Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Recycling by product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Products made from a variety of materials can be recycled using a number of processes.

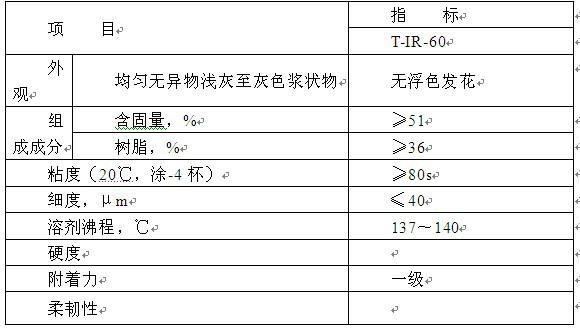

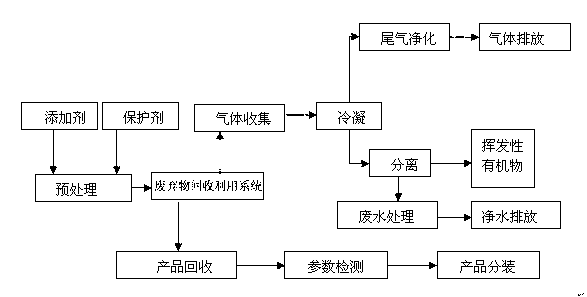

Method for preparing paint raw material from paint waste residue

ActiveCN102558938AReduce contentReduce mass ratioPlastic recyclingPolyurea/polyurethane coatingsSolid componentOrganic solvent

The invention discloses a method for preparing a paint raw material from a paint waste residue, and the method comprises the following steps of: preprocessing the paint waste residue, classifying, removing impurities, then adding an additive and a protecting agent, and uniformly dispersing; sending the preprocessed paint waste residue to an organic waste recycling system, setting a proper temperature and then carrying out separation modification; recycling solid components to form thick plaster-shaped modified resin and packaging; collecting mixed steam of a solvent and water through gas and then condensing so as to separate gas from liquid, carrying out tail gas purification on the gas part and discharging the gas part when the gas part reaches the standard, carrying out oil-water separation on the liquid part to ensure that water is separated from the solvent, collecting the solvent for concentrated utilization, and carrying out wastewater treatment on the water and then dischargingwhen the gas part reaches the standard. A large quantity of organic solvent is not adopted in the method, water can be well separated from the paint waste residue, and the prepared paint raw materialhas the advantages of lower organic solvent content, lower danger and the like, thus the paint raw material can be safely used in various medium- and low-end coating raw materials.

Owner:NANJING ENVIRO TECH ENVIRONMENTAL TECH & DEV

Method for simultaneously removing PM2.5 granules, SO2 and NOx from flue gas and recycling by-product

InactiveCN101496986ANon-corrosiveNo cohesionCombination devicesExternal electric electrostatic seperatorWater vaporHigh pressure

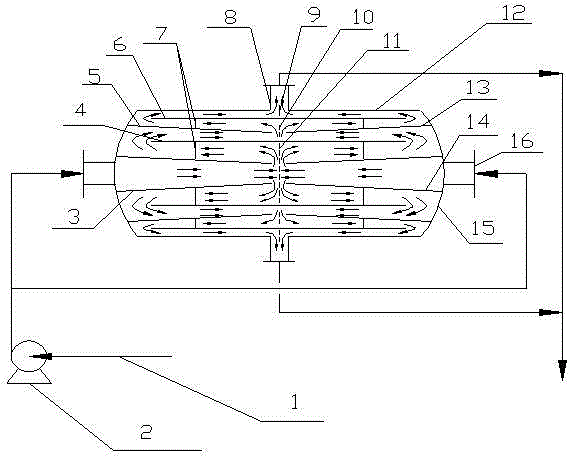

The invention discloses a method for simultaneously removing PM2.5 particles, SO2 and NOx of smoke gas and reclaiming byproducts. The smoke gas to be treated is introduced to a pulse corona electric field and absorption liquid is sprayed to purify the smoke gas at the same time; the pulse corona electric field is produced by an acicular corona wire connected with negative pulse high voltage and a netty metal electrode connected with positive pulse voltage; the absorption liquid is sprayed on the netty metal electrode to form liquid film; after the PM2.5 particles are charged, the PM2.5 particles move to the liquid film by electrostatic force and are adsorbed and caught by the liquid film; vapor and oxygen of the smoke gas are decomposed into O, OH, O3, HO2 and other oxidative free radicals; SO2 and NO of the smoke gas are oxidized into high valent state substances which are easy to absorb; subsequently, the substances are absorbed by the absorption liquid; and the reacted absorption liquid is crystallized through sensible heat drying of the smoke gas to be treated to generate reclaimable byproducts. The method realizes simultaneous removing of the PM2.5 particles, SO2 and NOx of the smoke gas and recycles the removed byproducts.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Method for synthesizing p-acetamido benzene sulfonyl chloride by phosphorus pentachloride

