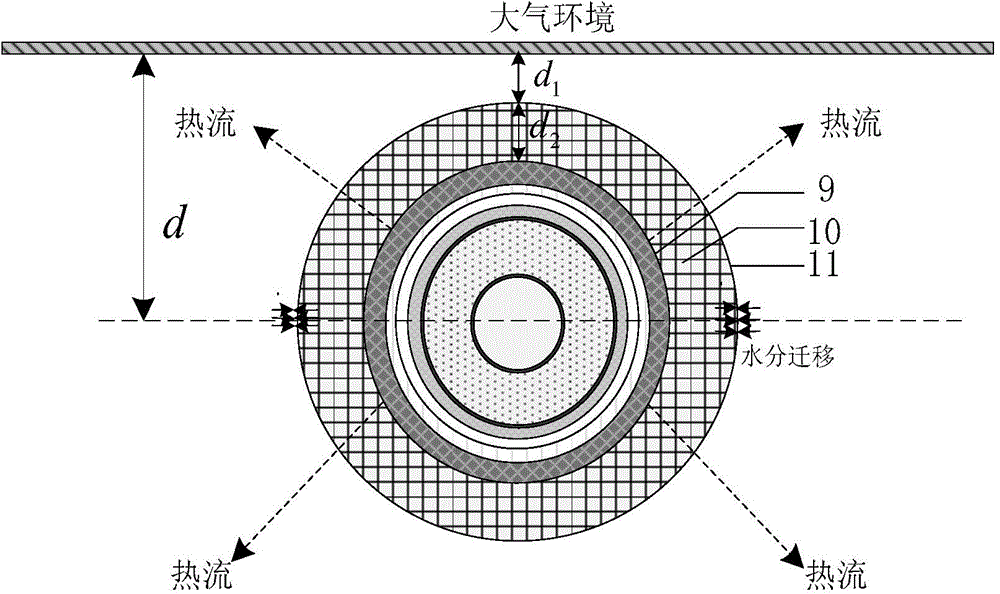

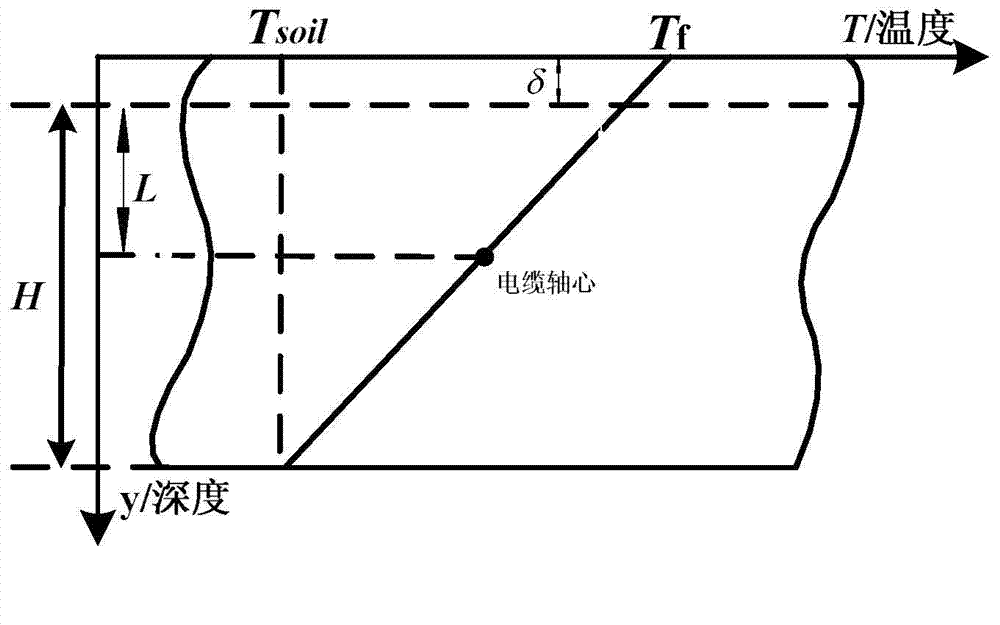

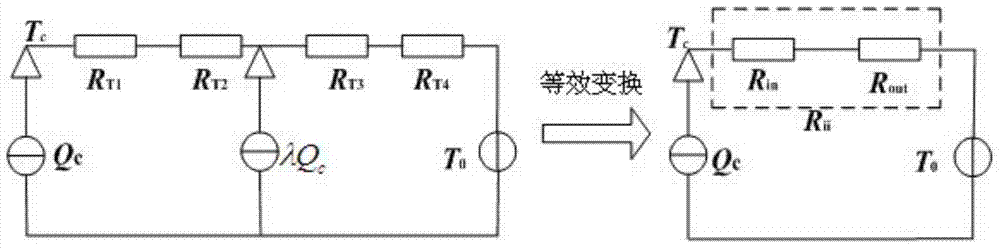

Method for calculating current carrying capacity of directly-buried single-core cable considering soil local dryness

InactiveCN104657609AReduce mistakesEasy to calculateSpecial data processing applicationsCarrying capacityHeat resistance

The invention discloses a method for calculating current carrying capacity of a directly-buried single-core cable considering soil local dryness. The method comprises the following steps of S1, modeling a directly-buried single-core cable body to obtain a thermal circuit model of the directly-buried single-core cable body; S2, building a thermal circuit model with local dry soil and natural soil double layers for the external soil of the directly-buried single-core cable; S3, connecting the thermal circuit model of the cable body and the thermal circuit model of the external soil, so as to obtain the thermal circuit model of the directly-buried single-core cable; S4, solving the thermal circuit model, and calculating, so as to obtain the current carrying capacity of the directly-buried single-core cable considering the local dryness condition. The method has the advantage that the external soil of the directly-buried cable is divided to obtain a local dryness boundary which is coaxial with the cable body, and the actual soil heat transfer property is approximated by heat resistances of the local dry soil and natural soil double layers, so the simplicity and feasibility are realized, and the calculating is convenient.

Owner:SOUTH CHINA UNIV OF TECH

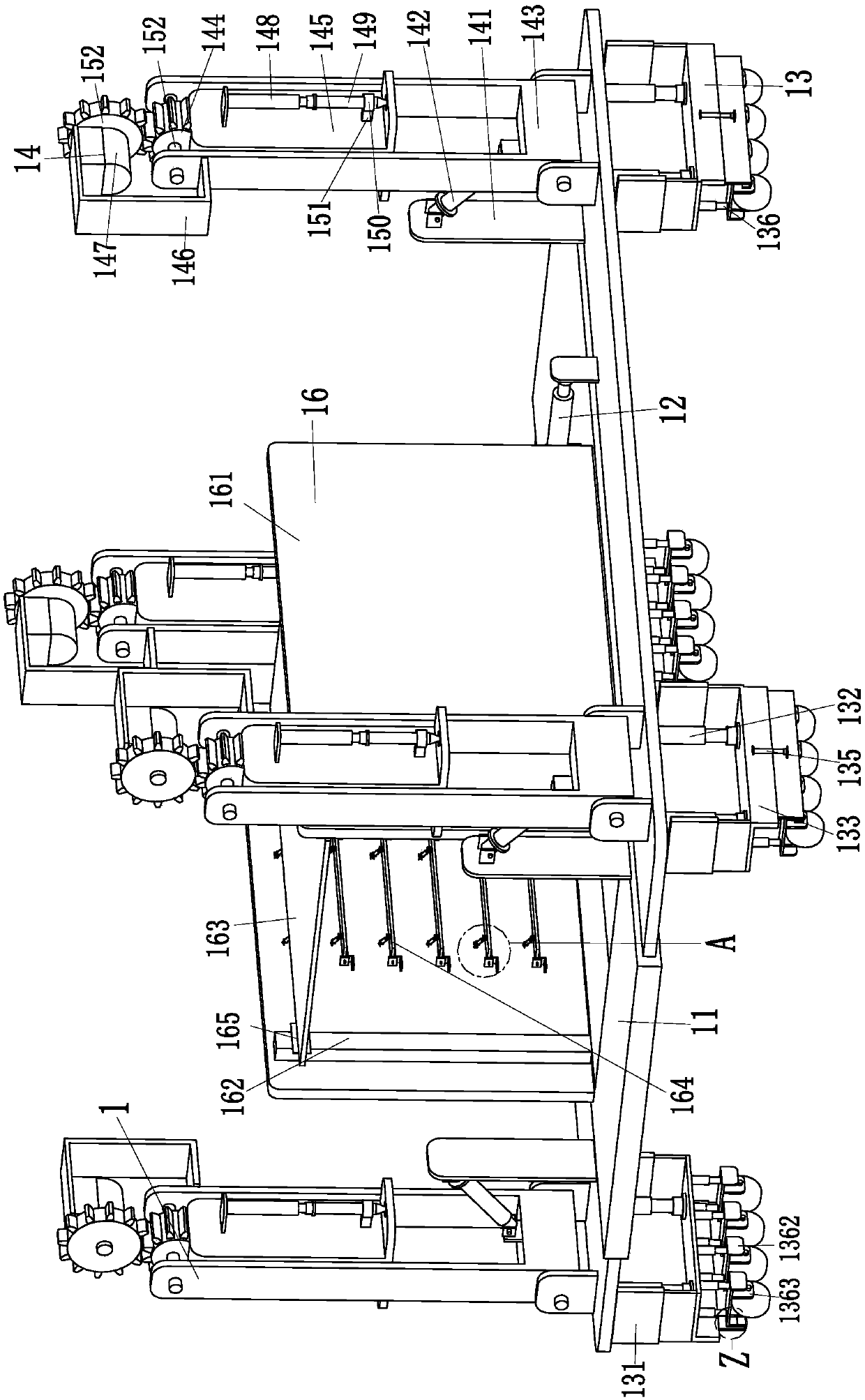

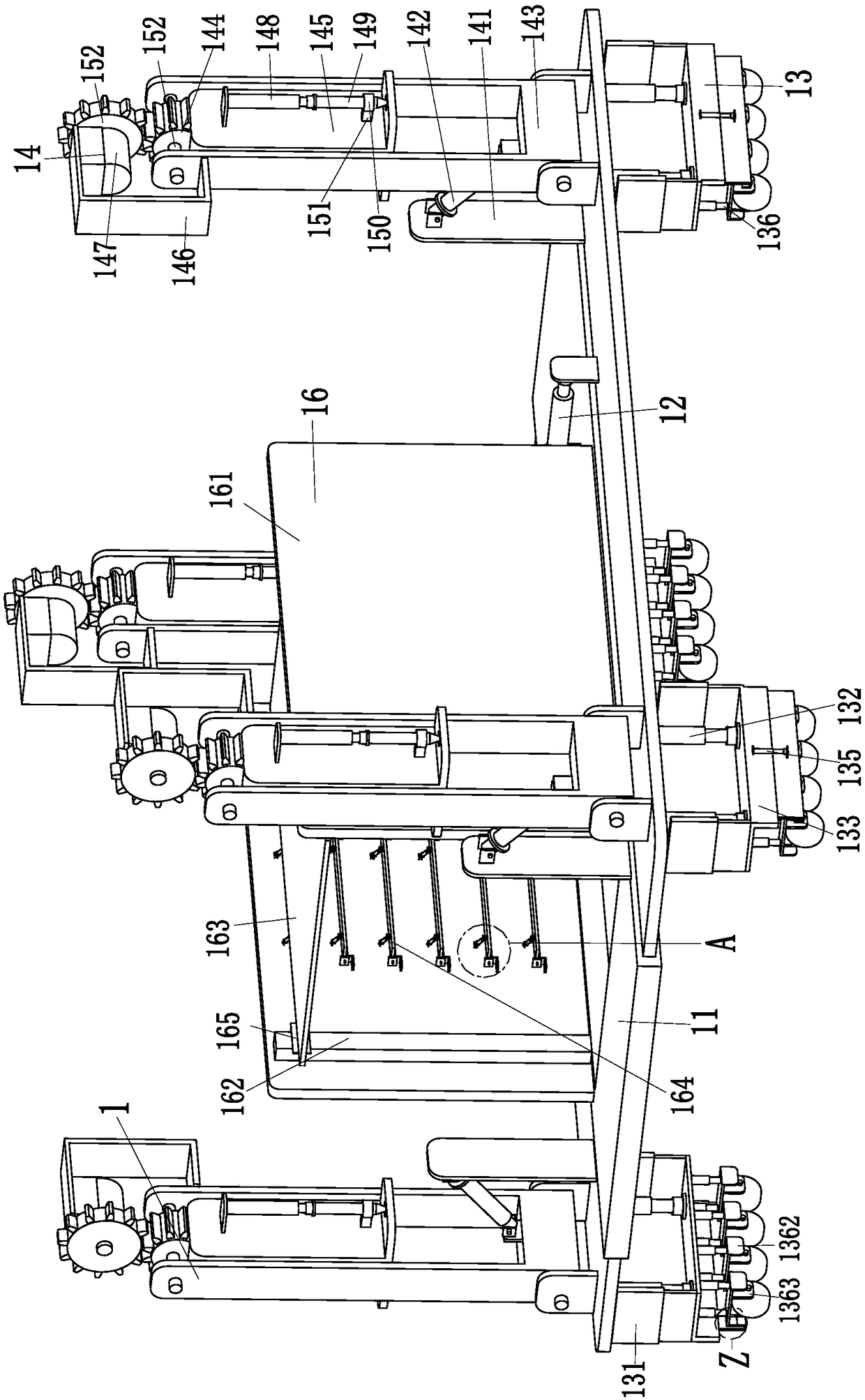

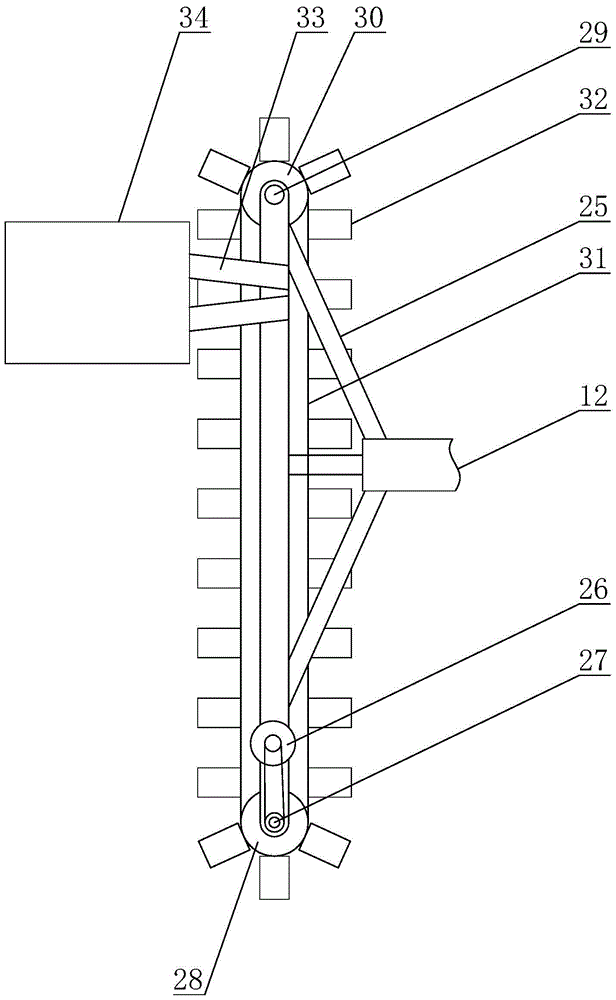

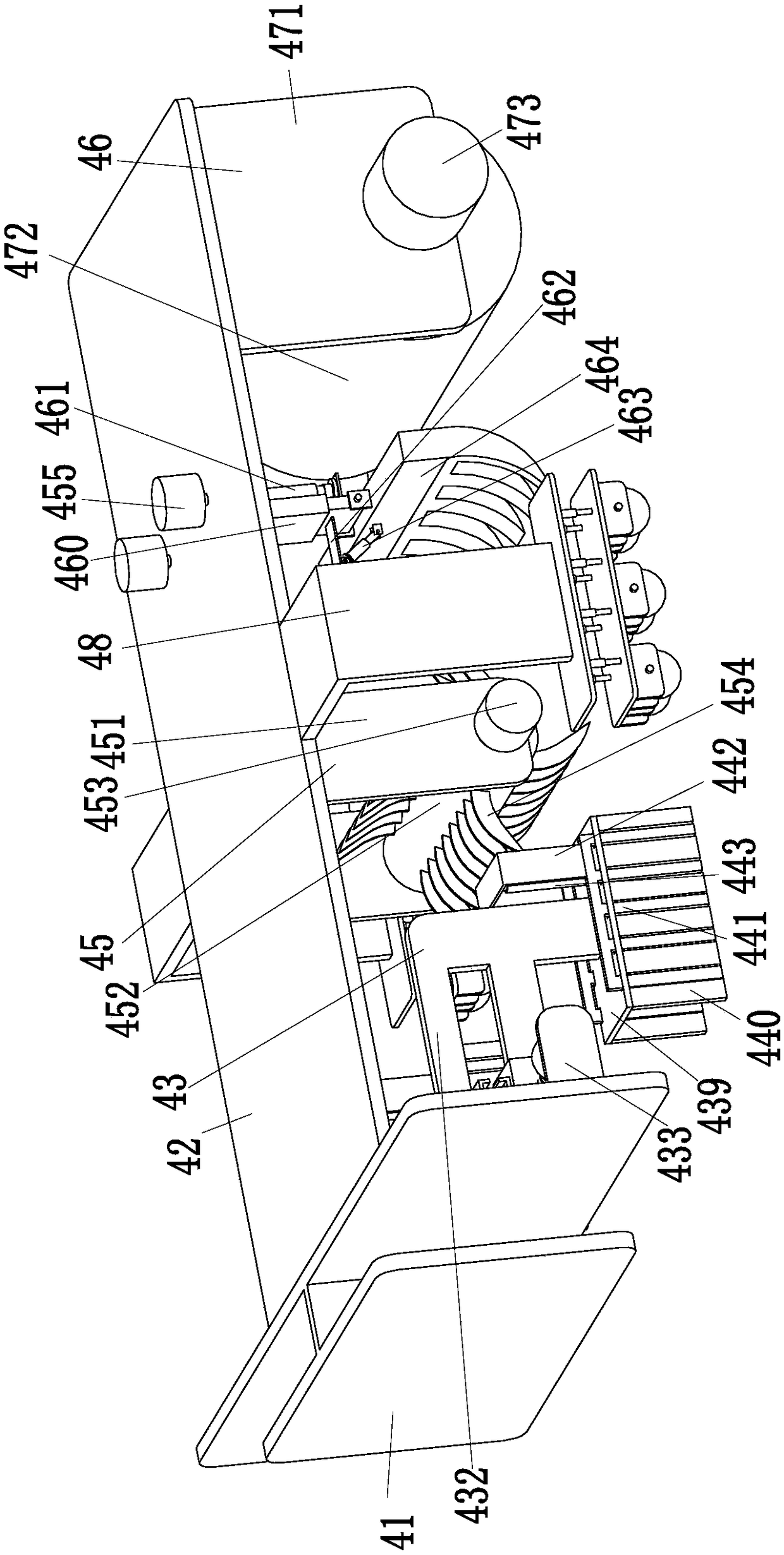

Intelligent robot for direct-buried laying of communication cable

InactiveCN108063416AReduce labor intensityImprove work efficiencyCable installations on groundManipulatorDirect-buried cableEngineering

The invention relates to an intelligent robot for the direct-buried laying of a communication cable. The robot comprises a traveling device, an excavating device and a backfill device. The excavatingdevice is installed at the front end of the traveling device, and the backfill device is installed at the rear end of the traveling device. In an existing direct-buried cable laying process, the trenching and the backfilling and rolling of soil by the staff are needed, the staff need to use tools for trenching in trenching, later work is affected if a trench is not flat in manual trenching, a later backfill effect is affected if the sizes of artificially excavated soil blocks are not consistent, at the same time, the soil processing is cumbersome after the manual trenching, when soil is backfilled, flapping and pressing the soil after the backfilling of the artificially excavated soil are needed, if manual pressing is not compact, an existing vehicle vibrates in walking to affect the process of the work in going forward due to a steep land surface, and the existing vehicle easily shakes without a fixing device when the existing vehicle works at a fixed place, the above problems are solved by the intelligent robot in the invention, and the function of the intelligent laying of the communication cable can be realized.

Owner:倪敏芳

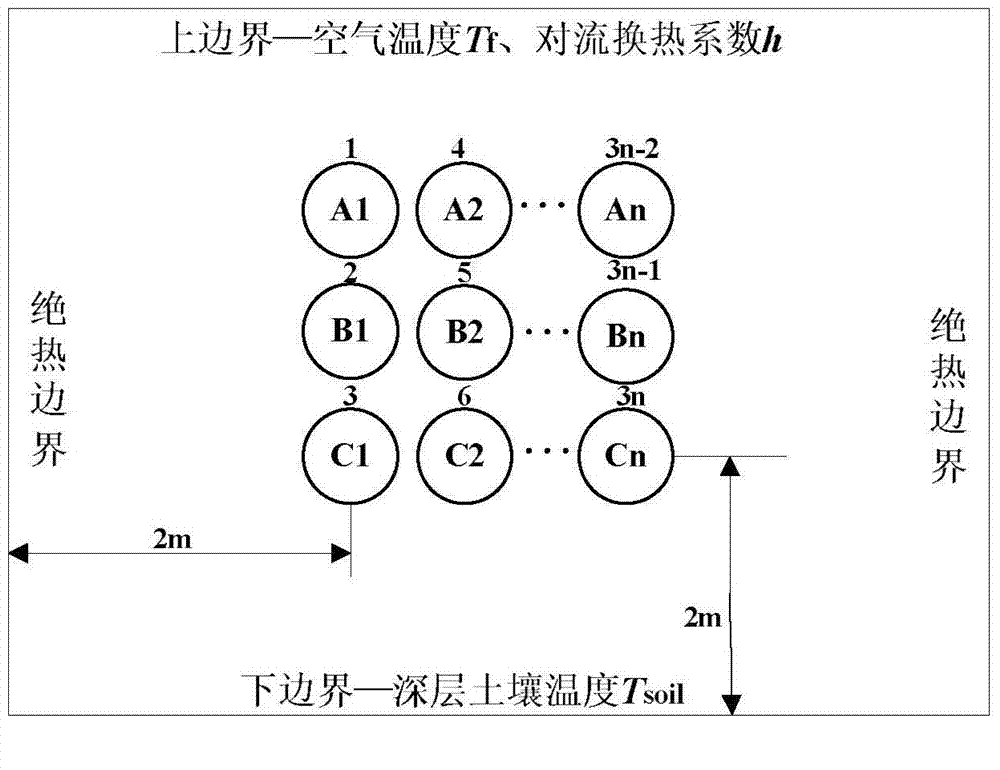

Calculation method of temperature of conductors of multi-loop soil directly buried cables

ActiveCN104750995AVersatilitySpecial data processing applicationsElectrical conductorDirect-buried cable

The invention discloses a calculation method of temperature of conductors of multi-loop soil directly buried cables. The method comprises the following steps: determining a cable and a soil temperature field two-dimensional solving region and numbering each loop of cable in sequence; determining a boundary condition and a physical parameter of the temperature field solving region; calculating initial temperature of each cable conductor under the conditions that all loops are not electrified; solving the thermal resistance parameter of each cable by comprehensively utilizing an analysis method and a definite element method, and further solving the conductor temperature rise caused by loss of the cables; calculating an interaction coefficient between every two cables, and further solving the temperature of each cable conductor caused by an external cable heat source; constructing a multi-loop soil directly buried cable conductor temperature calculation model to accurately calculate the conductor temperature of each cable. The method is suitable for various main laying forms of a current power cable, in particular a cluster laid cable lines with relative lack in research, and the calculation precision is improved while the cable conductor temperature calculation method is simplified.

