Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97 results about "Selenous acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Selenous acid (or selenious acid) is the chemical compound with the formula H₂SeO₃. Structurally, it is more accurately described by (HO)₂SeO. It is the principal oxoacid of selenium; the other being selenic acid.

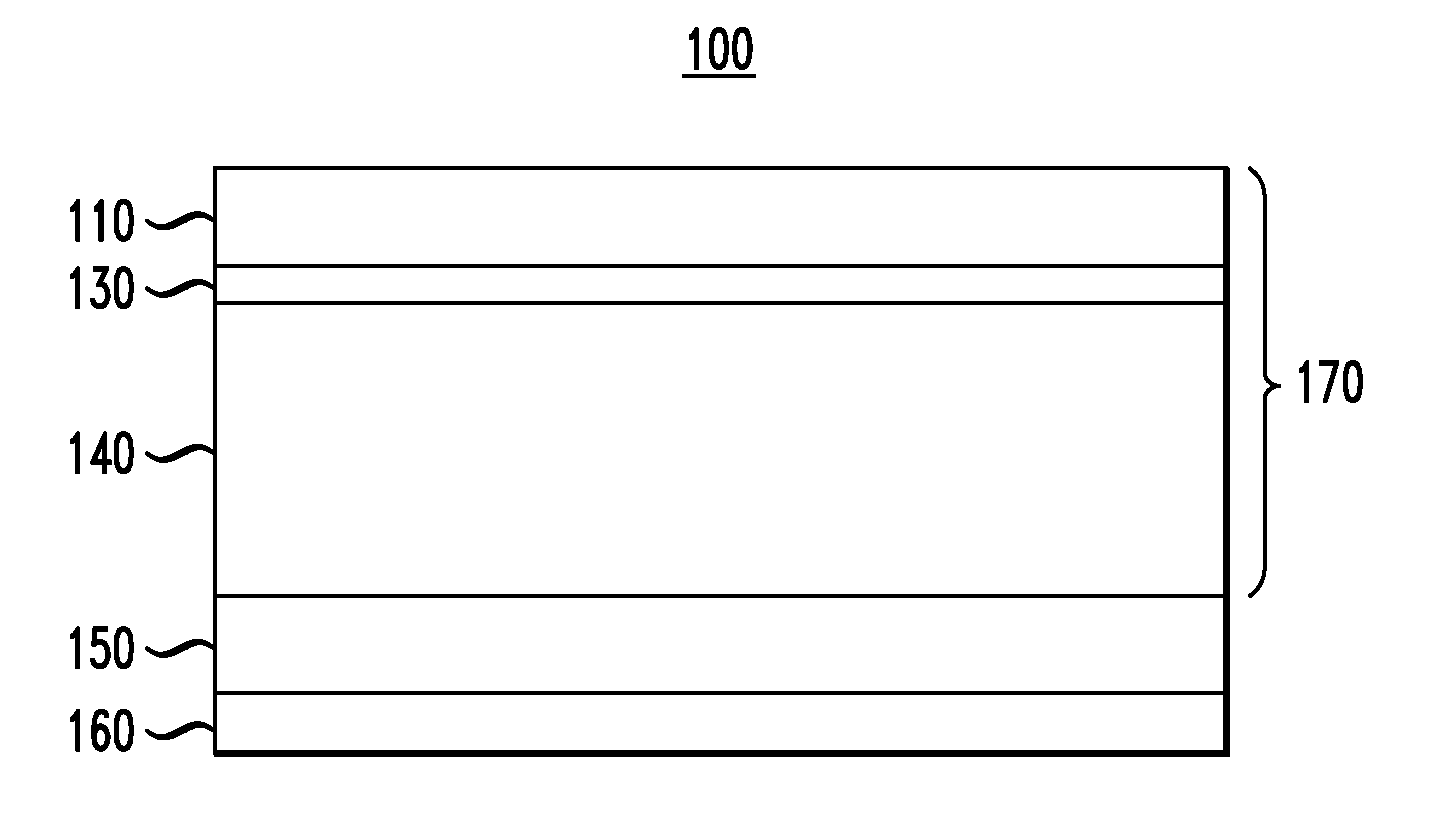

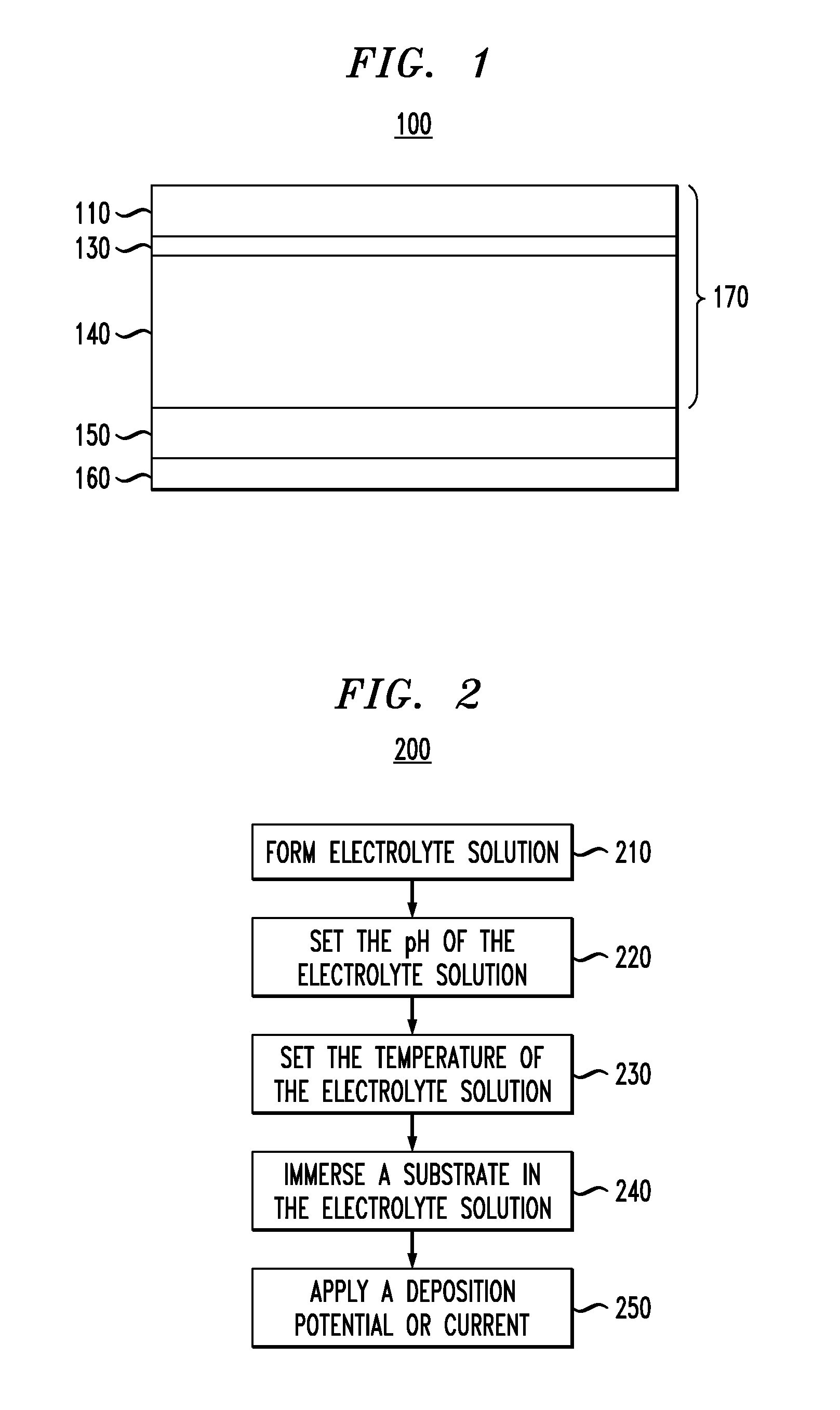

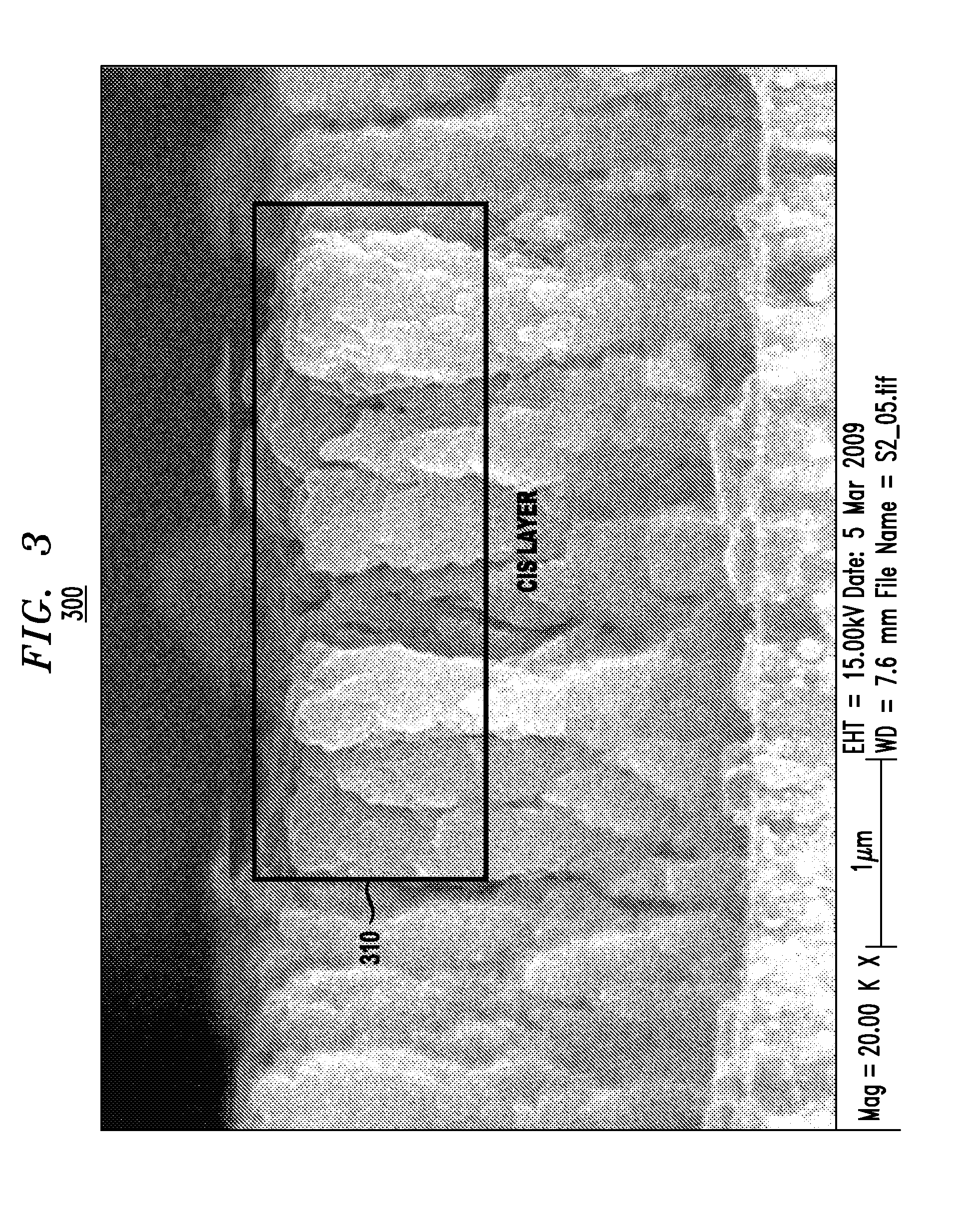

Forming a Photovoltaic Device

InactiveUS20110108115A1Increase the bandgapImproves light energy to electrical energy conversion efficiencySemiconductor/solid-state device manufacturingPhotovoltaic energy generationElectricityIndium

Methods for forming photovoltaic devices, methods for forming semiconductor compounds, photovoltaic device and chemical solutions are presented. For example, a method for forming a photovoltaic device comprising a semiconductor layer includes forming the semiconductor layer by electrodeposition from an electrolyte solution. The electrolyte solution includes copper, indium, gallium, selenous acid (H2SeO3) and water.

