Method for preparing high-purity silica

A technology of high-purity silicon dioxide and hydrated silicon dioxide, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of unstable product quality, long production process, environmental pollution, etc., and achieve good product quality, stable quality, The effect of short working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

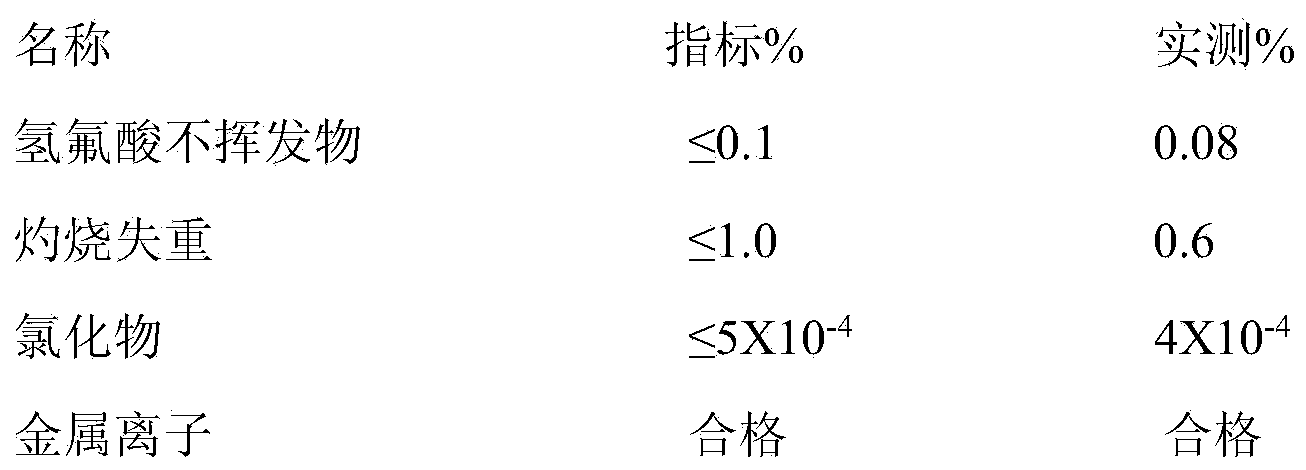

Examples

Embodiment 1

[0022] A preparation method of high-purity silicon dioxide, the steps are as follows:

[0023] (1) Hydrolysis: Put 1000 ml of tetraethyl orthosilicate in a 5000 ml glass beaker, add 1000 ml of 10% ammonia water, heat under stirring, stop heating after the solution boils, and continue stirring for 30 minutes, stop stirring, and the precipitate Stand overnight, the precipitate is hydrated silica;

[0024] (2) Drying: Dry the sediment that has been left standing overnight with a centrifuge, put the dried hydrated silica into a 3000ml porcelain dish, and bake in a drying oven at about 100°C for 2-3 sky.

[0025] (3) Ignition: put the dried hydrated silica into a high-temperature furnace and heat up at about 900°C for 8 hours, then take it out after natural cooling to obtain high-purity silica.

[0026] In this example, the purity of ethyl orthosilicate is 99.99%, and 10% ammonia water is a self-made high-purity reagent.

Embodiment 2

[0028] A preparation method of high-purity silicon dioxide, the steps are as follows:

[0029] (1) Hydrolysis: Put 1000 ml of tetraethyl orthosilicate in a 5000 ml glass beaker, add 2000 ml of 5% ammonia water, heat under stirring, stop heating after the solution boils, and continue stirring for 40 minutes, stop stirring, and the precipitate Stand overnight, the precipitate is hydrated silica;

[0030] (2) Drying: Dried the sediment left standing overnight with a centrifuge, put the dried hydrated silica into a 3000ml porcelain dish, and baked it in a drying oven at about 102°C for 3 days.

[0031] (3) Burning: put the dried hydrated silica into a high-temperature furnace and heat up at 950°C for 8 hours, then take it out after natural cooling to obtain high-purity silica.

[0032] In the step (1), the purity of ethyl orthosilicate is ≥99.99%, and the purity requirement of ammonia water is the same as that of ethyl orthosilicate.

Embodiment 3

[0034] A preparation method of high-purity silicon dioxide, the steps are as follows:

[0035] (1) Hydrolysis: Put 1000 ml of tetraethyl orthosilicate in a 5000 ml glass beaker, add 1500 ml of 5% ammonia water, heat under stirring, stop heating after the solution boils, and continue stirring for 20 minutes, stop stirring, and the precipitate Stand overnight, the precipitate is hydrated silica;

[0036] (2) Drying: The sediment left standing overnight was dried with a centrifuge, and the dried hydrated silica was put into a 3000 ml porcelain dish, and baked in a drying oven at 90° C. for 2.5 days.

[0037] (3) Burning: put the dried hydrated silica into a high-temperature furnace and heat up at 850°C for 7.5 hours, then take it out after natural cooling to obtain high-purity silica.

[0038] In the step (1), the purity of ethyl orthosilicate is ≥99.99%, and the purity requirement of ammonia water is the same as that of ethyl orthosilicate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com