Owner:STATE GRID CORP OF CHINA +1

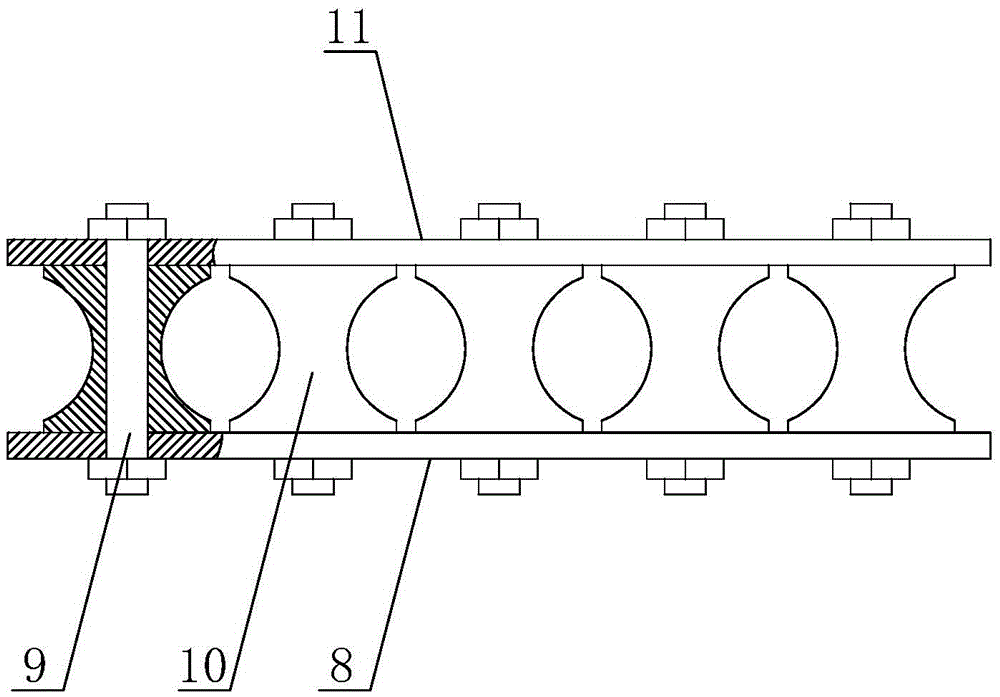

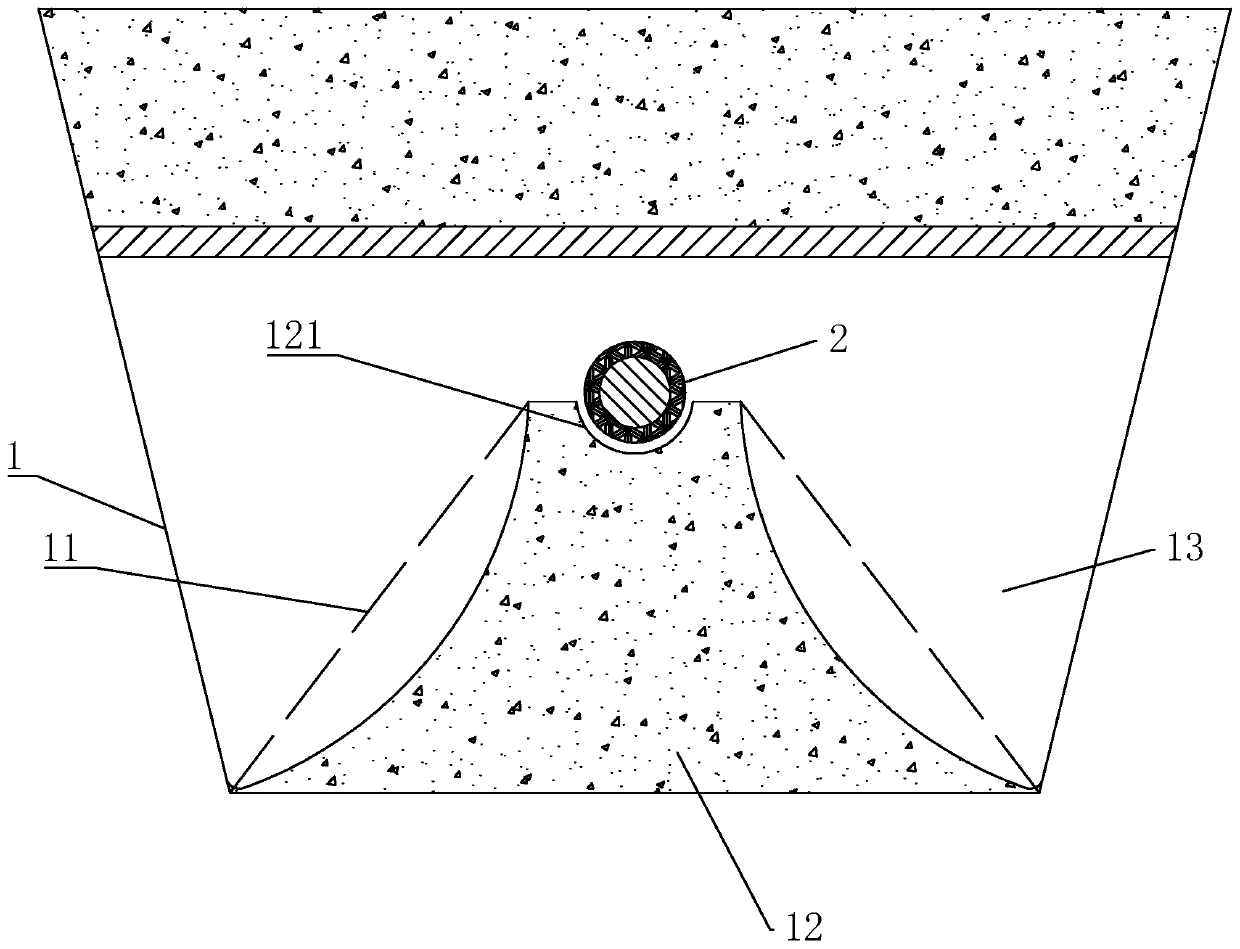

Buried cable laying method and cable protection sleeve special for method

ActiveCN108565785AEnhance storage and drainage capacityExtended service lifeCable installations in underground tubesApparatus for laying cablesDirect-buried cableEngineering

The invention discloses a buried cable laying method and a cable protection sleeve special for the method and belongs to the field of cable laying. According to the buried cable laying method, by improving the water storage and drainage capacity of a cable groove, the cable protection sleeve is not easily in contact with accumulated water, and accordingly the problem is solved that the cable protection sleeve swells and deforms when being soaked in the accumulated water. The buried cable laying method is characterized by comprising the following steps of S1, engineering line repetition measurement of a cable line; S2, disk distribution for a cable; S3, cable laying; S4, backfill of the cable groove; S5, burying of stakes. The third step comprises the following specific processes of 3-1, digging of the cable groove, wherein foundation pits are dug, stacks are formed, rough shaping and fine shaping are conducted, and the cable groove is poured and formed; 3-2, cable laying, wherein manual cable laying is conducted, the cable is laid at one side of the cable groove, and the cable protection sleeve wraps the cable; a specially-assigned person straightens out the cable and puts the cable into the cable groove. The buried cable laying method is suitable for buried cable laying.

Owner:中铁十五局集团电气化工程有限公司

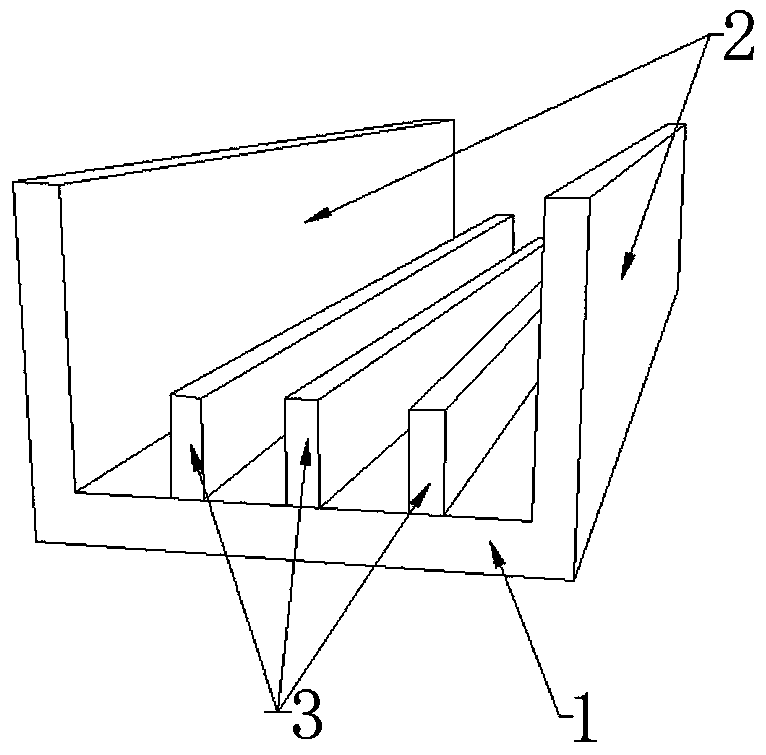

Excavation device of direct burial cable trench

InactiveCN105633899AReduce laying costsReduce the amount of post-construction workCable installations on groundSoil-shifting machines/dredgersMilling cutterDirect-buried cable

The invention discloses an excavation device of a direct burial cable trench and belongs to the electric power planning technical field. The excavation device comprises a first supporting frame; the bottom of the first supporting frame is provided with foundation bolts; the top of the first supporting frame is provided with a guide rail; the guide rail is provided with a supporting seat; the supporting seat is in sliding connection with the guide rail; the first supporting frame is provided with a traction mechanism for driving the supporting seat to move; a supporting plate is arranged below the supporting seat; the supporting plate is provided with guide columns; the supporting seat is provided with a guide sleeve which is adaptive to the guide columns; the supporting seat is provided with a supporting plate lifting mechanism; the bottom of the supporting plate is provided with a supporting cylinder; the bottom of the supporting cylinder is provided with a disc milling cutter; and one end of the supporting plate is provided with a cleaning device. With the excavation device of the invention adopted, a cable trench of a corresponding width can be excavated in a road, and the engineering amount of later-stage construction can be decreased, and cable laying cost can be reduced.

Owner:STATE GRID CORP OF CHINA +1

Preparation method of high-heat-resistance high-strength half tubes used for embedded electric cables

ActiveCN102604339AHigh compressive strengthImprove notched impact strengthElectrical apparatusOcean bottomDirect-buried cable

The invention relates to a preparation method of high-heat-resistance high-strength half tubes used for embedded electric cables, which includes steps of utilizing 63-75 weight parts of polyethylene glycol terephthalate as raw materials, adding 13-18 weight parts of propylene-ethylene random copolymer, 8-12 weight parts of fire retardant masterbatches, 3.5-6.0 weight parts of maleic anhydride grafting polyethylene and 0.5-1.0 weight part of Triisodecyl (2,4-di-tertiary butyl phenyl) phosphite ester, and preparing the half tubes by drying, dewatering, mixing, stirring, extruding, pelleting, extruding, forming, cooling and forming. The half tubes prepared by the preparation method are high in vicat softening temperature, fine in insulation performance, high in corrosion resistance and fire retardant level, resistant to creep deformation, fine in pressure and tension resistance and applicable to fields of protection modifying of directly-embedded cables, protection of ground access cables and paving protection tubes of seabed cables and the like.

Owner:FUJIAN NORMAL UNIV

Buried cable pile

InactiveCN103606875AAvoid damageReasonable structureElectrical apparatusBoardsDirect-buried cableEngineering

The invention discloses a buried cable pile which is reasonable in structure and capable of effectively preventing a person or a car from colliding with the buried cable pile. According to the technical scheme, the buried cable pile comprises a spring, wherein a buried body is arranged on a base, the spring is arranged at the upper portion of the buried body, and an indication pillar is arranged at the upper portion of the spring and is made of plastics. The buried cable pile is reasonable in structure, good in use effect and capable of effectively avoiding damaging people or cars.

Owner:STATE GRID CORP OF CHINA

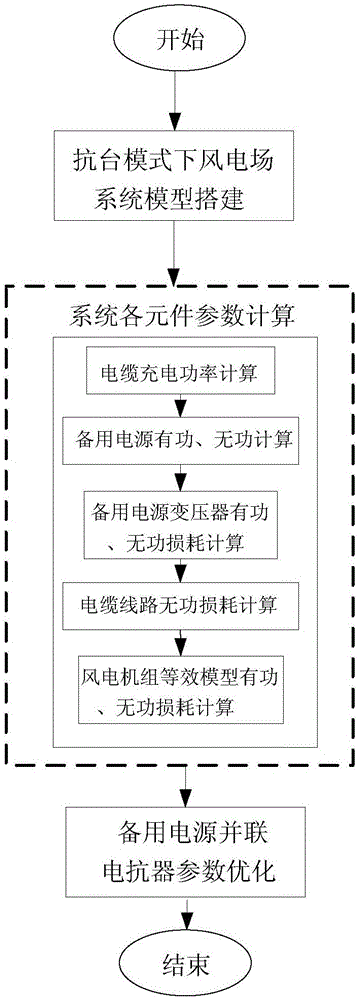

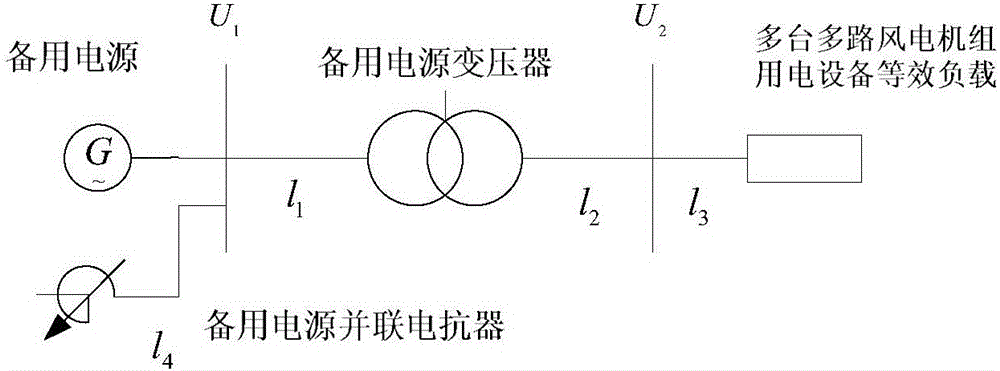

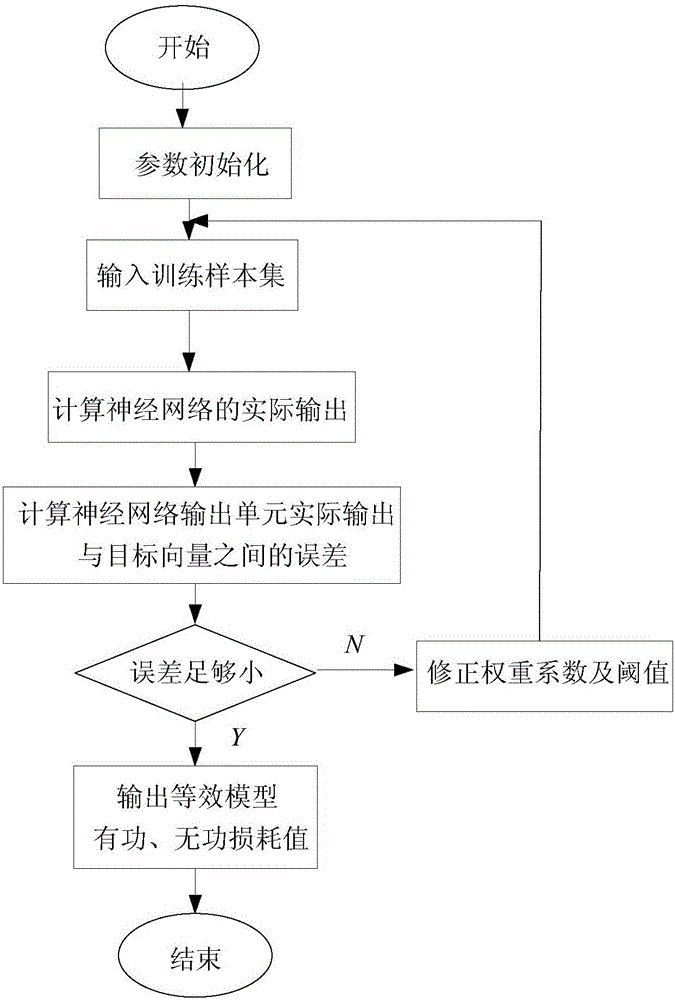

Parameter optimization method for backup power parallel reactor based on anti-typhoon running mode of wind power plant

ActiveCN106229995AAvoid difficultiesSimple designSingle network parallel feeding arrangementsReactive power adjustment/elimination/compensationTransformerDirect-buried cable

The invention relates to a parameter optimization method for a backup power parallel reactor based on an anti-typhoon running mode of a wind power plant. The method comprises the following steps: firstly, integrally modeling for the system under the anti-typhoon running mode, wherein the system model comprises a backup power supply, a backup power parallel reactor, a backup power transformer, a direct buried cable and a plurality of multi-path wind turbine generator equivalent models; respectively calculating power loss of system elements in the models; confirming the parameter of the reactor requiring parallel connection according to the system power factor before optimization and the realized power factor after optimization. The parameter optimization method for the backup power parallel reactor based on the anti-typhoon running mode of the wind power plant, provided by the invention, is used for optimizing the oversize capacity current into lower sensitive current and is beneficial to the closing operation of the circuit breaker.