Owner:IBM CORP

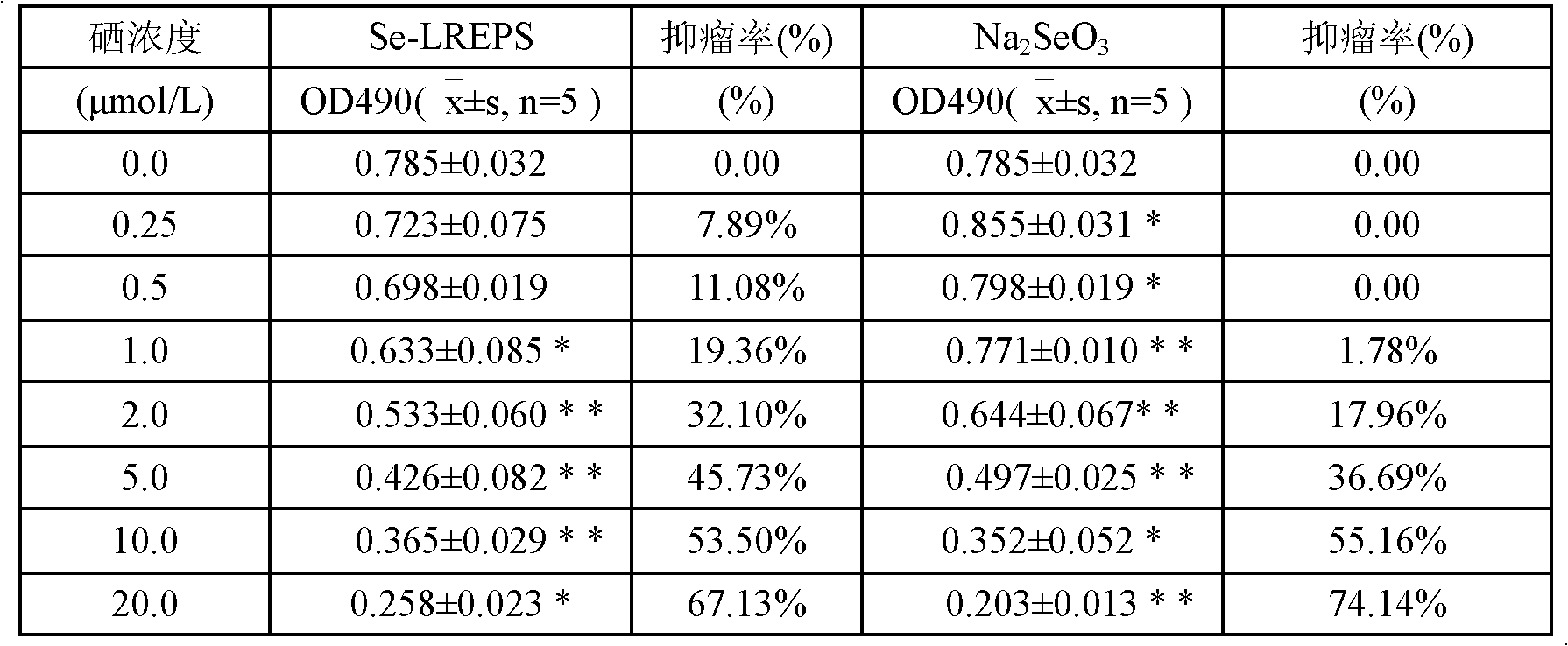

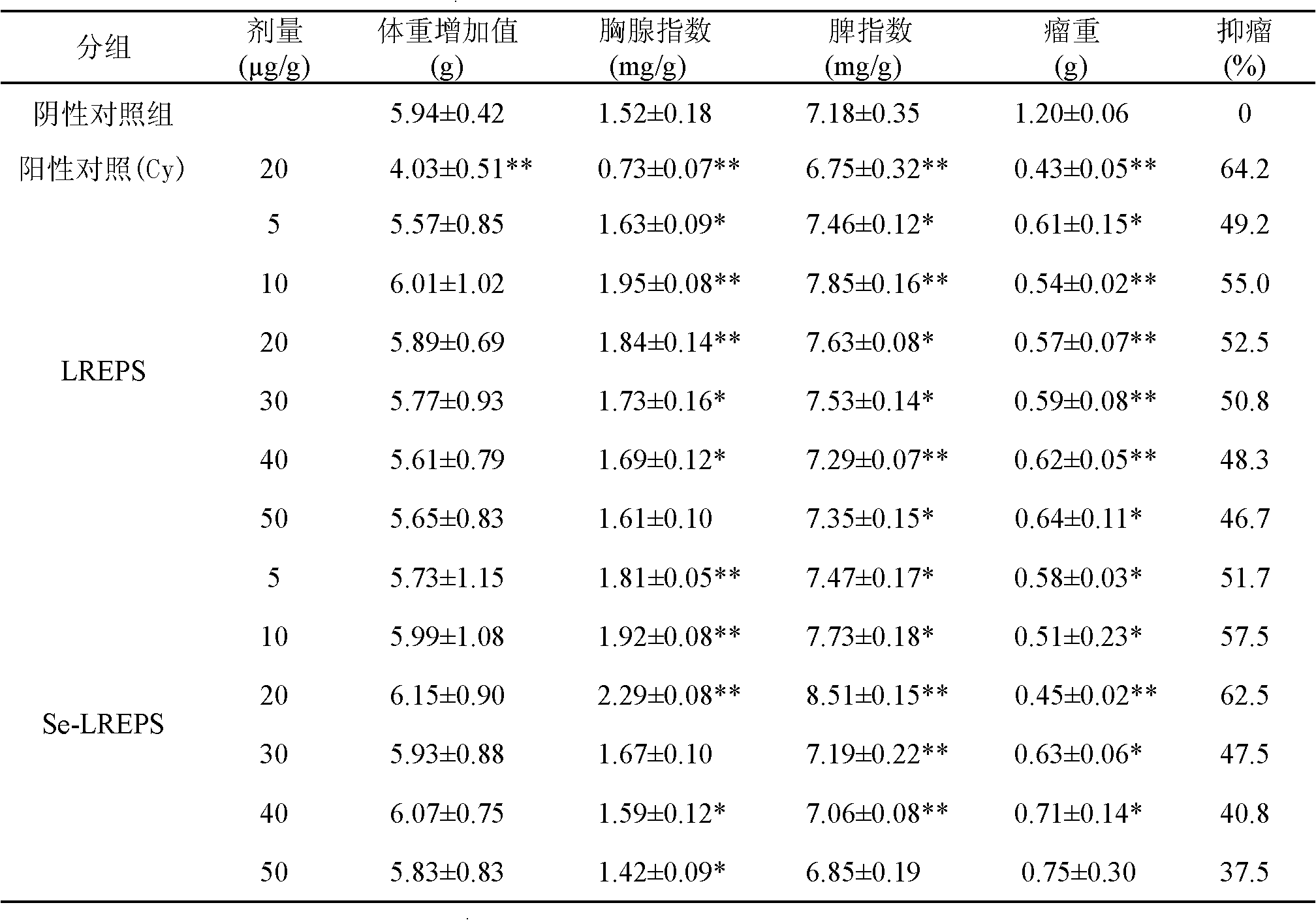

Preparation for polysaccharide selenite and application thereof

InactiveCN101104644AHigh yieldQuality improvementOrganic active ingredientsAntineoplastic agentsSulfateSugar

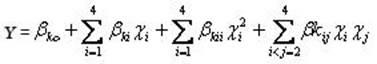

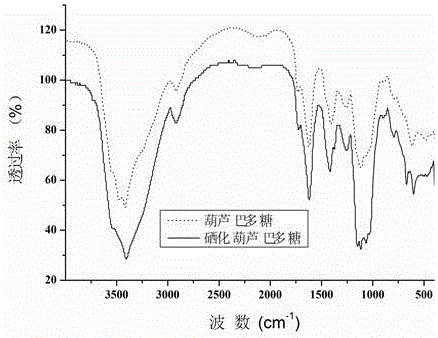

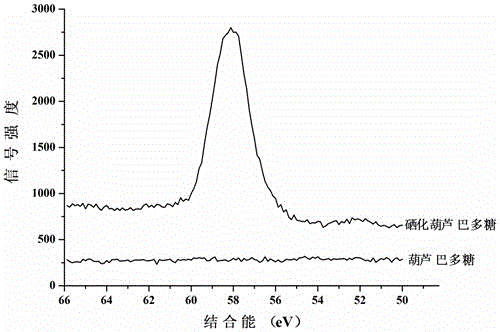

Disclosed are a preparation method and the applications of a polysaccharide selenous acid ester, belonging to the polysaccharide selenide technical field. The invention is characterized in that the polysaccharide selenous acid ester is made essentially by reaction between polysaccharide or carbohydrate complex and selenide reagent which is selenium Oxyhalide or the compound contains the selenium Oxyhalide. Feeding molar ratio of the selenide reagent and hydroxyl groups in the polysaccharide is 1:0.1-20. The invention also comprises the applications of the polysaccharide selenous acid ester in preparing anticancer drug and ant-oxidation drug. The polysaccharide selenous acid ester is produced by the reaction between the selenium reagent and the hydroxyl groups in sugar units, but not by selenite radicals substituting sulfate groups of the polysaccharide sulfate. The yield and the quality of the product are both higher than that of the products produced by other methods, and the selenium content is much higher than that of the products produced by the present technique.

Owner:陈艺新

Se-enriched plant growth regulator

A Se-enriched plant growth regulator is an aqueous product prepared from the sodium (potassium or ammonium) selenate (or selenite) and the sodium (potassium or ammonium) salt of 5-nitroguaiacol, 2,4-dinitrophenol, or catechol. Its advantages are high chemical and physical stability, and high effect on increasing the content of organoselenium in grains of crops and promoting photosynthesis.

Owner:天津市农业技术推广站

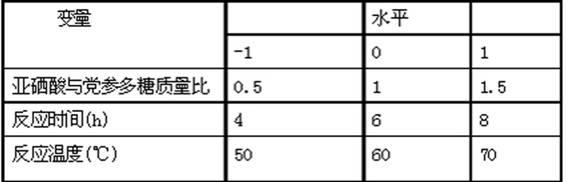

Method for selenizing pilose asiabell root polysaccharides and application of product

ActiveCN102532339AIncrease selenium contentImprove anti-tumor activityOrganic active ingredientsImmunological disordersBarium dichlorideCodonopsis pilosula

The invention provides a method for selenizing pilose asiabell root polysaccharides. The method comprises the following steps of: adding selenous acid into an aqueous solution of the pilose asiabell root polysaccharides with stirring, adding a catalyst, reacting at the temperature of between 50 and 70 DEG C for 4 to 8 hours, cooling, separating, and purifying to obtain a selenized pilose asiabell root polysaccharide product, wherein the catalyst is barium chloride. By the method, the content of selenium in the pilose asiabell root polysaccharides can be improved to 500-5,000mu g / g, the anti-tumor activity and immunity improving activity of the selenized pilose asiabell root polysaccharides are obviously improved compared with those of non-selenized pilose asiabell root polysaccharides, and the product can be used for preparing anti-tumor medicines or medicines or health care products for improving immunity.

Owner:LANZHOU UNIVERSITY

Polysaccharide sulfate selenide compound and its preparation method and application

InactiveCN101104643AHigh yieldQuality improvementOrganic active ingredientsAntineoplastic agentsFuranSulfate radicals

Disclosed are a selenium polysaccharide sulfate compound and a preparation method and applications of the selenium polysaccharide sulfate compound, belonging to the polysaccharide selenide technical field. The selenium polysaccharide sulfate compound is characterized in containing pyran sugar units or / and furan sugar units. The preparation method adopts reaction between polysaccharide sulfate and selenide reagent which is selenous acid and selenite. Molar ratio of the selenide reagent and groups of the polysaccharide sulfate is 1: 0.1-10. The compound of the invention is applied in preparing anticancer drug and ant-oxidation drug. The polysaccharide selenide sulfate of the invention is produced by substitution reaction between selenous acid and sugar unit sulfate radicals. Therefore, the yield and the quality of the product are both higher than that of the product produced by other methods. The invention also has advantage of high selenium content: the highest content of the selenium can reach to 45 percent which is much higher than 12.5 percent reported in literature.

Owner:陈艺新

Selenium-rich soybean sprouts and production method thereof

InactiveCN102939891AImprove disease resistanceImprove systemicizationCultivating equipmentsSoilless cultivationSelenateRoom temperature

The invention discloses selenium-rich soybean sprouts and a production method thereof and belongs to the technical field of production of selenium-rich agricultural products. The production method comprises the following particle steps of: inoculating rhodopseudomonas bacteria AYGHJ-16 in a culture medium to prepare a selenium-rich bacterial agent; diluting the selenium-rich bacterial agent into selenium-rich bacterial agent diluent of which the volume is 20 to 50 times the volume of the selenium-rich bacterial agent with water; after placing soybean seeds into the 50-times selenium-rich bacterial agent to carry out seed soaking for 24 to 48 hours, enabling the soybean seeds to sprout and grow at a room temperature of 20 to 25 DEG C; in the sprouting process, spraying the soybeans with the 20-times selenium-rich bacterial agent at time intervals of 4 hours, so that after sprouting and growing for 5 to 6 days, bud seedlings grow to 8 to 10cm; and after taking out the bud seedlings, flushing the bud seedlings clean with tap water so as to obtain the selenium-rich soybean sprouts. The selenium-rich soybean sprouts produced by the method has the selenium content of 1 to 1.5mg / L, does not contain inorganic selenate or selenite and can meet the requirement of people for long-term safety selenium supplement.

Owner:SHANGHAI BOCHEN BIOTECH

Liquid vitamic C compounded nanometer elementary selenium its preparation method and storage method

InactiveCN100998603AEliminate unwanted effectsExpand the scope of applicationOrganic active ingredientsMetabolism disorderPreservation methodsDosage form

A liquid-phase nano-Se containing VC used as a bioactive health-care product stored in liquid phase is prepared through dropping the solution of selenium oxide or selenite into VC solution while stirring until the red color is not changed. It can be used to prepare medicines.

Owner:BEIJING BOAI XIKANG NITRITION TECH

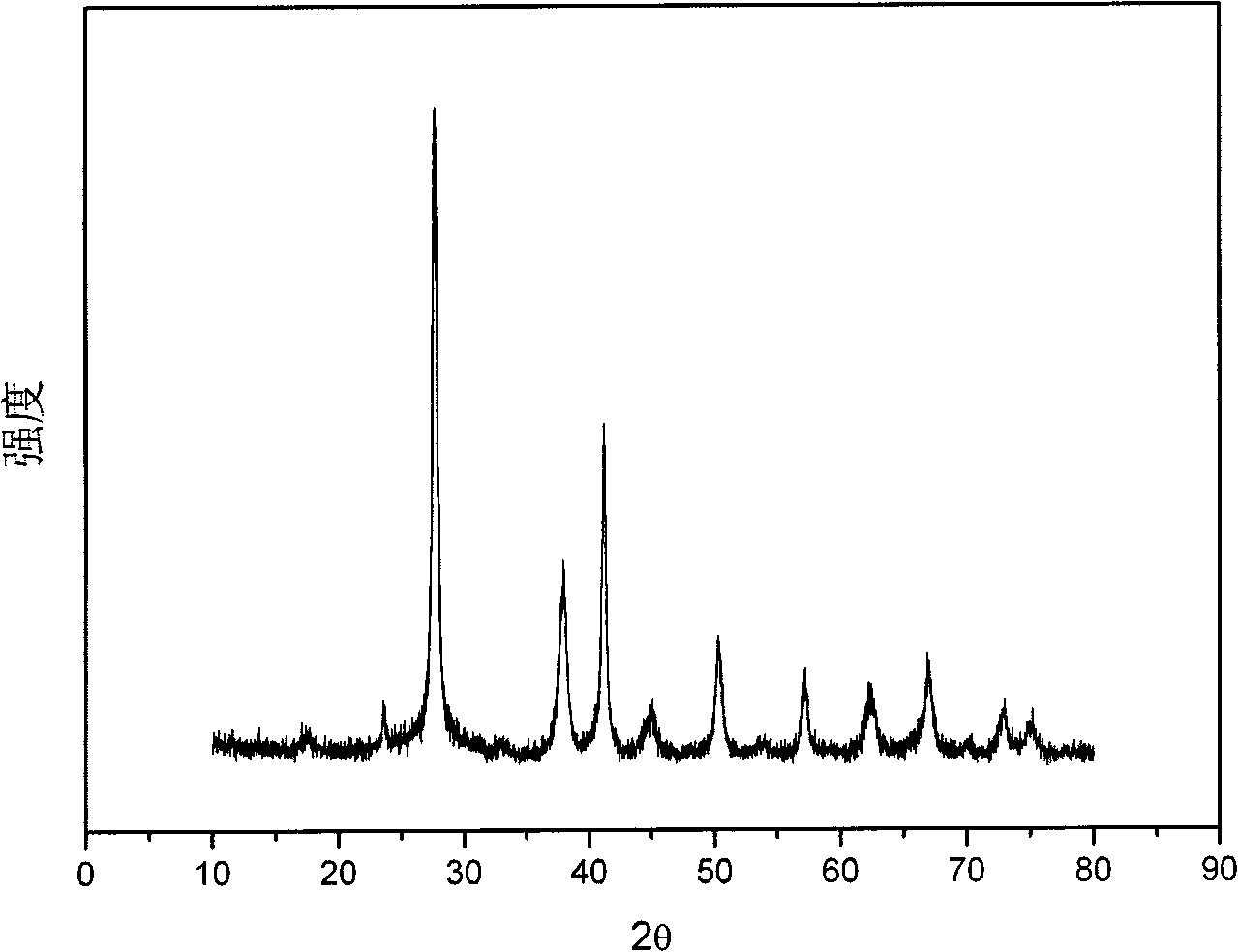

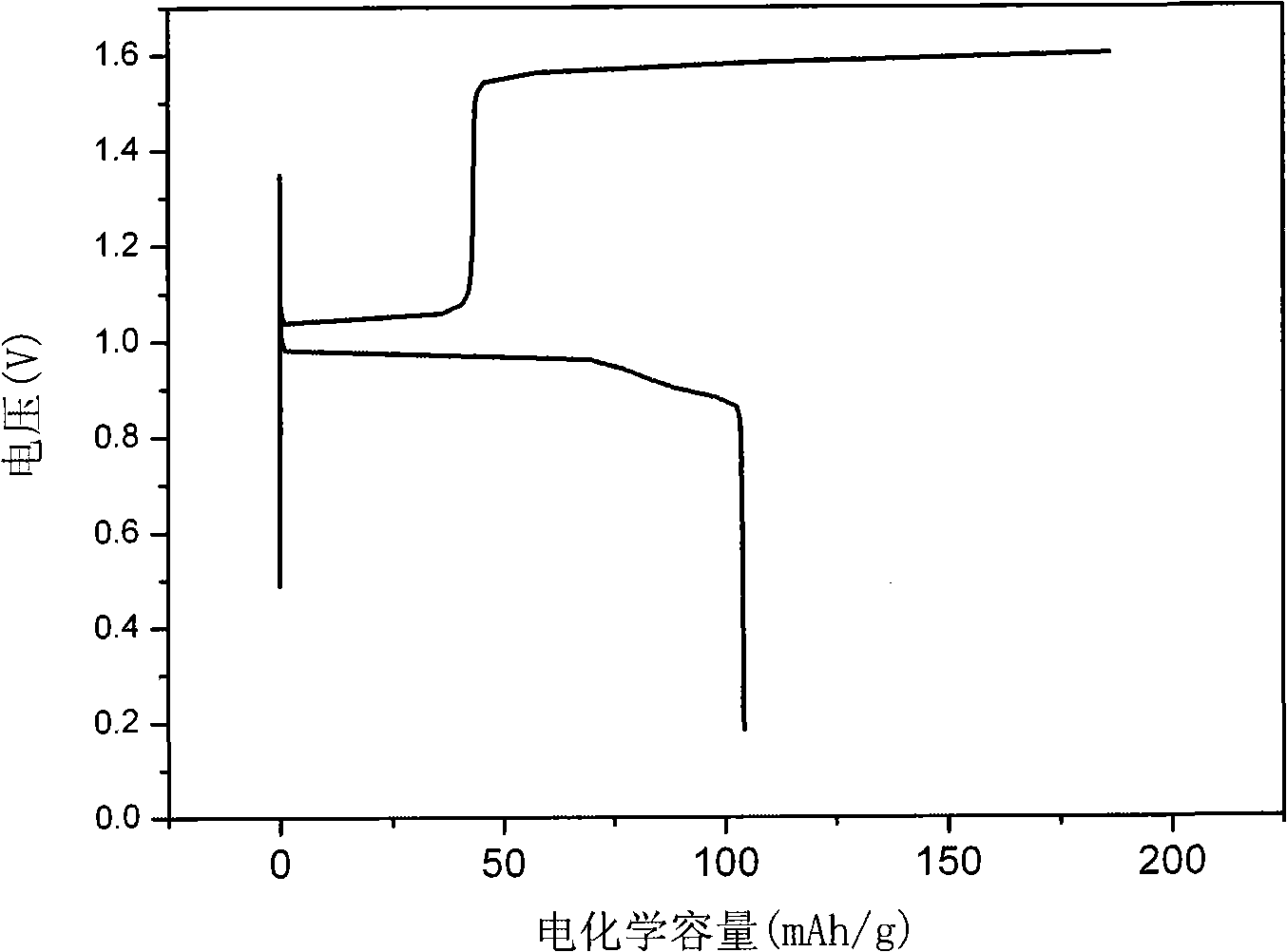

Bismuth base hydrogen storage material and preparation method thereof

ActiveCN101513994AUniform sizeSingle formCell electrodesBinary selenium/tellurium compoundsTe elementSolvent

