Direct buried cable laying method and special cable protection sleeve for the method

A cable protection sleeve and cable laying technology, applied in cable laying equipment, cable installation, cable installation in underground pipelines, etc., can solve the problems of cable sheath deformation, affecting cable service life, etc., to prolong service life , enhance the storage and drainage capacity, not easy to swell and deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

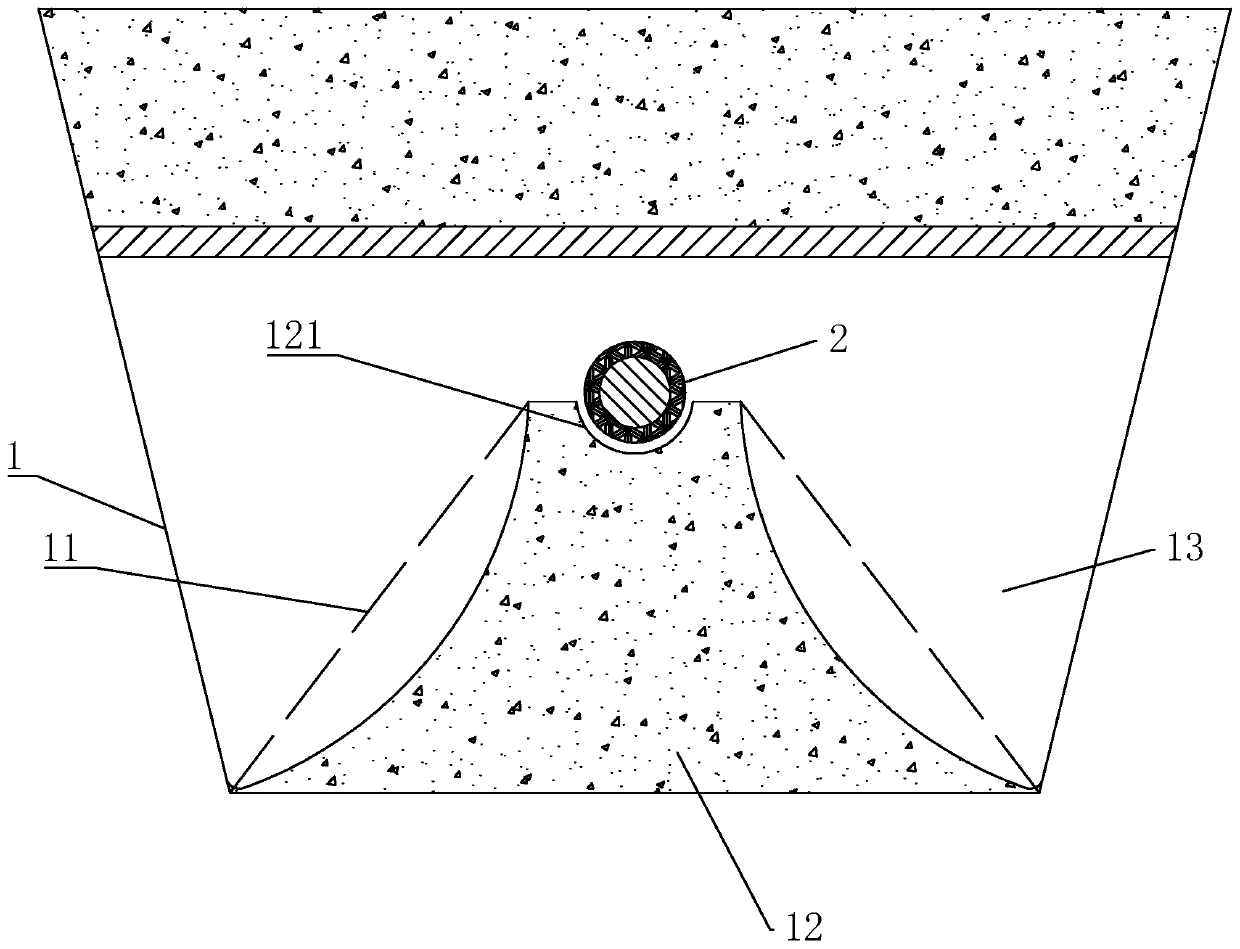

[0072] Embodiment 1: A direct-buried cable laying method includes the following steps: re-testing S1 for cable line engineering, cable distribution plate S2, cable laying S3, cable trench backfilling S4, and stake burying S5.