Owner:ZHEJIANG WINDEY

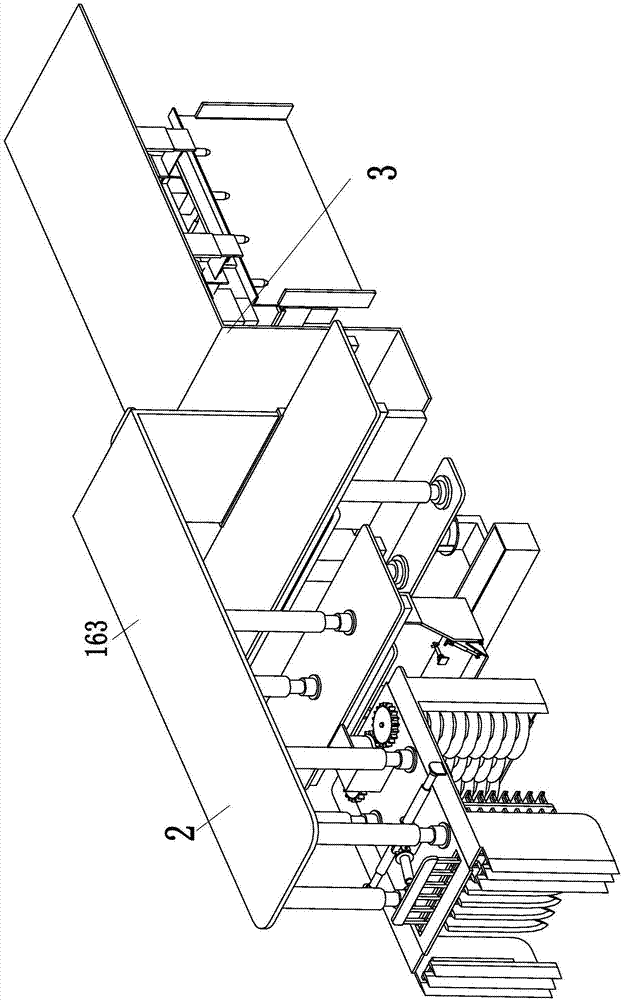

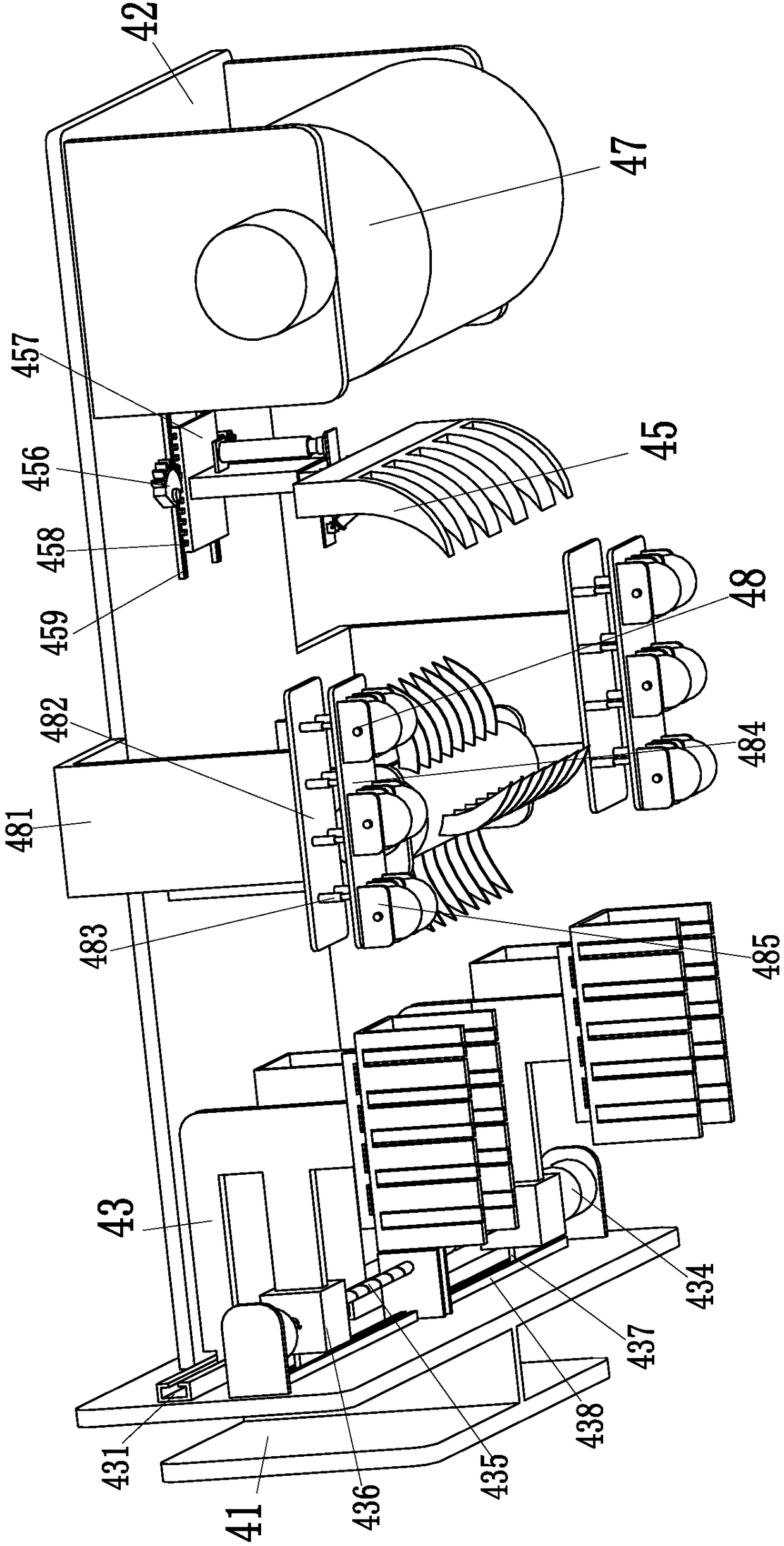

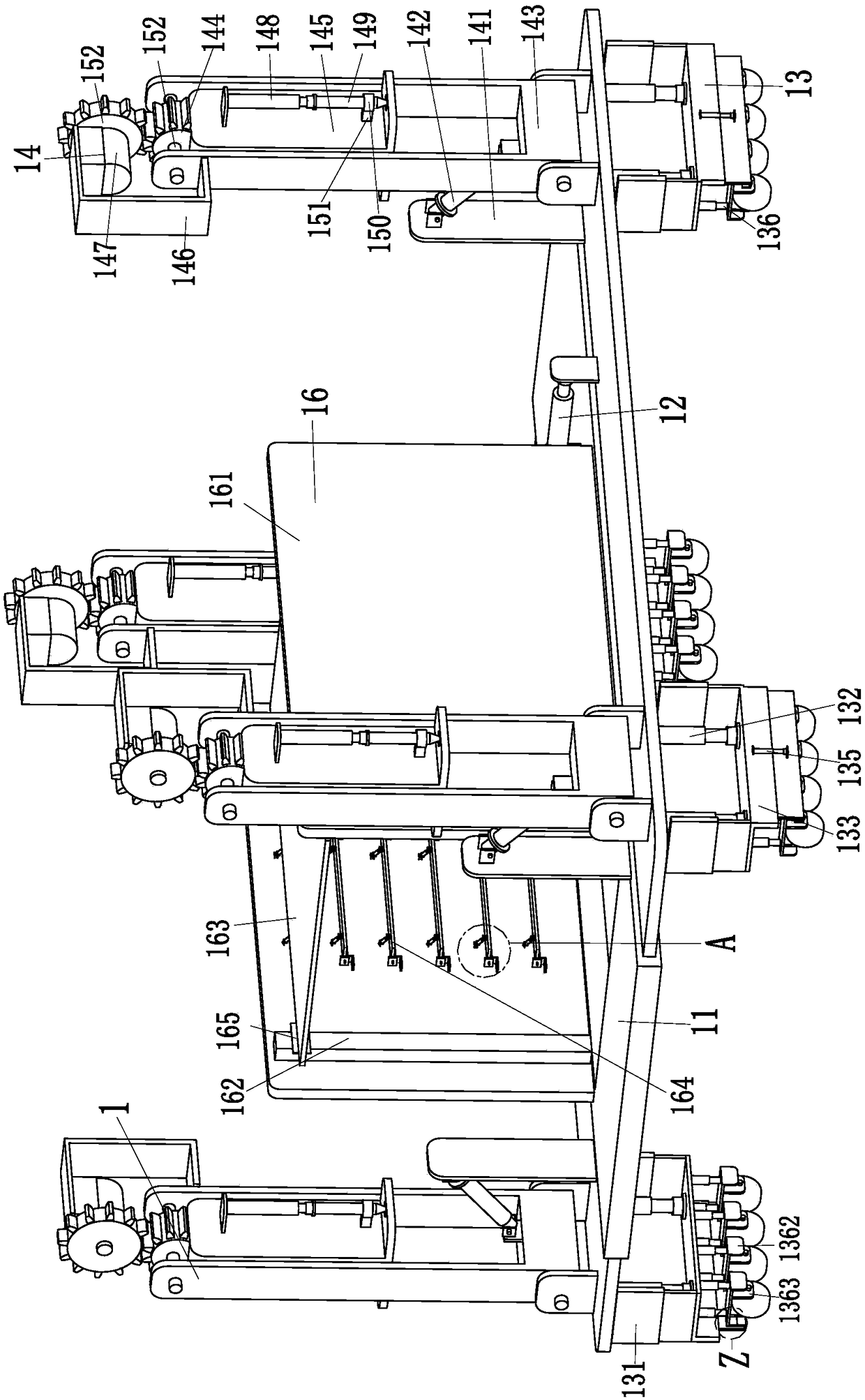

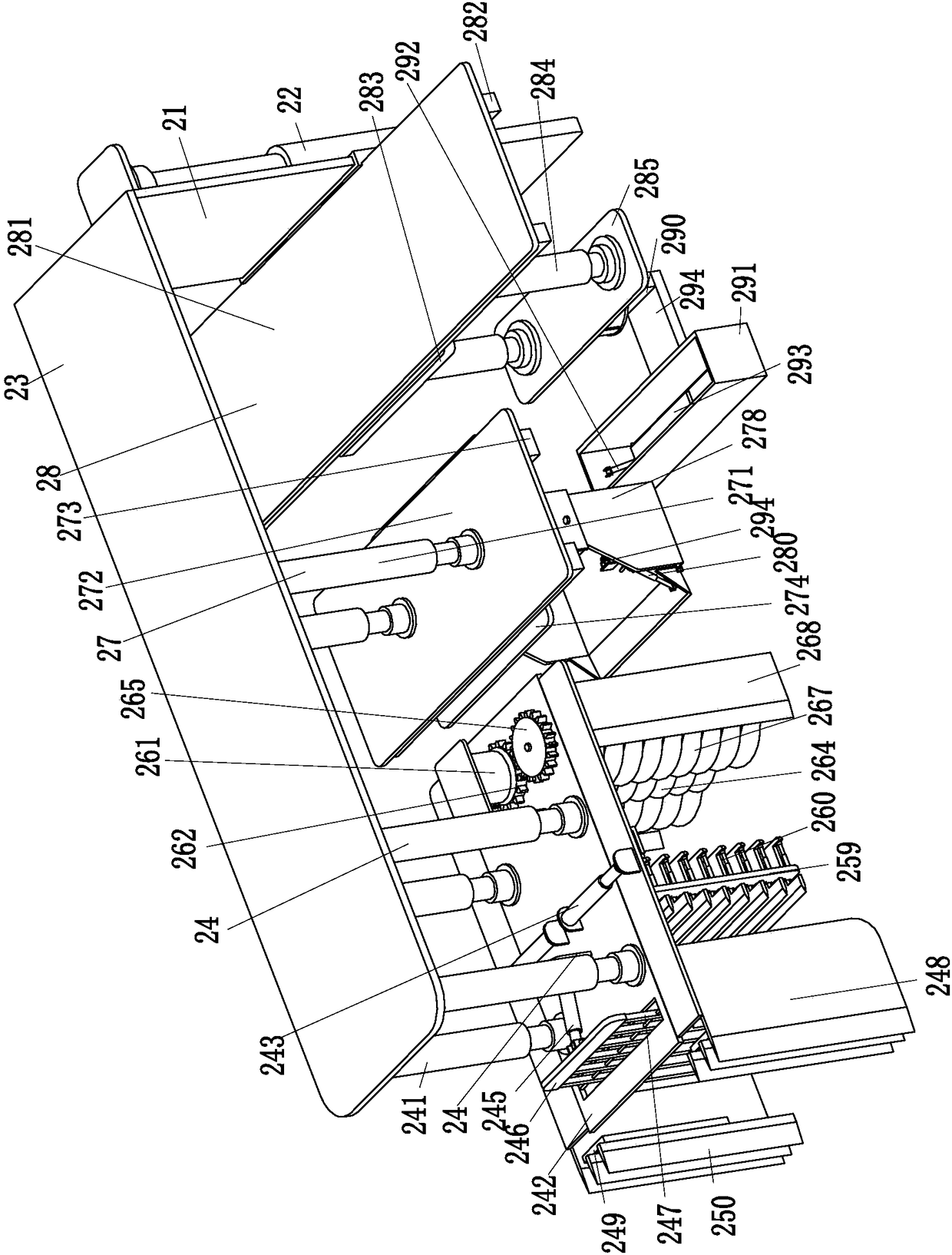

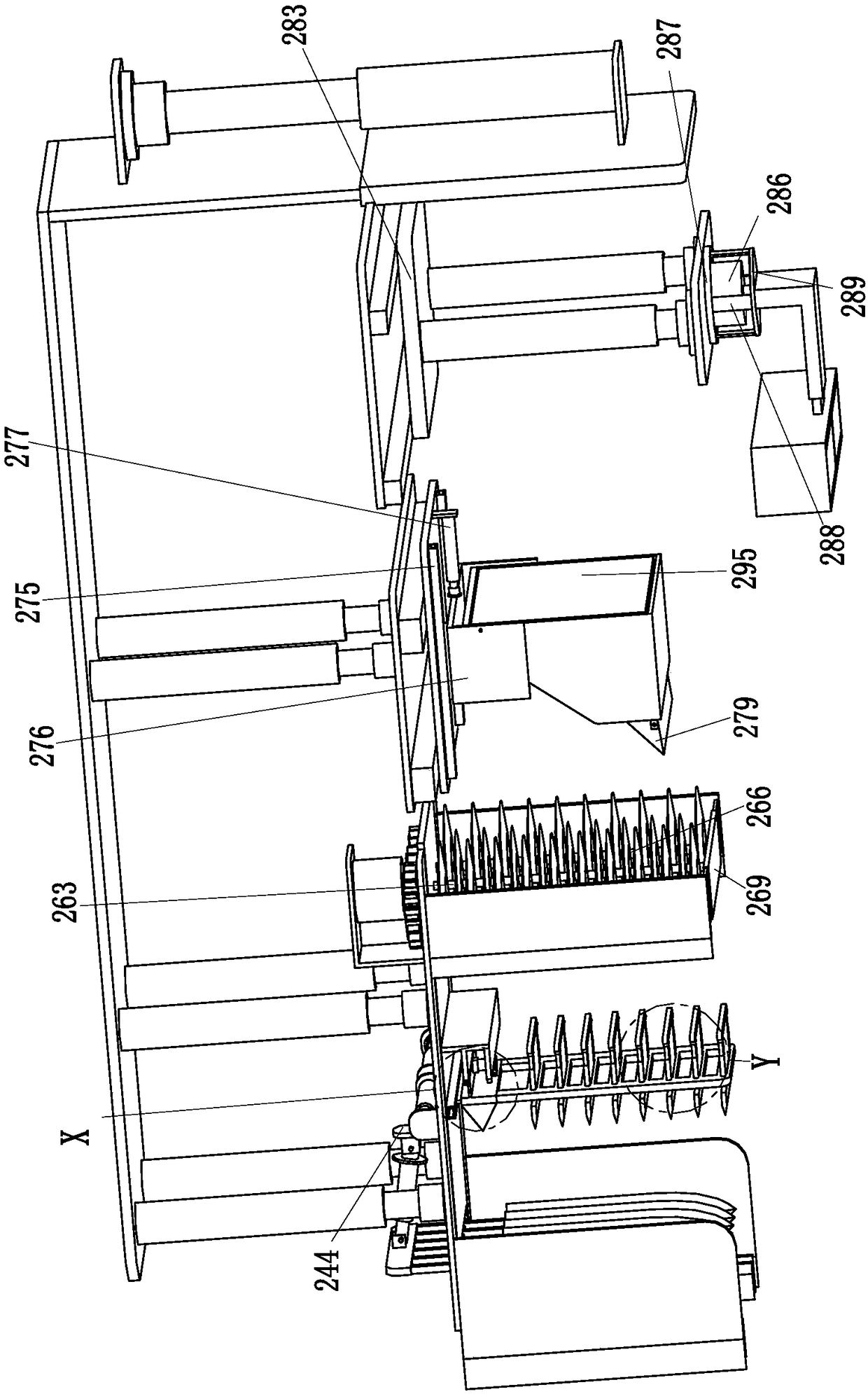

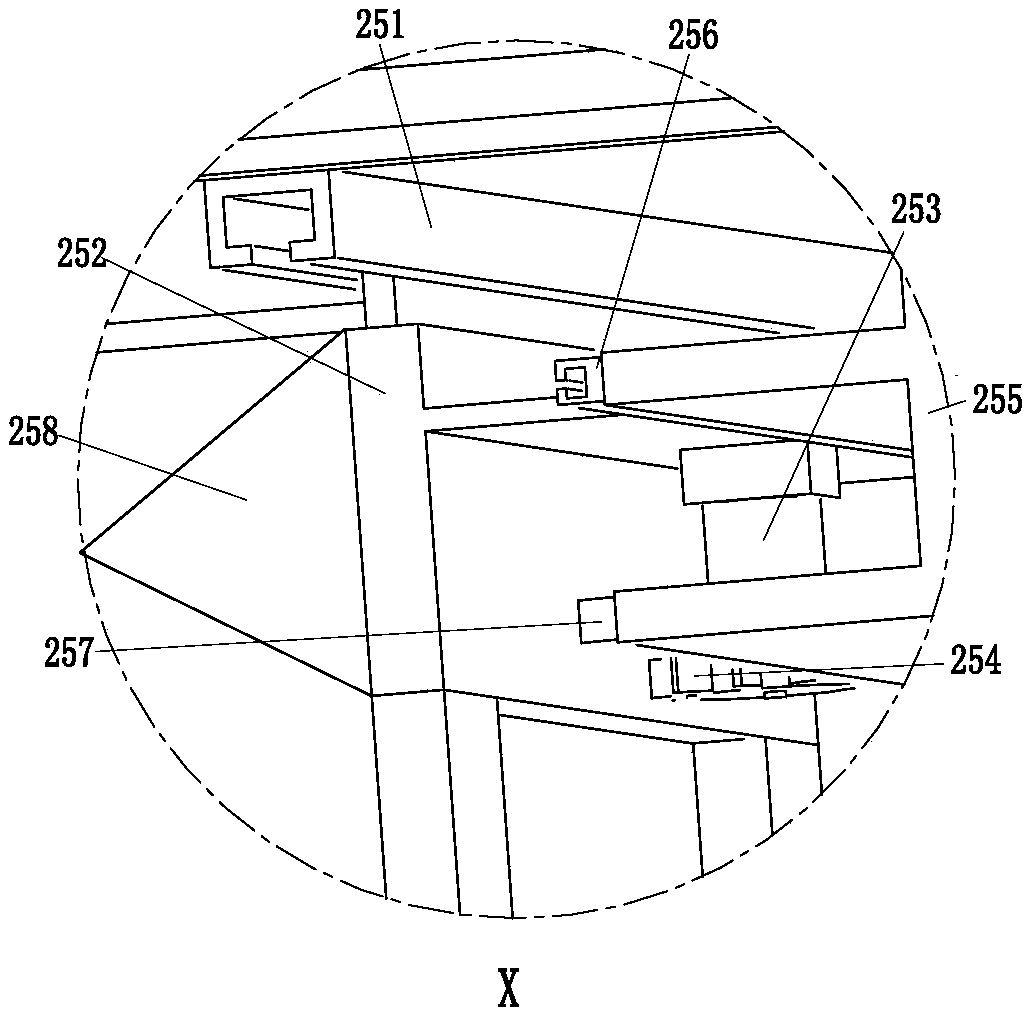

Direct-buried type communication cable laying equipment with capacity of realizing intelligent excavation and laying

InactiveCN107989093AReduce labor intensityImprove work efficiencySoil-shifting machines/dredgersFoundation engineeringSoil treatmentDirect-buried cable

The invention relates to direct-buried type communication cable laying equipment with capacity of realizing intelligent excavation and laying. The equipment comprises a lifting plate, an excavation device and a grouting device, wherein the excavation device is mounted at the front end of the lifting plate; the grouting device is mounted on the lifting plate. With the adoption of the equipment, theproblems that a worker is required to perform ditching and manual grouting and laying in conventional direct-buried cable mounting process and potential safety hazards are produced because of back injury caused by the fact that the worker needs to dig a ditch by a tool during ditching and bends down to work for a long time are solved, and furthermore, the problems that soil treatment is tedious after manual ditching, the bottom of the ditch is required to be subjected to grouting rolling manually during laying, the manual rolling is uneven as well as gaps are easily produced between cement slabs, the cement slabs are mounted unstably, time consumption of the laying process is high, labor intensity is high, efficiency is low and the like due to the fact that the cement slabs are required to be subjected to grouting solidification outside by the worker during grouting on the side surface and then transported to designated positions for mounting are solved, so that the equipment can realize functions of intelligent excavation and laying of communication cables.

Owner:刘静

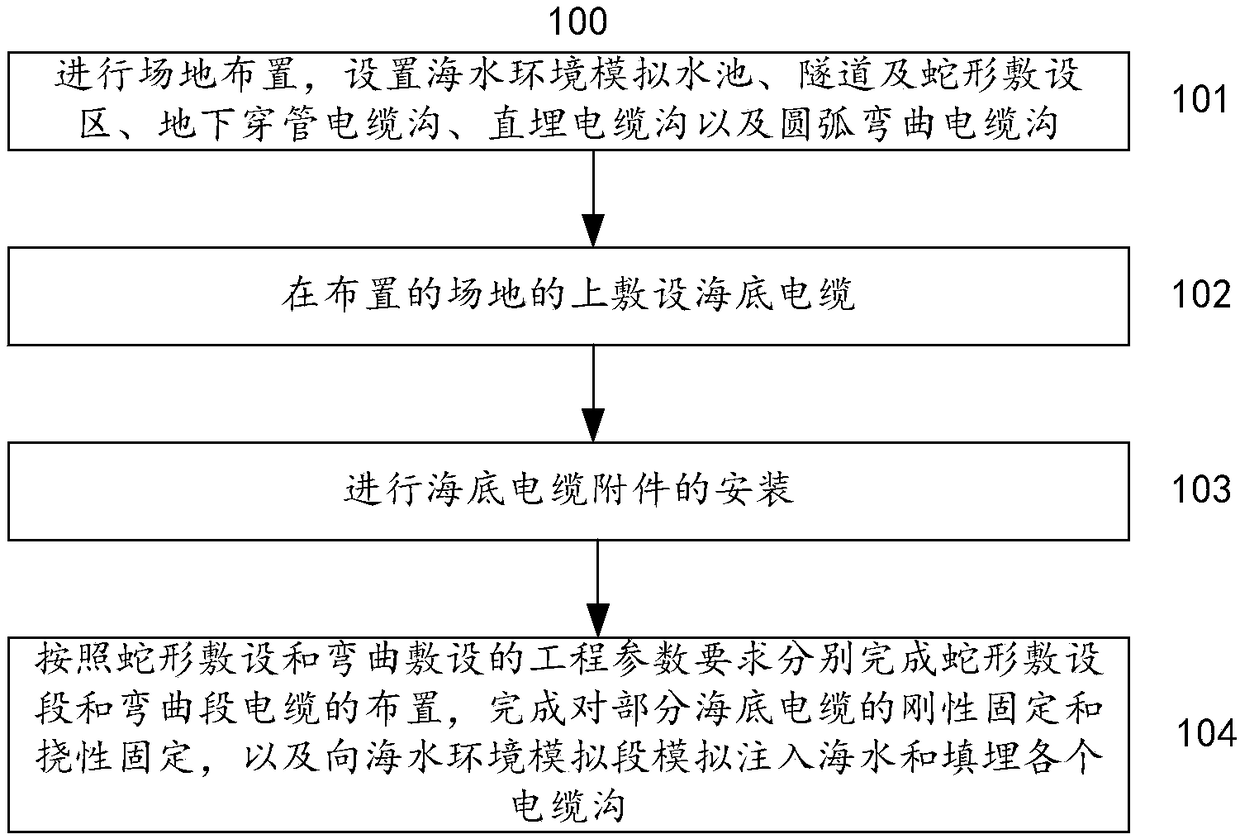

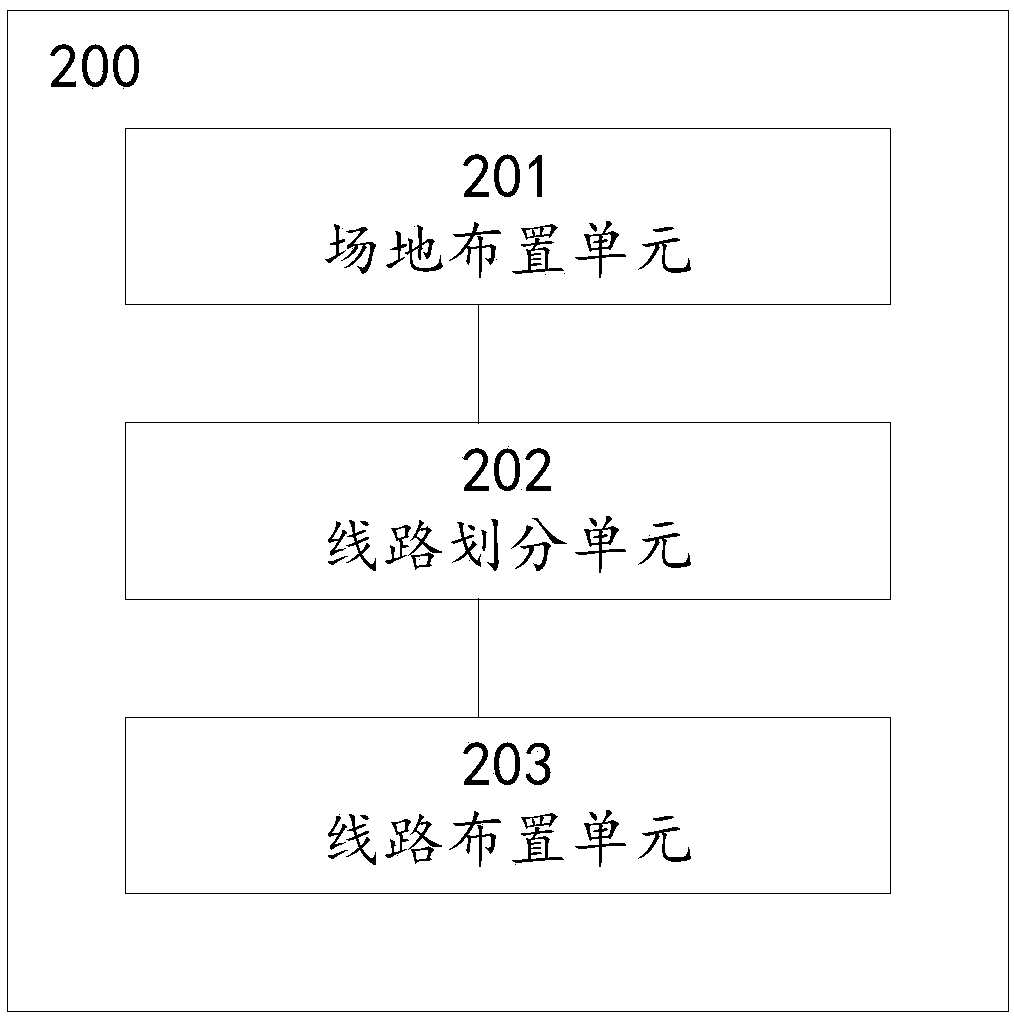

Method and system for arranging line for preliminary qualification test of submarine cable system

InactiveCN108594084APre-qualification test trueTesting dielectric strengthOcean bottomMarine engineering

The invention provides a method and system for arranging a line for a preliminary qualification test of a submarine cable system, and the method comprises the steps: arranging a place, and setting a seawater environment simulation pool, a tunnel, a snake-shaped laying region, an underground threading cable trench, a directly buried cable trench, and an arc-shaped bent cable trench; laying a submarine cable at the arranged place, and dividing the laid line into various laid segments according to the difference of operation environments and laying states; installing submarine cable accessories;and completing the burying and seawater simulation environment arrangement according to the laying requirements. The method and system can achieve the arrangement of the submarine cable line on the land, increase the seawater environment simulation segment, enable the arrange of the line for the preliminary qualification test of the submarine cable system to completely represent the conditions ofthe laying design in the submarine cable standard, can guarantee that the long-term performances of the submarine cable system are checked truly, effectively, scientifically and objectively through the preliminary qualification test.