The invention relates to a bismuth base (bismuth selenide, bismuth telluride) hydrogen storage material and a preparation method thereof, relating to low temperature liquid phase synthesis of bismuth base material and the application thereof on hydrogen storage, lithium storage and electrode material. The invention is characterized in that water is taken as solvent, bismuth salts such as bismuth nitrate, bismuth chloride and the like as a bismuth source, and water-soluble tellurium (selenium) acid salts (such as sodium tellurite, selenium substituted sodium sulfate, sodium selenite) or tellurium (selenium) acids (such as orthotelluric acid, tellurous acid and selenous acid) as a tellurium source (selenium) source; proper coordination agents (such as nitrilotriacetic acid, hexamethylene diamine tetraacethyl and the like) and reducing agents (such as vitamin C, sodium borohydride and the like) are added for liquid phase reaction synthesis at the low temperature of 60-80 DEG C. The bismuth selenide crystal grains prepared by the invention take on flower shapes with the sphere diameter of 1-6mum, and the bismuth telluride crystal grains take on sheet shapes with nanometer diameter; the hydrogen storage performance reaches over 100mAh.g. The method has the advantages of cheap raw material, simple technique, convenient operation, easy mass production, etc.

Owner:中国科学院上海硅酸盐研究所苏州研究院

Removal of dissolved selenium from aqueous solutions

ActiveUS20160289092A1Easy to disassembleQuantity minimizationOrganic anion exchangersIon-exchanger regenerationSelenateSulfate radicals

Processes for treating aqueous solutions to remove dissolved selenium species, for example in the presence of an excess of sulphate anions, which include the use of strongly basic anion exchange resins, or co-precipitation and adsorption of the selenate (and selenite) with mixed ferrous and ferric iron, or combinations thereof. Co-precipitation and adsorption of selenate may take place in an electrolytic cell in the presence of ferrous and / or ferric iron.

Owner:BIOTEQ ENVIRONMENTAL TECH

Method for treating selenium-containing wastewater

ActiveCN104556540ASolving Tolerance IssuesReduce the burden onWater treatment parameter controlWater contaminantsWastewaterSelenate ion

The invention discloses a method for treating selenium-containing wastewater. The method comprises the following steps: adjusting the pH of the selenium-containing wastewater to be 7-9, performing ozone oxidization in an ozone reactor, oxidizing selenious acid radical ions (SeO3<2->) into selenate radical ions (SeO4<2->), then performing aerobic biological treatment, putting the wastewater into a flocculating settling pool, adding a flocculating agent, stirring and performing solid-liquid separation to obtain wastewater subjected to selenium removal. The method disclosed by the invention is high in removal rate of selenium from the wastewater, wide in application range, easy and convenient to operate and particularly suitable for high-concentration selenium-containing wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

Controlled-release zinc magnesium selenium phytate fertilizer and preparation method thereof

InactiveCN101805236AMeet the needs of multiple absorptionMeet the needs of intake of trace elementsFertiliser formsFertilizer mixturesReaction temperaturePhytic acid

The invention discloses a controlled-release zinc magnesium selenium phytate fertilizer and a preparation method thereof. The fertilizer is prepared by the method which comprises the following steps: firstly, dissolving a phytic acid and a selenious acid in water to prepare aqueous solution and heating the aqueous solution; secondly, orderly adding zinc oxide and magnesium oxide into the prepared aqueous solution with stirring to perform reaction at the temperature of 40 to 85 DEG C for 2 to 5 hours; thirdly, mixing and uniformly stirring magnesium potassium chloride and calcium superphosphate to obtain a mixture, adding the product prepared in the former step into the mixture and uniformly stirring the mixture; and finally, granulating, drying and coating the obtained product to obtain finished products. The fertilizer can be simultaneously applied together with a basal fertilizer, meets the multiple-absorption requirements of crops, decreases labor intensity, and fulfills the aim of maximally storing the trace elements in fruits of the crops and meets the requirements of human bodies or animal bodies on the intake of trace elements because the trace elements in the fertilizer can be released after the fertilizer is applied for a certain time.

Owner:蔡瑞琳 +1

Method for Radix Platycodonis polysaccharide regulated preparation of nutritional liquid fertilizer containing nano-selenium

InactiveCN106977272AEfficient use ofAvoid reunionMagnesium fertilisersNitrogenous fertilisersSilicon dioxideHydrolysis

The invention discloses a method for the Radix Platycodonis polysaccharide regulated preparation of a nutritional liquid fertilizer containing nano-selenium. The method comprises the following steps: preparing a nano-selenium solution from Radix Platycodonis polysaccharides and seleninic acid by using an ascorbic acid reduction technology; preparing a soybean meal composite amino acid stock solution from soybean meal by using a sulfuric acid hydrolysis technology, adsorbing and decolorizing the stock solution by active carbon modified through 0.25% KOH solution treatment, filtering the stock solution, sterilizing the obtained filtrate by cobalt60 to prepare a soybean meal composite amino acid solution; and uniformly mixing magnesium sulfate, zinc sulfate, manganese sulfate, ferrous sulfate, borax, copper sulfate, sodium molybdate, silica, Arabic gum and water with the nano-selenium solution and the soybean meal composite amino acid solution to prepare the nutritional liquid fertilizer containing nano-selenium. The soybean seed composite amino acid solution and trace elements are compounded to make the trace elements exist in a chelated state, so the utilization rate of the trace elements is increased, the absorption of the plants to macro-elements is promoted, the crop yield is increased, and the crop quality is improved.

Owner:GUANGZHOU JUCHAN MODERN AGRI RES INST CO LTD

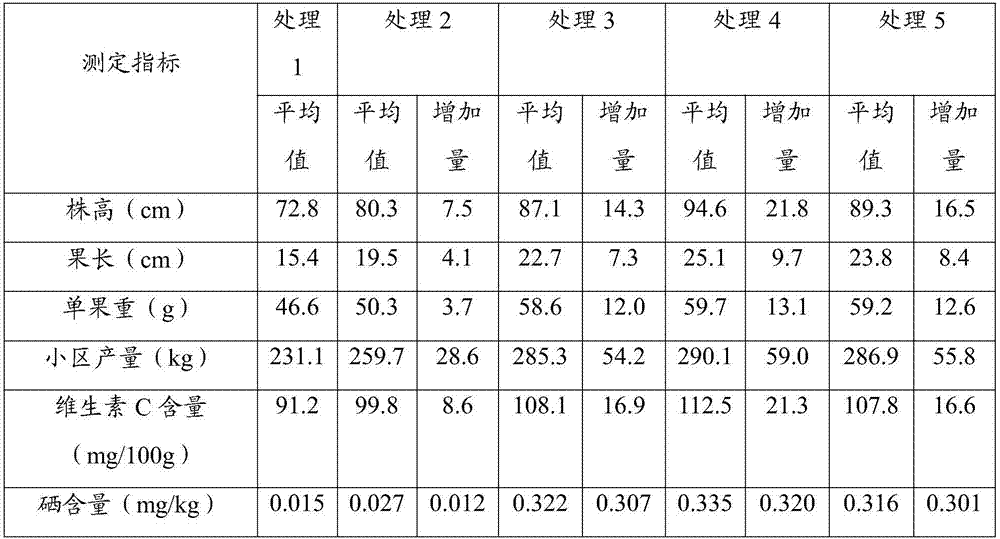

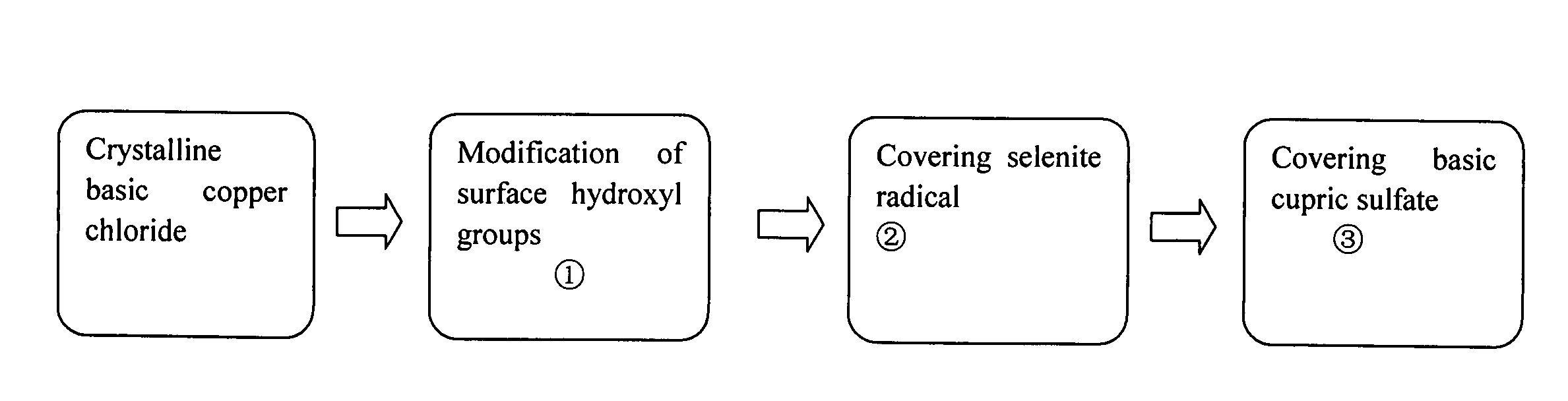

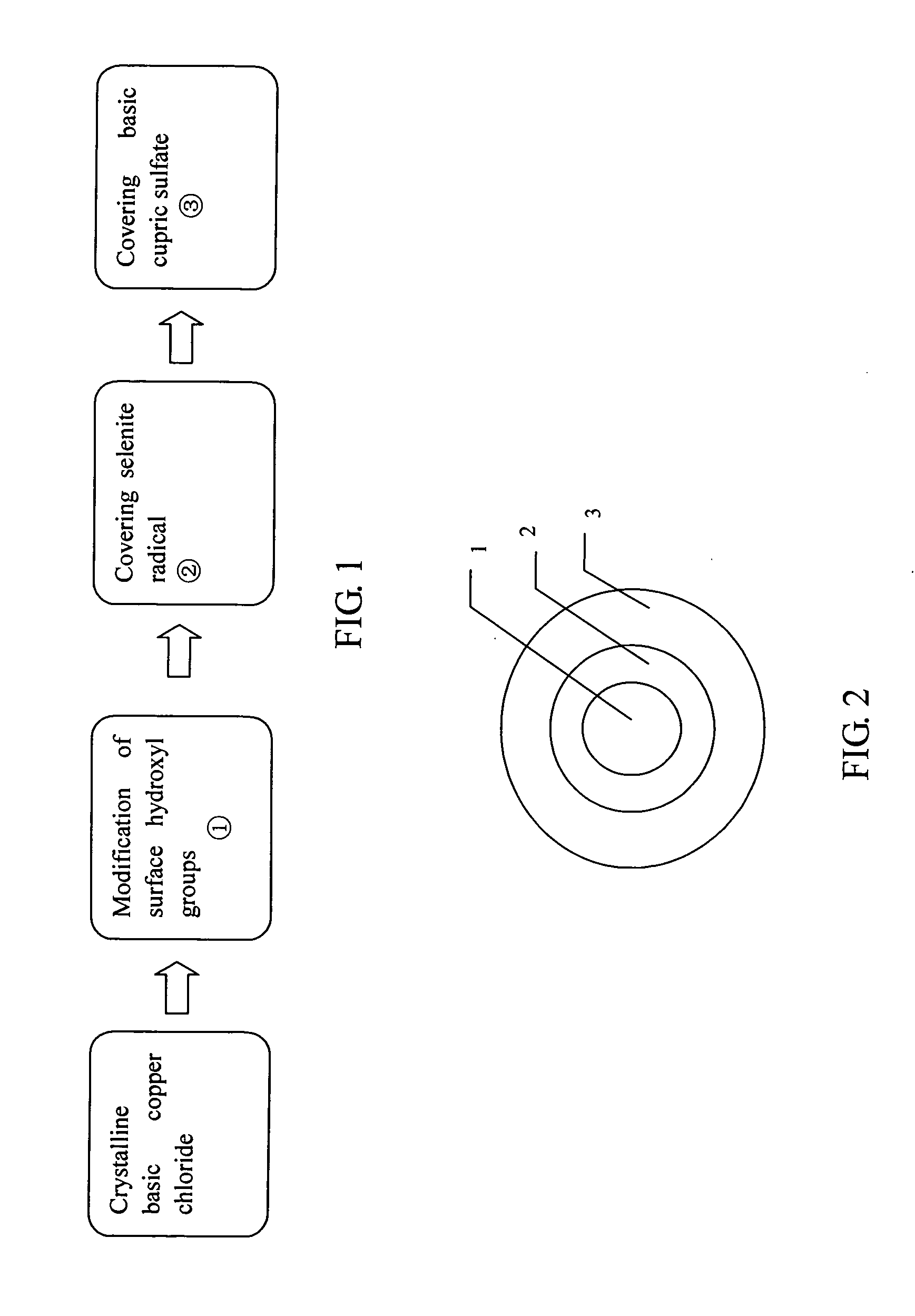

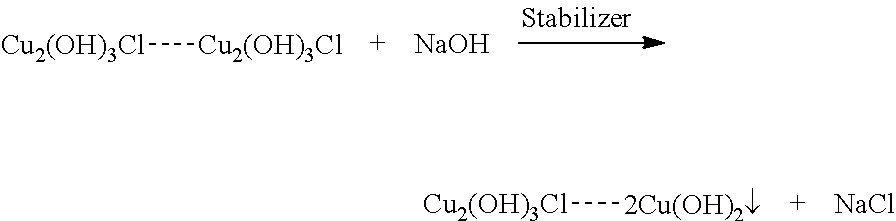

Selenium covered basic copper chloride, its preparation method and the use

ActiveUS20110223298A1Easy to mergeLow priceAlcoholic beverage preparationFood ingredientsSolubilityFiltration

