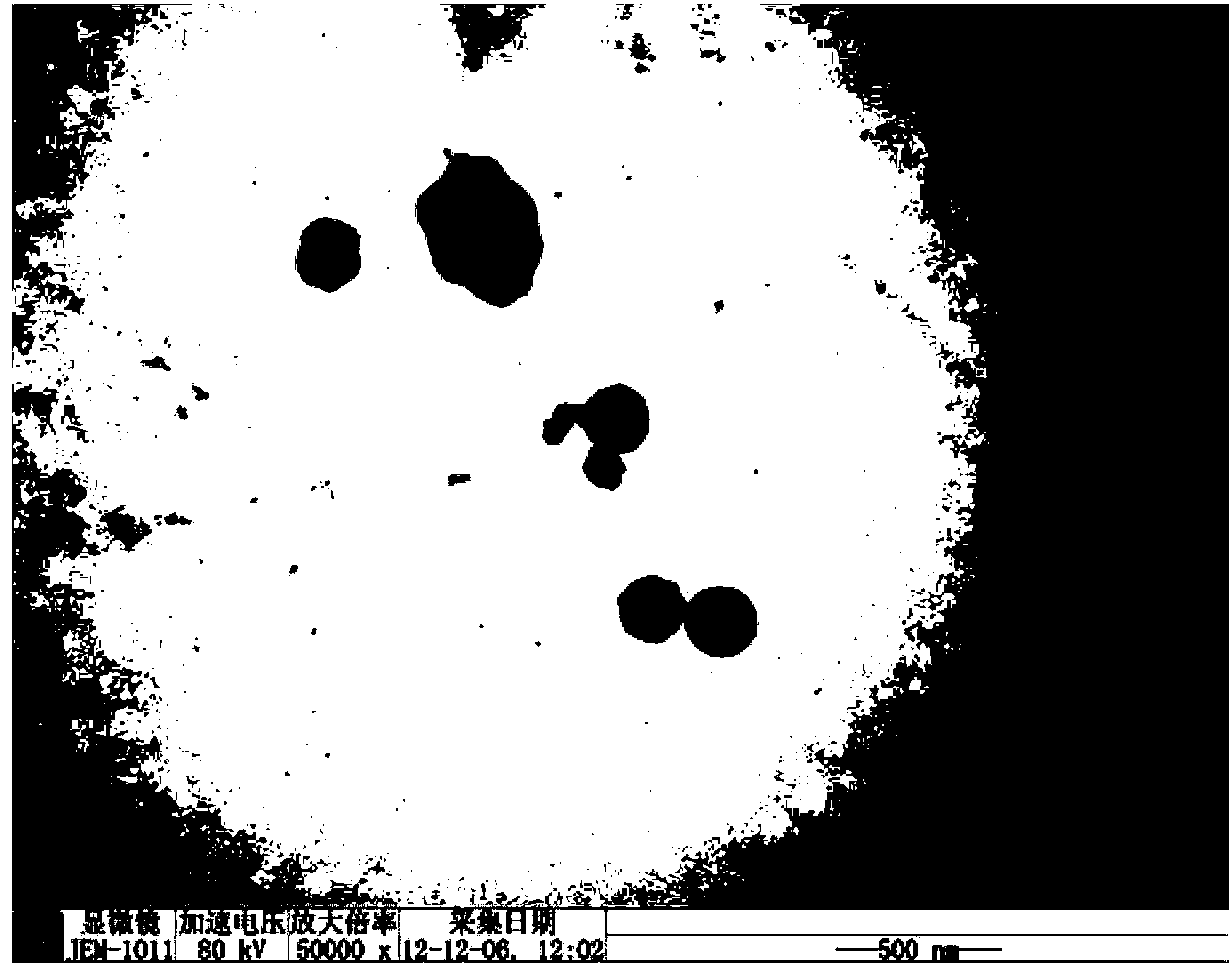

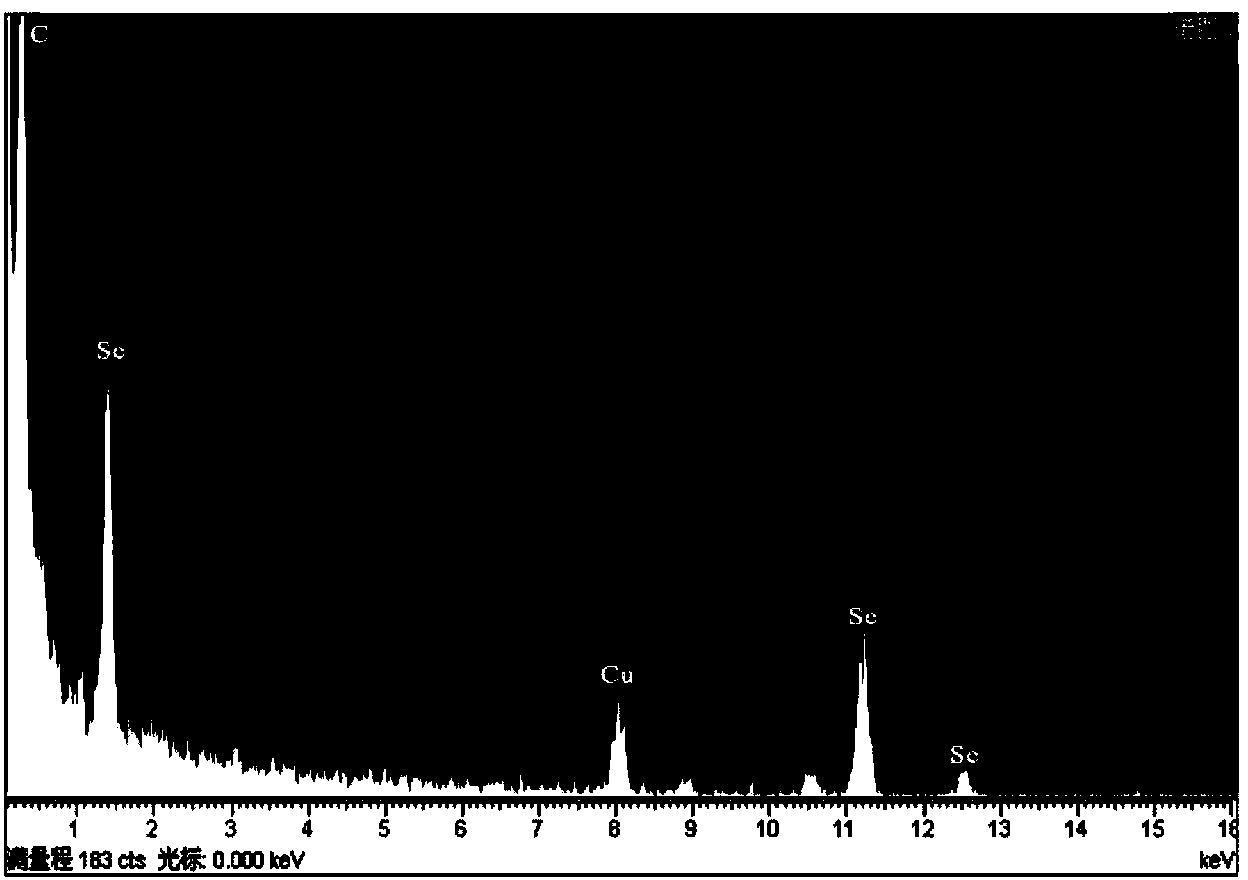

Method for preparation of red elemental selenium by photosynthetic bacteria

A technology for photosynthetic bacteria and elemental selenium, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of difficult to obtain pure red elemental selenium, difficult to separate, etc., and achieves easy construction, high purity, and growth. fast reproduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Prepare media with the following components: MgSO 4 ·7H 2 O150mg, CaCl 2 2H 2 O80mg, sodium acetate 1800mg, EDTA20mg, yeast extract powder 1200mg, K 2 HPO 4 1000mg, (NH 4 ) 2 SO 4 1500mg, FeSO 4 ·7H 2 O10mg, KH 2 PO 4 800mg, trace element solution 3ml, deionized water 1000ml, pH 7.

[0024] Wherein the trace element solution is composed of: H 3 BO 3 240mg, MnSO 4 4H 2 O200mg, Na 2 MoO 4 2H 2 O70mg, CuSO 4 7mg, ZnSO 4 ·7H 2 O24mg, deionized water 100ml.

[0025] Insert 1 / 10 of the photosynthetic bacteria into the sterilized culture medium, under light intensity of 1000lux, 30°C, and anaerobic conditions, cultivate for 5 days, repeat twice, and use as the inoculation strain for subsequent use.

[0026] The above-mentioned activated photosynthetic bacteria liquid was inoculated in the 1.0mmol / L selenite medium containing 15% of the total amount, and cultivated for 7 days under light intensity of 1500lux, 30°C and anaerobic conditions. The culture was...

Embodiment 2

[0030] Prepare media with the following components: MgSO 4 ·7H 2 O300mg, CaCl 2 2H 2 O100mg, sodium acetate 2500mg, EDTA30mg, yeast extract powder 1500mg, K 2 HPO 4 1500mg, (NH 4 ) 2 SO 4 2000mg, FeSO 4 ·7H 2 O15mg, KH 2 PO 4 1000mg, trace element solution 5ml, deionized water 1500ml, pH 7.