Owner:CHINA ELECTRIC POWER RES INST +1

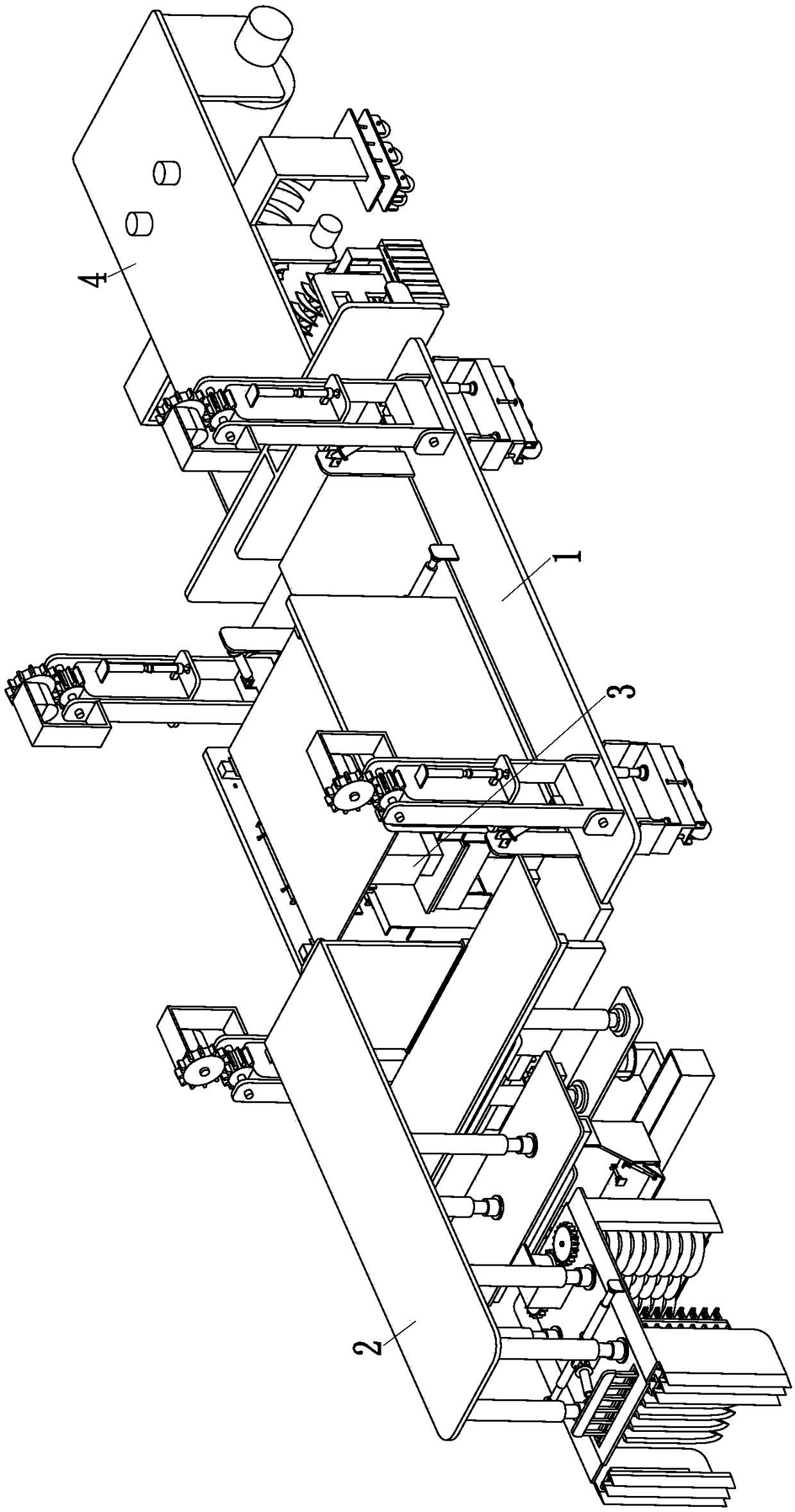

Direct-buried 1KV polyvinyl chloride insulated power cable laying machine with intelligent backfilling

InactiveCN108092185AEnsure safetyImprove securityApparatus for overhead lines/cablesApparatus for laying cablesPower cableDirect-buried cable

The invention relates to a direct-buried 1KV polyvinyl chloride insulated power cable laying machine with intelligent backfilling. The direct-buried 1KV polyvinyl chloride insulated power cable layingmachine comprises a frame, a horizontal plate, two backfilling mechanisms, a soil loosening mechanism, a rolling mechanism and two auxiliary mechanisms. A transverse plate is installed on the frame.The lower end front side of the horizontal plate is equipped with two symmetrically arranged backfilling mechanisms, the lower end middle of the horizontal plate is equipped with the soil loosening mechanism, the lower end back side of the horizontal plate is equipped with the rolling mechanism, and the left and right ends of the horizontal plate is equipped with the two symmetrically arranged auxiliary mechanisms. In an existing direct-buried cable laying process, the backfilling and rolling of soil by the staff are needed, flapping and pressing the soil after the backfilling of the artificially excavated soil are needed, the process is cumbersome, long-term bending work can easily cause body injury and cause potential safety hazards, the sizes of excavated soil blocks are not consistent,the manual pressing is not compact, the above problems can be solved by the direct-buried 1KV polyvinyl chloride insulated power cable laying machine in the invention, and the functions of automatically backfilling and rolling the soil in laying a direct-buried cable can be achieved.

Owner:刘静

Method for rapidly repairing damage of directly-buried cable

ActiveCN112467638ALow costGuaranteed originalityApparatus for repairing insulation/armouring cablesAdhesive beltDirect-buried cable

The invention provides a method for rapidly repairing the damage of a directly-buried cable, which is particularly suitable for repairing the damage of a cable outer sheath or the main insulation of the cable, the insulation sealing performance of the cable is recovered by using a high-voltage waterproof insulation composite adhesive tape in a semi-lapping manner, the mechanical damage resistanceof the cable is recovered by using an industrial armor wrapping tape, and the cable does not need to be cut off. The original main body structure of the cable does not need to be damaged, and only thedamaged part of the cable needs to be repaired to prevent water and moisture from entering the cable to cause insulation faults of the cable. Compared with a traditional repairing method, the high-voltage waterproof insulation composite adhesive tape is used for recovering the insulation sealing performance of the cable in a half-lap wrapping mode, the industrial armor wrapping tape is used for recovering the cable, rapidness and convenience are achieved, and the cost is low; no intermediate joint is generated, the primitiveness of the cable is ensured, and the original electrical insulationperformance of the cable is ensured; and only a fault point needs to be excavated, and the earth excavation amount is reduced.

Owner:西北水利水电工程有限责任公司

Equipment for automatically laying direct-buried 10KV overhead insulated cable

InactiveCN108075401AReduce labor intensityImprove work efficiencyApparatus for overhead lines/cablesApparatus for laying cablesDirect-buried cableSoil surface

The invention relates to equipment for automatically laying a direct-buried 10KV overhead insulated cable, and the equipment comprises a walking device, a digging device, a slip casting device and a backfill device. The front end of the walking device is provided with the digging device, and the walking device is provided with the slip casting device. The rear end of the walking device is providedwith the backfill device. The equipment can solve problems that a worker needs to use tools for digging, manual casting and laying and the backfilling and rolling of soil in a laying process of a direct-buried cable, and the long-time stoop is liable to cause hidden troubles; a problem that during laying, the slip casting and rolling of a trench bottom needs to be performed manually, and the manual rolling enables soil not to be uniform; a problem that during the backfilling of soil, the soil needs to be manually backfilled for hitting and pressing, and the manual pressing enables soil not tobe compact; and a problem that during advancing, the vibration of a conventional equipment vehicle affects the work progress during walking because of the steep soil surface. The equipment can achieve the automatic laying of the direct-buried cable.

Owner:吴传江

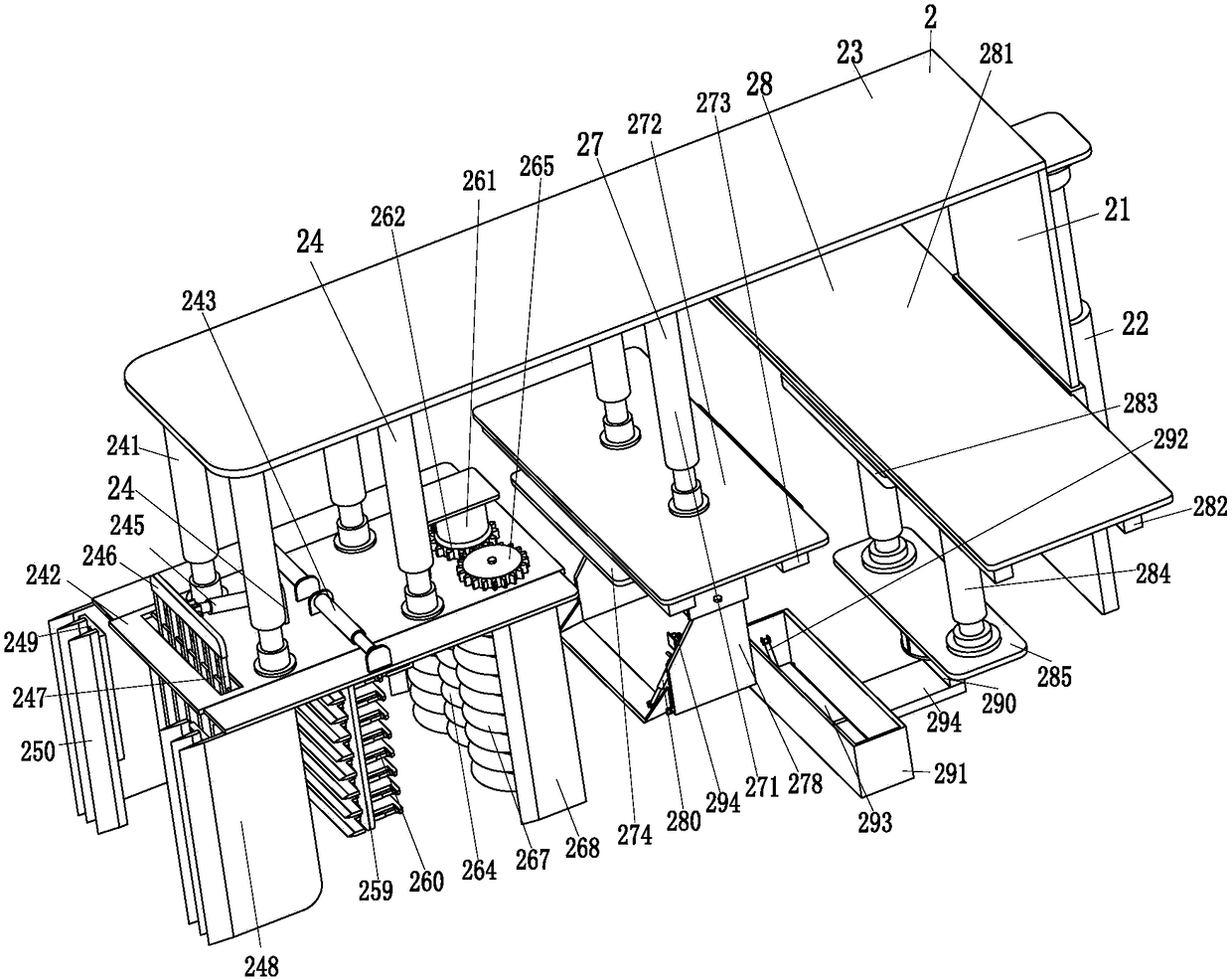

Buried 750V polyvinyl chloride insulated control cable laying machine capable of automatically digging trench

InactiveCN108092186AReduce labor intensityImprove work efficiencyApparatus for overhead lines/cablesApparatus for laying cablesDirect-buried cablePolyvinyl chloride

The invention relates to a buried 750V polyvinyl chloride insulated control cable laying machine capable of automatically digging a trench. The machine comprises an auxiliary expansion board, a largeair cylinder, a top plate, a soil crushing mechanism, a soil shoveling mechanism and a recovery mechanism. The lower end of the auxiliary expansion board is equipped with the large air cylinder. The top end of the large air cylinder is installed at the upper end of the auxiliary expansion board. The front end of the lower end of the auxiliary expansion board is equipped with the top plate. The lower end front side of the top plate is equipped with the soil crushing mechanism. The lower end middle part of the top plate is equipped with the soil shoveling mechanism. The lower end back side of the top plate is equipped with the recovery mechanism. In an existing direct-buried cable laying process, the trenching by the staff is needed, the staff need to use tools for trenching, long-term bending work causes body injury and causes potential safety hazards, a later backfill effect is affected if the sizes of artificially excavated soil blocks are not consistent, the soil processing is cumbersome after the manual trenching, the process takes a long time, the labor intensity is large and the efficiency is low, the above problems can be solved by the buried 750V polyvinyl chloride insulatedcontrol cable laying machine in the invention, and the functions of automatic digging and transportation in laying the cable can be achieved.