A preparation method for selenium covered basic copper chloride includes the steps of: (a) adding crystalline basic copper chloride (TBCC), water and stabilizer in a reactor; adding sodium hydroxide solution with stirring; reacting to form a hydroxyl-modified crystalline basic copper chloride after discharge, washing, and negative pressure leaching; (b) adding the hydroxyl-modified crystalline basic copper chloride and water in the reactor, adding selenous acid with stirring; adding copper sulfate pentahydrate after reaction; forming selenium covered basic copper chloride comprising crystalline basic copper chloride, basic cuprous selenide, and basic cupric sulfate after discharge, rinsing, negative pressure filtration, and drying. The selenium covered basic copper chloride is used as feed addictives of trace elements having nonhygroscopic property, good liquidity, and stable chemical property. The selenium covered basic copper chloride is easy to incorporate with feed, low price, low cost in adding, weak acidic solubility, easy to absorb.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD

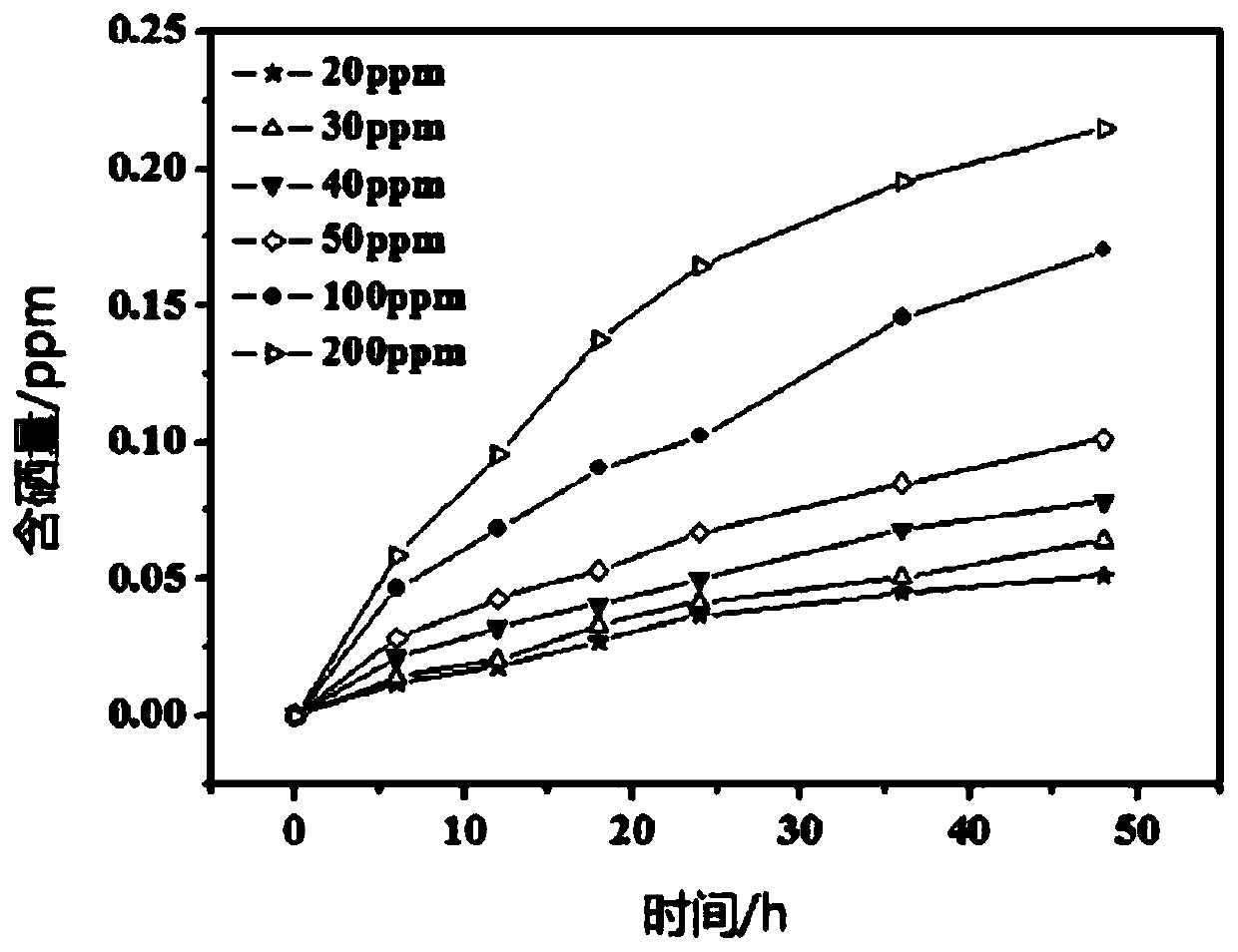

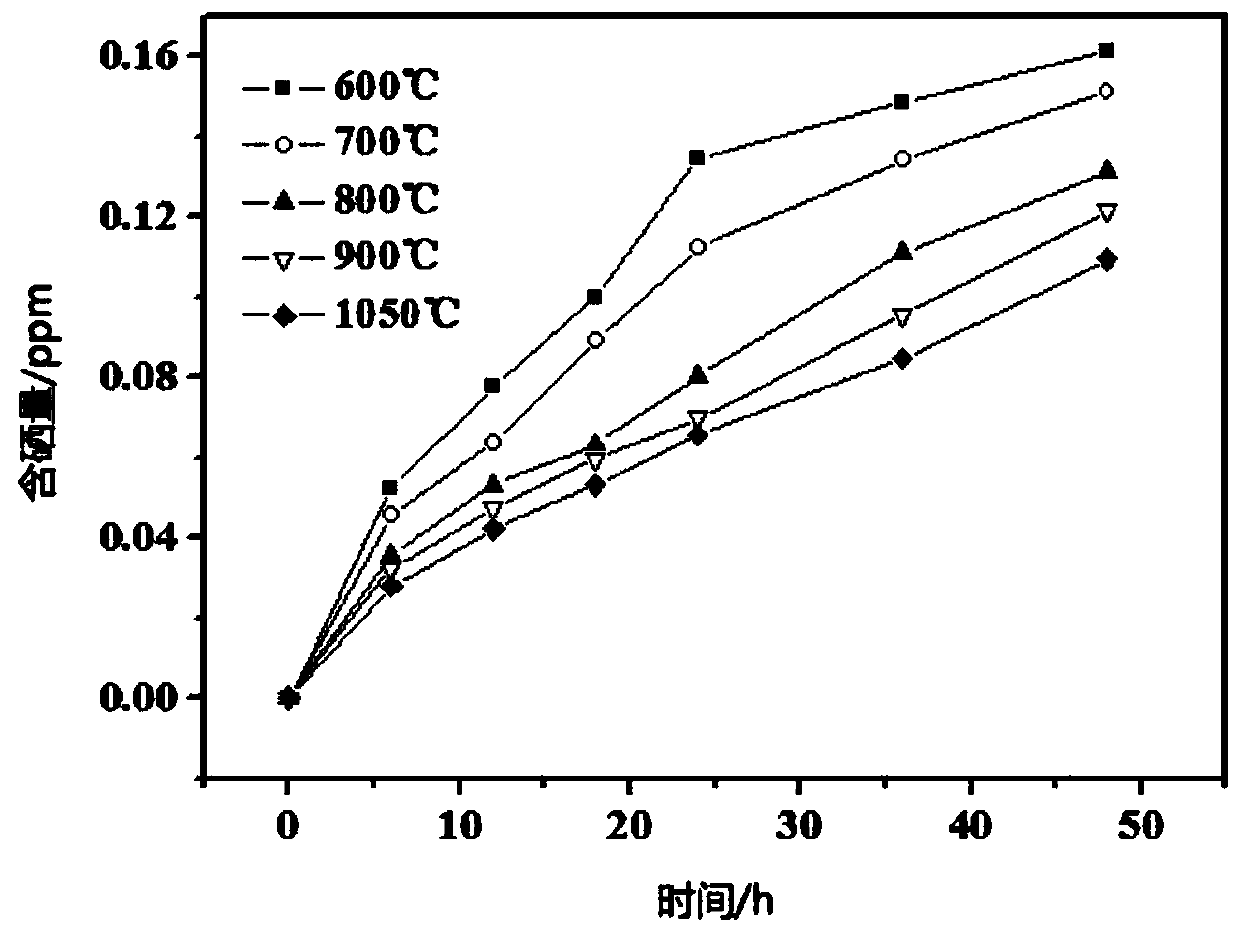

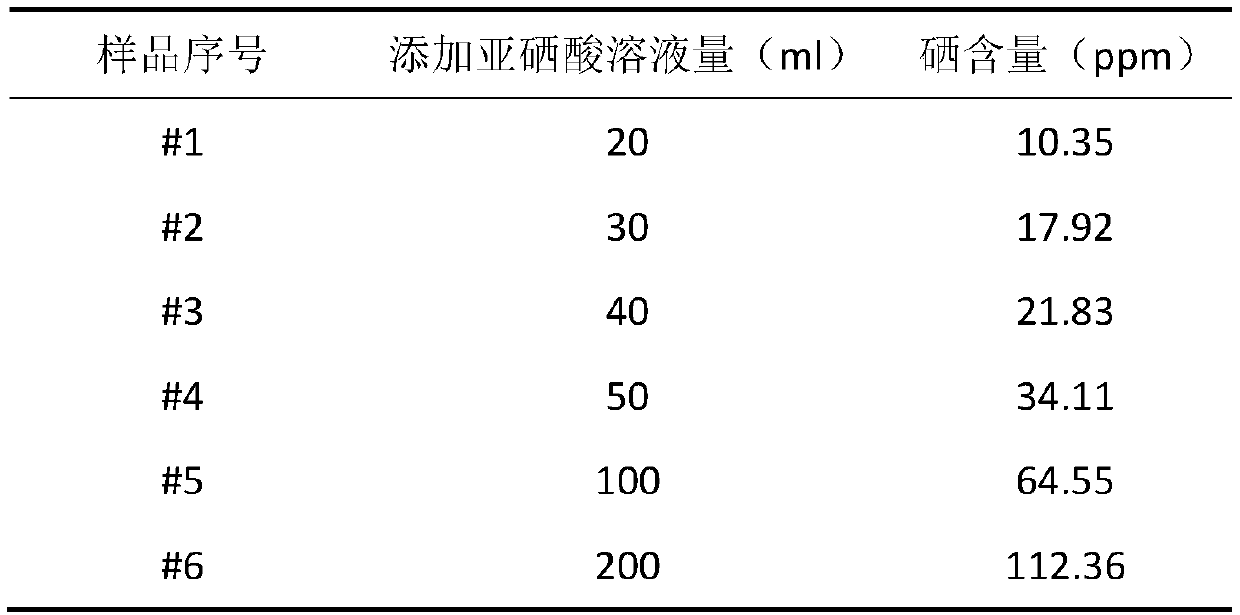

Selenium-rich ceramic material and preparation method thereof

PendingCN110483012ASimple processLow costPreparing sample for investigationFluorescence/phosphorescenceDissolutionSelenous acid

The invention belongs to the technical field of ceramic materials, and particularly discloses a selenium-rich ceramic material and a preparation method thereof. The preparation method comprises the following steps: 1) preparing a soluble selenous acid or selenite solution; 2) adding the soluble selenous acid or selenite into ground and crushed pottery clay dry powder to prepare a selenium-enrichedpottery clay powder material; 3) preparing a selenium-rich pottery clay green body from the selenium-rich pottery clay powder through a pottery making process; 4) sintering the selenium-rich potteryclay green body to prepare a selenium-rich ceramic material; and 5) detecting the selenium content and the selenium element dissolution amount of the prepared selenium-rich ceramic material. The selenium content of the selenium-rich ceramic material prepared by the method is 10.0-110.0 mg / kg, the selenium element can be automatically dissolved out when the selenium-rich ceramic material is soakedin water or food when in use, and the dissolution amount can meet the daily requirements of human bodies and does not exceed the normal intake.

Owner:NORTHWEST UNIV +1

Synthesis and application of selenized fenugreek polysaccharides

ActiveCN105713104AEasy to makeNo emissionsOrganic active ingredientsDigestive systemHigh activityHepatic Cancers

The invention discloses a method for synthesizing selenized fenugreek polysaccharides. The method comprises the following steps: preparing a fenugreek polysaccharide formamide solution; preparing an ionic liquid; activating selenous acid by using the ionic liquid; and synthesizing the selenized fenugreek polysaccharides. The ionic liquid is utilized to activate the selenous acid to prepare the high-activity selenization reagent, and the bioactive selenized fenugreek polysaccharides are efficiently synthesized under mild conditions. The selenium content is up to 27554-29773 mu g / g. The reagent is friendly to the environment and simple to prepare, does not need any toxic seleniferous intermediate, and does not have the waste liquid discharge, thereby effectively shortening the reaction required lime, and widening the application range of the fenugreek polysaccharides as natural active substances. The activity test indicates that the synthesized selenized fenugreek polysaccharides have obvious in-vitro inhibiting actions on HepG2 liver cancer cells.

