Constant-tension and autonomous straightening paying-off device attached to direct-buried cable paying-off vehicle

A technology of pay-off device and pay-off car, which is applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., which can solve the problems of difficult operation and inapplicability of direct burial laying, so as to achieve simple operation and ensure laying Requirements, the effect of tension stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

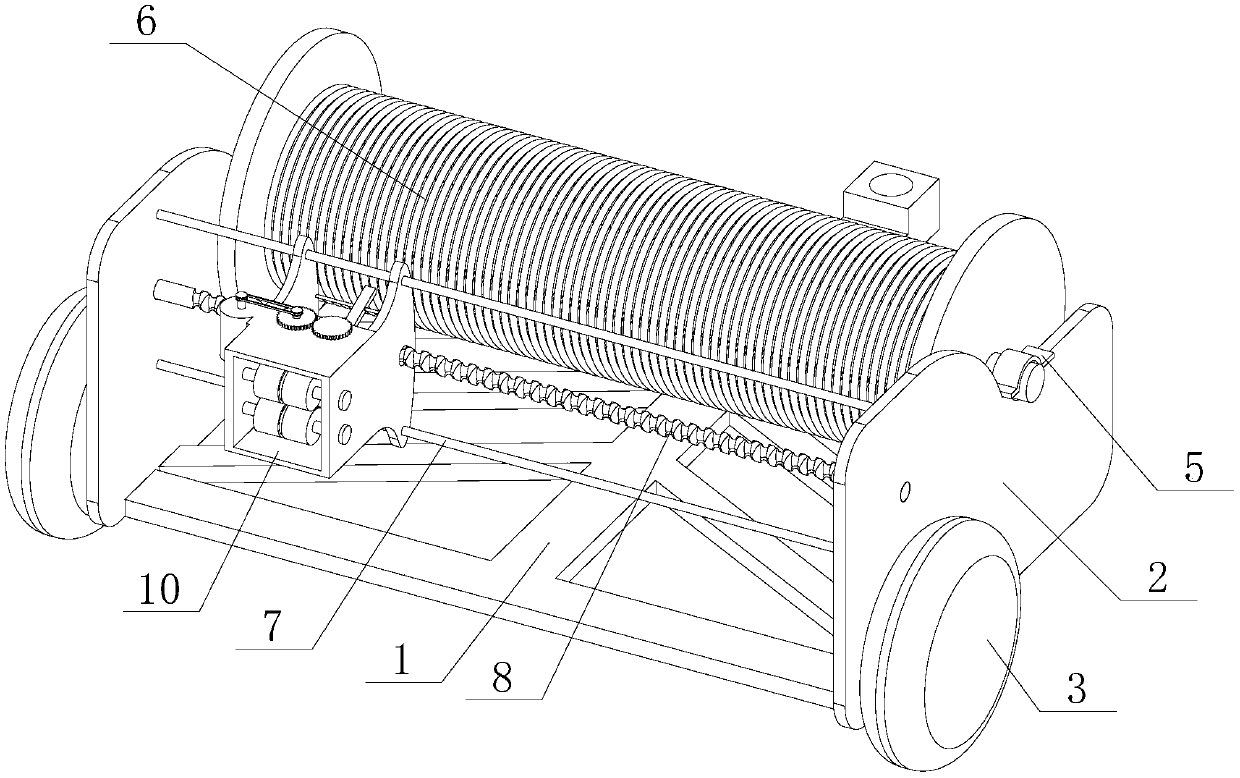

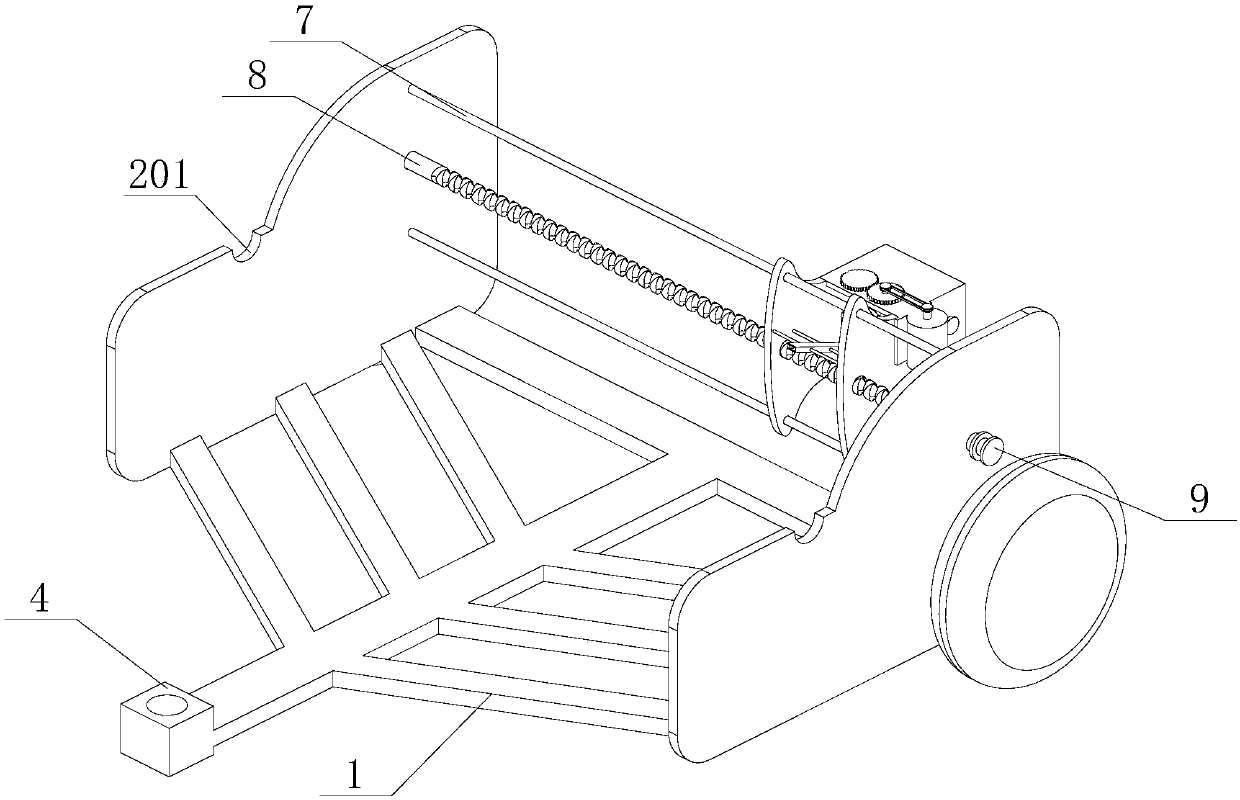

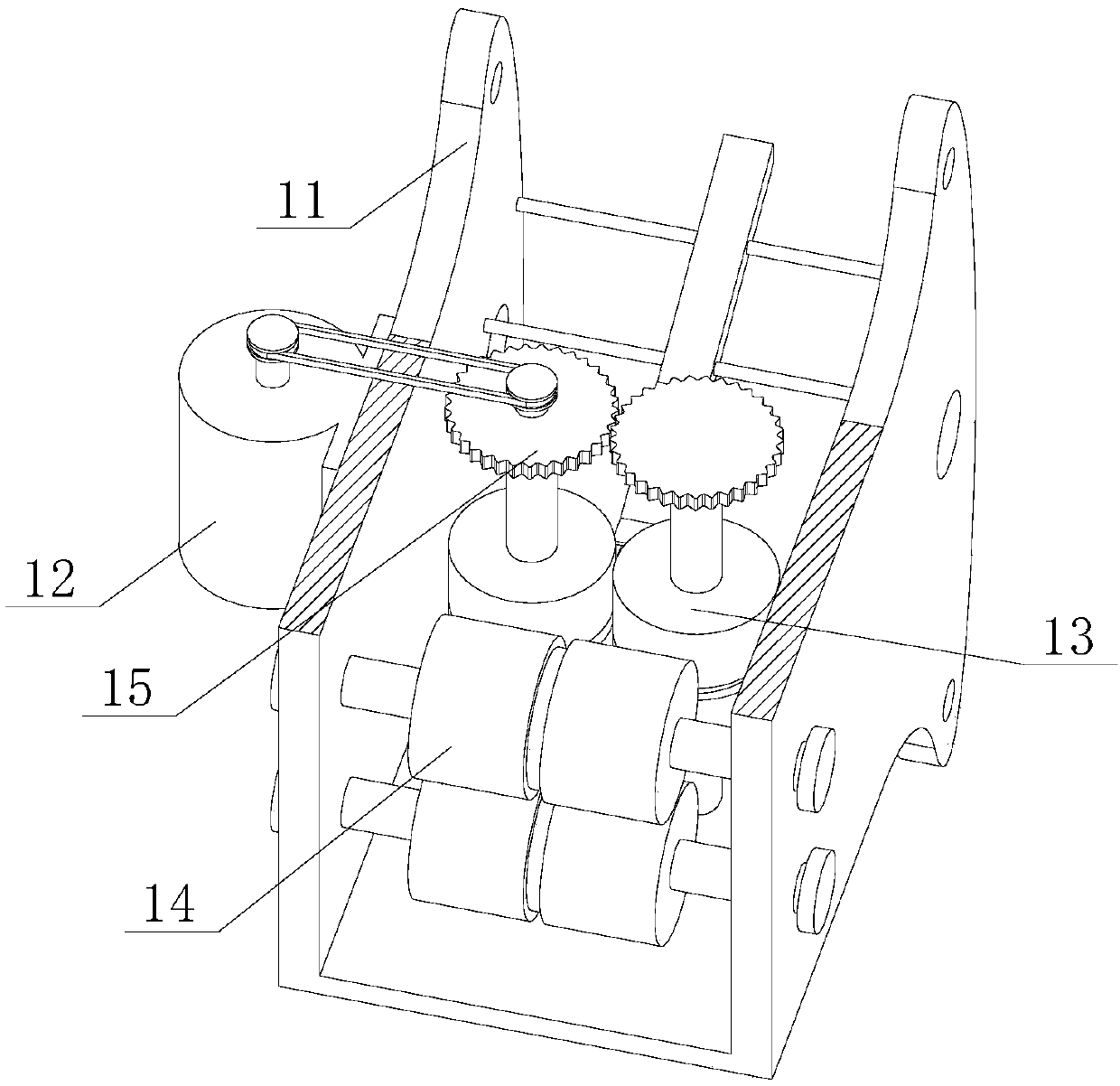

[0023] Such as figure 1 The direct-buried cable pay-off vehicle is equipped with a constant tension self-pressing straight pay-off device, which aims to provide a pay-off device suitable for the requirements of direct-buried cables. This pay-off device has two purposes, one is constant tension The second is to straighten the cable. Based on the above purpose, the device is provided with two functional units, namely a constant tension auxiliary unit and a straightening and pulling unit.

[0024] This device is used in conjunction with the pay-off car. Such as figure 1 and figure 2 As shown, the device takes the bracket 1 as the base structure, and two side plates 2 are installed on the bracket 1, and the retention groove 201 provided on the side plate 2 is used to cooperate with the movable card 5 to install the wire roller 6. During use, the wire roller 6 of the cable is placed on the retention groove 201 by a lifting device, and through the cooperation of the retention g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com