Wet process refining technology for purifying selenium

A wet process technology, which is applied in the field of wet refining process for purifying selenium in the absorption liquid of the alloy blowing tower, can solve the problems of long process flow, high production cost, and long production cycle, and achieve economic indicators and production costs. The effect of low cost and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

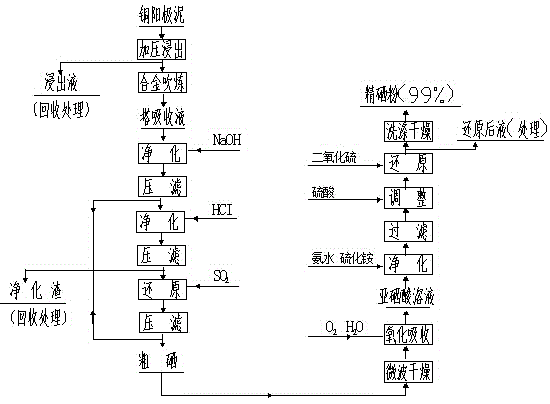

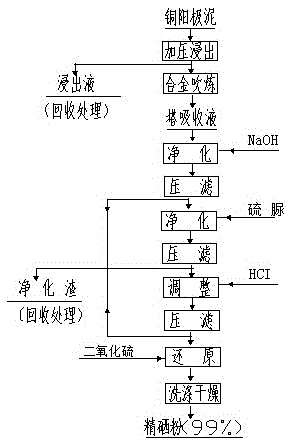

[0042] like figure 2 Shown, a kind of wet refining process of purifying selenium comprises the following steps:

[0043] Step 1: Take 4500mL of the tower absorption liquid produced by the alloy conversion furnace with pH=7, the selenium content is 40g / L, add 40gNaOH to adjust the pH=12 of the tower absorption liquid, stir and react for 0.1h, and after standing for 0.1h, flocculent precipitation appears. And the flocculent precipitate is getting bigger and bigger. After 2 hours, there is no more precipitation. First place two layers of filter paper in the Buchner funnel, add activated carbon layer 1cm thick, then place two layers of filter paper, and pour the tower absorption liquid onto the filter paper , using negative pressure suction filtration; activated carbon can be reused many times, after using it for more than 4 times, it can be boiled and washed with pure water before use. .

[0044] Step 2: Heat the filtered liquid obtained in Step 1 to 60°C on an electric heatin...

Embodiment 2

[0047] like figure 2 Shown, a kind of wet refining process of purifying selenium comprises the following steps:

[0048] Step 1: Take 4000mL of the tower absorption liquid with pH=8 produced by the alloy converting furnace, the selenium content is 20g / L, add 26gNaOH to adjust the pH=13 of the feed liquid, stir and react for 0.5h, after standing for 0.2h, flocculent precipitation appears, and The flocculent precipitate is getting bigger and bigger. After 2 hours, there is no more precipitation. First place two layers of filter paper in the Buchner funnel, add activated carbon layer 1.2cm thick, then place two layers of filter paper, and pour the tower absorption liquid onto the filter paper , using negative pressure suction filtration; activated carbon can be reused many times, after using it for more than 4 times, it can be boiled and washed with pure water before use. .

[0049] Step 2: Heat the filtered solution obtained in step 1 to 60°C on an electric heating plate, add...

Embodiment 3

[0052] like figure 2 Shown, a kind of wet refining process of purifying selenium comprises the following steps:

[0053] Step 1: Take 5000mL of the tower absorption liquid with pH=6 produced by the alloy converting furnace, the selenium content is 18g / L, add 55gNaOH to adjust the pH=12 of the feed liquid, stir and react for 0.1h, after standing for 0.2h, flocculent precipitation appears, and The flocculent precipitate is getting bigger and bigger. After 2 hours, there is no more precipitation. First place two layers of filter paper in the Buchner funnel, add activated carbon layer 1cm thick, then place two layers of filter paper, pour the tower absorption liquid onto the filter paper, Use negative pressure suction filtration; activated carbon can be reused many times, after using it for more than 4 times, it can be boiled and washed with pure water before use.

[0054] Step 2: Heat the filtered liquid obtained in step 1 to 63°C on an electric heating plate, add 15g of thiour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com