Owner:NORTHWEST NORMAL UNIVERSITY

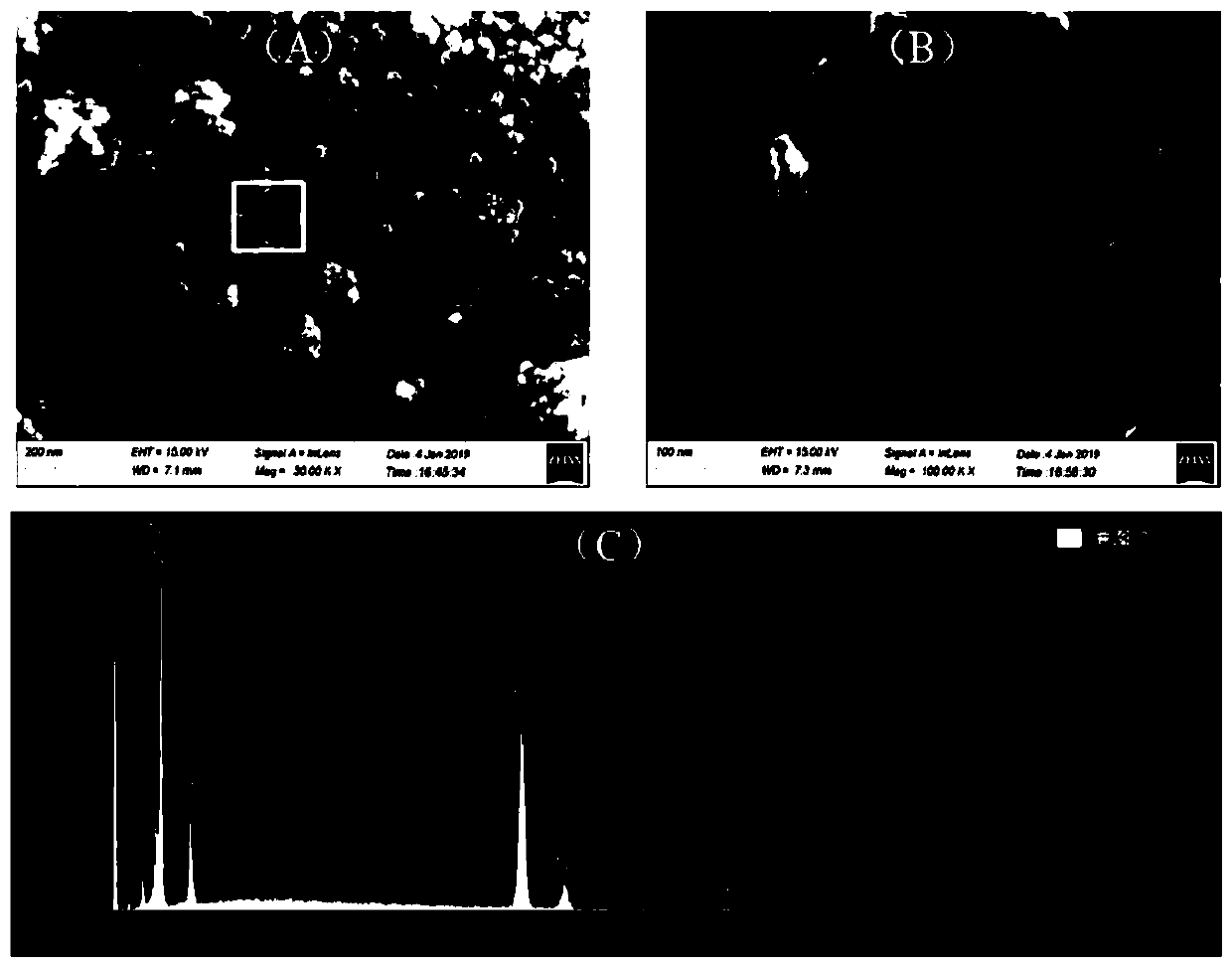

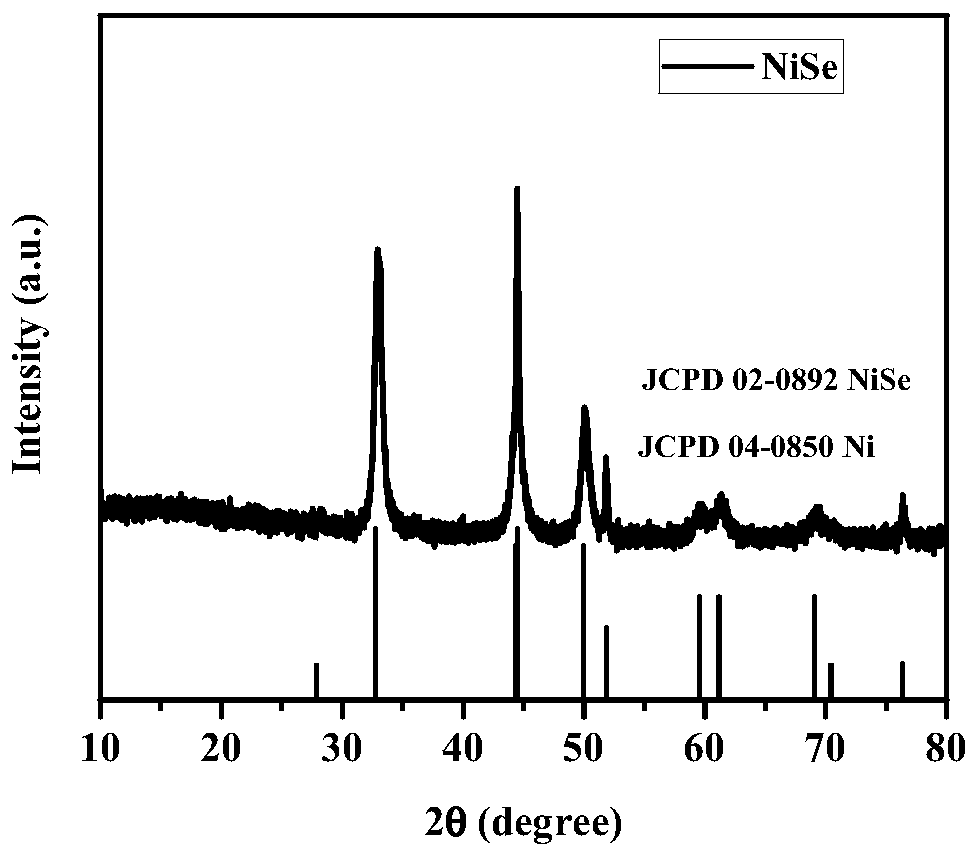

Metal selenium compound negative electrode material for lithium/sodium ion batteries, preparation method and application

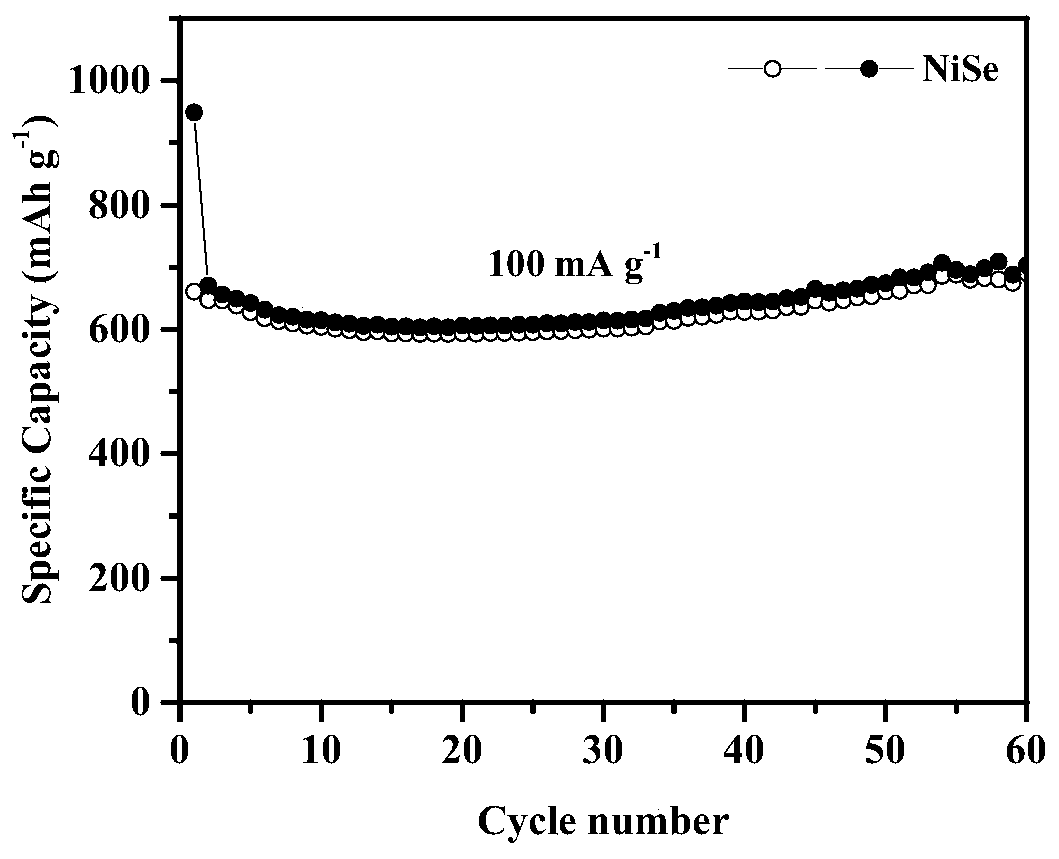

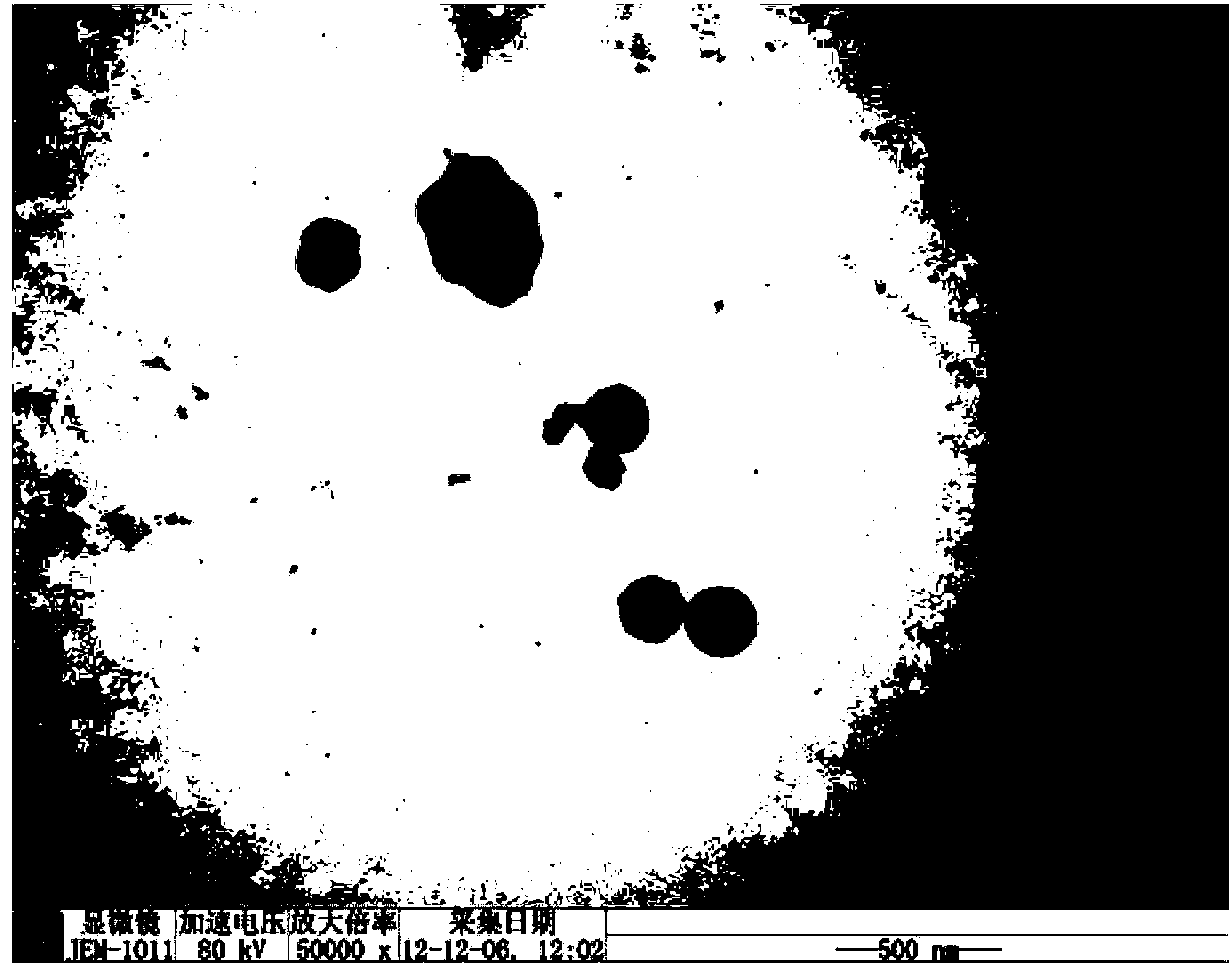

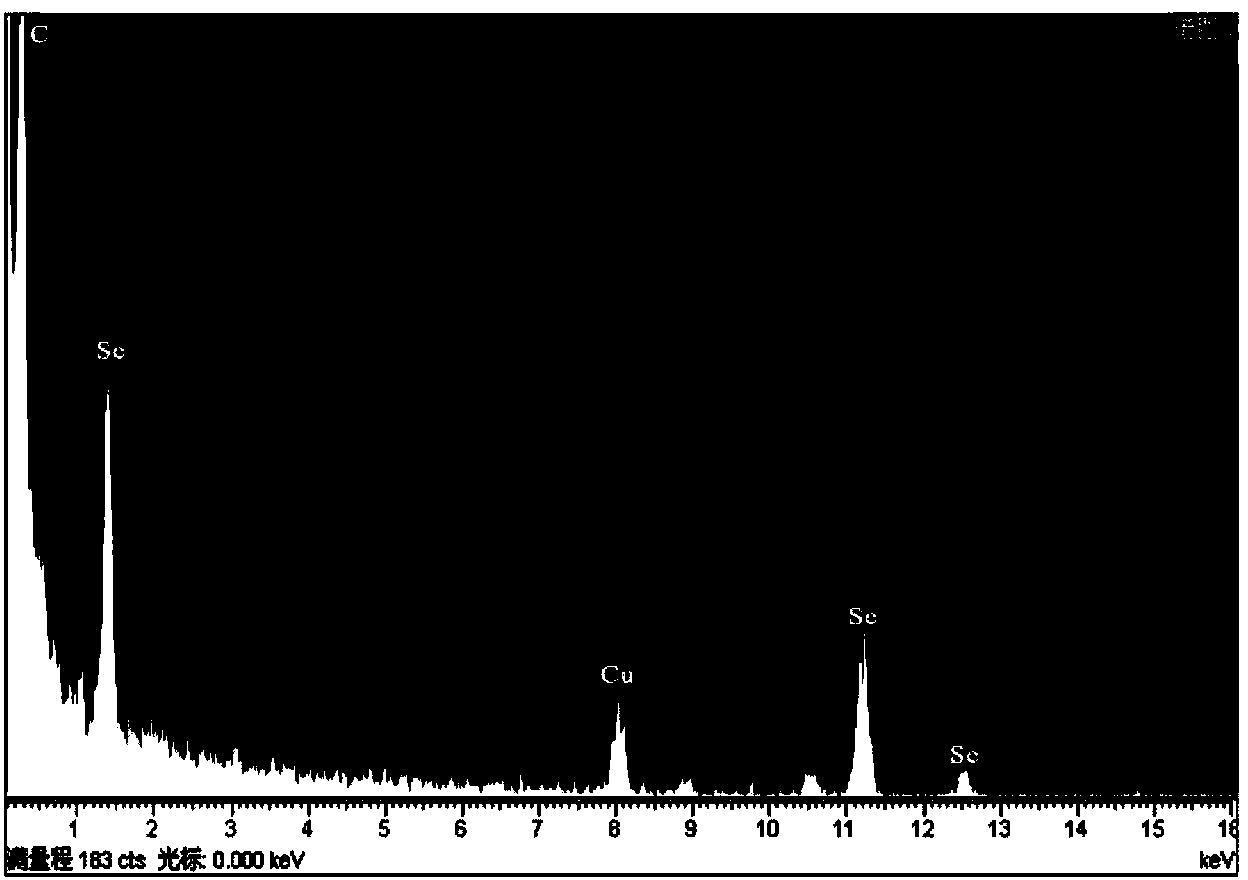

ActiveCN110902658AImprove cycle performanceExcellent rate performanceSecondary cellsNegative electrodesSelenium CompoundPhysical chemistry

The invention provides a preparation method of a metal selenium compound negative electrode material for lithium / sodium ion batteries. The method is characterized by including the steps of: S1, carrying out ultrasonic treatment on a foam metal in an acid solution, and performing acidification treatment; and S2, impregnating the foam metal subjected to acidification treatment in a mixed solution ofselenite and a reducing agent for ultrasonic treatment, and then carrying out high-temperature hydrothermal reaction to obtain the metal selenium compound negative electrode material for lithium / sodium ion batteries. The lithium / sodium ion batteries prepared from the negative electrode material have excellent cycle performance and rate capability.

Owner:XIAMEN UNIV OF TECH

Method for preparation of red elemental selenium by photosynthetic bacteria

InactiveCN103361380AFast growth and reproductionShorten the production cycleMicroorganism based processesFermentationBiologyPhotosynthetic bacteria

The invention discloses a method for preparation of red elemental selenium by photosynthetic bacteria, and particularly provides a method for reducing Se4<+> to red elemental selenium by photosynthetic bacteria under anaerobic light conditions. The steps include: directly inoculating well activated free photosynthetic bacteria or immobilized photosynthetic bacteria into a photosynthetic bacteria culture medium containing selenite, conducting culture under certain temperature and lighting anaerobic conditions, and then carrying out separation, washing and drying, thus obtaining the red elemental selenium. The red elemental selenium synthesized by photosynthetic bacteria under anaerobic light conditions in the invention has the characteristics of small particle size, uniform distribution, good dispersibility, and high purity. The process for production of red elemental selenium by the bacteria has the advantages of safety, reliability, no pollution, easily controllable reaction conditions, and low production cost, thus being suitable for large scale production.

Owner:SHANXI UNIV

Metabolic screening p-hydroxyl phenylalanine urine detection reagent

InactiveCN107490689ARaw materials are easy to getSave raw materialsDisease diagnosisTreatment effectPhenylalanine

The present invention relates to a metabolic screening p-hydroxyl phenylalanine urine detection reagent, which is formed by mixing a 0.1-0.15 g / ml mercury sulfate aqueous solution, a 0.5-1 g / ml mercury nitrate aqueous solution, a 0.1-0.2 g / ml nickel nitrate aqueous solution and a 1-2 g / ml selenous acid aqueous solution according to a volume ratio of 1:0.6-1.2:0.8-1.5:0.5-1.0. According to the present invention, the detection reagent has characteristics of strong universality, high sensitivity, good specificity and the like in tumor detection, further has advantages of simple detection process, short detection time and easy result judgment, and is particularly suitable for the large-scale population census and the tumor clinical auxiliary diagnosis and treatment effect dynamic examination.