Owner:倪立秧

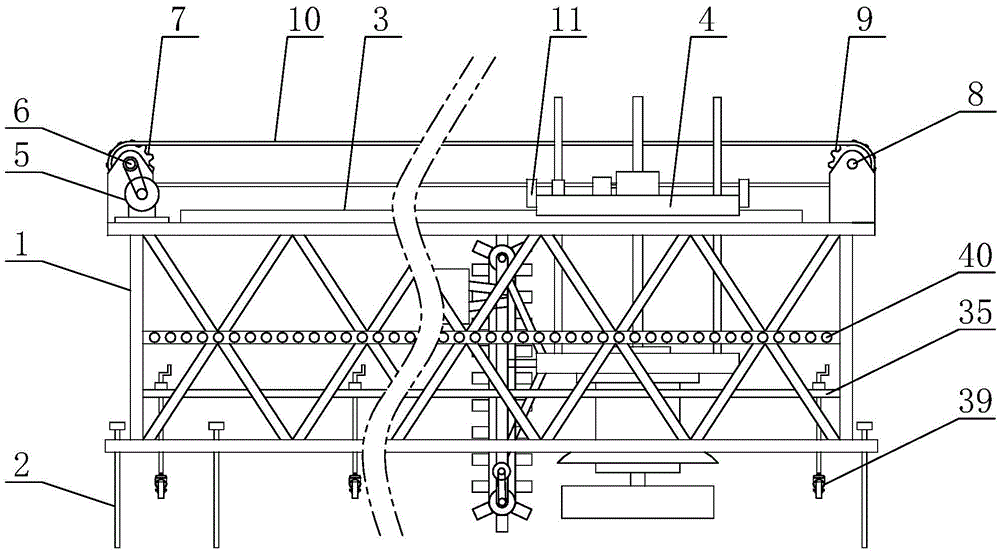

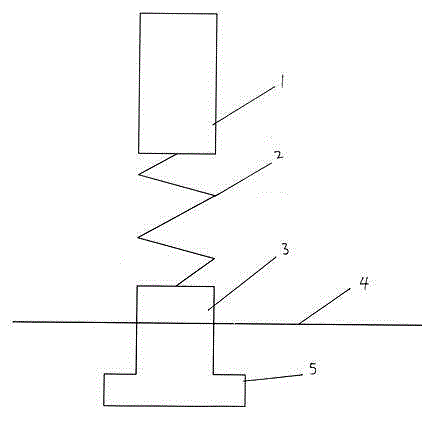

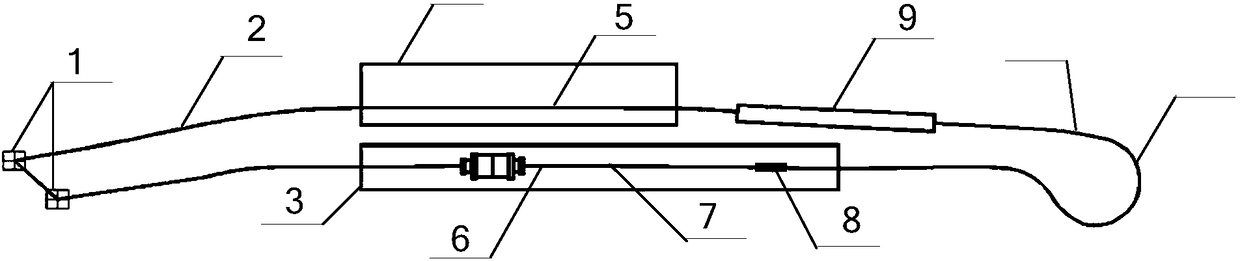

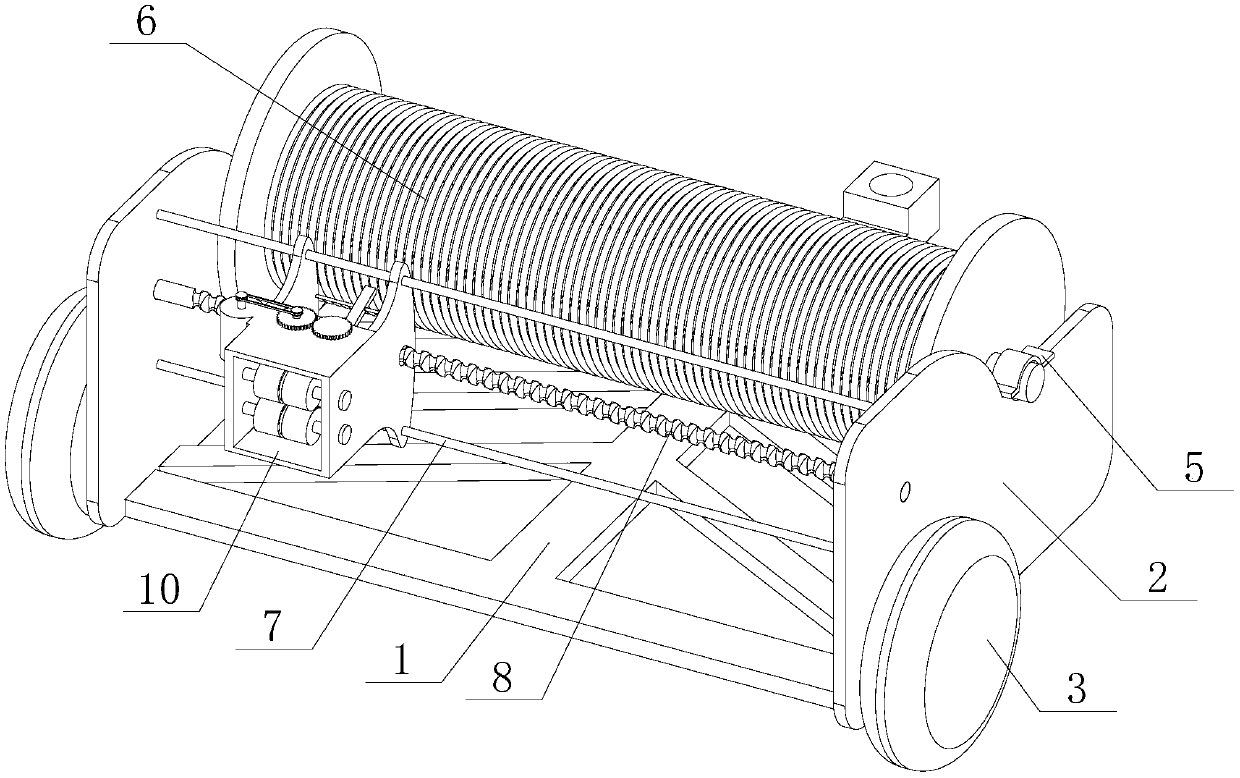

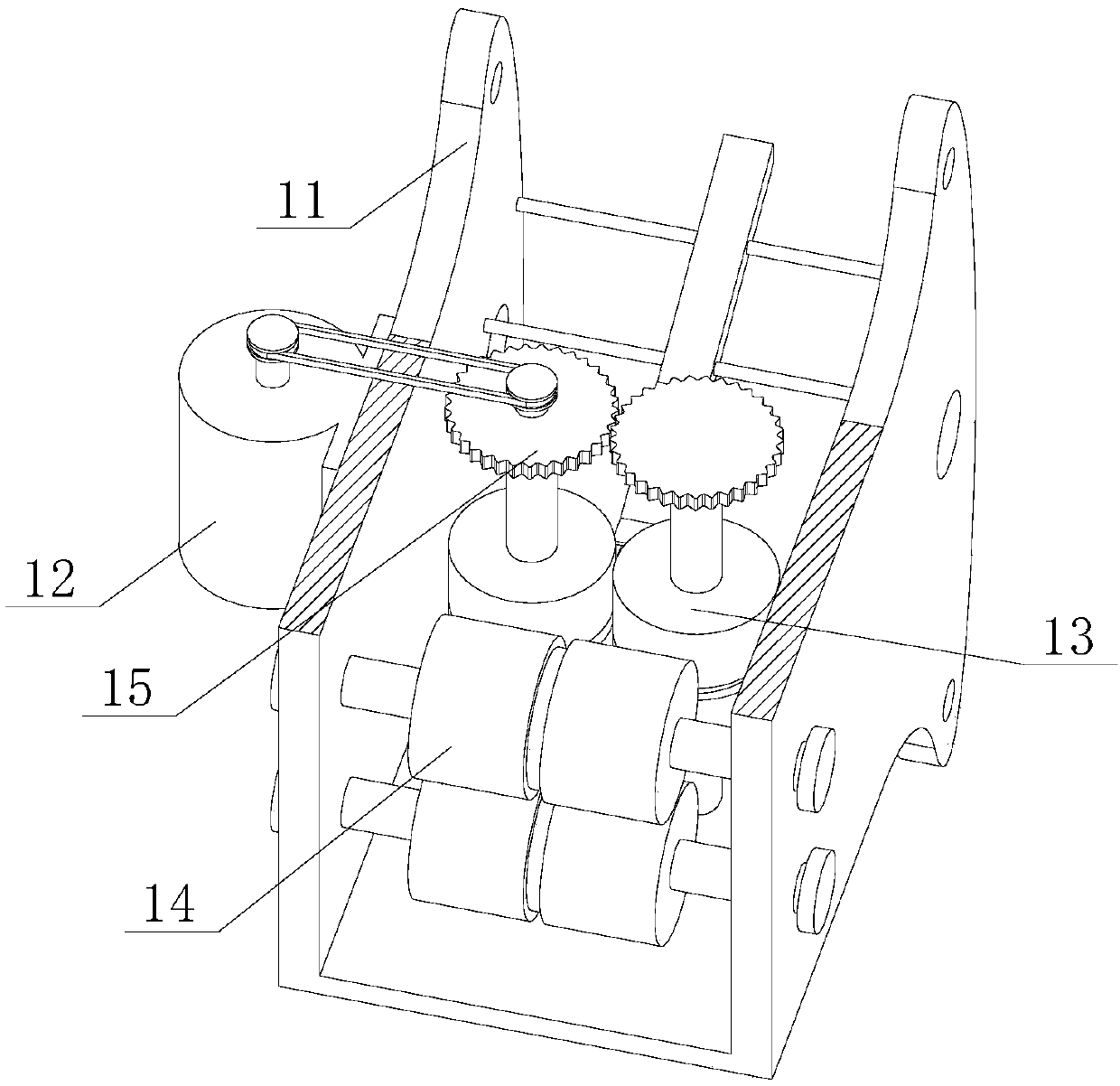

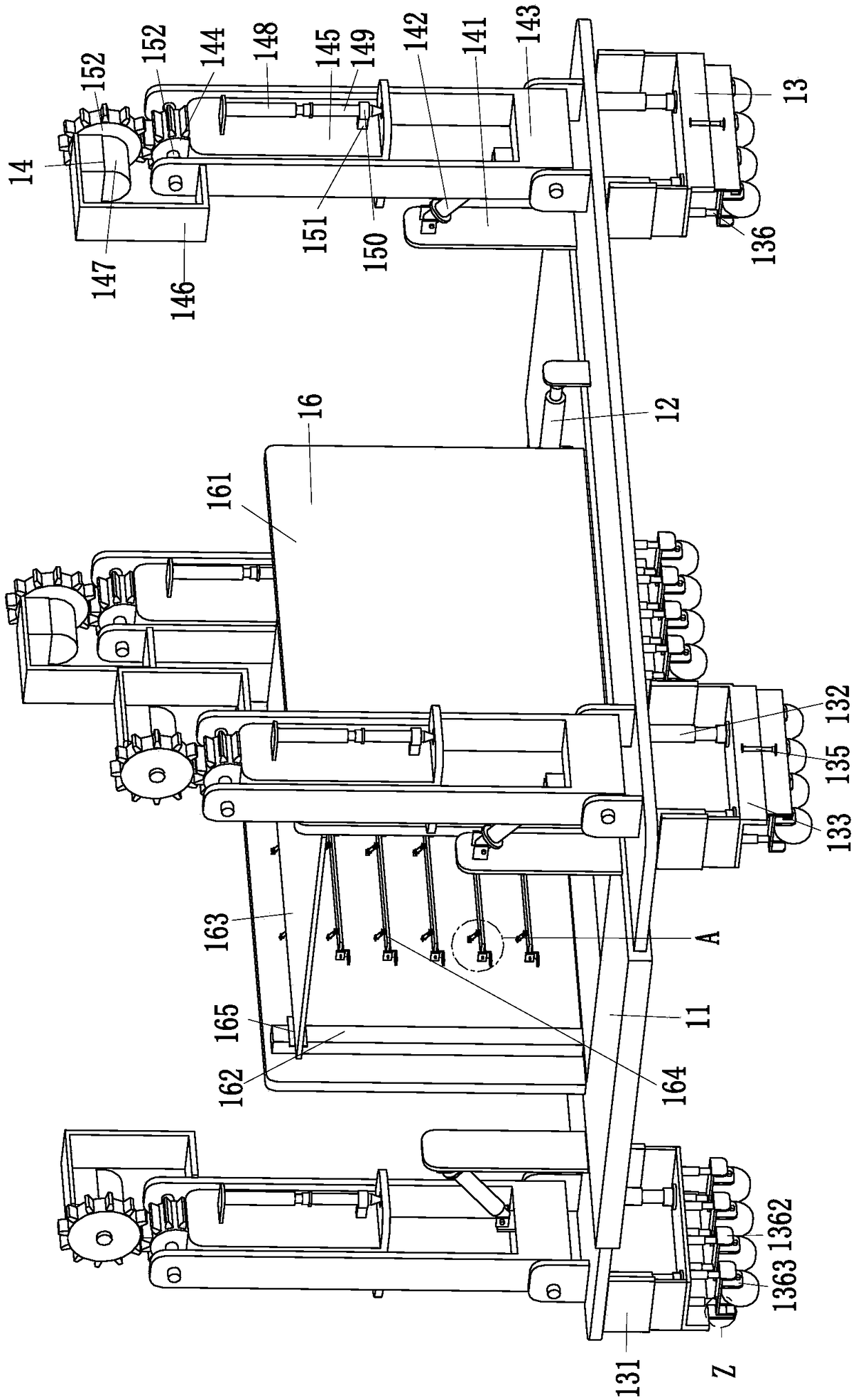

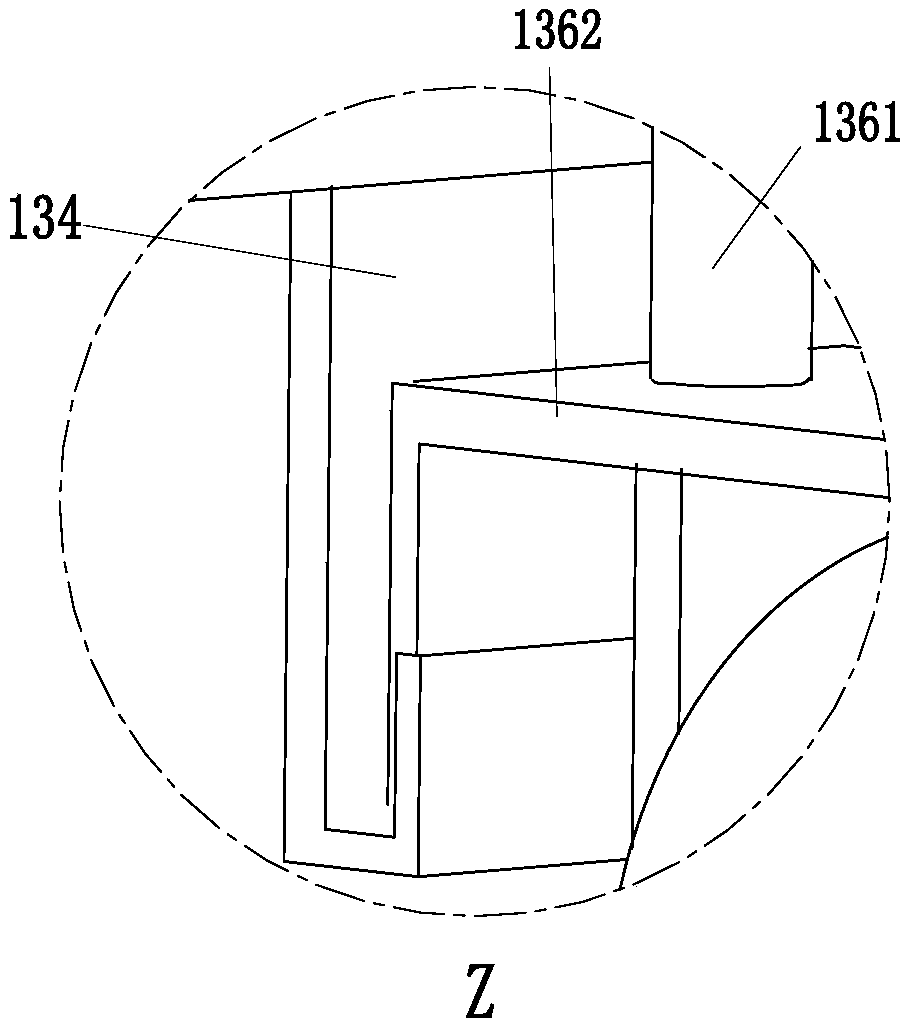

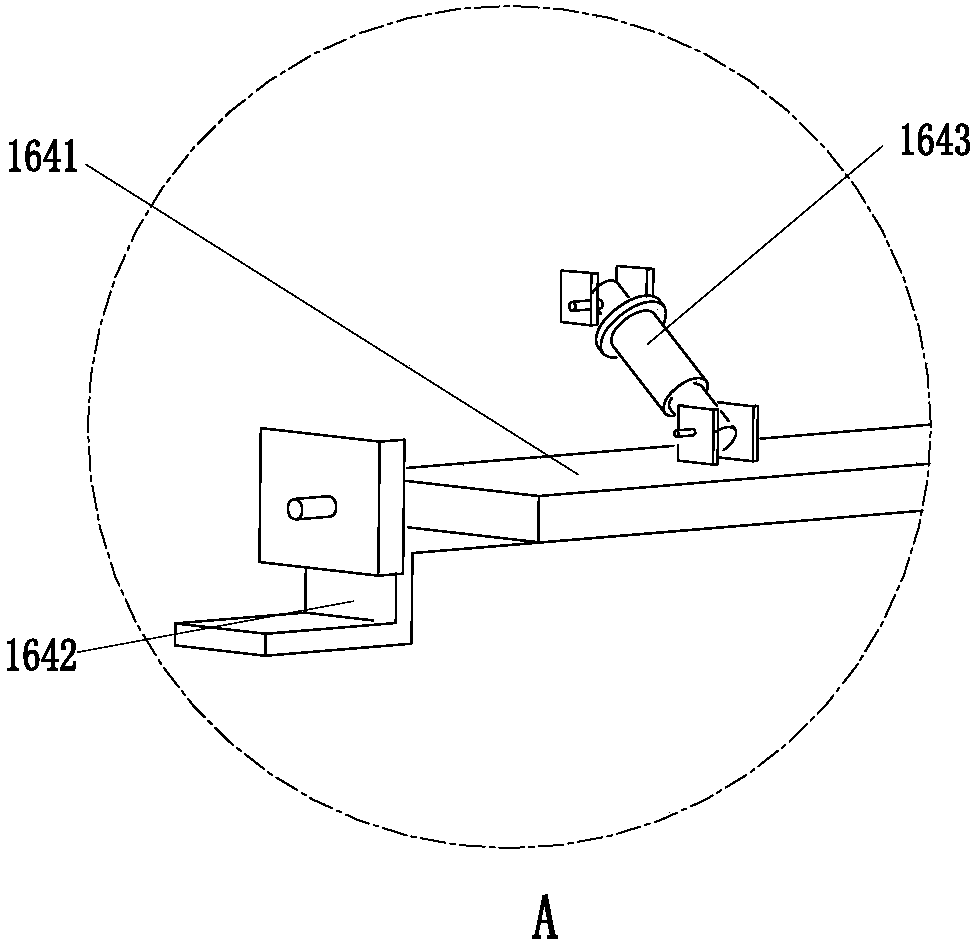

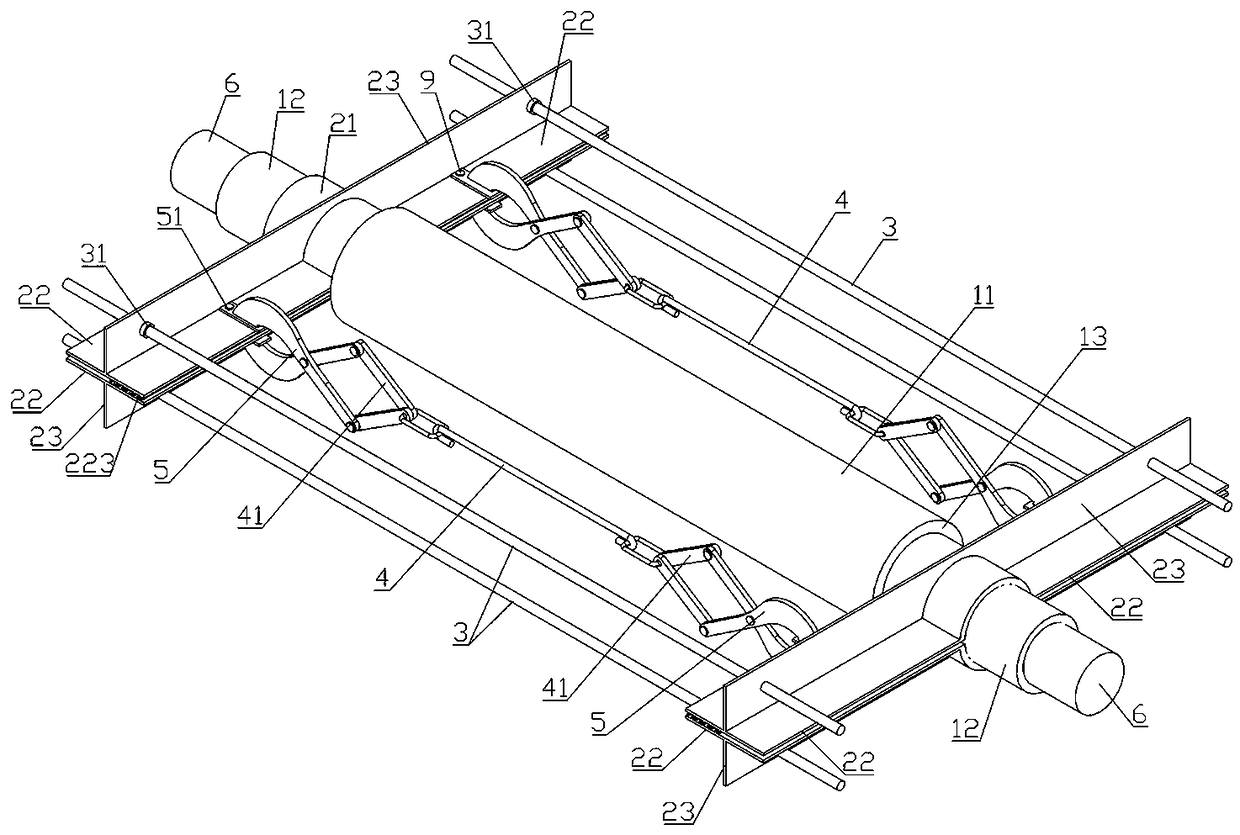

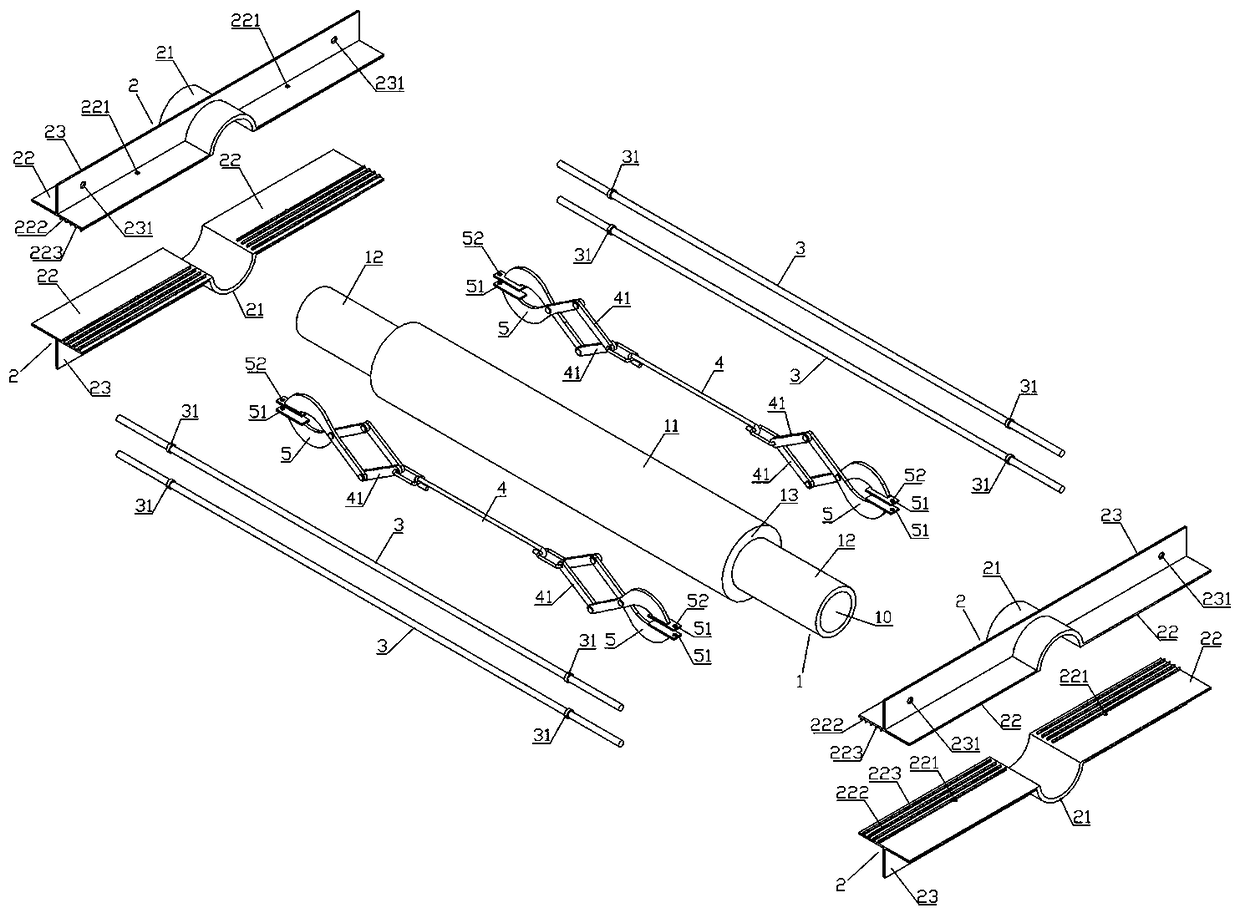

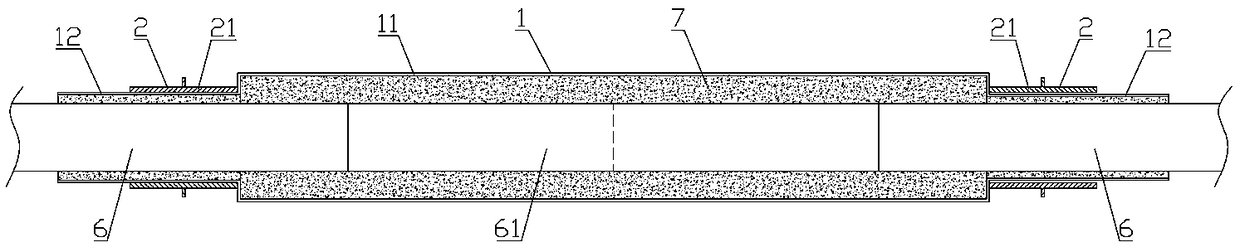

Constant-tension and autonomous straightening paying-off device attached to direct-buried cable paying-off vehicle

InactiveCN109626121AEasy to operateStable tensionFilament handlingTransmission beltDirect-buried cable

The invention provides a constant-tension and autonomous straightening paying-off device attached to a direct-buried cable paying-off vehicle. The problems that an existing paying-off vehicle is largein paying-off operation difficulty and unsuitable for direct-buried laying are effectively solved. The constant-tension and autonomous straightening paying-off device comprises a bracket, two side plates are mounted on the bracket, a line roller is mounted on the side plates, two guiding rods and a reciprocating lead screw are mounted on the two side plates, an engine of the paying-off vehicle isconnected with a rotating wheel of the reciprocating lead screw through a transmission belt, the guiding rods and the reciprocating lead screw are used for supporting and mounting a paying-off straightening device, a motor is mounted on the side wall of a rack of the paying-off straightening device, two pairs of longitudinal pressing wheels and transverse pressing wheels which are mounted correspondingly are mounted inside the rack, and the motor is connected with the longitudinal pressing wheels in a belt transmission mode. The constant-tension and autonomous straightening paying-off devicehas the beneficial effects that a reciprocating moving device and a bidirectional pressing wheel paying-off device are arranged in one device, and the purpose of constant-tension and straightening paying-off can be achieved through one device.

Owner:STATE GRID GASU ELECTRIC POWER RES INST +2

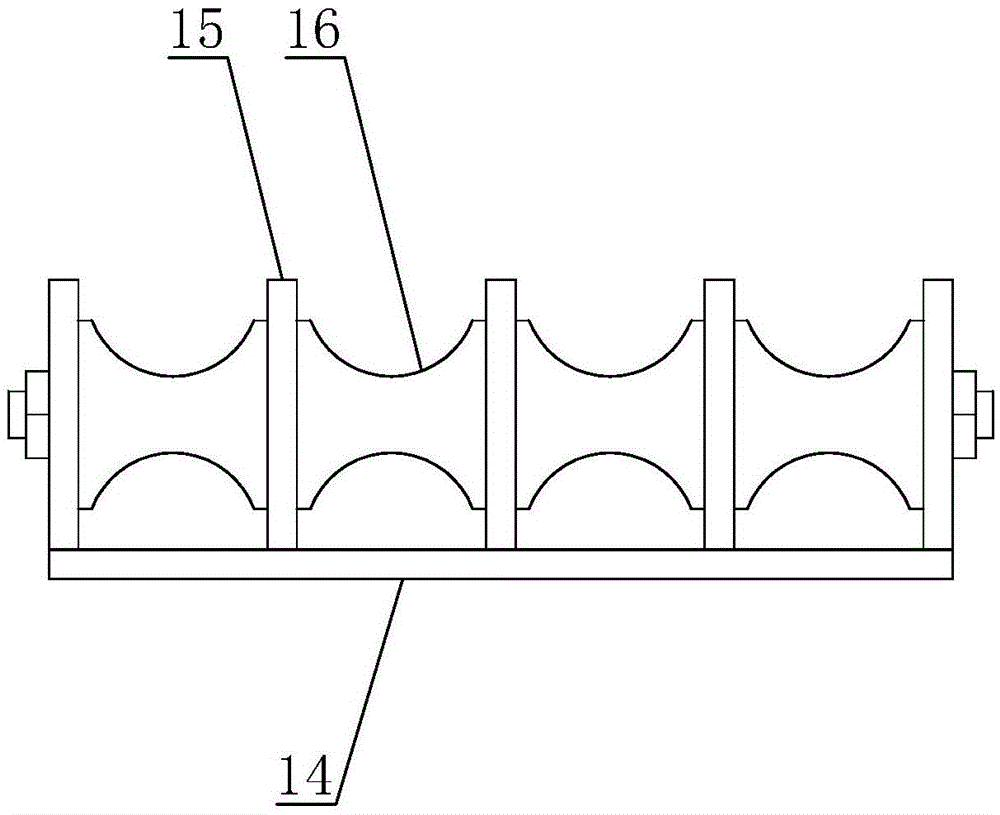

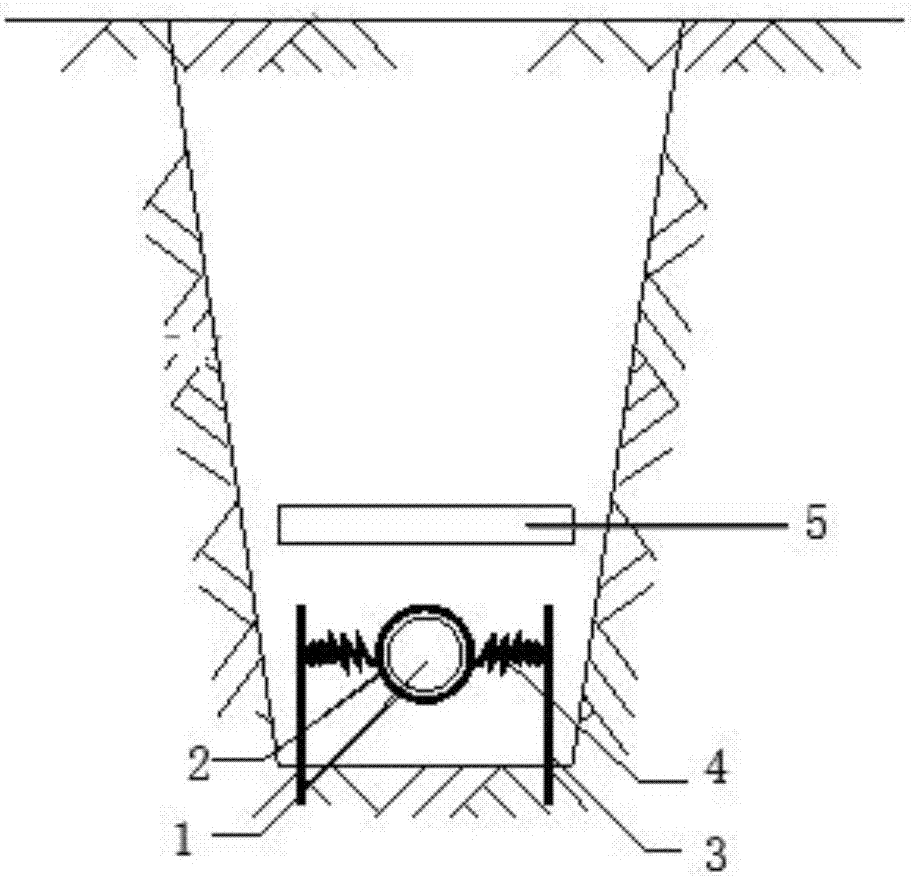

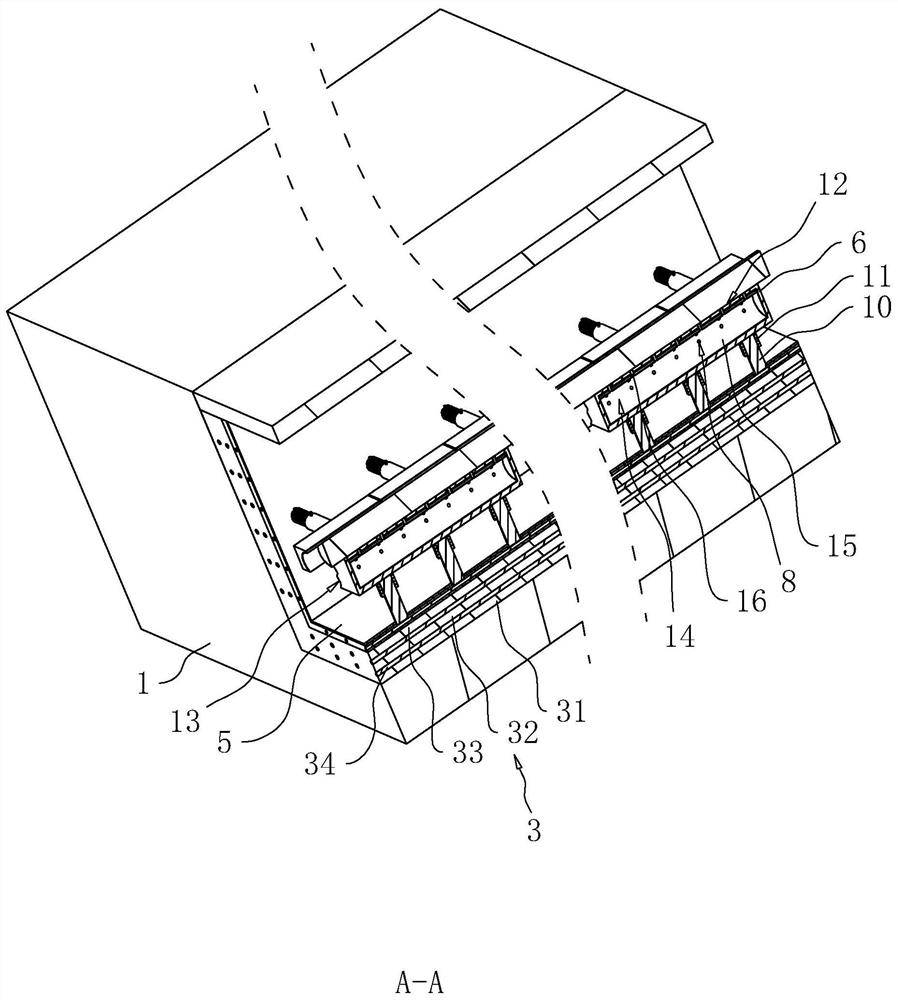

Method for directly burying multiple-circuit same-trench cables

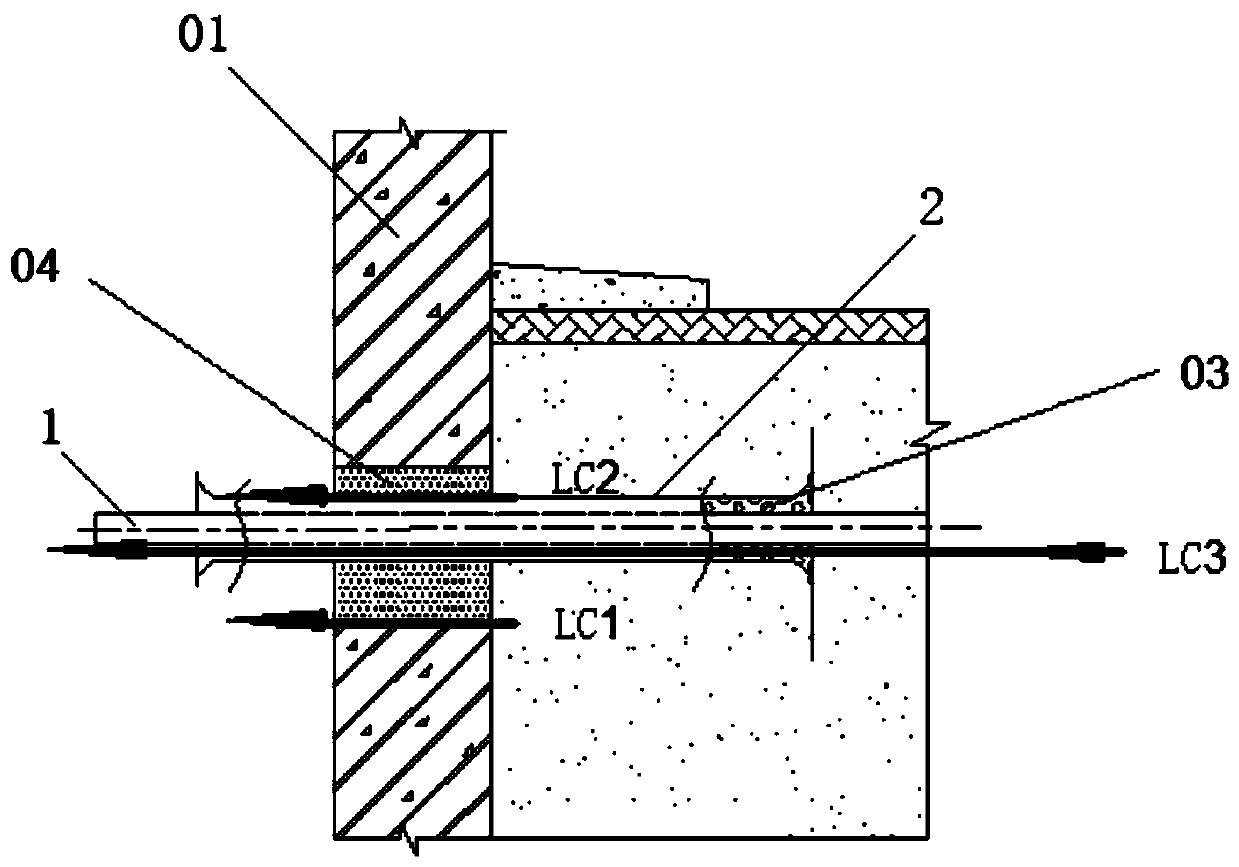

InactiveCN110690679AFire Hazard PreventionSolve the hidden danger of being easily damaged by external forceCable installations in underground tubesApparatus for laying cablesDirect-buried cableArchitectural engineering

