Method for treating selenium-containing wastewater

A treatment method and technology for wastewater, applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems of limited anaerobic biological tolerance, troublesome selection of chemicals, inability to treat selenium-containing wastewater, etc. Achieve the effect of easy implementation, improved biodegradability, and short ozone half-life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

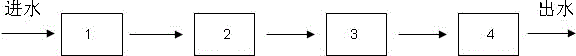

Image

Examples

Embodiment 1

[0031] The process flow of the invention is adopted to process the prepared high-concentration selenium-containing wastewater. Wastewater water quality: pH is 7.3, utilizes single-column ion chromatography to measure wherein selenate ion (SeO 4 2-) concentration is 326.3μg / L, selenite ion (SeO 3 2- ) concentration was 269.7μg / L.

[0032] Selenium-containing wastewater enters the ozone reactor, and the reaction time is 20 minutes (ozone and SeO 3 2- The molar ratio is 1:4), enter the MBBR reactor for aerobic reaction, and the MBBR is fed intermittently; the cycle runs for 12 hours, the water is fed for 4 hours, the aeration is 6 hours, the settlement is 1 hour, the drainage is 0.5 hours, and the idle drainage is 0.5 hours , Idle for 0.5 hours; periodic treatment of water volume 10L, influent flow rate 5L / h; filler dosing ratio (the ratio of the total volume of the filler to the volume of the container) is 30%. The aerobic biological treatment temperature is controlled at ...

Embodiment 2

[0034] The method of the invention is used to process the prepared high-concentration selenium-containing wastewater. Wastewater water quality: pH is 6.7, utilizes single-column ion chromatography to measure wherein selenate ion (SeO 4 2- ) concentration is 21228.3μg / L, selenite ion (SeO 3 2- ) concentration was 12757.7μg / L. Adopt the method of the present invention, carry out treatment test to above-mentioned waste water.

[0035] Add potassium hydroxide solution to adjust the pH of the selenium-containing wastewater to 8, and the selenium-containing wastewater enters the ozone reactor, and the reaction time is 5 minutes (ozone and SeO 3 2- The molar ratio is 1:2), after the ozone reaction, it enters the MBBR reactor for aerobic reaction, and the MBBR intermittently feeds water; the cycle runs for 12 hours, the water intake is 3.5 hours, the aeration is 7 hours, the settlement is 0.5 hours, and the drainage is 0.5 hours. Idle drainage for 0.5 hours, idle for 0.5 hours; ...

Embodiment 3

[0037] The process flow of the invention is adopted to process the prepared high-concentration selenium-containing wastewater. Wastewater water quality: pH is 5.3, utilizes single-column ion chromatography to measure wherein selenate ion (SeO 4 2- ) concentration is 28.7μg / L, selenite ion (SeO 3 2- ) concentration was 2549.2μg / L.

[0038] Add potassium hydroxide solution to adjust the pH of the selenium-containing wastewater to 7, and the selenium-containing wastewater enters the ozone reactor, and the reaction time is 20 minutes (ozone and SeO 3 2- The molar ratio is 1:3), enter the MBBR reactor for aerobic reaction, and the MBBR is fed intermittently; the cycle runs for 12 hours, the water is fed for 4 hours, the aeration is 6 hours, the settlement is 1 hour, the drainage is 0.5 hours, and the idle drainage is 0.5 hours , Idle for 0.5 hours; periodic treatment of water volume 10L, influent flow rate 5L / h; filler dosing ratio (the ratio of the total volume of the filler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com