Comprehensive treatment method and device for Se-containing wastewater

A comprehensive treatment and wastewater technology, applied in water/sewage treatment, water treatment parameter control, biological water/sewage treatment, etc., can solve problems such as troublesome selection of chemicals, limited tolerance of anaerobic organisms, inability to treat selenium-containing wastewater, etc. , to achieve the effect of reducing processing load, reducing toxicity and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

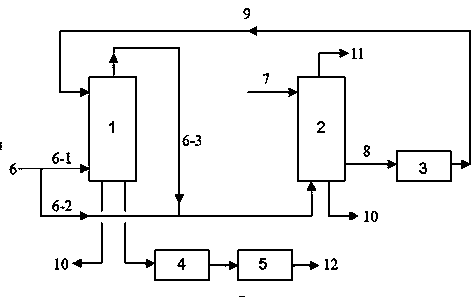

[0032] The selenium-containing wastewater is treated by the technological process of the invention. The quality of the wastewater was as follows: pH was 7.3, and single-column ion chromatography was used to determine the selenate ion (SeO) in the wastewater. 4 2- ) concentration was 3263.2 μg / L, selenite ion (SeO 3 2- ) concentration was 2697.3 μg / L, COD was 633 mg / L, and ammonia nitrogen was 52.4 mg / L. The concentration of sulfur dioxide in the flue gas is 3170mg / m³.

[0033] A two-stage gas-liquid contact reaction tower is used, and the wastewater containing selenium first enters the second reactor, and the volume ratio of liquid to gas is controlled to be 5L / m 3 , remove the sulfur dioxide in the flue gas, and purify the gas for discharge; the effluent from the second reactor enters the anaerobic reactor, and the biological contact tower is used to inoculate the de-selenium sludge taken from the selenium-containing environment. 8. The treatment time is 8h, and 55% of t...

Embodiment 2

[0036] The selenium-containing wastewater is treated by the method of the invention. Wastewater quality: pH was 6.7, and the selenate ion (SeO) was determined by single-column ion chromatography. 4 2- ) was 21228.3 μg / L, selenite ion (SeO 3 2- ) was 12757.7 μg / L, COD: 682 mg / L, ammonia nitrogen: 73.3 mg / L. The concentration of sulfur dioxide in the flue gas is 8630mg / m³.

[0037] A two-stage gas-liquid contact reaction tower is adopted, and the wastewater containing selenium first enters the second reactor, and the volume ratio of liquid to gas is controlled to be 25L / m 3 , remove the sulfur dioxide in the flue gas, and purify the gas for discharge; the effluent from the second reactor enters the anaerobic reactor, and the biological contact tower is used to inoculate the de-selenium sludge taken from the selenium-containing environment. The temperature is controlled at 30 °C and the pH is 7. -8, the treatment time is 12h, and 51% of the selenate ions in the wastewater ar...

Embodiment 3

[0040] The anaerobic activated sludge taken from the selenium-containing environment was used for the following domestication: (1) The nutrient salts ammonium chloride and potassium dihydrogen phosphate were added to the original selenium-containing wastewater in advance, so that the concentrations were 1 mg / L and 0.2 mg / L, respectively. L, and add a certain concentration of methanol as the hydrogen source; (2) adopt the continuous water inflow operation mode to control the SeO in the influent water 4 2- The concentration is 400μg / L, and the hydraulic retention time is controlled to be 8h. When the effluent SeO 4 2- When the concentration is lower than 100μg / L, the SeO 4 2- Anaerobic sludge with specific reducing ability; (3) Adopt intermittent influent operation mode, and gradually increase SeO in influent according to 100μg / L 4 2- The concentration of SeO in the anaerobic sludge 4 2- Bacteria with strong processing ability proliferate in large quantities; when SeO ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com