[0031] Wherein the trace element solution is composed of: H 3 BO 3 240mg, MnSO 4 4H 2 O200mg, Na 2 MoO 4 2H 2 O70mg, CuSO 4 7mg, ZnSO 4 ·7H 2 O24mg, deionized water 200ml.

[0032] Insert 1 / 20 of the photosynthetic bacteria into the sterilized culture medium, and cultivate it for 7 days under light intensity of 1500lux, 35°C and anaerobic conditions.

[0033] The above-mentioned highly active photosynthetic bacteria liquid was inoculated into 2.0mmol / L selenite medium containing 20% of the total amount, and cultivated for 9 days under light intensity of 1500lux, 35°C and anaerobic conditions. Other conditions are identical with embodiment 1.

Embodiment 3

[0035] The highly active photosynthetic bacteria in Example 1 were used to centrifuge at 8000×g for 10 min, wash the precipitate with physiological saline and centrifuge twice. Then weigh the wet cells of photosynthetic bacteria (embedding amount 30%) and mix them with PVA (mass concentration 10%) solution cooled to 35°C, and drop this mixture into the saturated boric acid solution with pH 6.5 with a syringe to form Small balls around 3mm. The formed pellets were immobilized in a refrigerator at 4°C for 18 hours, and then activated in the culture medium for 6 hours to prepare immobilized cells for use.

[0036] Sterilize 1000ml of photosynthetic bacteria culture medium containing 2.0mmol / L selenite at 121°C for 30 minutes, cool to room temperature, add immobilized bacteria (inoculated at 20%), and in anaerobic, light intensity 1000lux, After cultivating at 30°C for 7 days, the immobilized pellets were taken out to purify the red elemental selenium. The steps were the same as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com