Direct buried cable joint insulation and waterproofing processing device and method

A technology of cable joints and waterproof treatment, which is applied in the direction of cable joints, cable installation, cable accessories, etc., can solve the problems of limited insulation and waterproof effect, high laying cost, high requirements, etc., achieve good waterproof effect, meet insulation performance and waterproof performance, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

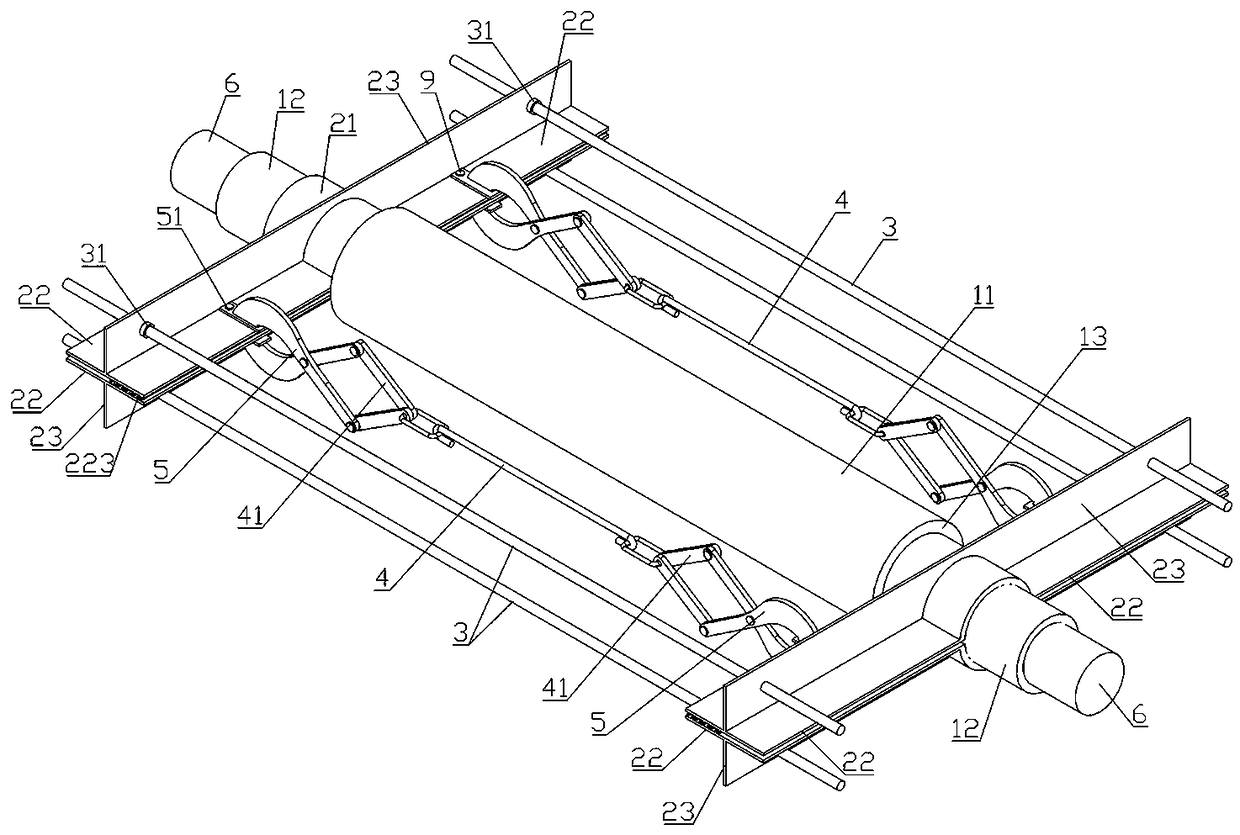

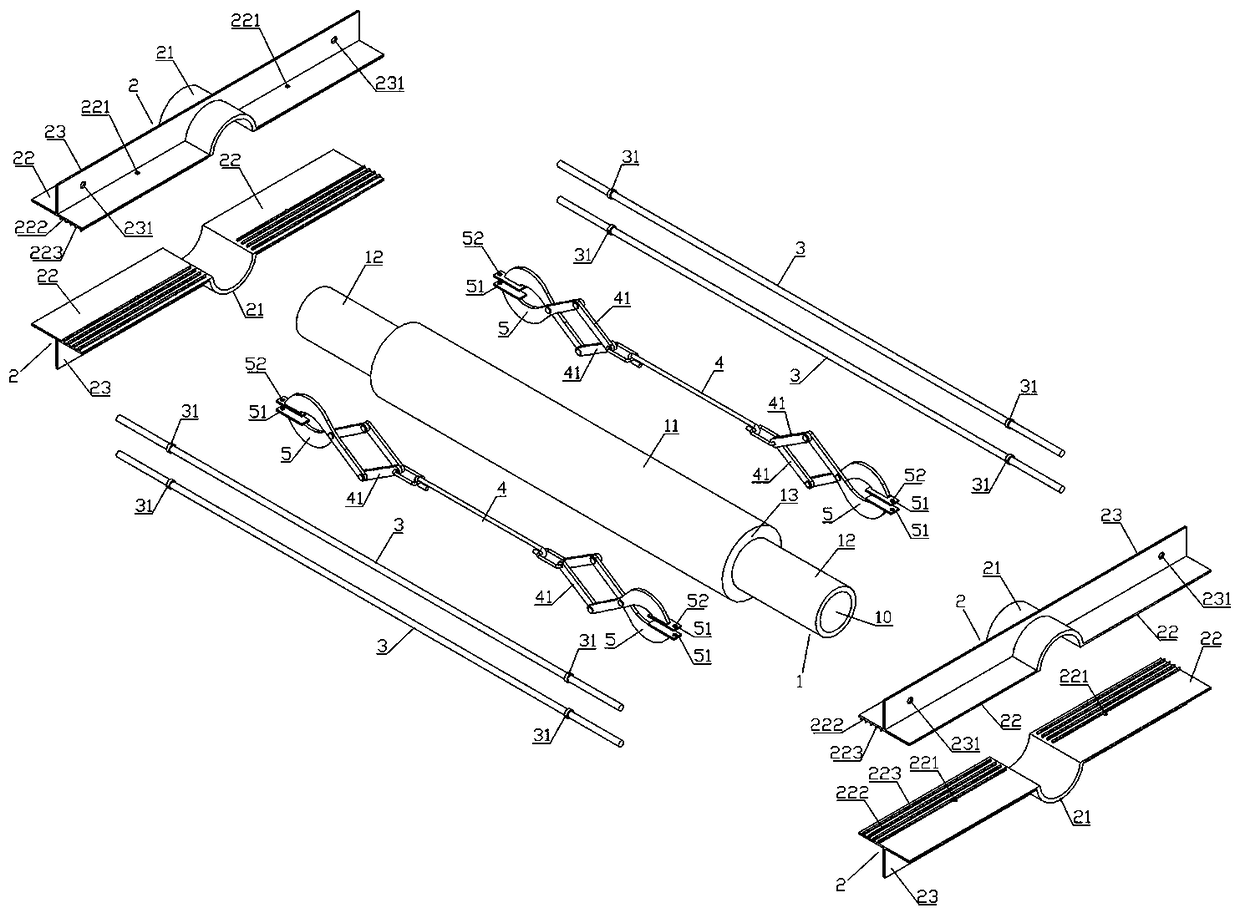

[0028] refer to figure 1 and figure 2 , a direct-buried cable joint insulation and waterproof treatment device, which includes an elastic outer sleeve 1, a pull device frame, a limit screw 3 and a device frame tension clamp.

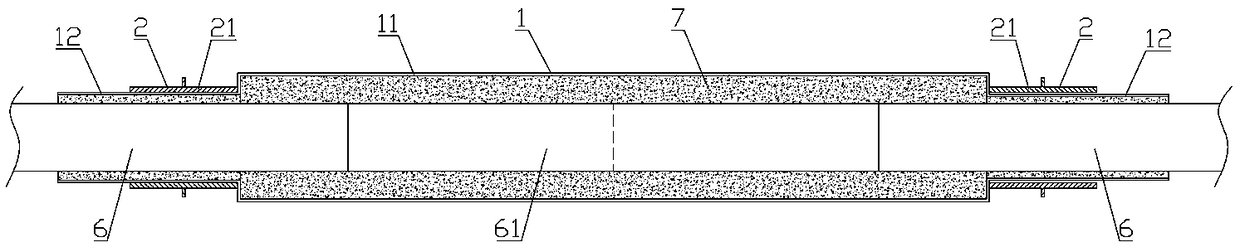

[0029] The elastic outer sleeve 1 is a circular tubular structure with a through hole 10 in the center made of rubber material. The middle part of the elastic outer sleeve 1 has a main pipe portion 11 and two ends have end pipe portions 12. The pipe wall of the main pipe portion 11 is Thickening makes the end pipe portion 12 have a limiting boss 13 near the main pipe portion 11 .

[0030] The said pull device frame is formed by two half-pipe splints 2 oppositely arranged and fastened, and the middle part of said half-pipe splint 2 has an arc-shaped half-pipe portion 21 arranged transversely, and the inner diameter of the arc-shaped half-pipe portion 21 is in line with the elastic jacket. The outer diameter of the end pipe portion 12 of the pipe 1 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com