InactiveCN101613308AHigh yieldReduce dosageSulfonic acid preparationSulfonyl chlorideChlorosulfuric acid

The invention relates to a method for synthesizing p-acetamido benzene sulfonyl chloride by phosphorus pentachloride, relating to the preparation method for sterilization and mould inhibition midbody of sulfonamides. The invention takes acetanilide and chlorosulfonic acid as raw materials, uses phosphorus pentachloride as chlorinating agent; under the action of organic dissolvent, the raw materials are sulfonated, chloridized, separated, and washed to obtain the product. The invention has the effects of little chlorosulfonic acid usage, high product yield, few generated waste acid,, completely cycling dissolvent, recycled by-products, low manufacturing cost, being convenient to popularize and apply, and the like. The products prepared by the method can be widely applied to the preparation of the sterilization and mould inhibition of sulfonamides and industries such as coating, plastics, pesticides, etc.

Owner:CHONGQING UNIV

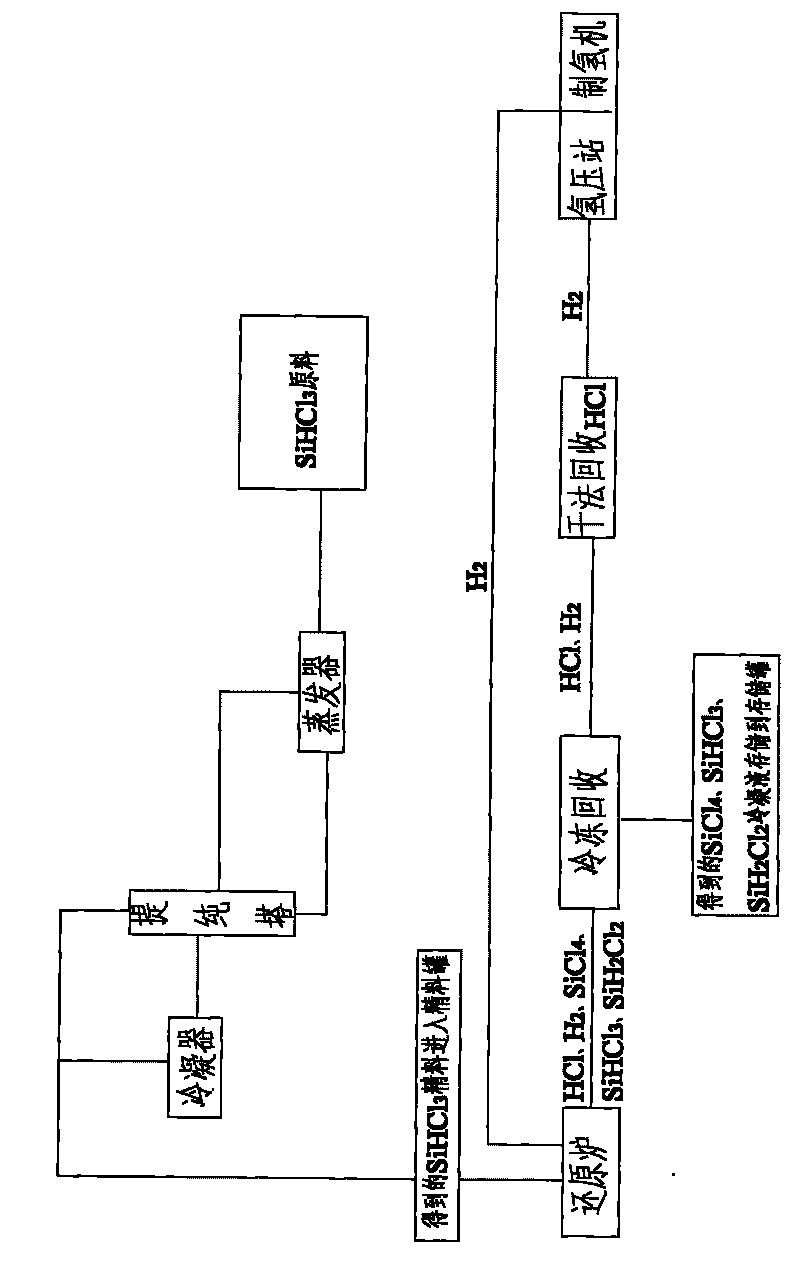

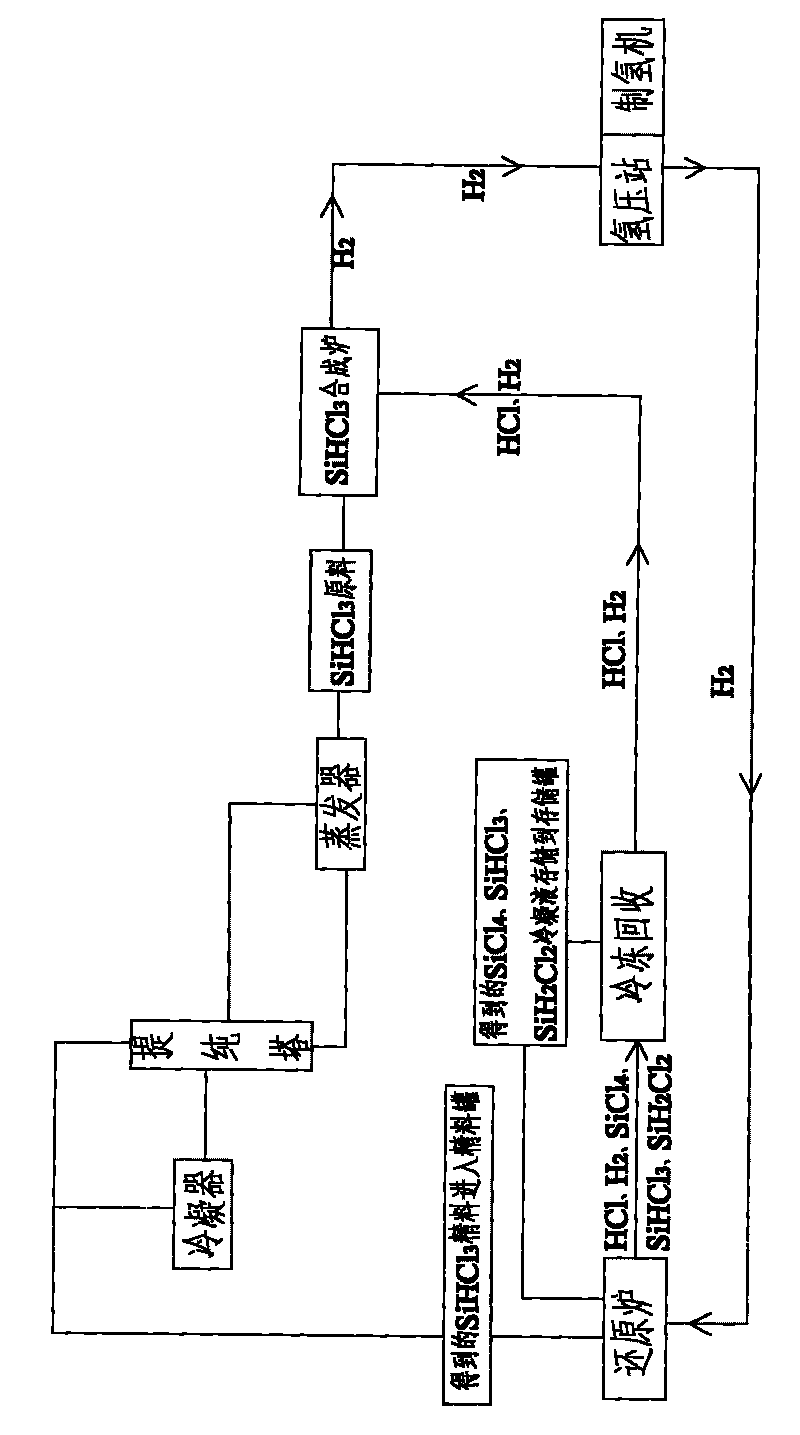

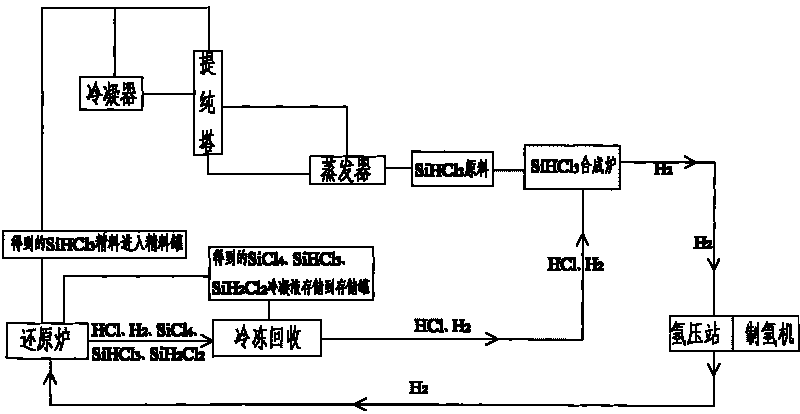

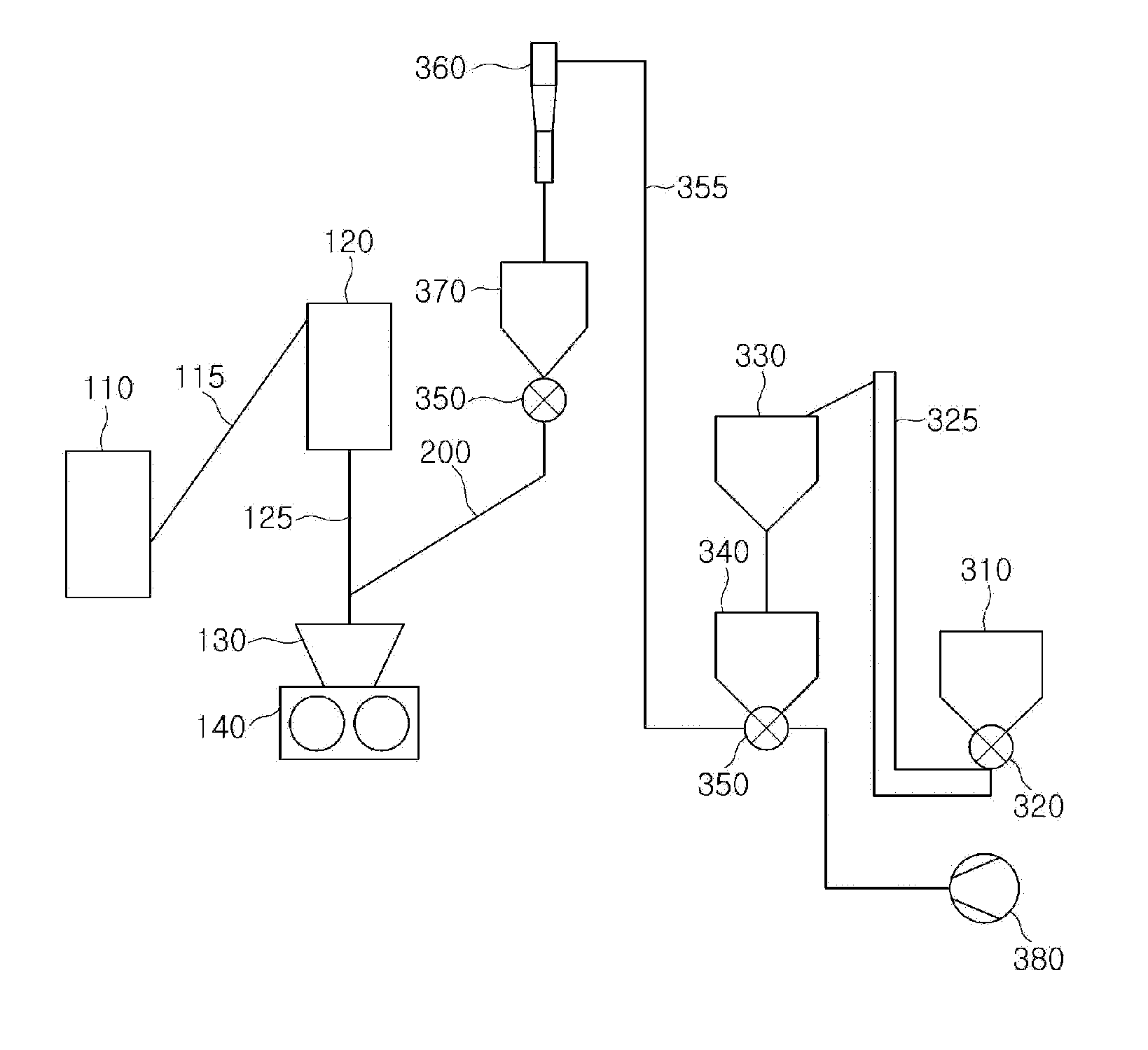

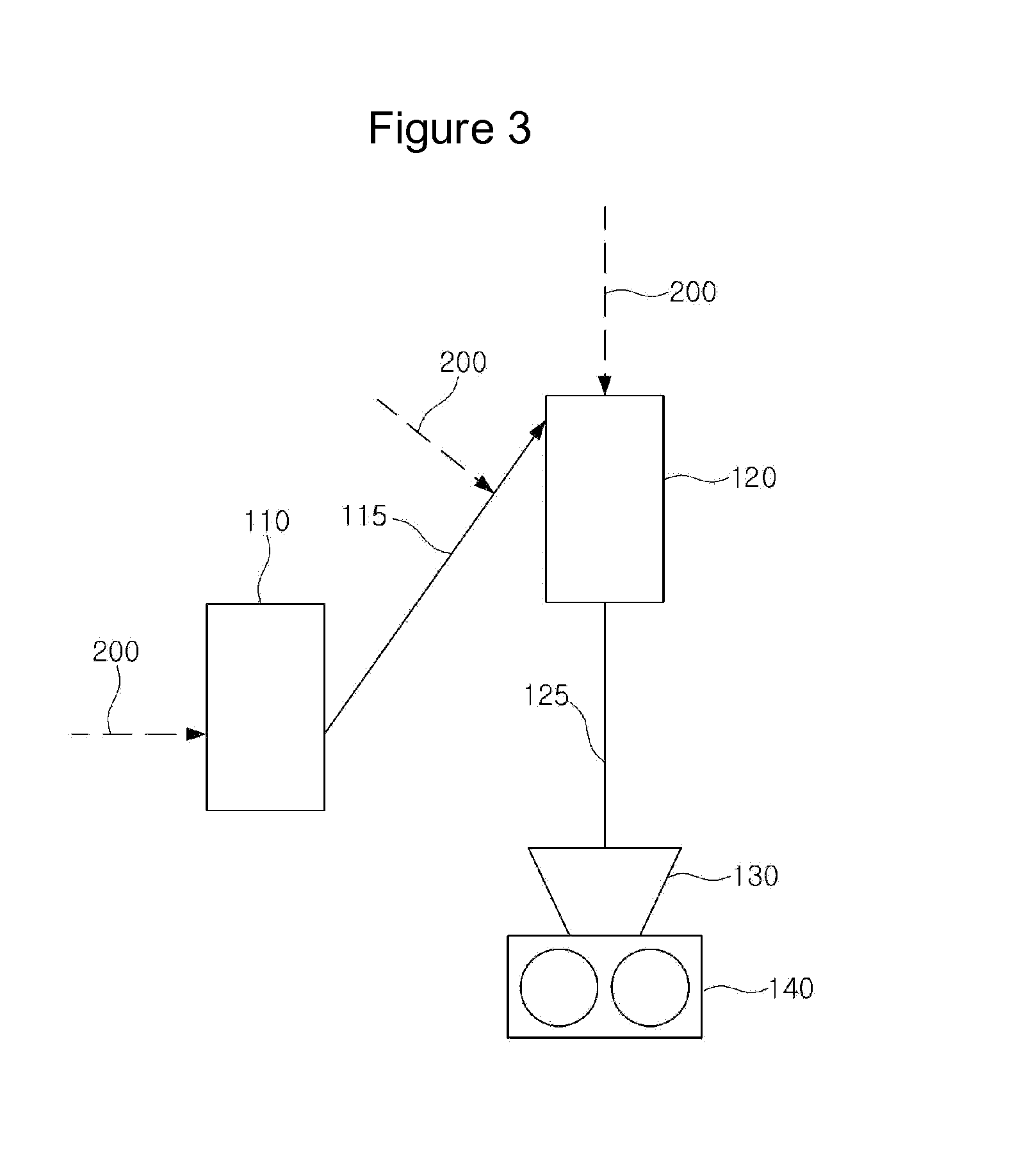

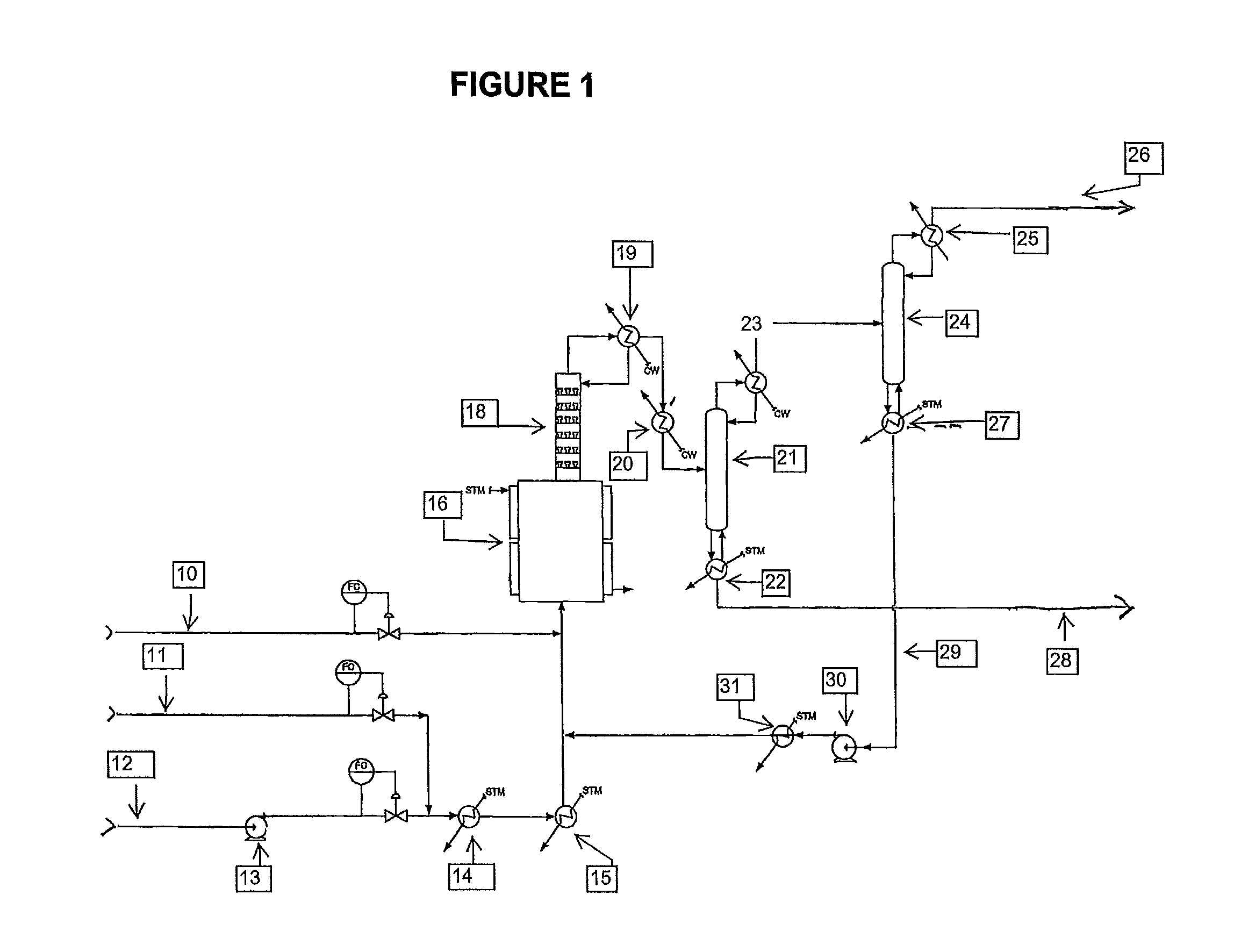

