Comprehensive utilization method of acid sludge generated in acid making by smelting fume

A technology for producing acid and acid mud from flue gas, which is applied in chemical instruments and methods, silicates, arsenic compounds, etc., can solve the problems of maximum separation of arsenic and metals, etc., and achieve a high degree of economical and refined utilization and a large economy Value, the effect of a wide range of adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

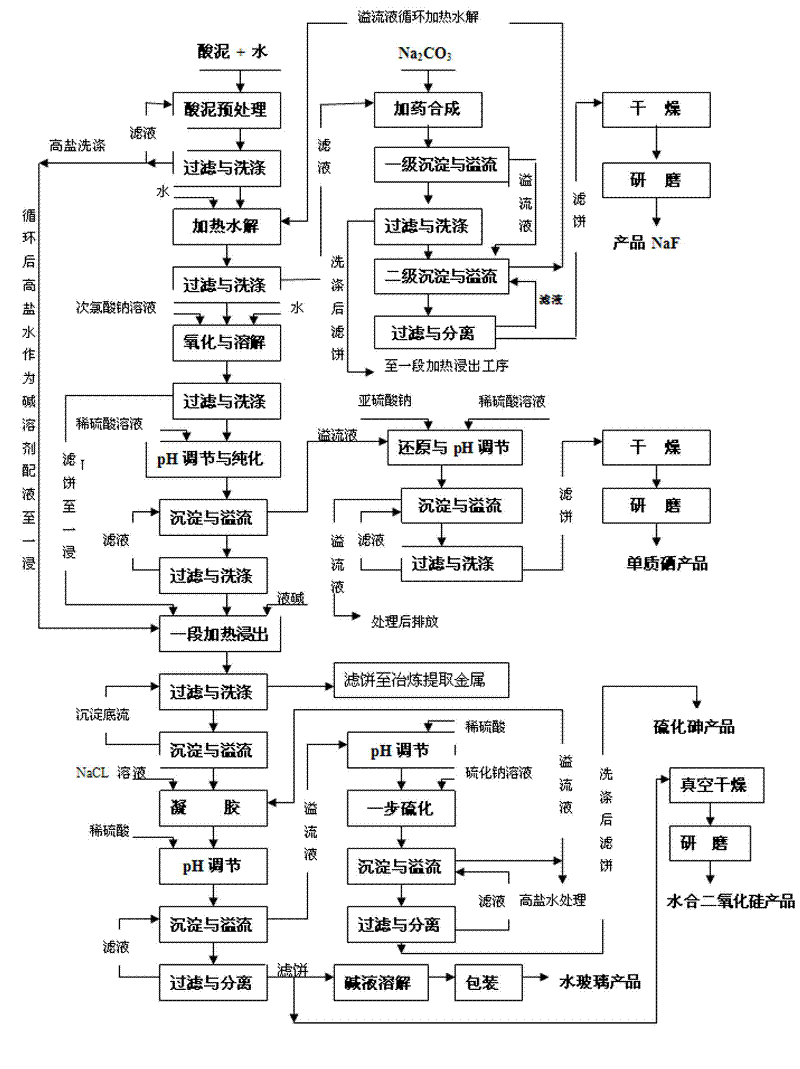

Image

Examples

Embodiment 1

[0069] The first step is to prepare sodium fluoride

[0070] 1. Raw material pretreatment: put 100g of acid mud and 600ml of water into a beaker for stirring and washing for 15 minutes, and the stirring speed is 250 rpm; then the washing mixture is filtered through a filter, and then the filter cake is washed with water. After the filter cake enters the heating and hydrolysis process, the filtrate and the washing solution are returned to the pretreatment and continue to be used as washing water for recycling; when the washing solution contains high salt, it is used as the alkaline leaching solvent preparation water in a heating leaching process;

[0071] 2. Heating and hydrolysis: put 100g of the pre-filtered filter cake and 600ml of water into a beaker, move the beaker into a water bath filled with water, set the temperature of the water bath to 100°C, and the stirring speed at 250 rpm. Hydrolysis under heating for 15 minutes. The mixed solution after hydrolysis is subjected...

Embodiment 2

[0106] The first step is to prepare sodium fluoride

[0107] 1. Raw material pretreatment: 100g of acid mud and 700ml of water were put into a beaker for stirring and washing for 20 minutes, and the stirring speed was 200 rev / min; the rest was the same as in Example 1;

[0108] 2. Heating and hydrolysis: put 100g of the pre-filtered filter cake and 800ml of water into a beaker, move the beaker into a water bath with water, set the temperature of the water bath to 100°C, and the stirring speed of 200 rpm. Under heating and hydrolysis for 30 minutes;

[0109] 3. Filtration and washing process: the same as in Example 1;

[0110] 4. Dosing and synthesis: Add 30 g of sodium carbonate to the beaker of clear liquid after precipitation under stirring, the pH is 8, the reaction time for dosing and synthesis is 40 minutes, and the stirring speed is 250 rpm;

[0111] 5. Primary precipitation: the same as in Example 1;

[0112] 6. Filtration and washing: the same as in Example 1;

[0...

Embodiment 3

[0140] The first step is to prepare sodium fluoride

[0141] 1. Pretreatment of raw materials: 100g of acid mud and 800ml of water were put into a beaker for stirring and washing for 30 minutes, and the stirring speed was 250 rev / min; the rest was the same as in Example 1;

[0142] 2. Heating and hydrolysis: put 100g of pre-filtered filter cake and 800ml of water into a beaker, move the beaker into a water bath with water, set the temperature of the water bath to 100°C, and stir at 230 rpm. Under heating and hydrolysis for 25 minutes;

[0143] 3. Filtration and washing process: the same as in Example 1;

[0144] 4. Dosing and synthesis: add 45 g of sodium carbonate to the beaker after precipitation, the pH is 10, the reaction time for dosing and synthesis is 20 minutes, and the stirring speed is 250 rpm;

[0145] 5. Primary precipitation: the same as in Example 1;

[0146] 6. Filtration and washing: the same as in Example 1;

[0147] 7. Secondary precipitation: the same as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com