Waterproof agricultural buried cable

A direct-buried, water-blocking technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of endangering the safety of humans and animals, unsafe power consumption, easy to break cores, etc., to improve product leakage, ensure power supply safety, and improve insulation. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

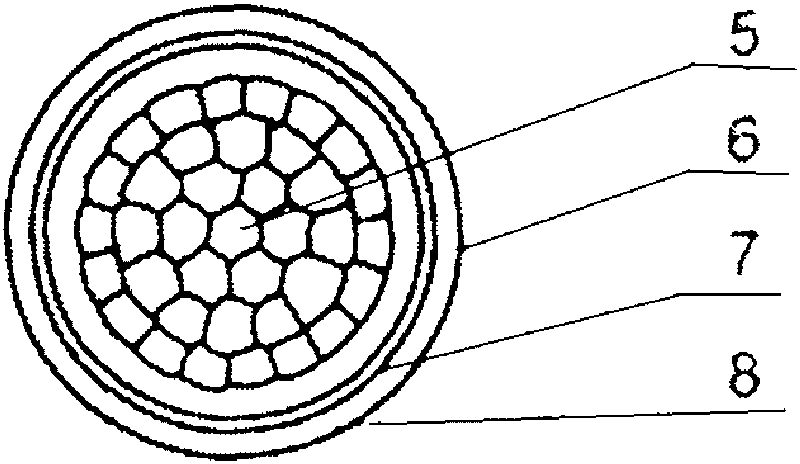

[0014] Such as figure 1 As shown, the existing agricultural direct-buried cable is composed of a conductor and an insulating layer and a sheath layer wrapped around the conductor from the inside to the outside in turn. Since its conductor is composed of multiple aluminum single wires twisted, there are large gaps between the conductors. The infiltrated water can slowly contact each aluminum wire and corrode the aluminum wire, which is prone to leakage and power failure.

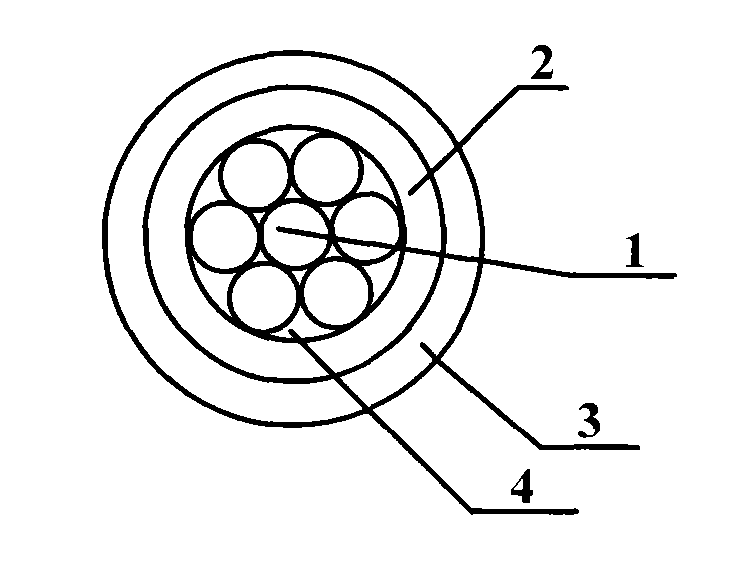

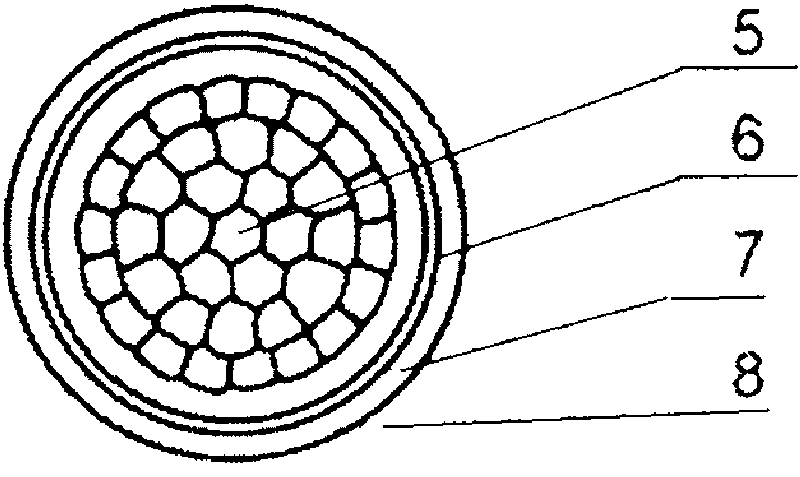

[0015] Such as figure 2 As shown, in the water-blocking agricultural direct-buried cable of the present invention, the conductor adopts a compact conductor without single-wire gaps, and a water-blocking layer is added between the insulating layer and the sheath layer. The invention has both longitudinal and radial water-blocking structures . The conductor is made of multiple copper-clad aluminum wires twisted and tightly pressed, so that there is no gap between each copper-clad aluminum wire, forming a ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com