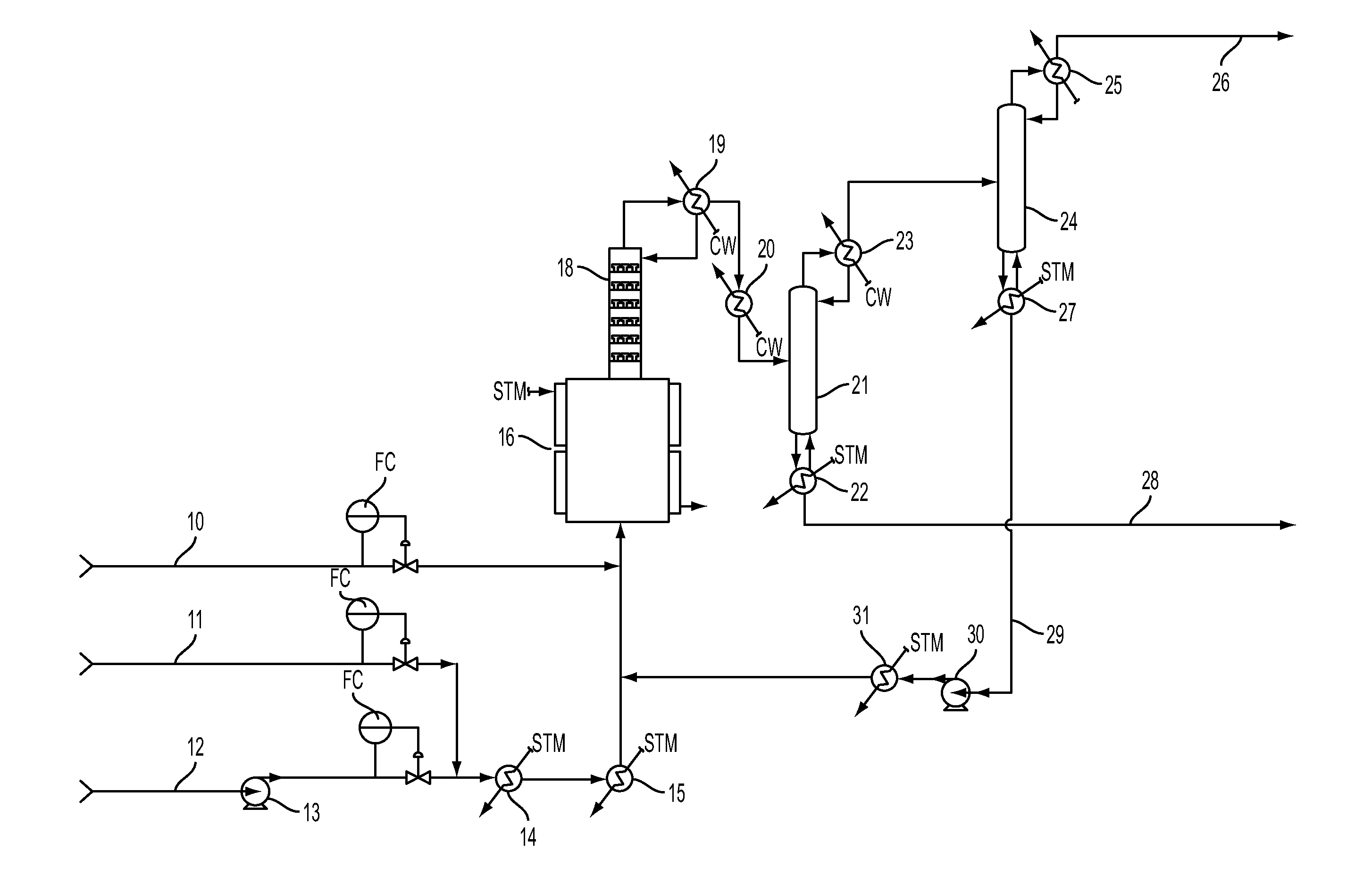

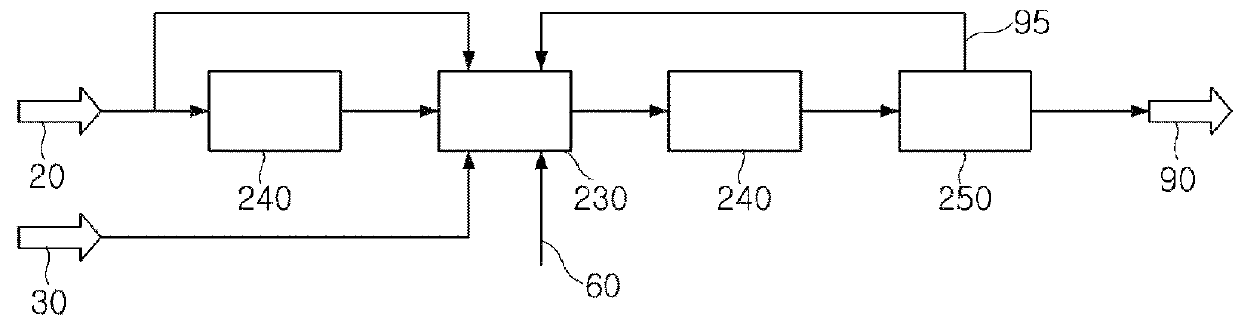

Method for generating polycrystalline silicon by recycling by-products

The invention provides a method for generating polycrystalline silicon by recycling by-products. The method adopts a technological process comprising: purifying SiHCl3 raw material to generate SiHCl3 concentrate, reducing the SiHCl3 concentrate by H2 in a reducing furnace to generate the polycrystalline silicon and the by-products which comprise HC1, H2, SiCl4, SiHCl3 and SiH2Cl2, freezing and recycling the by-products to obtain condensate which comprises SiCl4, SiHCl 