Method for butting buried cable steel tube on site during construction

A technology for steel pipes and cables, applied in the field of docking between cable steel pipes, can solve the problems affecting the construction period and quality of cable laying, the burrs of the nozzles of the cable steel pipes, and the inability of cables to pass through, so as to achieve a simple and practical production process, and ensure efficiency and quality. , The effect of convenient on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the embodiments and accompanying drawings, see Fig. 1 to Fig. 3:

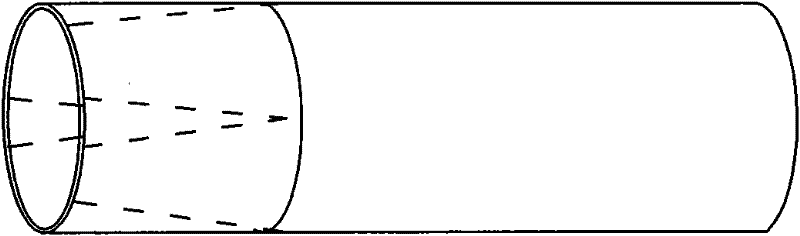

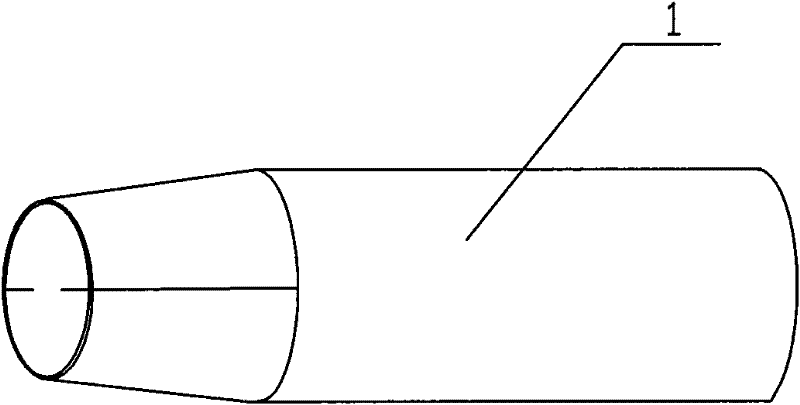

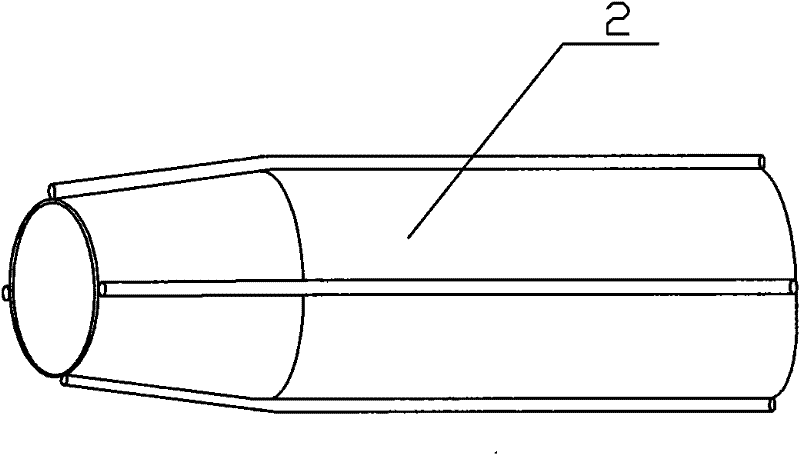

[0022] According to the present invention, the bushing used for butt jointing of directly buried cable steel pipes includes a butt joint sleeve 5. In order to make the butt joint sleeve 5 fit smoothly outside the cable steel pipe 6, the pipe diameter of the butt joint sleeve 5 needs to be enlarged. , the method is to make a wedge-shaped reaming pipe 2 for diameter expansion on the spot earlier. The production process of the wedge-shaped reaming pipe 2 is as follows: use a cutting machine to cut a section of steel pipe of the same material as the cable steel pipe 6, symmetrically cut out three or four triangular openings on the side wall of the nozzle at one end, reduce the size and weld to make the wedge-shaped pipe 1, Three or four steel bars with a dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com