Owner:格朗生物技术(上海)有限公司

Normal-temperature blackening liquid for steel and iron and application thereof

InactiveCN106811742AReasonable formulaHigh film forming efficiencyMetallic material coating processesPhosphatePhosphoric acid

The invention relates to the technical field of surface treatment of metal materials, in particular to normal-temperature blackening liquid for steel and iron and application thereof. Specifically, the normal-temperature blackening liquid for steel and iron comprises selenous acid, copper sulfate, nickel sulfate, zinc dihydrogen phosphate, phosphoric acid, citric acid, octylphenol polyoxyethylene ether-10 and water; and each 1 L of the normal-temperature blackening liquid contains 1-6 g of selenous acid, 1-10 g of copper sulfate, 1-2 g of nickel sulfate, 1-5 g of zinc dihydrogen phosphate, 1-10 mL of phosphoric acid, 1-5 g of citric acid, 1-4 mL of octylphenol polyoxyethylene ether-10 and the balance of water. The normal-temperature blackening liquid is reasonable in formula and high in film forming efficiency, improves such performances as glossiness, binding force and compactness of blackening films, and solves the problem of weak stability; the application method is convenient and feasible, and is suitable for large-scale popularization; and through adding of additives, the use level of selenium element in the blackening liquid is reduced, and the pollution is reduced.

Owner:JIANGSU UNIV OF TECH

Method for preparing polysaccharide selenite and application thereof

InactiveCN105622770AHigh yieldQuality improvementOrganic active ingredientsAntinoxious agentsSulfateCarbohydrate complex

The invention belongs to a method for preparing polysaccharide selenite and an application thereof, which belong to the technical field of polysaccharide selenide. The invention is characterized in that the polysaccharide selenous acid ester is made essentially by a reaction of polysaccharide or a carbohydrate complex and a selenide reagent; the selenide reagent is selenium oxyhalide or the compound containing the selenium oxyhalide. A feeding molar ratio of the selenide reagent and hydroxyl groups in the polysaccharide is 1:0.1-20. The invention also comprises the applications of the polysaccharide selenous acid ester in preparation of anticancer drugs and ant-oxidation drugs. The polysaccharide selenous acid ester is produced by the reaction of the selenium reagent and the hydroxyl groups in sugar units, but not by selenite radicals substituting sulfate groups of the polysaccharide sulfate; the yield and the quality of the product are both higher than that of the products produced by other methods, and the selenium content is much higher than that of the products produced by the present technique.

Owner:CHONGQING GUANTAI TECH CO LTD

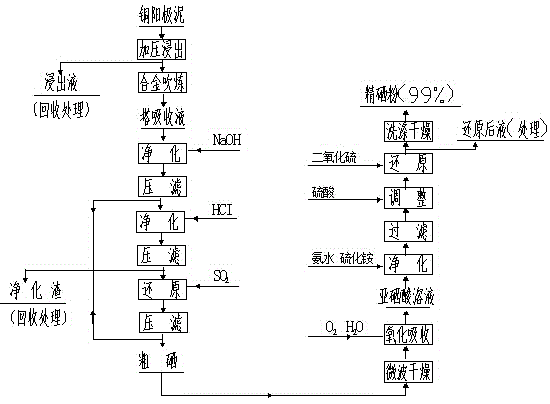

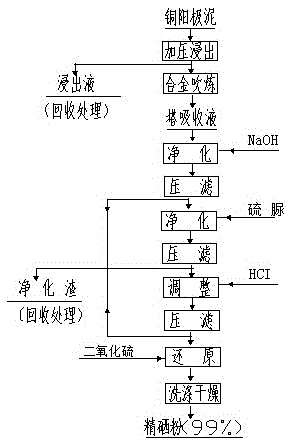

Wet process refining technology for purifying selenium

ActiveCN105600758AHigh purityReduce consumptionChemical industryElemental selenium/telluriumThioureaAlloy

The invention discloses a wet process refining technology for purifying selenium. The wet process refining technology for purifying selenium mainly comprises the steps that firstly, NaOH is added into alloy blowing tower absorption liquid to remove part of base metal, and activated carbon is used for adsorption, filtering and purification; secondly, thiourea and HCI are sequentially used for deep impurity reduction, and a pure selenous acid solution is obtained through filtering; thirdly, sulfur dioxide is used for reduction, and fine selenium powder with high purity is obtained. As a single wet process refining technology, compared with a traditional technology, the wet process refining technology for purifying selenium has the advantages of being short in process, easy to implement, low in labor intensity, small in energy consumption, low in production cost, short in production cycle, good in operation environment, free of generation of middle overstock materials and the like; the tower absorption liquid obtained through alloy blowing absorption is subjected to three times of purification, impurity removing and filtering, and the fine selenium powder with the grade up to 99.1% can be obtained as long as sulfur dioxide is introduced for reduction, the direct yield is increased to 83.5% from original 79.8%, the production cycle is shortened to 3 d from original 7 d, the processing cost can be reduced to 13 yuan / kg, and good popularization value and economic benefits are achieved.

Owner:JINCHUAN GROUP LIMITED

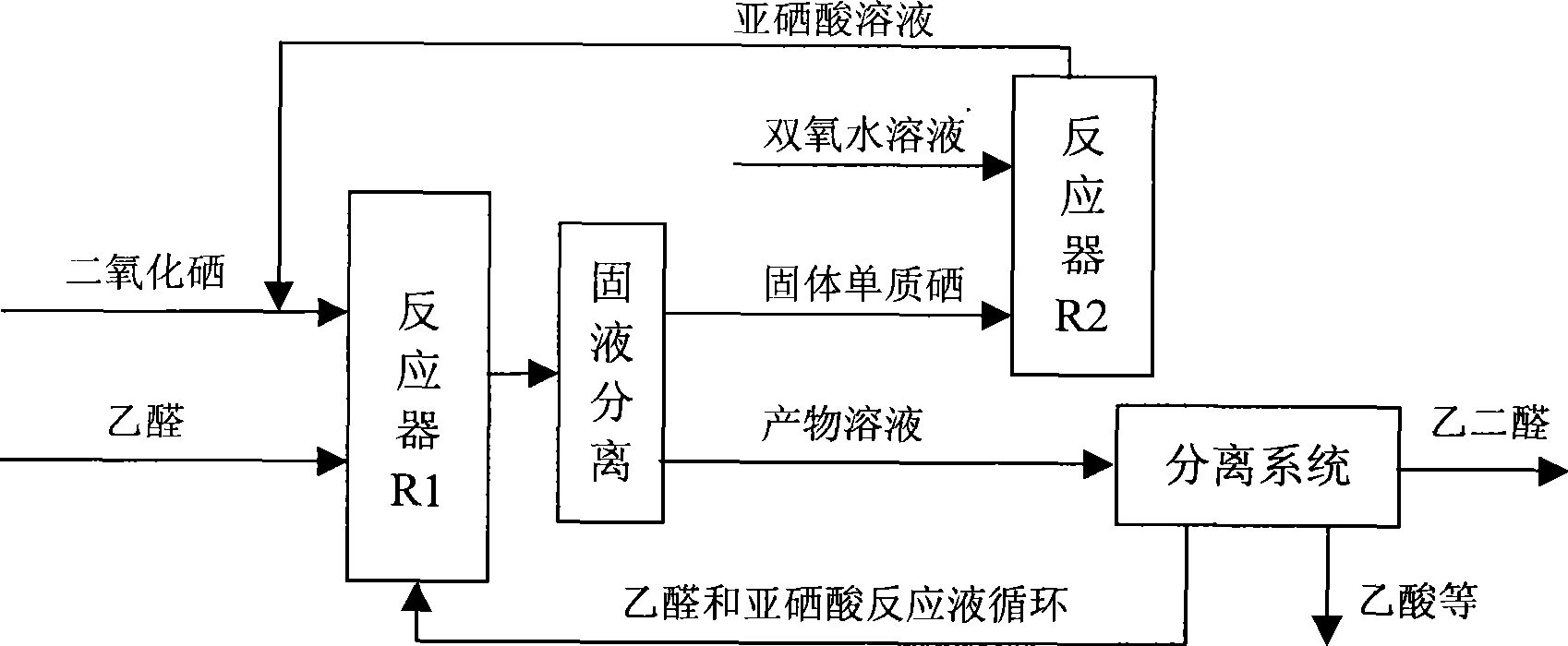

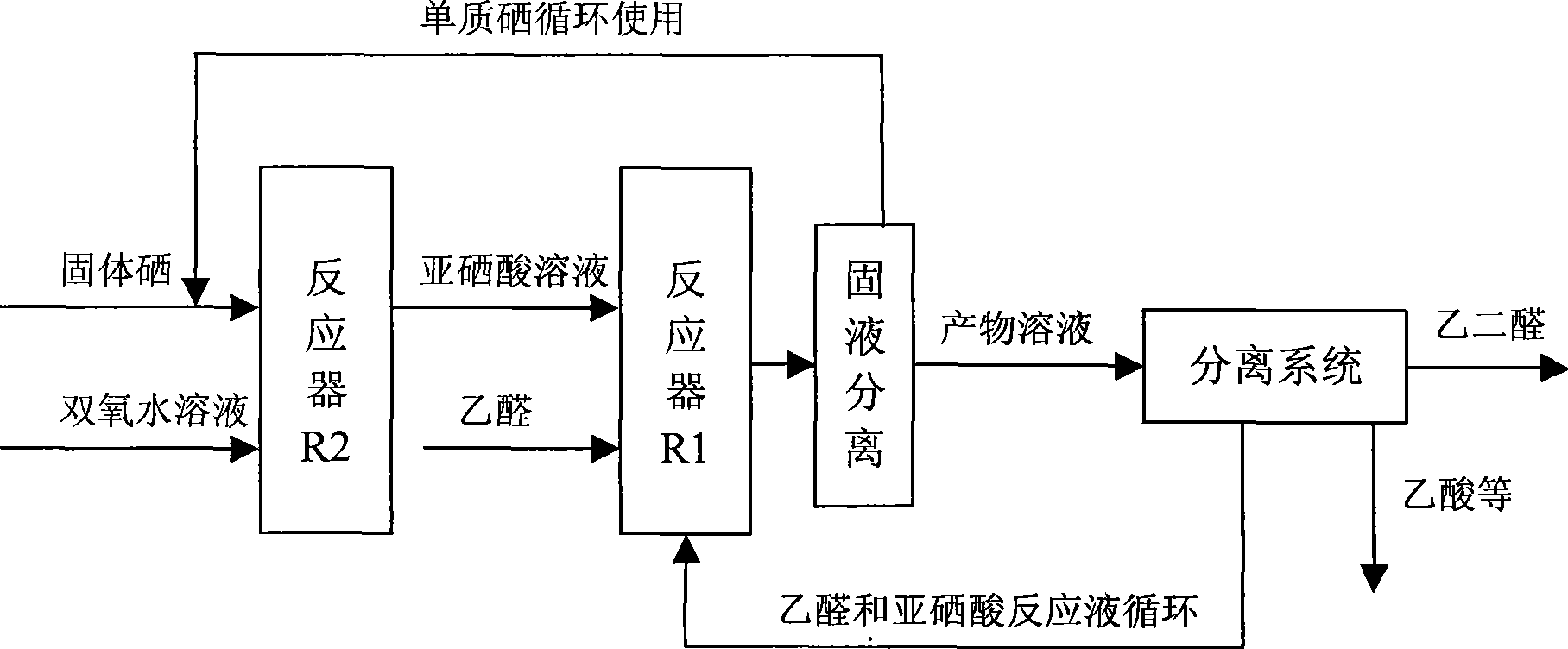

Preparation of biformyl by oxidizing acetaldehyde

InactiveCN101475453AImprove efficiencyImprove market competitivenessCarbonyl compound preparation by oxidationGlyoxalAcetaldehyde

The invention relates to a method for preparing glyoxal by oxidizing acetaldehyde, which is characterized in that selenium dioxide is used to prepare selenous acid aqueous solution taken as oxidant; glyoxal is formed by using the selenium dioxide to selectively oxidize acetaldehyde; meanwhile, the selenium dioxide is reduced into simple-substance selenium separated out; reaction products are separated to generate a glyoxal solution and simple-substance selenium; the simple-substance selenium separated out by use of hydrogen peroxide is the selenium dioxide; selenous acid solution is formed, returned and used for oxidizing acetaldehyde so as to prepare glyoxal. Or commercially available solid selenium is taken as raw material; selenium dioxide is first prepared by using hydrogen peroxide to oxidize simple-substance selenium; glyoxal is prepared by utilizing the prepared selenous acid solution to oxidize acetaldehyde; and then selenium is cyclically used. Under optimum conditions, the yield and selectivity of glyoxal and the yield of selenous acid are all more than 85 percent. The method for preparing glyoxal has the advantages of mild reaction conditions, high selectivity and high yield, cyclically uses selenium in a system, and has broad industrial application prospects.

Owner:NANJING UNIV OF TECH

Selenized microbial exopolysaccharide, and preparation method and uses thereof

InactiveCN102633899ANo generationShort reaction time for selenizationOrganic active ingredientsAntineoplastic agentsFreeze-dryingRhizobium sp.

The invention provides a selenized microbial exopolysaccharide and a preparation method thereof. The preparation method comprises the steps of: adding micromolecular Rhizobium sp. exopolysaccharide to nitric acid solution, stirring, adding selenous acid and barium chloride, adding sulfuric acid dropwise, removing precipitates by centrifugation, regulating the pH of supernatant to 7 by sodium hydroxide, putting the supernatant in a dialysis bag for dialysis, concentrating the dialysate under reduced pressure and then adding edible alcohol, separating out selenized microbial exopolysaccharide, and collecting and freeze-drying the selenized microbial exopolysaccharide to obtain selenized micromolecular microbial exopolysaccharide. The content of selenium in the exopolysaccharide can reach 586 to 790 mu g / g according to measurement; mice tests show that the exopolysaccharide has excellent antitumor activity; and the exopolysaccharide can be used in preparing antitumor medicines and healthcare products.

Owner:SHANXI UNIV

Preparation method of water-soluble nano elemental selenium for livestock and poultry

ActiveCN110759320ARich production channelsSolve the shortcomings of poor stability and easy grayingAccessory food factorsElemental selenium/telluriumBiotechnologyZoology

The invention discloses a preparation method of water-soluble nano elemental selenium for livestock and poultry. The preparation method comprises the following steps: (1) respectively weighing a selenite, a dispersing agent, a reducing agent and a carrier in parts by mass for standby application; 2) adding the selenite into water for dissolving, and performing uniform stirring for standby application; 3) adding the dispersing agent into the solution obtained in the step 2), performing continuous stirring until a colorless transparent solution turns to red without getting darker; 4) performingcontinuous stirring, adding the reducing agent into the solution obtained in the step 3) to make the color of the solution gradually turn red, and performing continuous stirring for 25 min until the reducing agent is completely dissolved, and the reaction is basically finished; and 5) adding the carrier into the solution obtained in the step 4), performing uniform stirring, and then performing shearing and homogenizing. According to the prepared nano elemental selenium, sodium selenite is reduced through the reducing agent, the highly toxic substance is converted into elemental selenium capable of being utilized by animals, and a production way of elemental selenium is enriched. In addition, a stable nano elemental selenium microcapsule is prepared by using the dispersing agent and the carrier and combining the solid dispersion technology.

Owner:ZHEJIANG WANFANG BIO TECH CO LTD

Controlled-release selenium fertilizer and preparation method thereof

ActiveCN105439738AEasy to storeThe improved ones will be effectively storedLayered/coated fertilisersFertilizer mixturesBULK ACTIVE INGREDIENTBeta-Cyclodextrins

The invention relates to a preparation method of a controlled-release selenium fertilizer. The preparation method comprises the following steps: (1) heating beta-cyclodextrin or starch and water in a weight ratio of 1:(3-5), and performing stirring until the solution is gelatinized; (2) heating selenite and styrylphenol polyoxyethylene ether, and performing stirring; and (3) adding a product of the step (2) and sodium lignin sulfonate into beta-cyclodextrin or gelatinized starch, and then adding polyvinyl alcohol and bentonite for mixing and tabletting. According to the preparation method of the controlled-release selenium fertilizer, provided by the invention, beta-cyclodextrin or starch wrapping is performed at first, then active ingredients are effectively sealed for safekeeping, and then particles are embedded together with polyvinyl alcohol and bentonite to realize controlled release.