3 and SiH2Cl2 and gas which consists of HCL and H2, processing the gas to obtain H2 and conveying H2 to the reducing furnace to perform the hydrogen reduction reaction, wherein the method for processing the gas which consists of HCL and H2 comprises the steps of reacting the gas with silicon powders to give SiHCl3 and using the generated SiHCl3 as the SiHCl3 raw material; and allowing the condensate which comprises SiCl4, SiHCl3 and SiH2Cl2 circularly to enter the reducing furnace to undergo the hydrogen reduction reaction. The method provided by the invention for generating the polycrystalline silicon can improve use efficiency of the raw materials, reduce pollution and improve purity and quality of the product.

Owner:EXCELLENCE INTEGRITY GROUP

Method for recycling by-products in metronidazole production process

InactiveCN107325054AReduce dosageIncrease profitOrganic chemistryChemical industryEthylene oxideEther

The invention discloses a method for recycling by-products in a metronidazole production process, and solves problems that by-products such as ethylene glycol and ethers thereof are not used frequently and pollute the environment, and the utilization rate of ethylene oxide is low in prior art. In the method disclosed by the invention, the by-products such as ethylene glycol and ethers thereof generated in metronidazole synthesis process are recycled, measures for reducing the use amount of a formic acid solvent, increasing the concentration of formic acid and sulfuric acid, and the like are adopted, and the bring-in amount of water is reduced, so that the utilization rate of ethylene oxide is increased. In the method, the by-products such as ethylene glycol and ethers thereof are partially used as the solvents, so that the use amount of the formic acid solvent is reduced, the utilization rate of ethylene oxide is increased, and a problem of waste liquid pollution is also solved.