The invention provides a method for directly burying multi-circuit same-trench cables, which belongs to the technical field of engineering construction. The technical problem of fire and explosion isolation between multiple cables in the same cable trench is solved. The method comprises the steps that a trench is excavated in the ground, and concrete baseplates are produced according to a laid cable circuit; b shields are made on the left and right sides of the upper surfaces of the concrete baseplates; c the concrete baseplates and the shields are placed into the dug trench; partition walls are arranged on the upper surfaces of the concrete baseplates connected end to end; a groove is formed by adjacent partition walls and concrete baseplates; a bottom sand layer is laid on the bottom ofeach groove to form a channel cable trench; d cable support rollers are arranged in the cable trench constructed in step c, and cables are laid; e after the cables are laid, river sand is dumped to cover the cables; and f cement covers are put on the upper sides of the shields on both sides of the cable trench, and direct burying of multi-circuit same-trench cables is completed. According to the invention, the hidden danger that directly buried cables are easily damaged by external force is reduced, and the hidden danger of the expansion of electric accidents in the same trench is reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

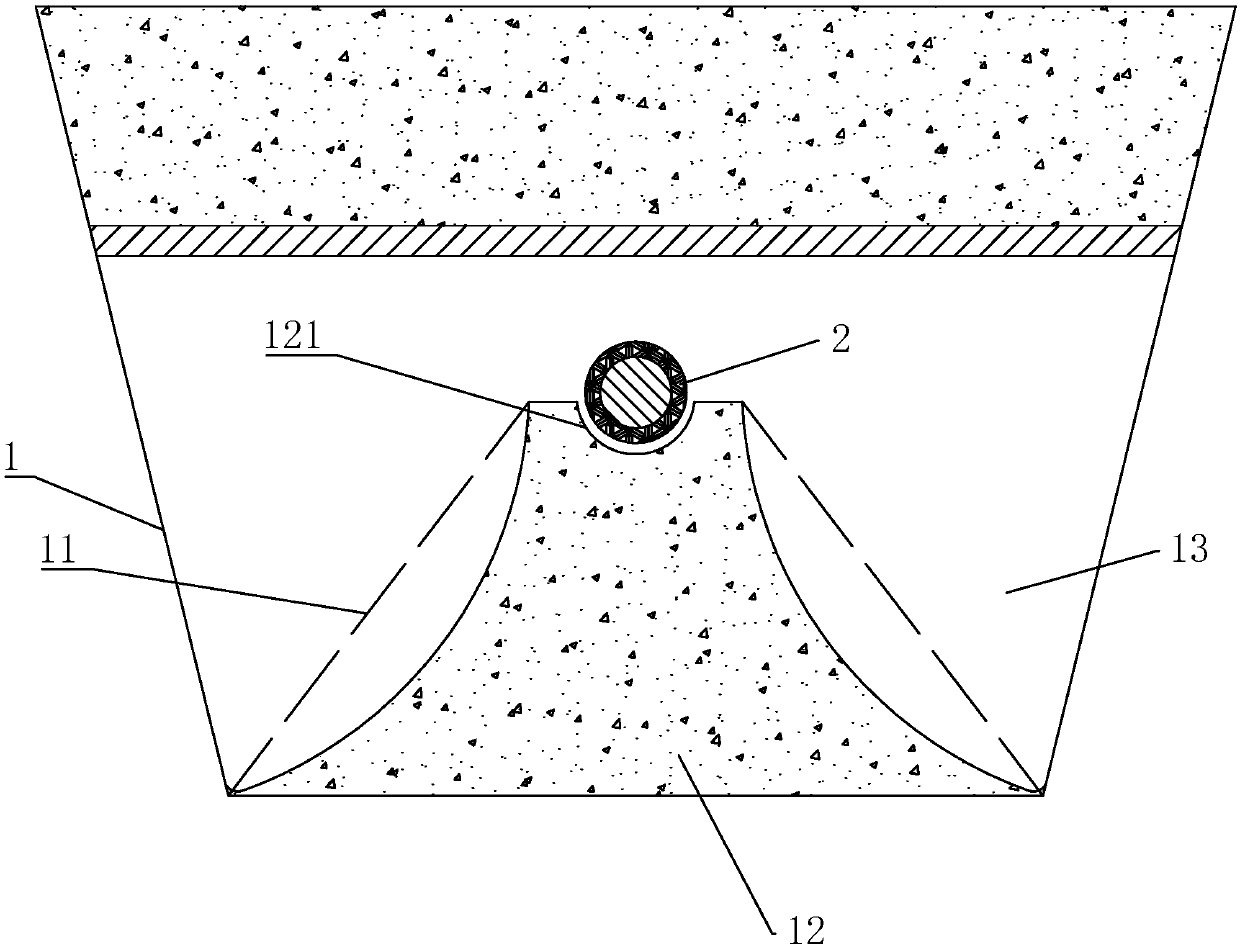

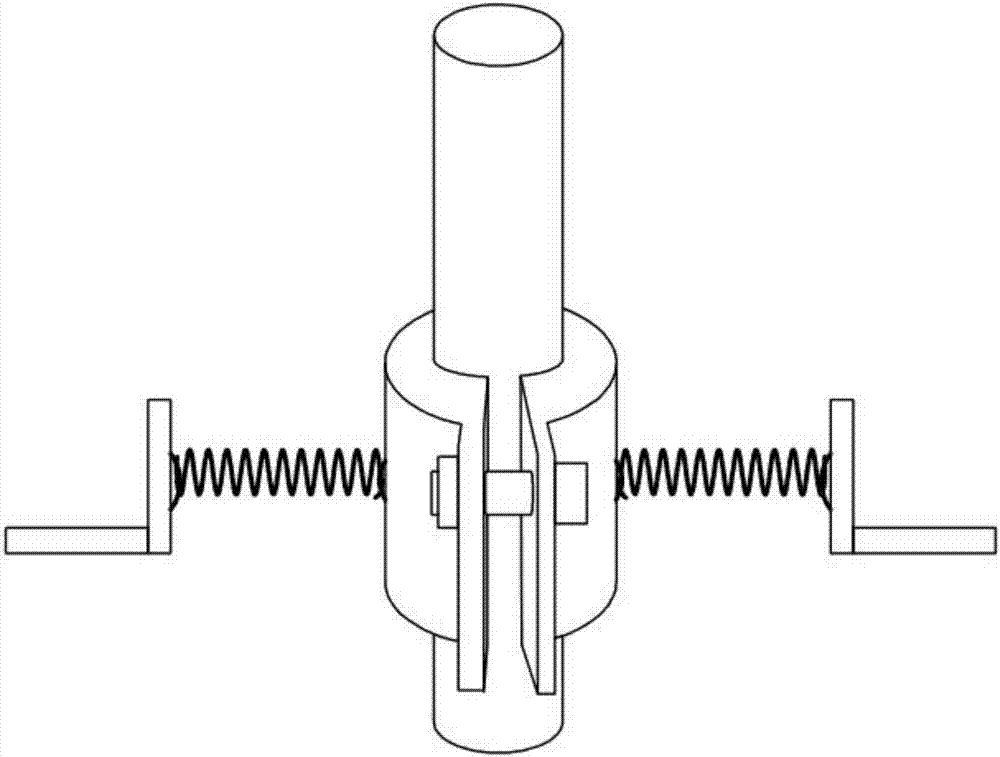

Slope direct-buried cable protection device for mountainous area

InactiveCN107257119AReduce impact damageEnsure power reliabilityCable installations on groundDirect-buried cableEngineering

The invention relates to the field of power transmission line cables. Aiming at displacement damages caused by the rain washing to a pre-buried cable in a mountainous area in the prior art, the invention provides a slope direct-buried cable protection device for the mountainous area. The device is characterized in that a cable is provided with cable protection sleeves at set intervals; parts, located at two sides of the cable protection sleeve, of the cable are respectively provided with a pre-buried part buried in soil; elastic parts are respectively disposed between the pre-buried parts and the cable protection sleeves. The device is simple in structure. During the laying of a slope direct-buried cable, angle irons are respectively buried at two sides of the cable at intervals, and the cable is sleeved by a protection sleeve layer. The protection sleeves are connected with the angle irons through an adjustable elastic device. When the soil covering the surface of the cable is lost, the cable can be fixed through the angle irons, and the elastic device can counteract the impact on the cable from a part of external forces, thereby achieving the protection of the cable. The device can reduce the impact damages caused by the external force to the cable, protect the cable, and guarantee the power utilization reliability of a scenic region.

Owner:ANHUI HUADIAN ENG CONSULTATING & DESIGN +2

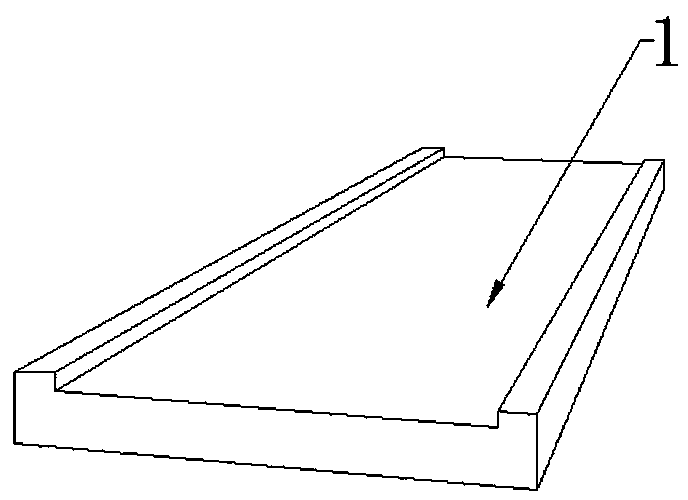

Directly-buried cable laying method

ActiveCN112038980AAffect the service lifeIncrease spacingCable installations on groundApparatus for laying cablesWater storageDirect-buried cable

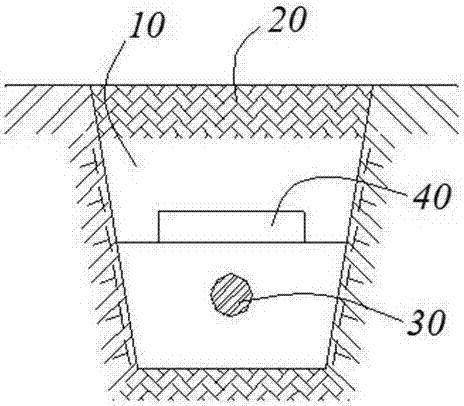

The invention relates to a directly-buried cable laying method which comprises the following steps of S1, planning a cable path, and digging a groove in the surface of a ground layer; S2, laying broken stone hardcore layers on the trench bottom wall and two side trench walls of a trench, and pouring concrete waterproof plaster layers on the surfaces of the broken stone hardcore layers to form a cable trench; S3, installing a plurality of drainage boxes on the trench bottom wall of the cable trench, defining a water storage and drainage space by the side walls of the drainage boxes and the trench wall of the cable trench, and enabling water in the water storage and drainage space to permeate into the drainage boxes through water seepage holes in the side walls of the drainage boxes to be collected; S4, along the planned cable path, dragging the cable to the top of the drainage box and fixing; S5, covering a cement cover plate above the cable trench along the planned cable path until thecable trench is closed; and S6, backfilling the cable trench, and completing the laying of the directly-buried cable. The method has the effect of preventing the cable from being soaked in rainwaterfor a long time to affect the service life.

Owner:南京开拓建设有限公司

Method for butting buried cable steel tube on site during construction

InactiveCN101832435BReduce the occurrence of impenetrableGuarantee laying efficiencySleeve/socket jointsCable installations in underground tubesSlagDirect-buried cable

The invention relates to the technical field of electric engineering construction, in particular to a method for butting a buried cable steel tube on site during construction. The method comprises the following steps of: (1) manufacturing a wedge-shaped chambering tube; (b) wedging the wedge-shaped chambering tube into a ring opening tube to expand the tube diameter of the ring opening tube, and welding fixed diameter steel bars to side walls on two sides of the opening of the ring opening tube to form a butting sleeve; (c) sleeving the tube ends of two polished cable steel tubes into the butting sleeve, and cutting off the fixed diameter steel bars on the butting sleeve; (d) totally fitting the tube orifices of the cable steel tubes, fixing the cable steel tubes by spot welding, and thentightly welding each connector; and (e) polishing the welding slag at the welded part, and coating anti-rusting paint on the cable steel tubes so as to finish butting the cable steel tubes. By using the method, materials are taken from the construction site, no extra material is needed, the manufacturing process is simple and practical, on-site construction is convenient, the construction cost issaved, the butting misalignment and burrs of the tube orifices can be reduced, and the efficiency and quality of paving cables are guaranteed.

Owner:CHINA FIRST METALLURGICAL GROUP

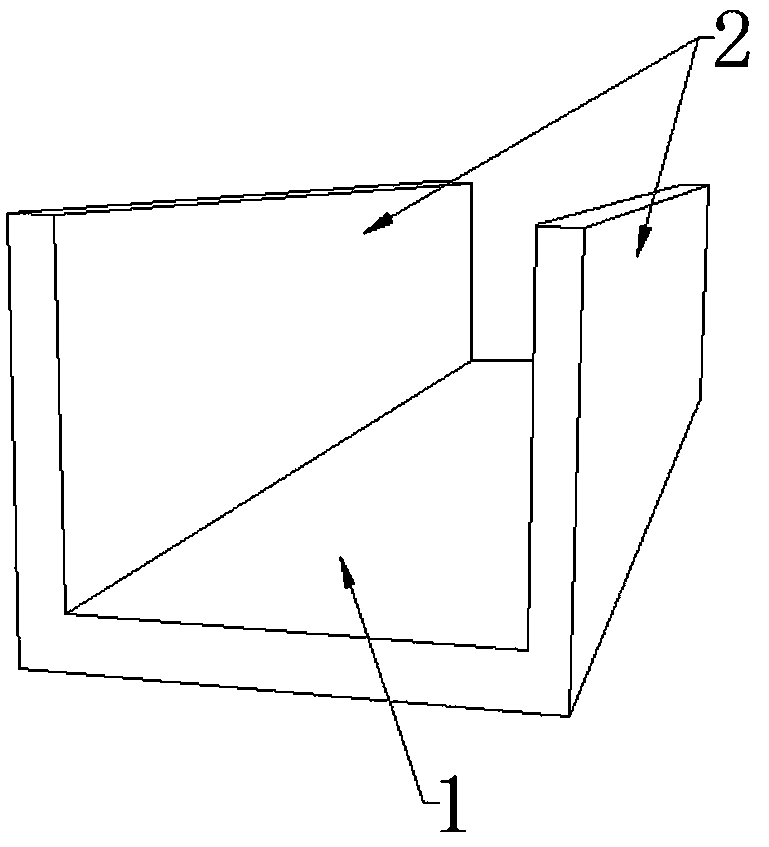

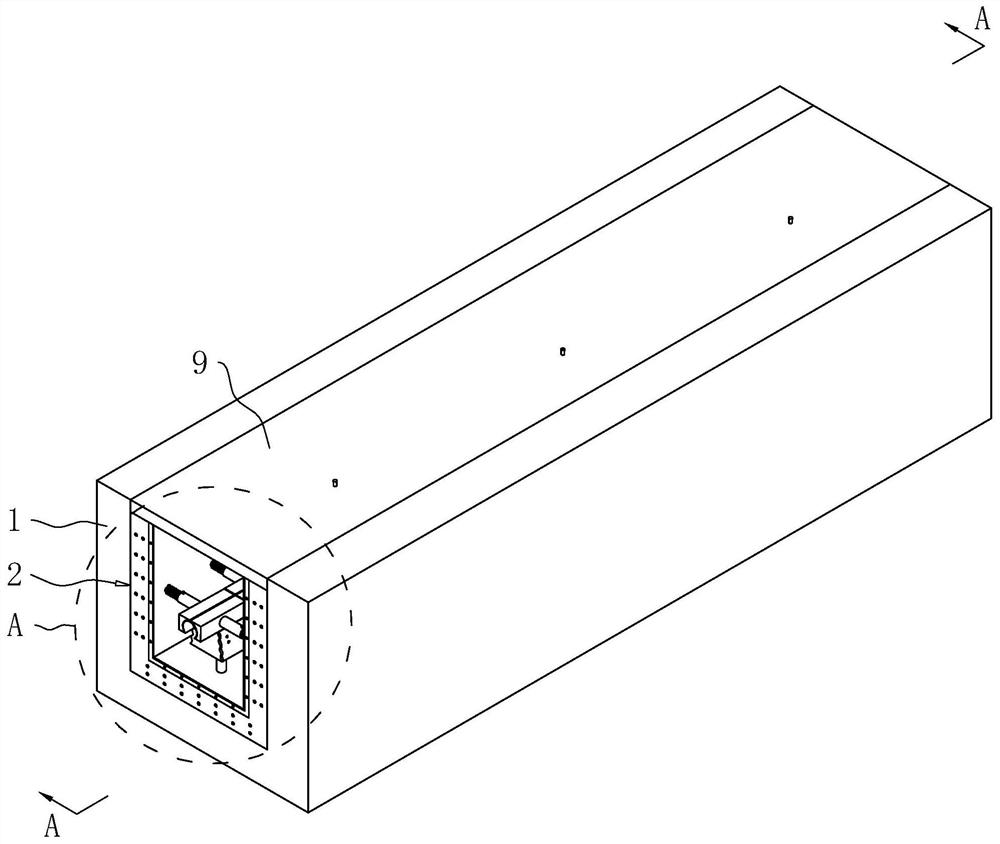

Direct-buried cable trench having protection structure

InactiveCN107294044AEffective protectionExtended service lifeCable installations on groundVertical projectionDirect-buried cable

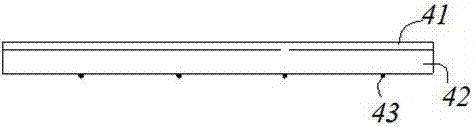

The invention discloses a direct-buried cable trench with a protective structure. The cable trench includes a trench and a cover plate located above the trench. Cables are laid in the trench, and a protective cover is fixed directly above the cable. plate, the cable line is located in the vertical projection of the protective plate, and the protective plate is fixedly installed between the side walls of the channel. The cable channel of the present invention can effectively protect the cable by adding a protective structure on the cable. The protective plate has a simple structure and is easy to install, greatly improving the service life of the cable.

