Sterilization moldproof aqueous putty powder and preparation method thereof

A putty powder, water-based technology, used in filling slurry and other directions, can solve the problems of poor adhesion and mildew resistance, not meeting environmental protection requirements, affecting the appearance of walls, etc. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

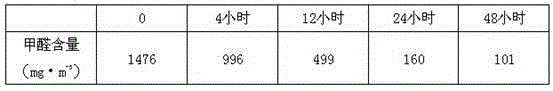

Image

Examples

Embodiment 1

[0025] The raw materials used are: 25 kg of natural hematite powder, 35 kg of lime calcium powder, 10 kg of silicon dioxide dihydrate, 0.8 kg of cellulose, 5 kg of rubber powder, 1 kg of pigment, 0.3 kg of triclosan,

[0026] Wherein, the fineness particle diameter of natural staphilite powder is 500 orders, and the fineness particle diameter of ash calcium powder is 400 orders; Cellulose is hydroxypropyl methylcellulose, and viscosity is 50,000 mPa·s; Pigment is Phenol cyanine; rubber powder is acrylic resin;

[0027] The preparation method is:

[0028] Take the mass ratio of the required raw materials, add the natural hematilite powder, ash calcium powder and silicon dioxide dihydrate into the mixer in sequence, stir for 20 minutes and mix evenly, then add the required quality of cellulose, Put the four small ingredients of rubber powder, pigment and triclosan into the blender, and continue to stir for 10 minutes to make it fully mixed, and the product is ready.

Embodiment 2

[0030] The raw materials used are: 50 kilograms of natural hematite powder, 20 kilograms of lime calcium powder, 5 kilograms of silicon dioxide dihydrate, 1.5 kilograms of cellulose, 2 kilograms of rubber powder, 0.5 kilogram of pigment, 0.05 kilogram of triclosan,

[0031] Among them, the fineness particle diameter of natural staphilite powder is 800 mesh, the fineness particle diameter of lime calcium powder is 600 mesh; The cellulose is hydroxyethyl cellulose, and the viscosity is 60,000 mPa·s; Green; rubber powder is propylene polyvinyl alcohol rubber powder;

[0032] Its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fine particle size | aaaaa | aaaaa |

| Fine particle size | aaaaa | aaaaa |

| Fine particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com