Owner:中山市天颐商业投资管理有限公司

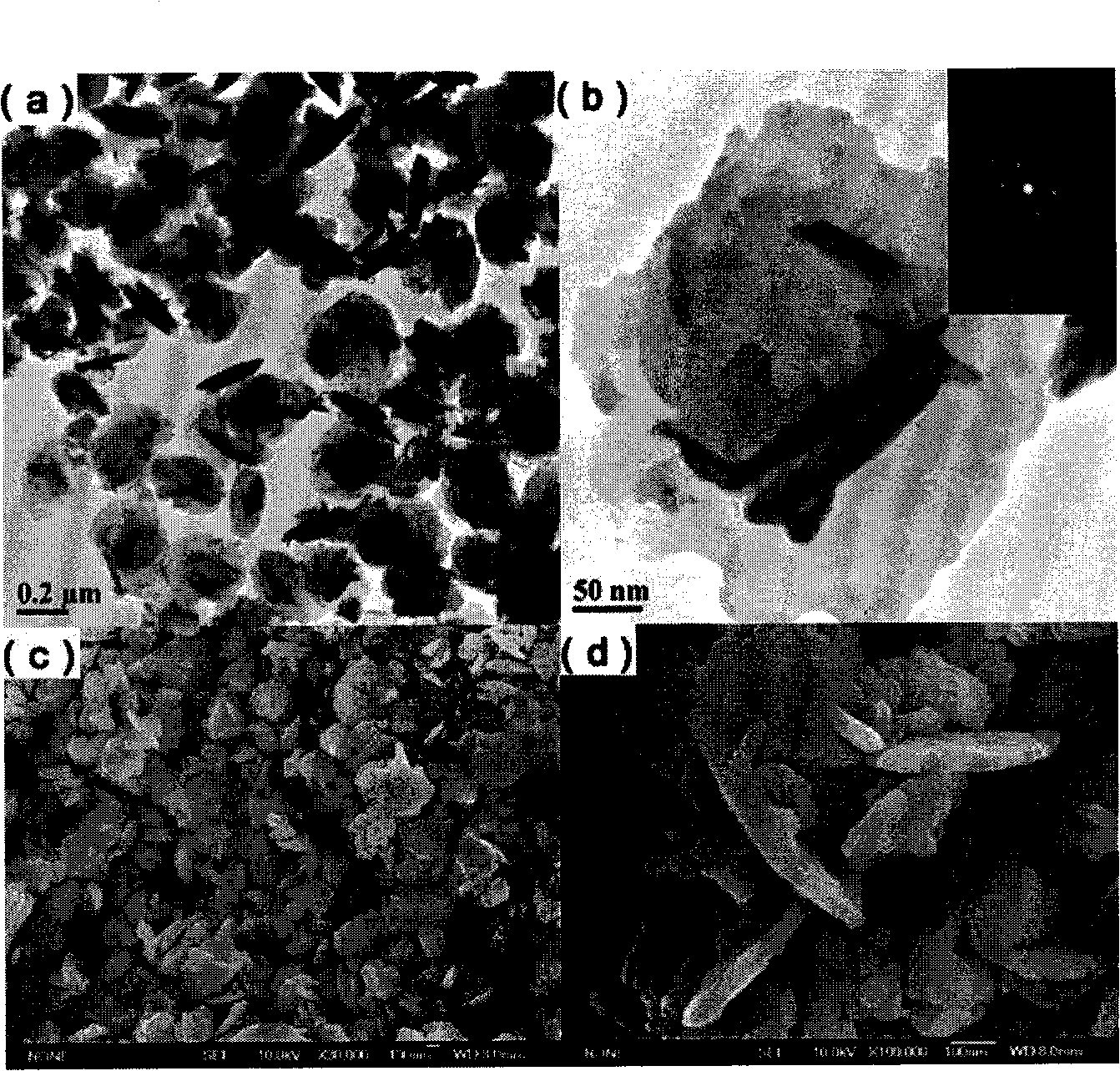

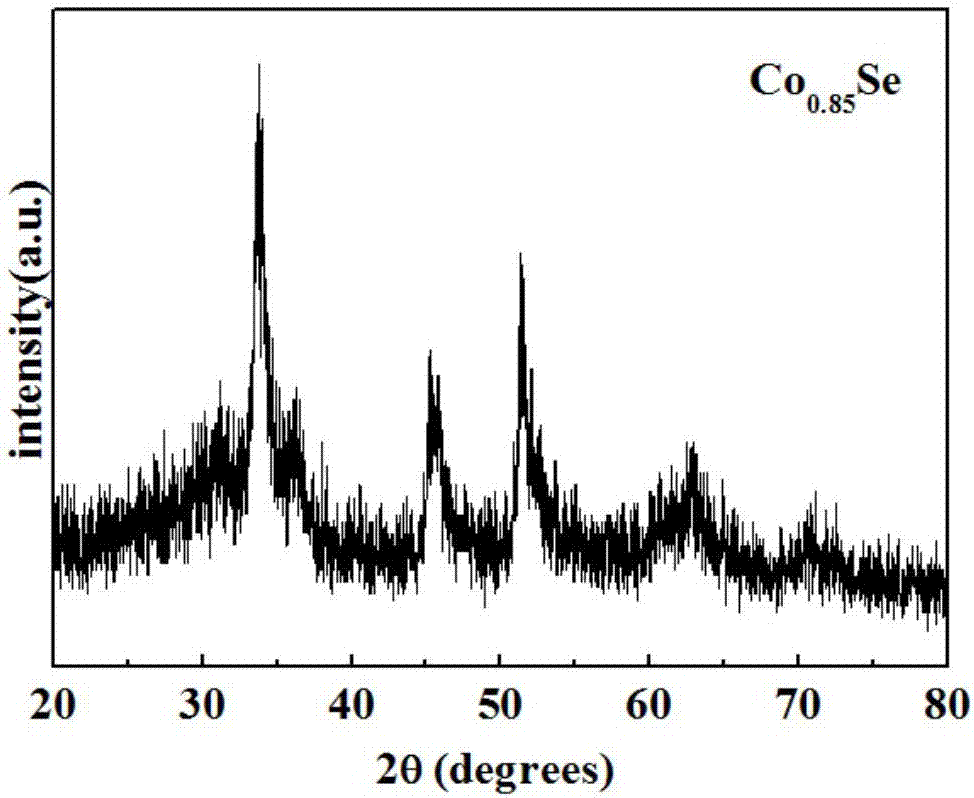

Preparation method of hollow Co0.85Se nanometer polyhedral particles

ActiveCN107473190ASpecial structureHigh specific surface areaMaterial nanotechnologyBinary selenium/tellurium compoundsMixed materialsSelenous acid

The invention discloses a preparation method of hollow Co0.85Se nanometer polyhedral particles. The preparation method comprises following steps: 1, cobalt nitrate hexahydrate and dimethyl imidazole are dissolved in methanol respectively so as to obtain two mixed solutions via stirring; 2, the mixed solution of dimethyl imidazole and methanol is added into the mixed solution of cobalt nitrate hexahydrate and methanol drop by drop for reaction with stirring, stirring is stopped when dropwise adding is completed, an obtained mixture is maintained at room temperature for a certain period of time, and then is subjected to centrifugation and washing so as to obtain a polyhedral precursor MOFs of Co; and 3, a certain amount of the polyhedral precursor MOFs of Co and deionized water are prepared into a mixed solution, selenous acid and hydrazine hydrate are added gradually, an obtained mixed material is stirred slightly, and then is delivered into a reaction vessel for hydro-thermal treatment, wherein hydro-thermal temperature is controlled to be 140 to 200 DEG C, and hydro-thermal treatment time is controlled to be 12 to 36h; after reaction, an obtained powder is subjected to centrifugation washing so as to obtain the hollow Co0.85Se nanometer polyhedral particles. According to the preparation method, the hollow Co0.85Se nanometer polyhedral particles are prepared via controlling the reaction conditions; the preparation method is novel; production period is short; and reference is provided for preparation of selenides of hollow structures.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method for single crystal selenium nanorod visible light catalytic material and use thereof

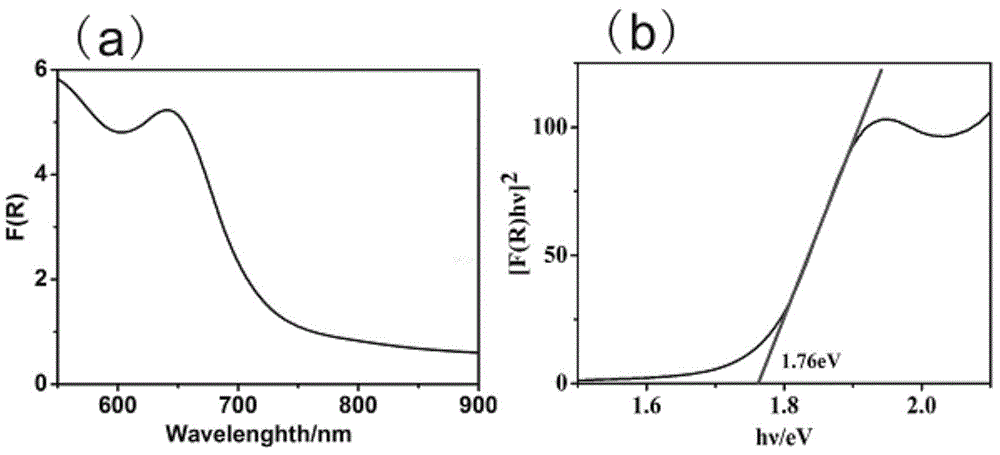

InactiveCN104525224AUniform shapeReasonable designMaterial nanotechnologyPhysical/chemical process catalystsDiffuse reflectionSingle crystal

The invention provides a preparation method for single crystal selenium nanorod visible light catalytic materials. The preparation method comprises the following steps that selenium dioxide and ascorbic acid are weighed, and the selenium dioxide is dissolved in deionized water to prepare a selenous acid solution; the selenous acid solution is dropped into an ascorbic acid solution, after the dropping is completed, red suspension liquid is prepared; the suspension liquid is stirred, precipitate is centrifuged and washed to be neutral, and at last a solid phase product alpha-Se is obtained after centrifugation; the prepared alpha-Se is transferred to a beaker containing a NaOH ethanol solution, after still standing and aging are performed, gray products are obtained after the mixture is washed and dried, and the gray products are the single crystal selenium nanorod visible light catalytic materials. According to the preparation method, the diameters of the prepared single crystal selenium nanorods are ranging from 100nm to 200nm, the length is tens of microns, the band gap of semiconductors of the nanorods measured by a diffuse reflection spectrum is 1.76eV, the single crystal selenium nanorods are used for degrading dye in an industry dye pollutant, and the degradation effect on methyl orange is particularly obvious.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Synthetic method of antitumor drug 6-hydroxy seleninic acid esterification chitosan copper

InactiveCN106519071ANo side effectsPromote absorptionOrganic active ingredientsAntineoplastic agentsReaction temperatureSelenous acid

The invention relates to a synthetic method of an antitumor drug 6-hydroxy seleninic acid esterification chitosan copper. According to the invention, 6-OH is subjected to seleninic acid esterification by a chitosan copper monomer, the chitosan copper is dissolved in an acid solution, the material is added in an seleninic acid aqueous solution, wherein the mol ratio of the chitosan monomer and seleninic acid in the chitosan copper is 1:1, the reaction temperature is controlled between 75-90 DEG C, heating and stirring can be carried out for 2-3 hours to obtain a seleninic acid esterification chitosan copper aqueous solution, ethanol is added until no precipitate is added, the material is filtered, ethanol with concentration of 75% is used for washing for 2-3 times, and drying is carried out to obtain the seleninic acid esterification chitosan copper pure product; and wherein an acid solution is a formic acid or acetic acid aqueous solution with concentration of 1%. The seleninic acid esterification chitosan copper is a preparation which has the advantages of no harm on environment, no toxic and side effect, easy absorption, and containing of selenium and trace element copper, can be taken as a novel selenium and trace element supplement preparation used for the fields of medicine, a health product, a cosmetic and agriculture, and can be taken as the novel antitumor drug.

Owner:HUBEI UNIVERSITY OF MEDICINE

Method for reducing selenite through liquid-phase catalytic hydrogenation

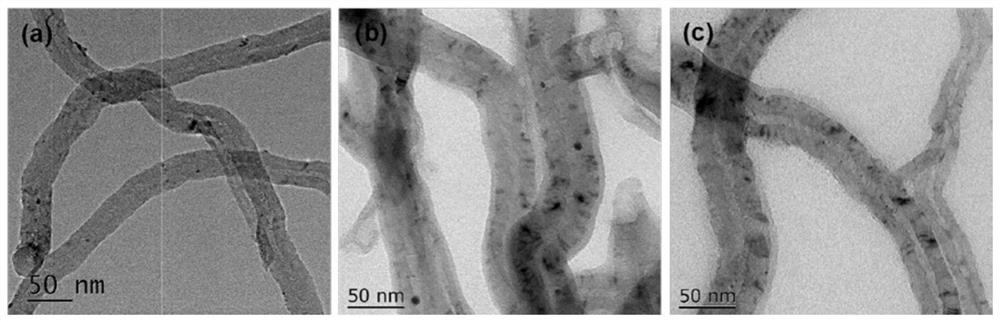

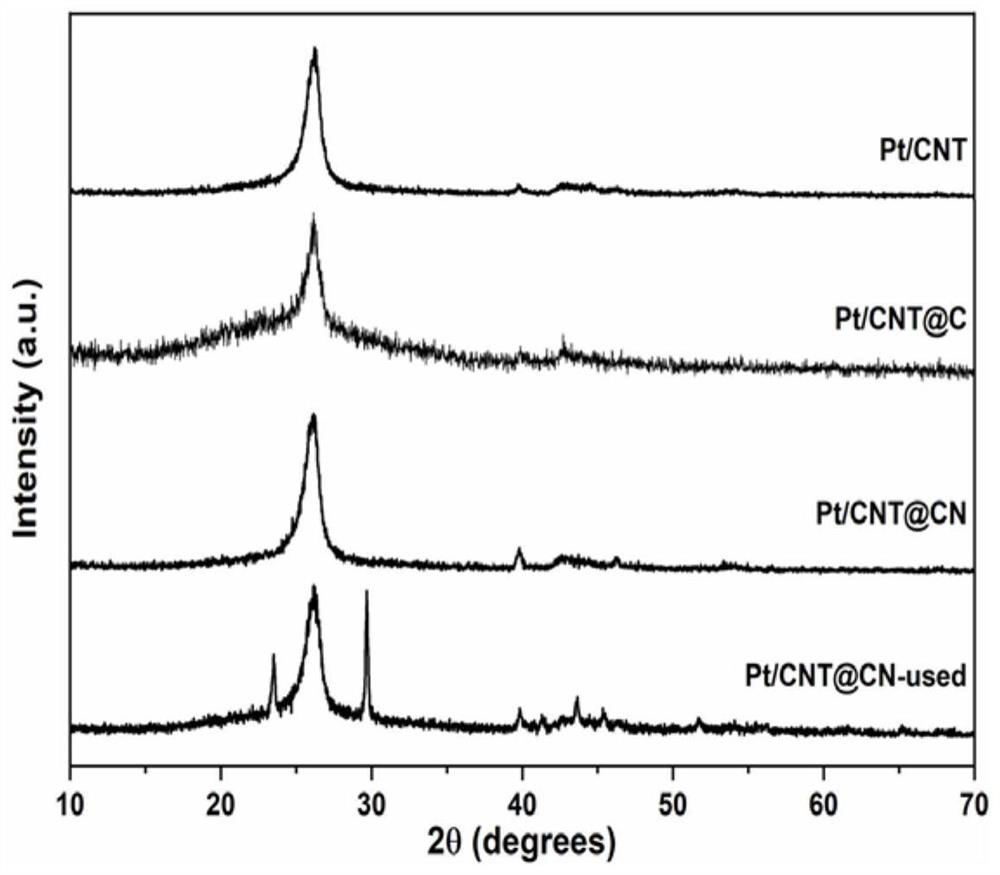

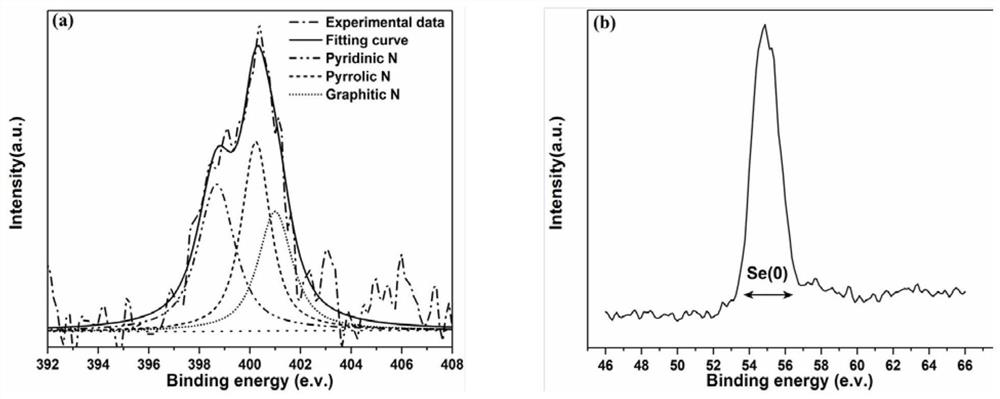

InactiveCN112774710ALow equipment requirementsReduce processing costsWater contaminantsCatalyst activation/preparationCarbon coatingPtru catalyst