Owner:HAIMEN THE CAIWEI TEXTILE SCI & TECH CO LTD

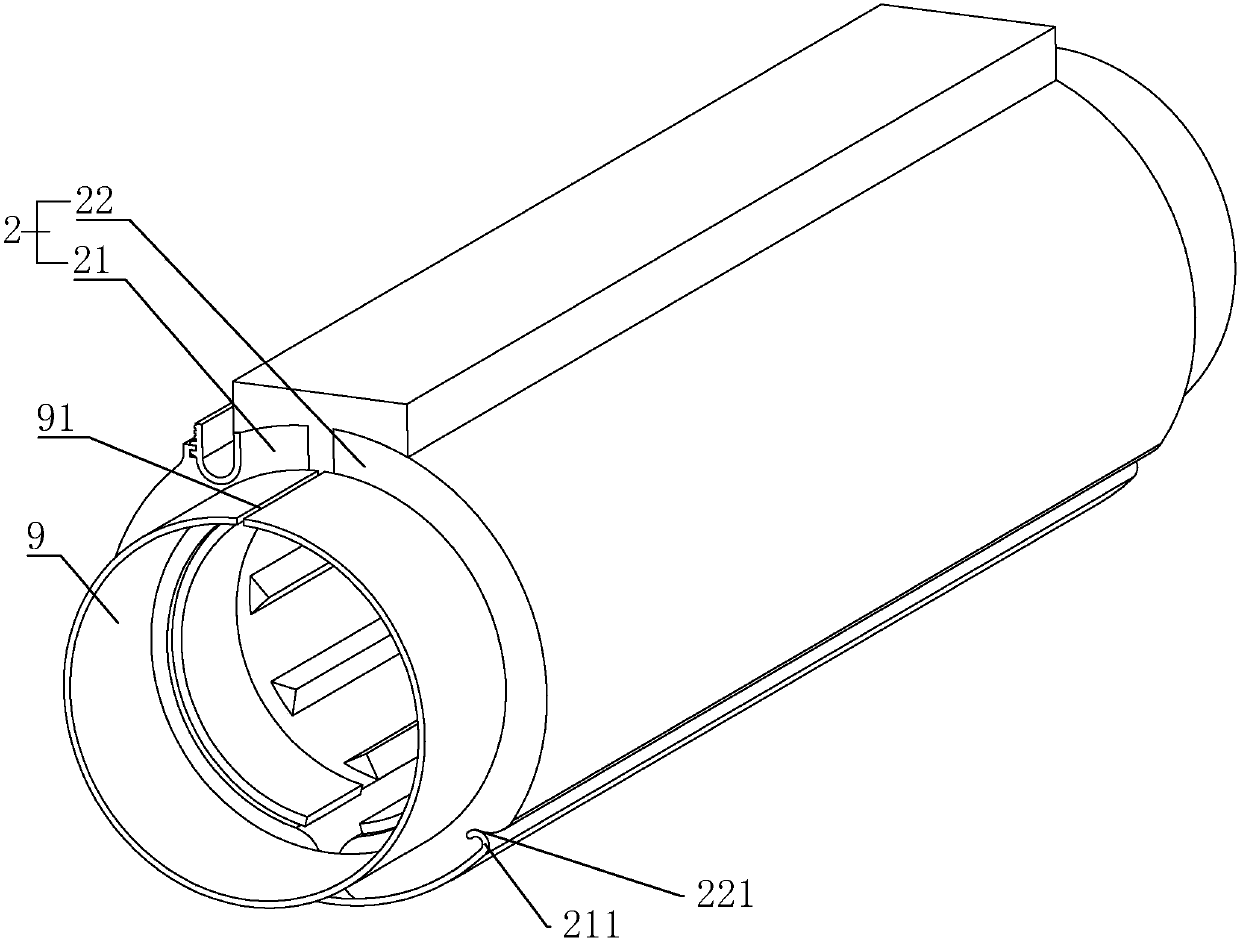

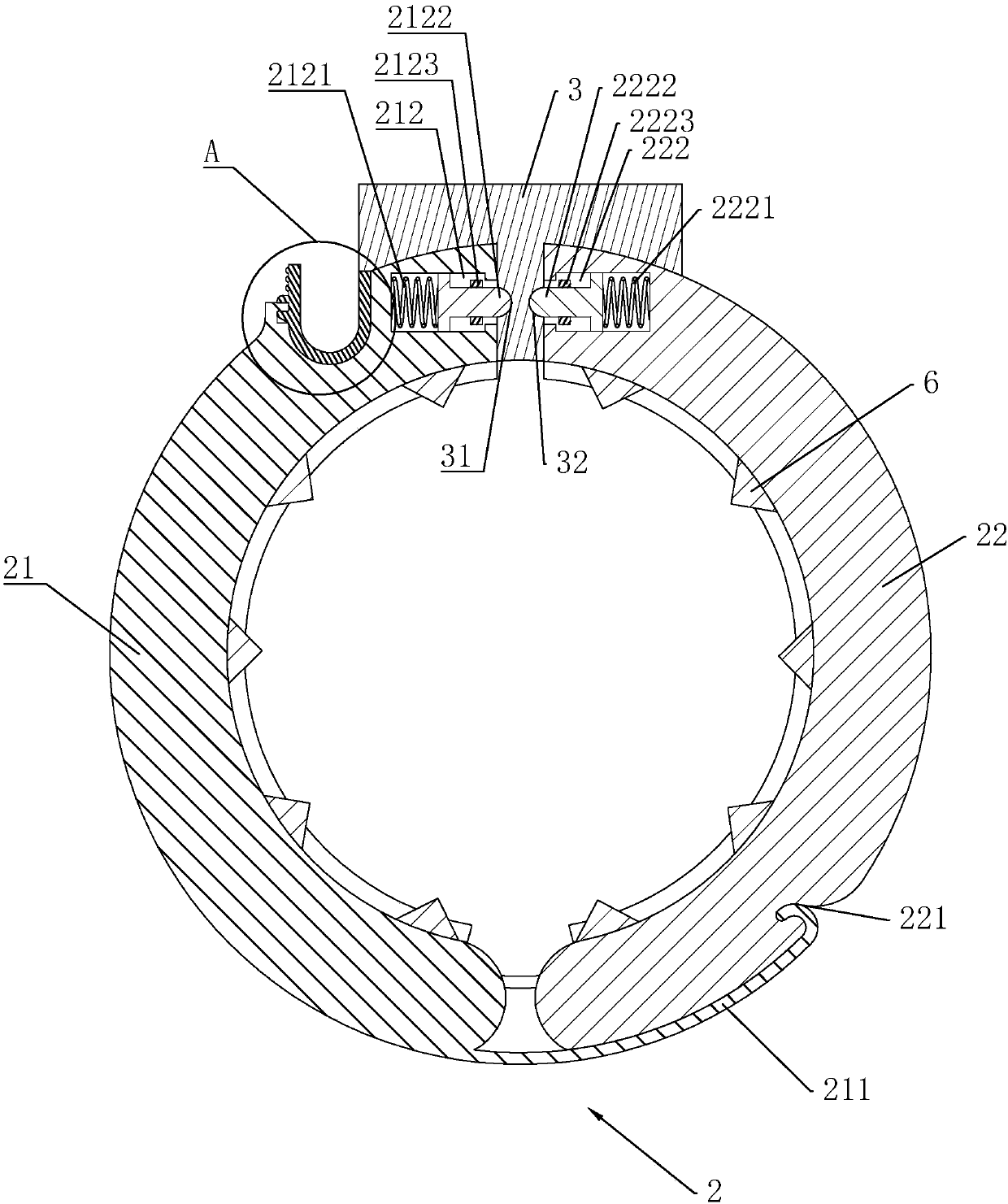

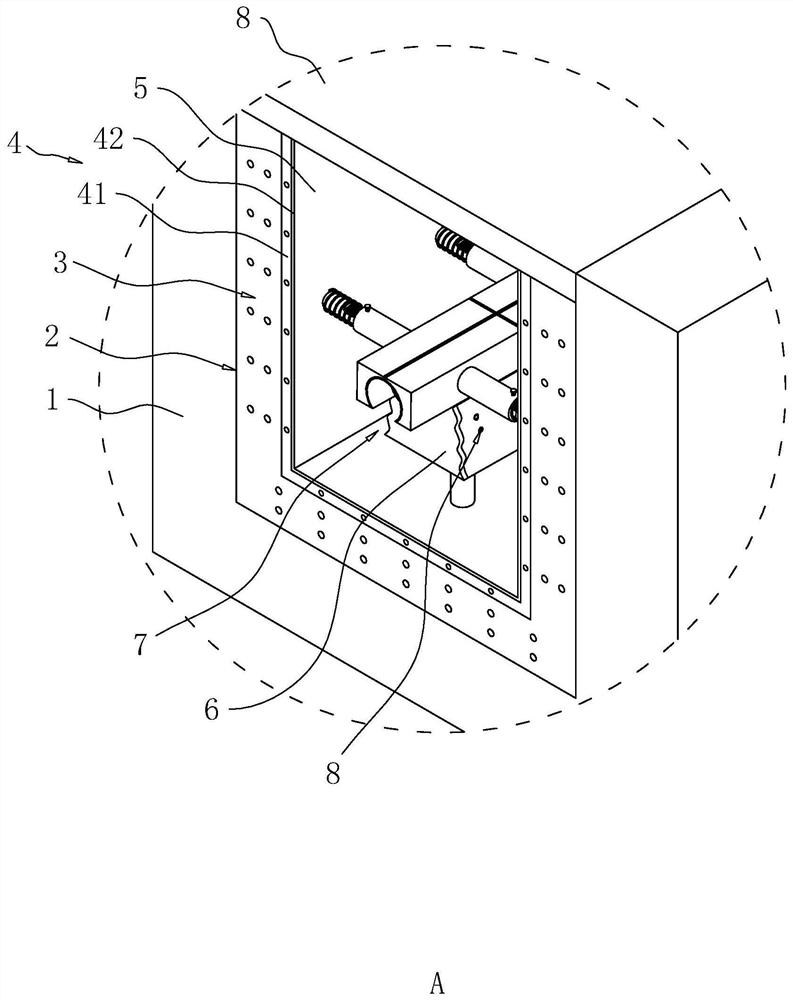

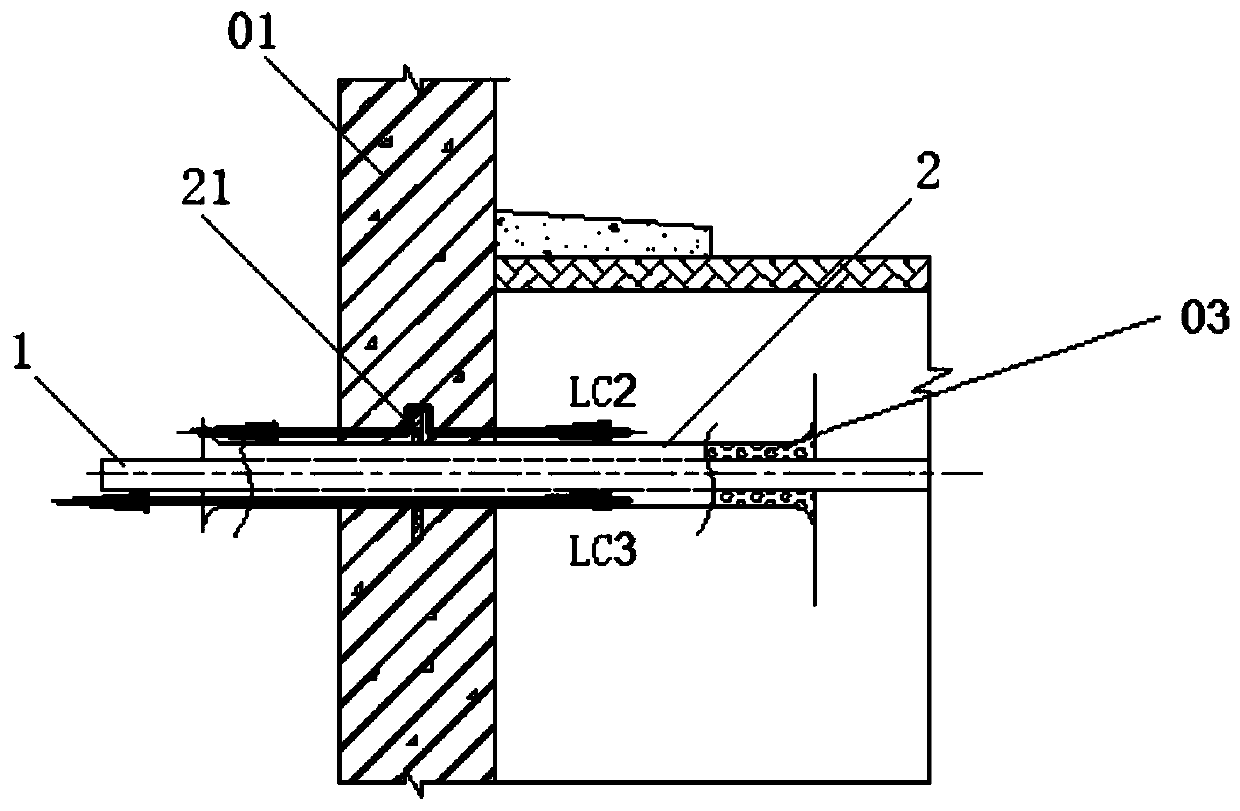

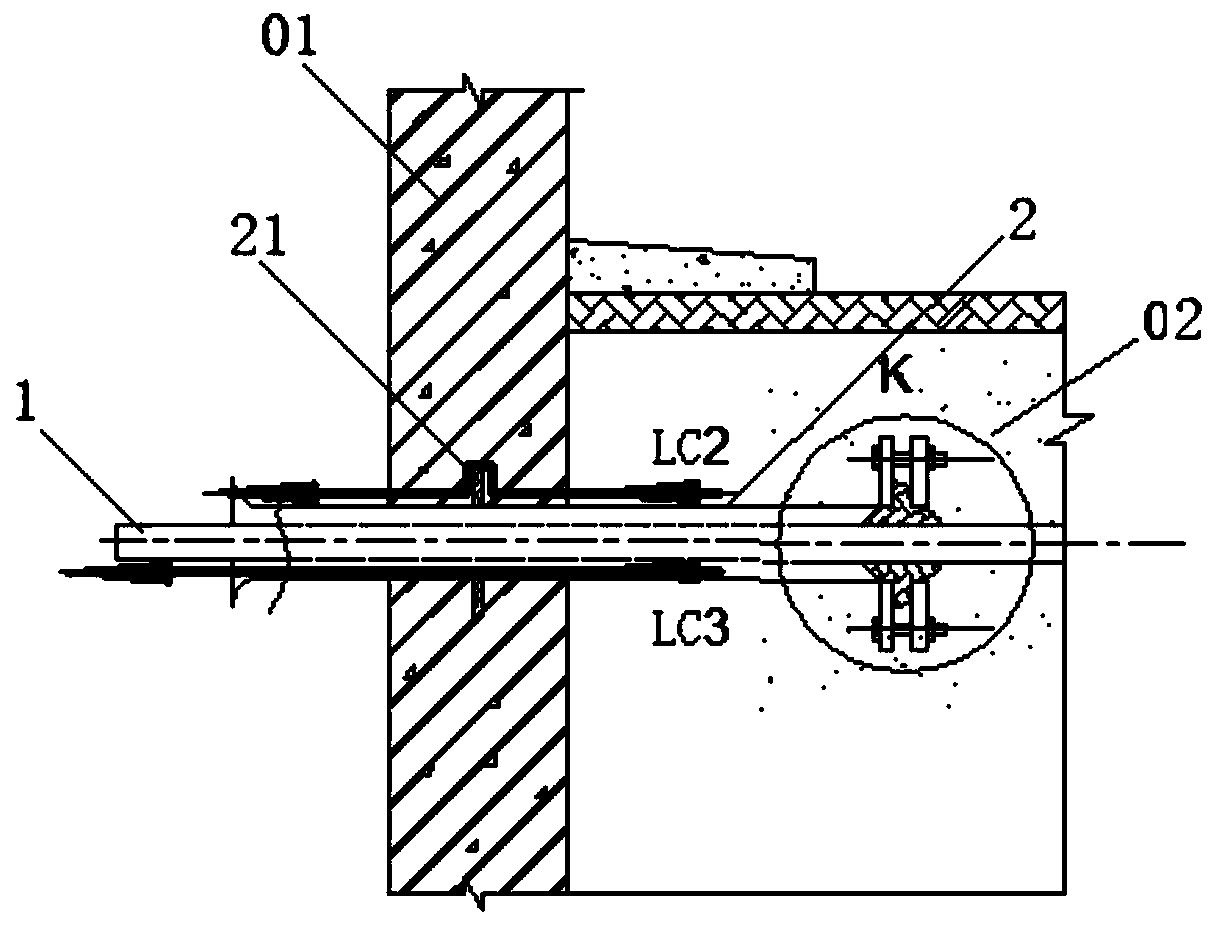

Flexible waterproof sealing structure for underground direct-buried cable or optical cable through-wall and construction method

PendingCN111585229AHigh mechanical strengthHigh strengthEngine sealsCable installations in underground tubesDirect-buried cableStructural engineering

The invention provides a flexible sealing structure for underground direct-buried cable or optical cable through-wall and a construction method. The structure comprises a through-wall protection tubeand a flexible sealing assembly arranged between the through-wall protection tube and a cable or an optical cable. The flexible sealing assembly is at least arranged on the upstream face side of the through-wall protection pipe. The flexible sealing assembly comprises a long pipe hoop, a flexible sealing piece located in the long pipe hoop and an end locking gland installed at the end of the longpipe hoop, a flexible sealing piece is arranged between a threaded adjusting check ring arranged in the long pipe hoop and the end locking gland, and the flexible sealing piece and the sealing faces of the through-wall protection pipe and the cable or the optical cable form static sealing. According to the invention, the flexible sealing assembly with a pre-pressing and pre-tightening adjusting mechanism is adopted between the cable or the optical cable and the through-wall protection tube; the functions of radial two-way positioning and axial side two-way positioning are achieved, a sealing ring set in the sealing cavity is made to be in three-way extrusion stress, a static sealing zero space between the through-wall protection pipe and the cable or the optical cable is formed, and therefore, the waterproof sealing effect is achieved.

Owner:BEIJING TRIUMPH INT ENG

750V polyvinyl chloride insulated control cable installation vehicle with automatic fixation and lifting

ActiveCN108063398AEnsure safetyShort time consumingApparatus for laying cablesDirect-buried cablePolyvinyl chloride

The invention relates to a 750V polyvinyl chloride insulated control cable installation vehicle with automatic fixation and lifting. The 750V polyvinyl chloride insulated control cable installation vehicle comprises a bidirectional telescopic board, two solid cylinders, four traveling mechanisms, fixing mechanisms and a lifting mechanism. The middle part of an upper end of the bidirectional telescopic board is equipped with the two solid cylinders, the bidirectional expansion board is provided with a lifting groove, and the two solid cylinders are arranged symmetrically. The top ends of the solid cylinders are installed at outer sides of the bidirectional telescopic board through flanges, and a lower end of the bidirectional telescopic board is uniformly equipped with the four traveling mechanisms. Left and right sides of an upper end of the bidirectional telescopic board are equipped with two fixing mechanisms which are symmetrically arranged. The upper end of the bidirectional telescopic board is equipped with the lifting mechanism. According to the 750V polyvinyl chloride insulated control cable installation vehicle, the problem that the push of a tool to lay a buried cable by the staff with a cart is needed in an existing buried cable laiding process, and since the surface of the earth is steep, existing equipment vehicle vibrates in walking can be solved, and the functionsof automatic vibration reduction, fixation and limited lifting can be achieved.

Owner:深圳市东大智勇工程有限公司

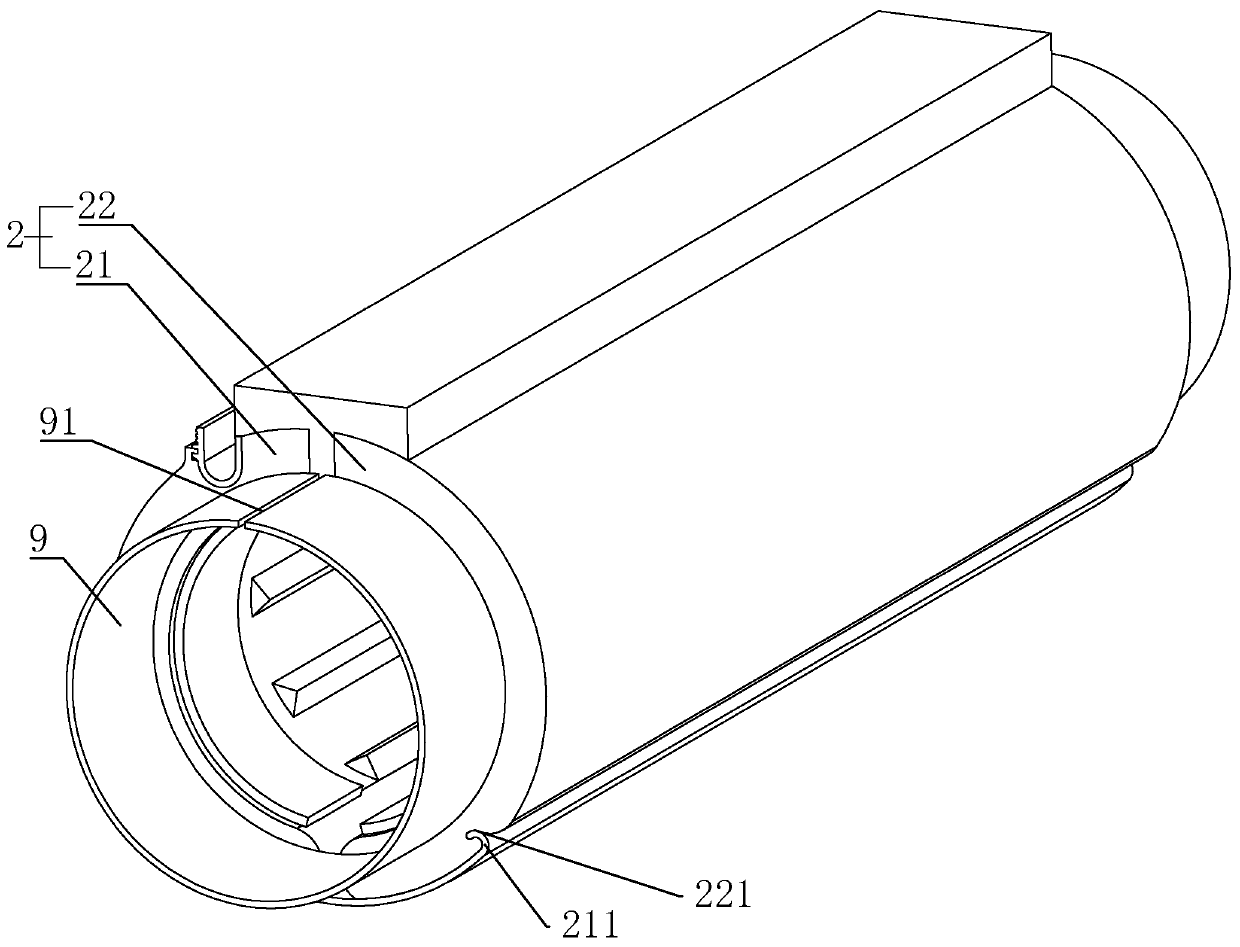

Direct buried cable joint insulation and waterproofing processing device and method

PendingCN108418172AWith elastic deformation abilityStable Fill GapCable junctionsApparatus for joining/termination cablesDirect-buried cableCounter-pull

The invention provides a direct buried cable joint insulation and waterproofing processing device, comprising: an elastic outer sleeve having a main pipe portion and end pipe portions; counter-pullingdevice frames, each composed of two half pipe clamping plates; and device frame tensioning clamps, each including a stay rope and two X-shaped plate clamps hinged in the middle, and each stay rope being hinged to connecting ends at one end of the X-shaped plate clamps. The two counter-pulling device frames are arranged on the elastic outer sleeve, and are connected with the two device frames tensioning clamps through four limiting screws. A direct buried cable joint insulation and waterproofing processing method is also proposed, which has the steps of first, positioning a cable joint in themiddle of the elastic outer sleeve, and loosening the stay ropes and slightly tightening clamping head bolts; second, initially tightening limiting nuts until the stay ropes are almost straight, and then initially tightening the clamping head bolts; third, injecting water expansion waterstop glue; fourth, after the limiting nuts are screwed to make the stay rope straight, screwing the clamping head bolts to press the elastic outer sleeve tightly; and fifth, wrapping with an iron sheet. The device and method in the invention have a good waterproof effect and stable and long-lasting insulation performance, and can effectively meet the insulation and waterproofing requirements of a direct buried cable.

Owner:GUANGDONG CONSTR ENG GRP

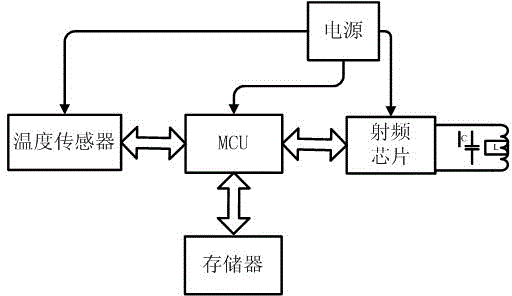

Underground cable positioning thermometer and application thereof

InactiveCN104165708AAvoid accidentsRapid response meansThermometer applicationsFault locationElectricityDirect-buried cable

The invention discloses an underground cable positioning thermometer which comprises a temperature sensor, a main control chip MCU, a radio frequency chip, an LC oscillating circuit and a power supply. The main control chip MCU is connected with the temperature sensor and the radio frequency chip, the LC oscillating circuit is connected with the radio frequency chip to achieve signal receiving and sending, and the power supply is used for supplying electricity to the components. The underground cable positioning thermometer overcomes the defects that fault discovery is not in time and repair, maintenance and searching are inconvenient due to the fact that buried cables are buried underground and provides a rapid response means for maintenance of the cables. Meanwhile, by using the underground cable positioning thermometer, an underground cable temperature data obtaining system can be established, an underground cable temperature data network is formed after temperature data are collected in real time, the data can be used for analysis of big data, and a reference is provided for study of the operation condition of the macro economy.