[0073] The specific process of the re-test S1 of the cable line engineering line is as follows:

[0074] 1-1. Re-measure the cable laying path: According to the design and construction path map, determine the path direction of the cable, the protection of bridges, culverts, aisles, rail crossings, the relative position and number of joints, and the soil conditions of the lines, so that the optical cable lines are safe and reliable. And easy to construct and maintain. One stake every 100 meters during measurement, and additional stakes are added at special locations for joints, remainders, inflection points, rail crossings, and road crossings;

[0075] 1-2. Reasonably calculate and allocate the remaining cable: the natural bending of the cable is 2%, de...

Embodiment 2

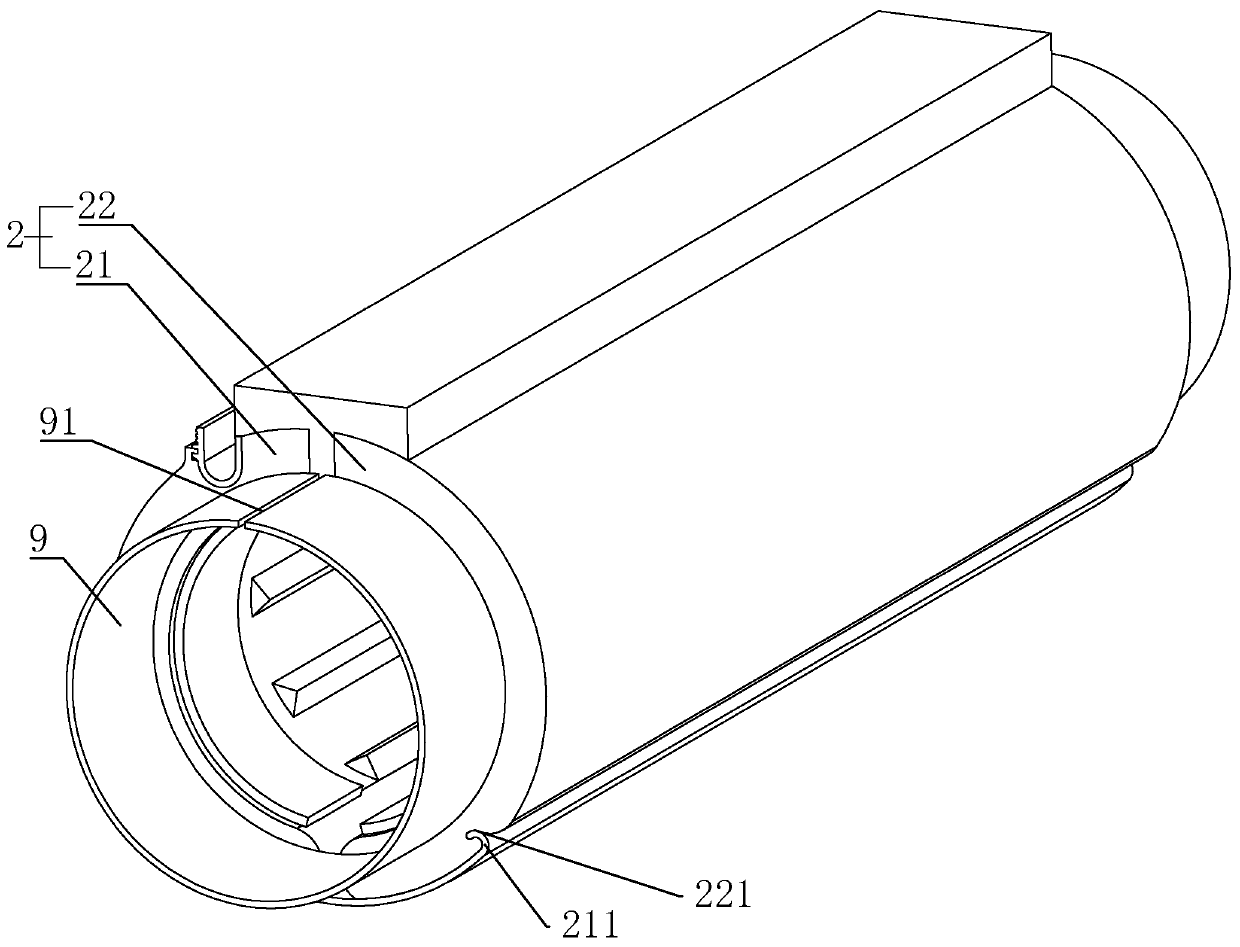

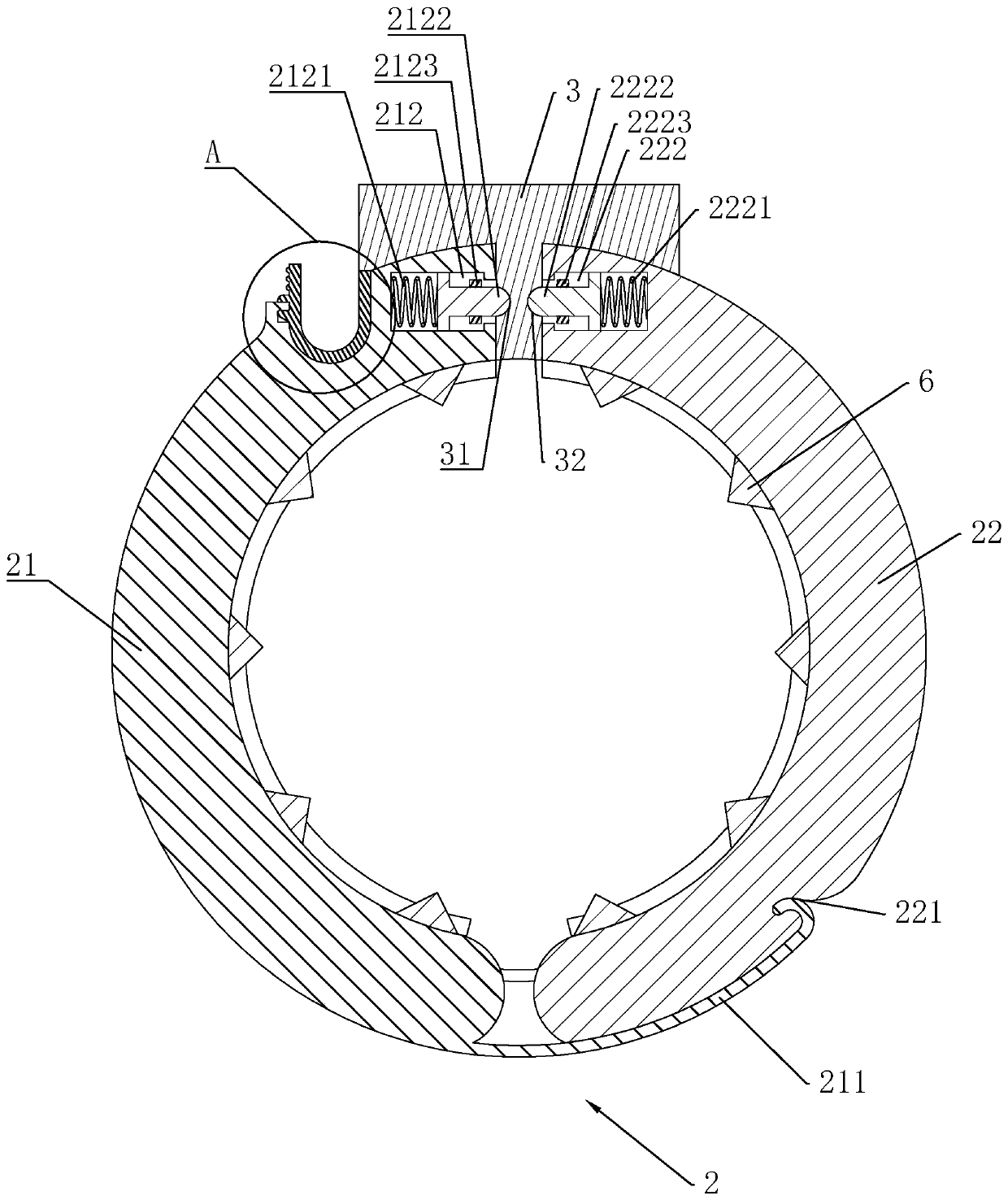

[0093] Embodiment 2: A special cable protection sleeve for direct buried cable laying method, such as figure 2 As shown, the length of each cable protection sleeve 2 is 1 meter, a flexible rubber hose 9 is arranged between adjacent cable protection sleeves 2, and the upper end of the rubber hose is provided with an opening 91, and the opening 91 can follow the cable The protective sleeve 2 is opened and opened. The arrangement of the rubber hose 9 is used to connect the adjacent cable protection sleeves 2, and at the same time, the cable protection sleeves 2 can be folded and stored so as to reduce the storage length of the cable protection sleeves 2 and reduce the length of the cable protection sleeves 2. The required storage and transportation space is described below with a single cable protection sleeve.

[0094] like figure 2 As shown in the figure, the traditional cable protection sleeve 2 is an integrally formed hollow tube structure, which not only wastes space dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com