The invention discloses a method for reducing selenite through liquid-phase catalytic hydrogenation, which comprises the following steps: (A) preparation of a catalyst: taking a multi-walled carbon nanotube as a carrier, firstly loading noble metal Pt or Pd through an impregnation method, and then forming a polyaniline coating layer on the surface of the carrier through in-situ oxidative polymerization; roasting to obtain a supported noble metal catalyst with a nitrogen-doped carbon coating layer; and (B) Se (IV) liquid phase hydrogenation reduction: under the action of the catalyst prepared in the step (A), removing Se (IV) in the water body through liquid phase catalytic hydrogenation. The catalyst with a wrapping structure is applied to liquid-phase catalytic hydrogenation reduction to remove selenite in a water body, the catalyst has high activity, and meanwhile the technical problems of loss of active components, poisoning and the like of the catalyst are solved; and the catalyst is easy to synthesize and mild in reaction condition, and has a wide application prospect in the field of water treatment.

Owner:NANJING UNIV

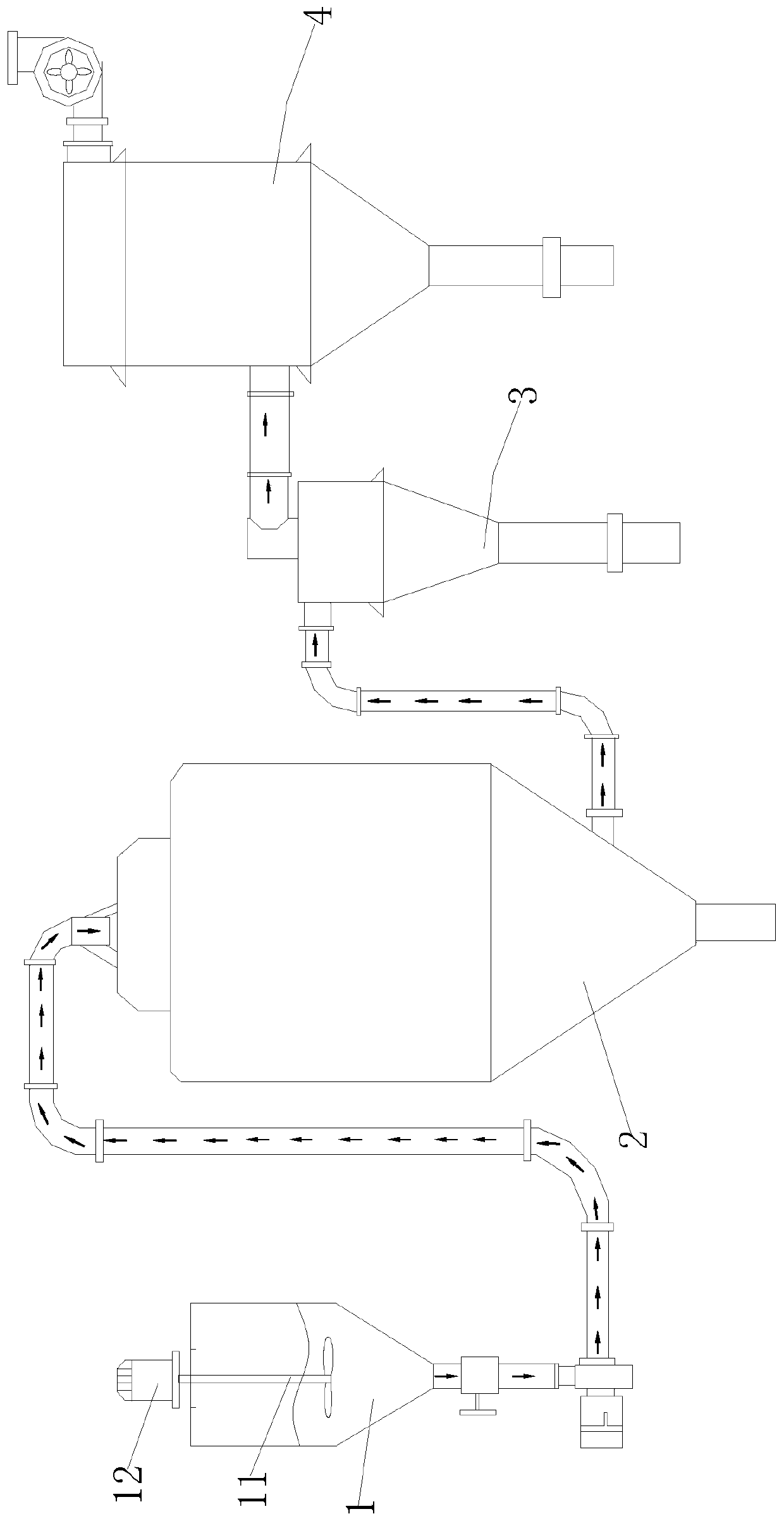

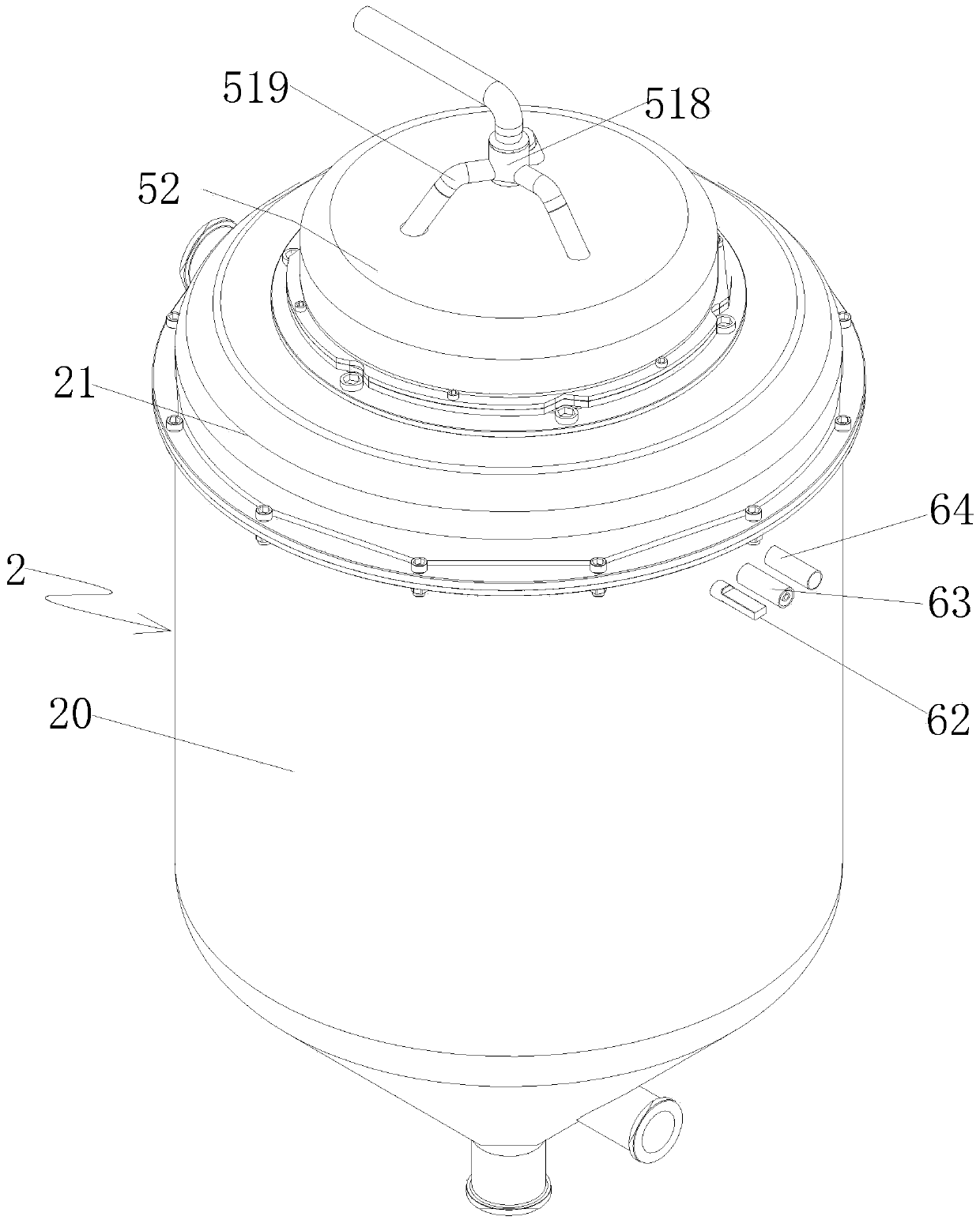

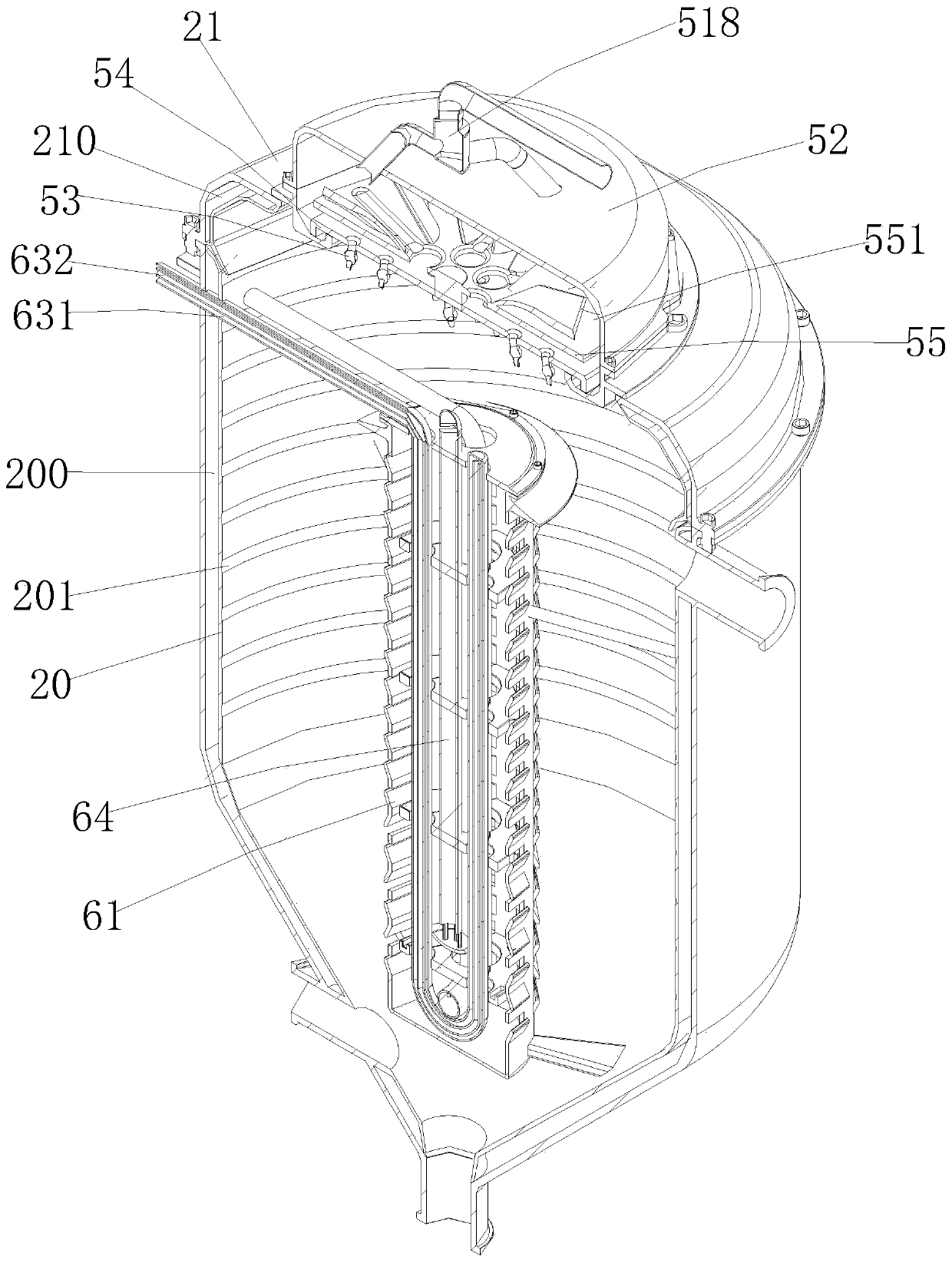

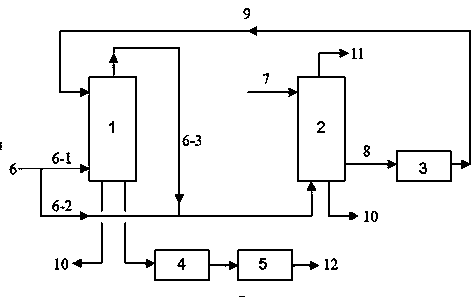

Comprehensive treatment method and device for Se-containing wastewater

ActiveCN108069562AReduce processing costsHigh removal rateWater treatment parameter controlWater contaminantsFlue gasSelenate ion

The invention relates to a comprehensive treatment method and device for Se-containing wastewater. Two stages of reactors are adopted, the Se-containing wastewater enters a second reactor firstly andis subjected to a reaction with sulfur-containing flue gas, SO2 in the flue gas is removed, and purified gas is discharged; effluent of the second reactor enters an anaerobic reactor, and selenate ions in the wastewater are reduced into selenite ions; effluent of the anaerobic reactor returns to a first reactor and is subjected to a reaction with the flue gas, and the selenite ions are removed; effluent of the first reactor enters an aerobic reactor, and effluent of the aerobic reactor is subjected to flocculating sedimentation, solid-liquid separation is performed, and a product is discharged. The Se-containing wastewater is treated by the sulfur-containing flue gas, so that the Se-containing wastewater and the sulfur-containing flue gas are treated efficiently simultaneously, waste is treated by waste, treatment cost of the Se-containing wastewater is reduced, the removal rate for Se pollutants in the wastewater is higher than 95%, and content of SO2 in the sulfur-containing flue gasis lower than 20 mg / L.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com