Owner:陈刚

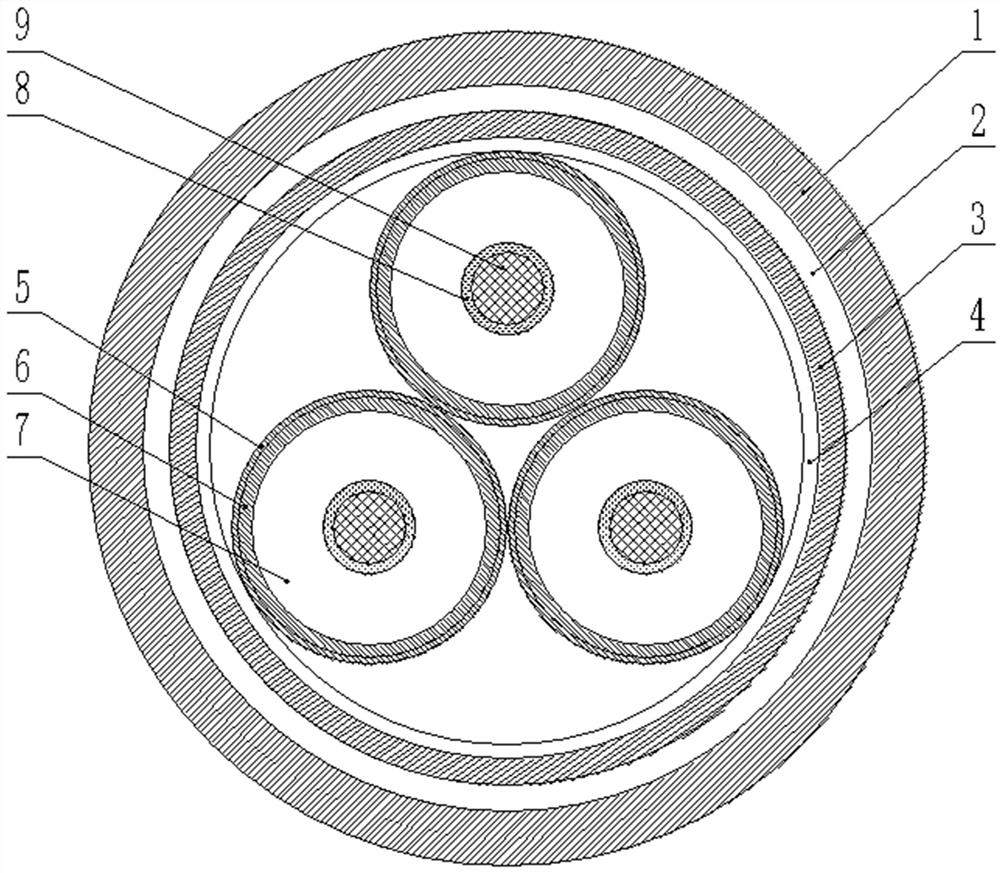

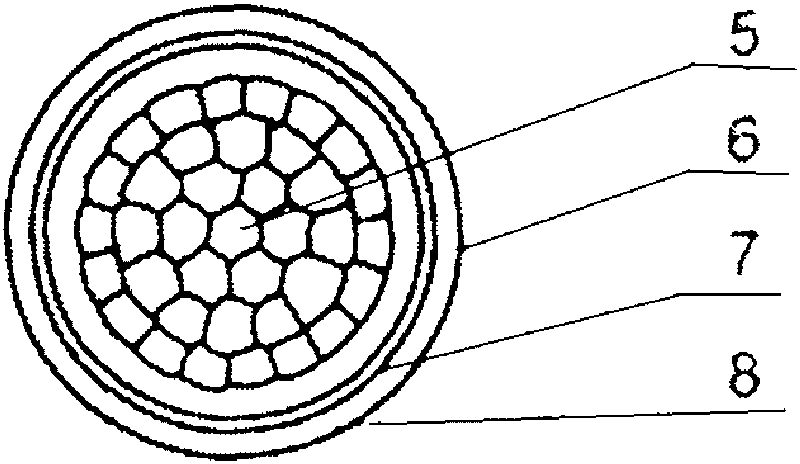

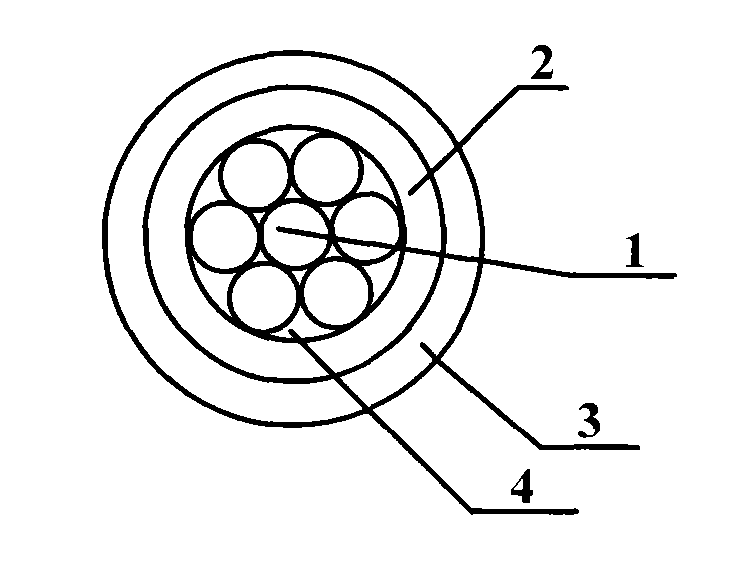

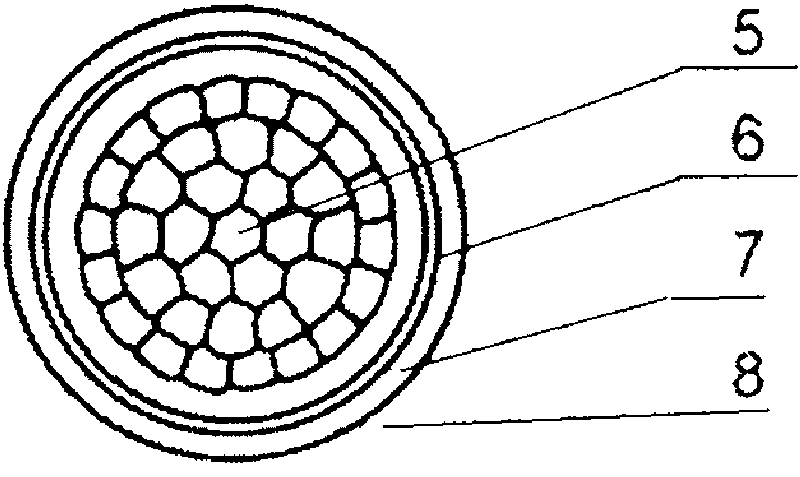

Waterproof agricultural buried cable

InactiveCN101710500AExtend your lifeEnsure safetyClimate change adaptationInsulated cablesElectrical conductorDirect-buried cable

Owner:广州市荔湾电线厂

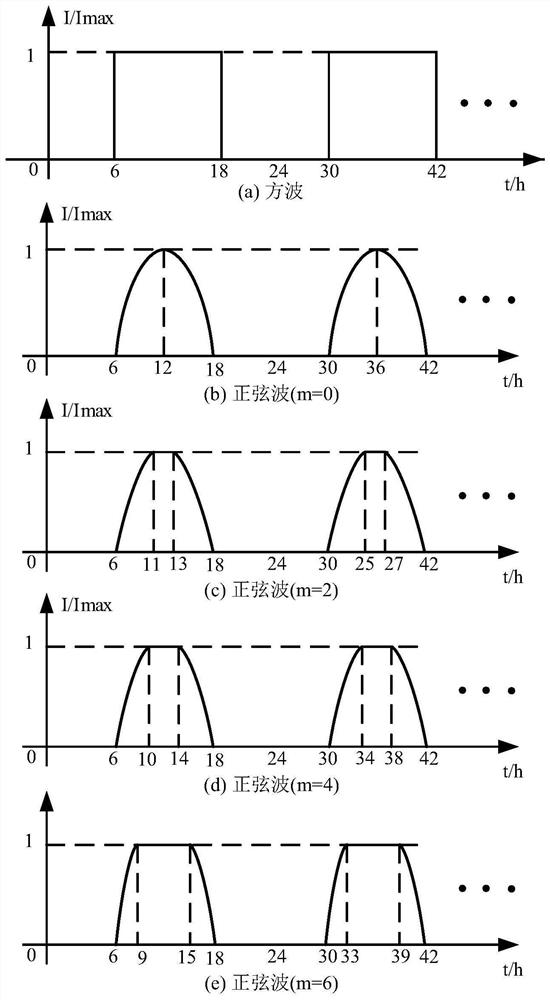

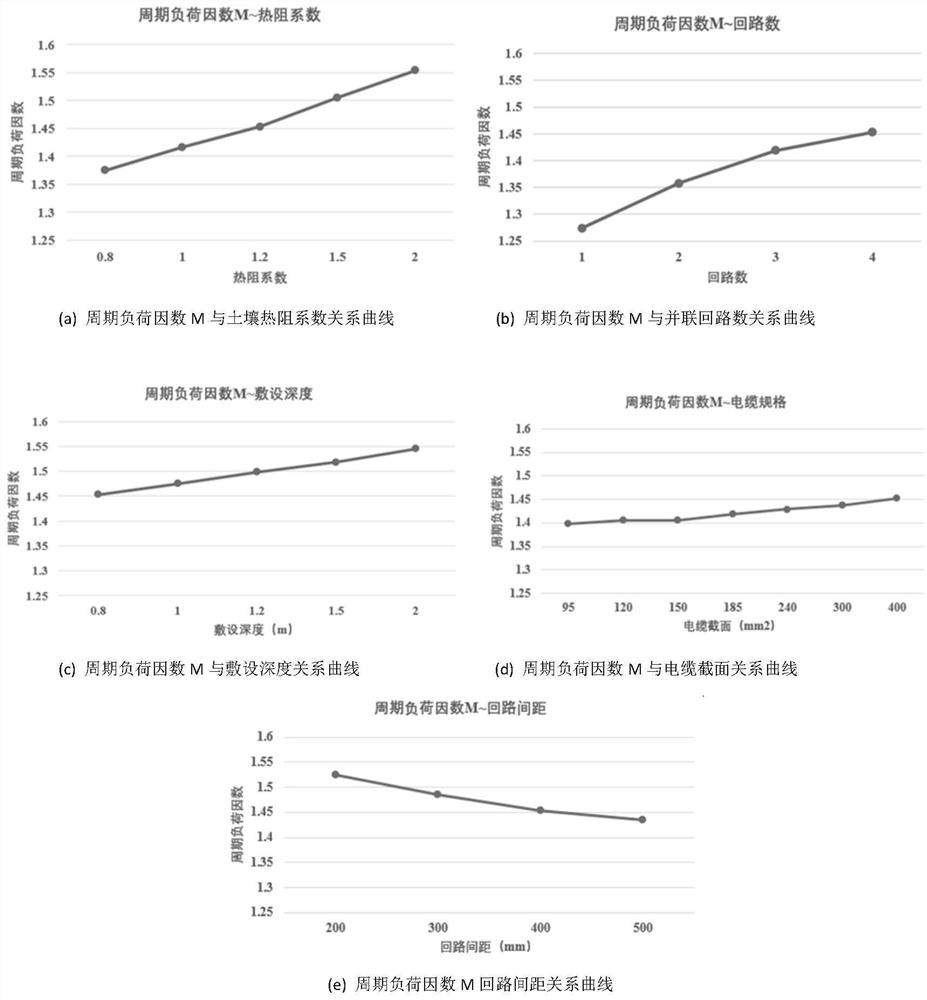

Photovoltaic system direct-buried cable current-carrying type selection method

PendingCN114154287ADesign optimisation/simulationSpecial data processing applicationsDirect-buried cableControl theory

The invention relates to a direct-buried cable current-carrying type selection method for a photovoltaic system. The method comprises the following steps: firstly, fitting a daily load period curve flowing through a cable in the photovoltaic system according to Pvsyst per hour data on the basis of the periodic load characteristic of the photovoltaic system; and then based on the confirmed daily load period curve and the actual laying environment and configuration of the buried cable, a cable period load factor is calculated through software (CYMCAP or the like), a cable current peak value under the period load is confirmed, and therefore the calculation method suitable for photovoltaic system buried cable type selection is provided. The invention further provides a 35kV direct-buried cable load factor M value table look-up method, the minimum value of M is confirmed, practical engineering application is facilitated, the cable section is effectively reduced, and therefore the cable cost is reduced.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Direct buried cable laying method and special cable protection sleeve for the method

ActiveCN108565785BEnhance storage and drainage capacityExtended service lifeCable installations in underground tubesApparatus for laying cablesDirect-buried cableEngineering

Owner:中铁十五局集团电气化工程有限公司

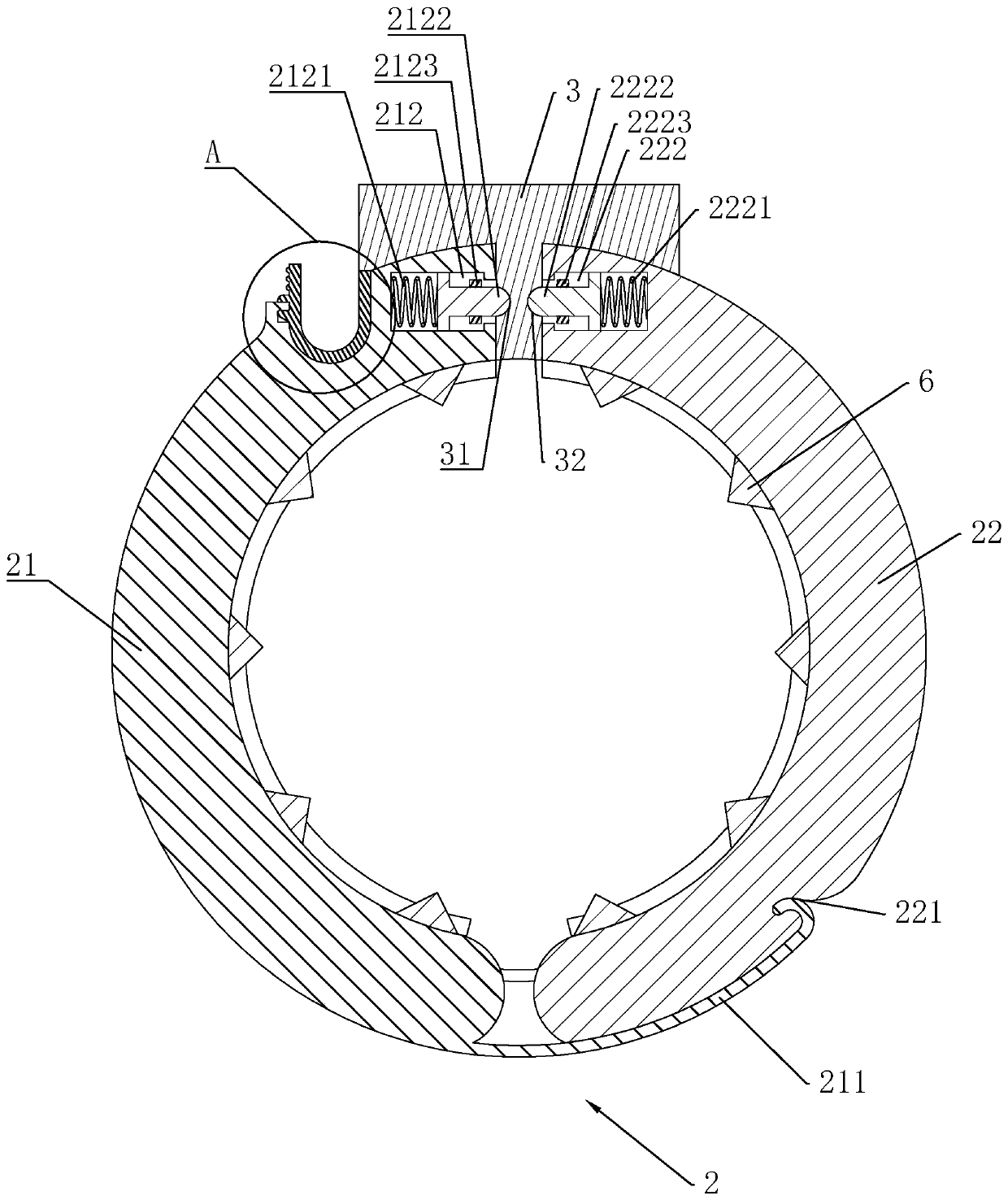

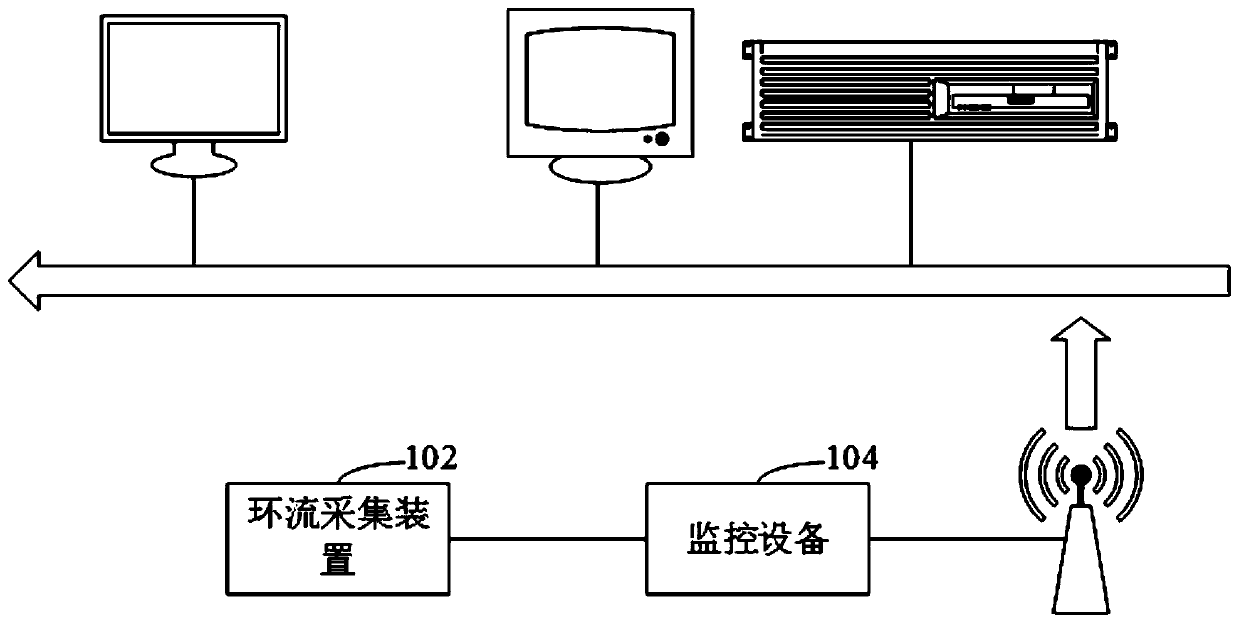

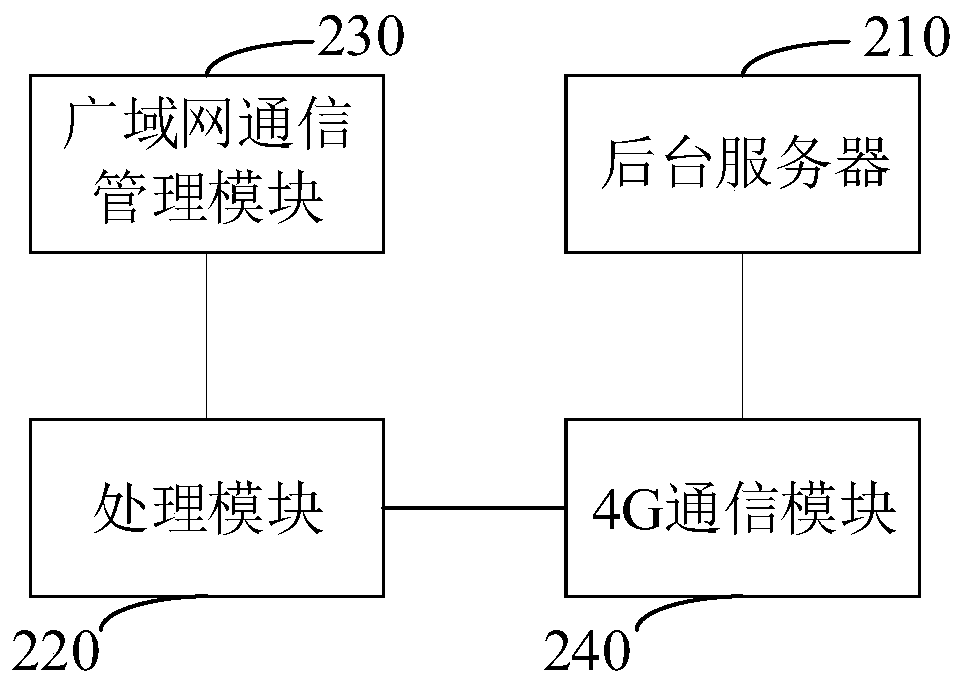

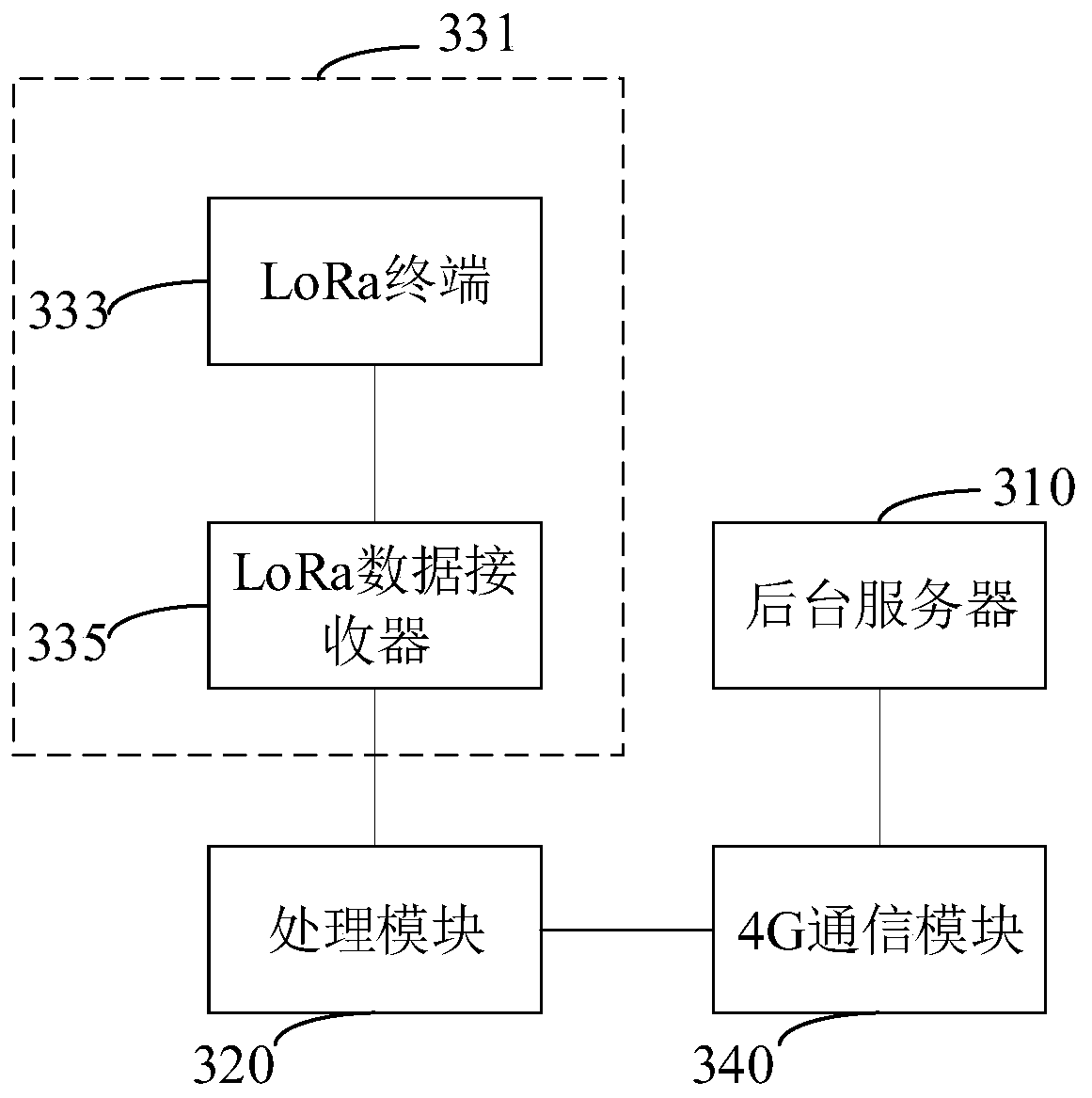

Communication system and method and monitoring system and method for cable monitoring data and storage medium

InactiveCN110267223ARealize integrated applicationReduce labor costsCircuit arrangementsParticular environment based servicesComputer hardwareCommunications system

The invention relates to a communication system and method and a monitoring system and method for cable monitoring data, and a storage medium. The communication system comprises a background server, a processing module, and a wide area network communication management module and a 4G communication module which are respectively connected with the processing module. The wide area network communication management module acquires the circulation data acquired by the circulation acquisition device and transmits the circulation data to the processing module; the processing module transmits the acquired image data to the 4G communication module and transmits the circulation data to the 4G communication module; and the 4G communication module transmits the image data and the circulation data to a background server. The wide area network communication management module can enable the cable monitoring data in the cable joint well to be remotely transmitted; the integrated application of the two communication modes is realized, and the external damage monitoring data and the online monitoring data of the high-voltage cable can be acquired at the same time, so that the states of the high-voltage cable body and the joint can be mastered in real time, and the labor cost of the traditional full-line manual supervision of the direct-buried cable is reduced to a certain extent.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com