Polydimethylsiloxane carbon black master batch and preparation method thereof

The technology of polydimethylsiloxane carbon black and dimethylsiloxane carbon black is applied in the field of polydimethylsiloxane carbon black masterbatch and its preparation, which can solve the problem of the decrease of product gloss and the influence of continuous production. , die accumulation and other problems, to achieve the effect of improving processing performance, good processing performance and less die accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

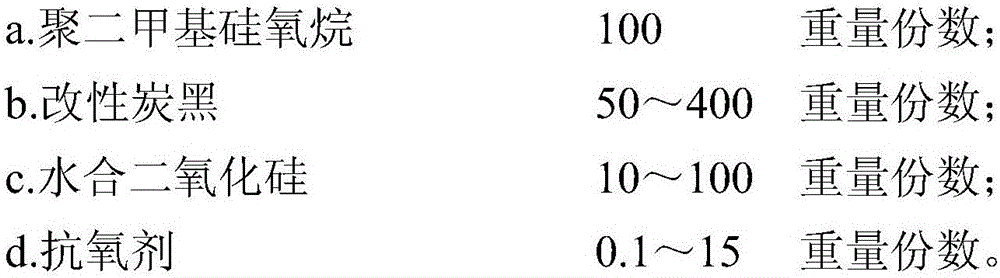

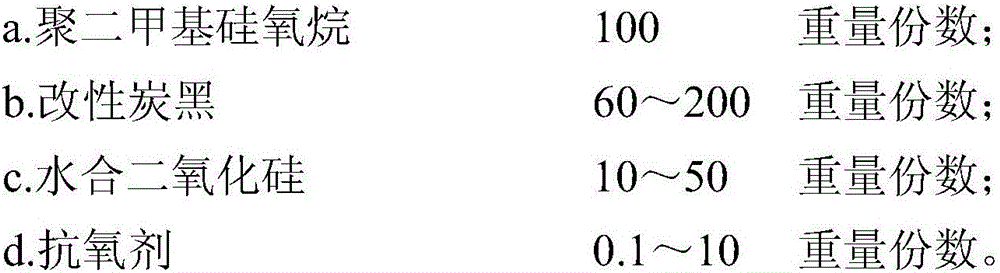

Method used

Image

Examples

Embodiment 1

[0033] Put 400 parts by weight of carbon black (brand: 50L, average primary particle size <25nm, 325 mesh residual content <50ppm, DBP oil absorption value 55ml / 100g) and 2000 parts by weight of concentrated nitric acid into a three-necked flask, and stir and react at 60°C for 5 hours , and then washed with deionized water until neutral, and dried at 50°C to obtain oxidized carbon black. 400 parts by weight of oxidized carbon black, 40 parts by weight of hydroxyl-terminated polydimethylsiloxane with a molecular weight of 2000, 2 parts by weight of dicyclohexylcarbodiimide, and 2 parts by weight of 4-dimethylaminopyridine were stirred at 50°C Modified carbon black was obtained in 4 hours.

[0034] Polydimethylsiloxane (relative molecular weight 100,000), antioxidant 1010 (tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, namely tetraerythritol ester) Put it into an internal mixer, discharge after melt blending, extrude and granulate to obtain the p...

Embodiment 2

[0038] Put 100 parts by weight of carbon black (same as Example 1) and 600 parts by weight of concentrated nitric acid into a three-necked flask, stir and react at 70°C for 12 hours, then wash with deionized water until neutral, and dry at 60°C to obtain oxidized carbon black. 100 parts by weight of oxidized carbon black, 20 parts by weight of hydroxyl-terminated polydimethylsiloxane with a molecular weight of 2500, and 1 part by weight of 4-dimethylaminopyridine were stirred at 75° C. for 8 hours to obtain modified carbon black.

[0039] The production technology of polydimethylsiloxane carbon black master batch is identical with embodiment 1. The specific formula of carbon black masterbatch is: polydimethylsiloxane (produced by U.S. Dow Corning Company, relative molecular weight 10,000), wherein modified carbon black is 100 parts by weight, antioxidant 1010 (same as embodiment 1) 0.5 parts by weight .

[0040] The production of the sheet was the same as in Example 1 except ...

Embodiment 3

[0042] Put 100 parts by weight of carbon black (same as Example 1) and 800 parts by weight of concentrated nitric acid into a three-necked flask, stir and react at 130°C for 24 hours, then wash with deionized water until neutral, and dry at 80°C to obtain oxidized carbon black. 100 parts by weight of oxidized carbon black and molecular weight are 50 parts by weight of hydroxyl-terminated polydimethylsiloxane of 5000, 1 weight part of 41-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride parts, stirred at 140°C for 10 hours to obtain modified carbon black.

[0043] The production technology of polydimethylsiloxane carbon black master batch is identical with embodiment 1. The concrete formula of carbon black masterbatch is: the part of polydimethylsiloxane (relative molecular weight 50,000) is 100 parts by weight, the part of modified carbon black is 50 parts by weight, antioxidant (same as embodiment 1) 0.5 parts by weight.

[0044] Except that the weight ratio of ASA ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com