Preparation of biformyl by oxidizing acetaldehyde

A technology of glyoxal and acetaldehyde, applied in the field of chemical technology, can solve problems such as strong corrosion and environmental pollution, and achieve the effect of simple equipment, improved technical level, and high market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

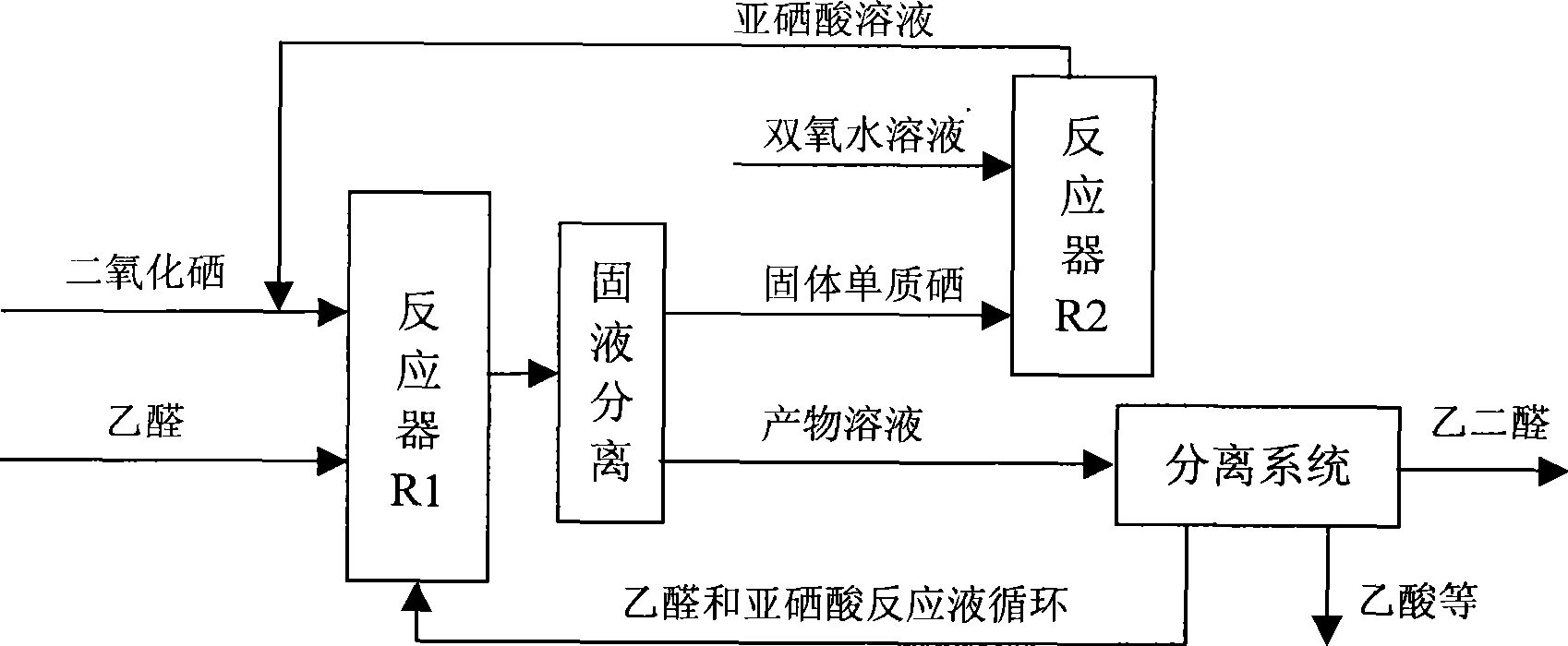

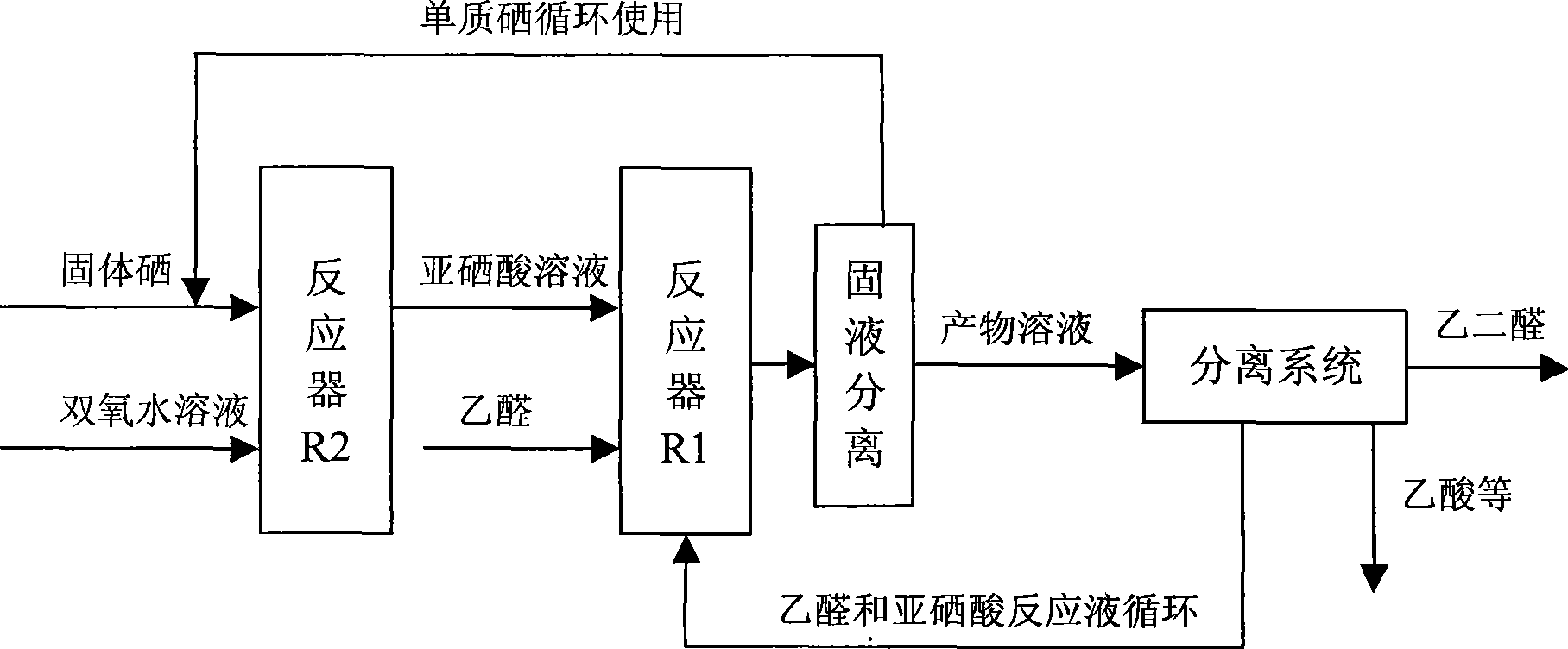

Image

Examples

Embodiment 1

[0026] 12.6g selenium dioxide (commercially available) is dissolved in water, is made into weight percent concentration and is 20% selenous acid solution; Adding weight percent concentration is 10g of acetaldehyde solution 10g of weight percent concentration in reactor R1, stirs, drops Add selenous acid solution, react at 65°C for 4 hours, selenium dioxide selectively oxidizes acetaldehyde to generate glyoxal product, and undergo solid-liquid separation to obtain liquid phase product solution and solid elemental selenium respectively, and analyze the liquid phase product components , the yield of glyoxal was 85.86%, and the selectivity was 86.15%.

Embodiment 2

[0028] Add the elemental selenium obtained in Example 1 into the reactor R2, add water, fully stir, then dropwise add a hydrogen peroxide solution with a concentration of 30% by weight, oxidize the elemental selenium into selenium dioxide, and generate an aqueous solution of selenium dioxide, i.e. selenic acid solution. Under the condition that the molar ratio of hydrogen peroxide and selenium is 1:1 and 25°C, the reaction is carried out for 4 hours, and the yield of selenous acid is 88.65%.

Embodiment 3

[0030] The selenous acid solution obtained in Example 2 was returned to reactor R1 to prepare glyoxal by oxidizing acetaldehyde. The conditions were the same as in Example 1, and the yield of glyoxal was 84.92%, and the selectivity was 86.03%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com