Owner:HUANGGANG NORMAL UNIV

Continuous preparation method of herbicide intermediate of 2, 4-dichlorophenol

InactiveCN102659530AReduce labor intensityEmission reductionOrganic chemistryOrganic compound preparationDichlorophenol2,4-Dichlorophenol

The invention provides a continuous preparation method of an herbicide intermediate of 2, 4-dichlorophenol. The method includes the steps of continuously and reversely feeding phenol and chlorine gas in a mass ratio of 1: (1.4-1.5), subjecting fed materials to continuous chlorination reaction through a multistage chlorination tower, enabling reacted liquid materials to flow into a 2, 4-dichlorophenol receiving tank, and recycling the gas with water through a tail gas absorption tower. The continuous preparation method replaces existing batch type mode to prepare the intermediate 2, 4-dichlorophenol of 2, 4-D acid, operation is simple, safety of preparation is controllable, discharge of three wastes is reduced, power consumption is reduced, and unit time output is increased. Simultaneously, the preparation can further improve yield of products, and recycle by-product acid with concentration of 30.5% during the reaction.

Owner:荆州沙隆达控股有限公司

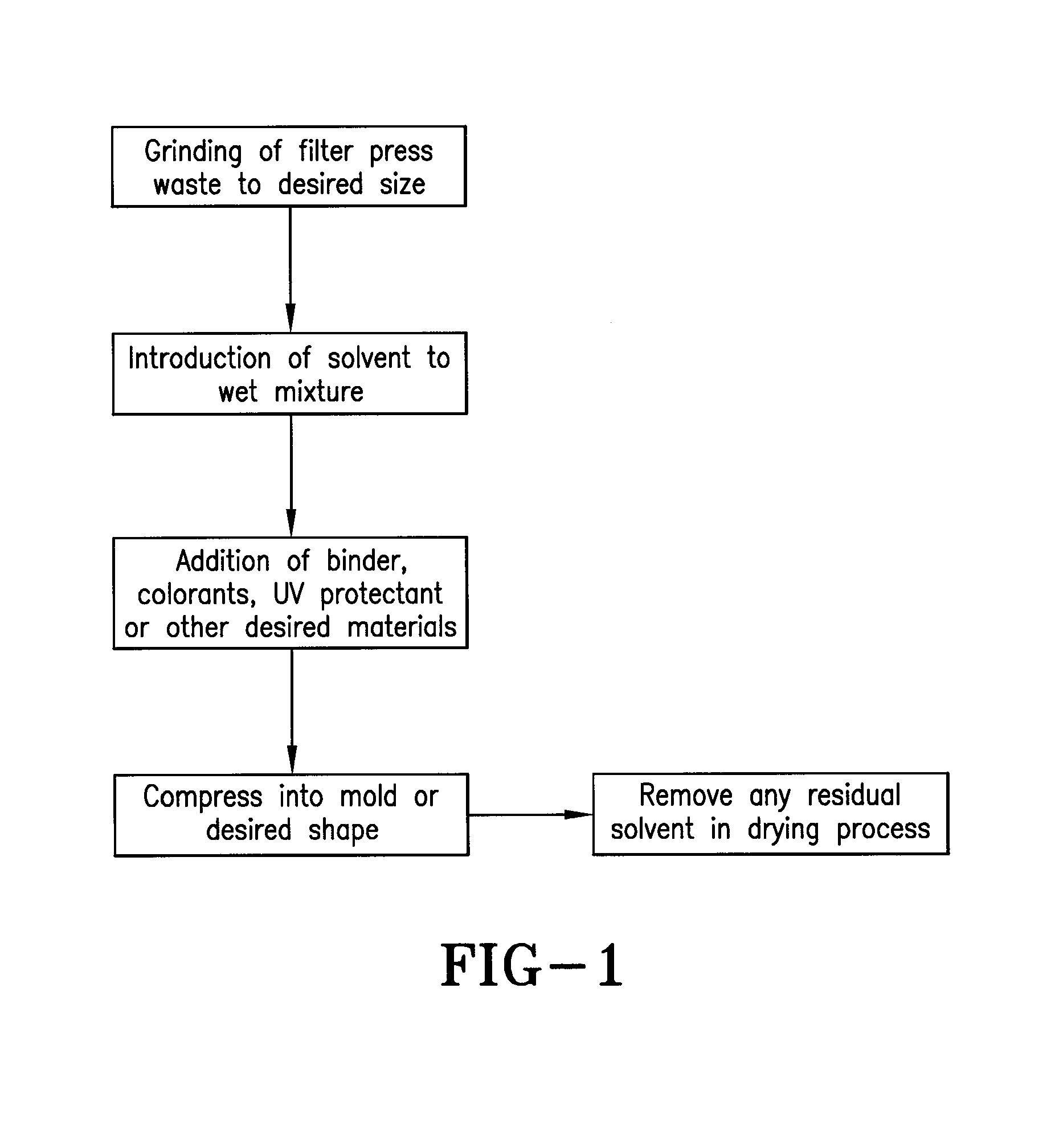

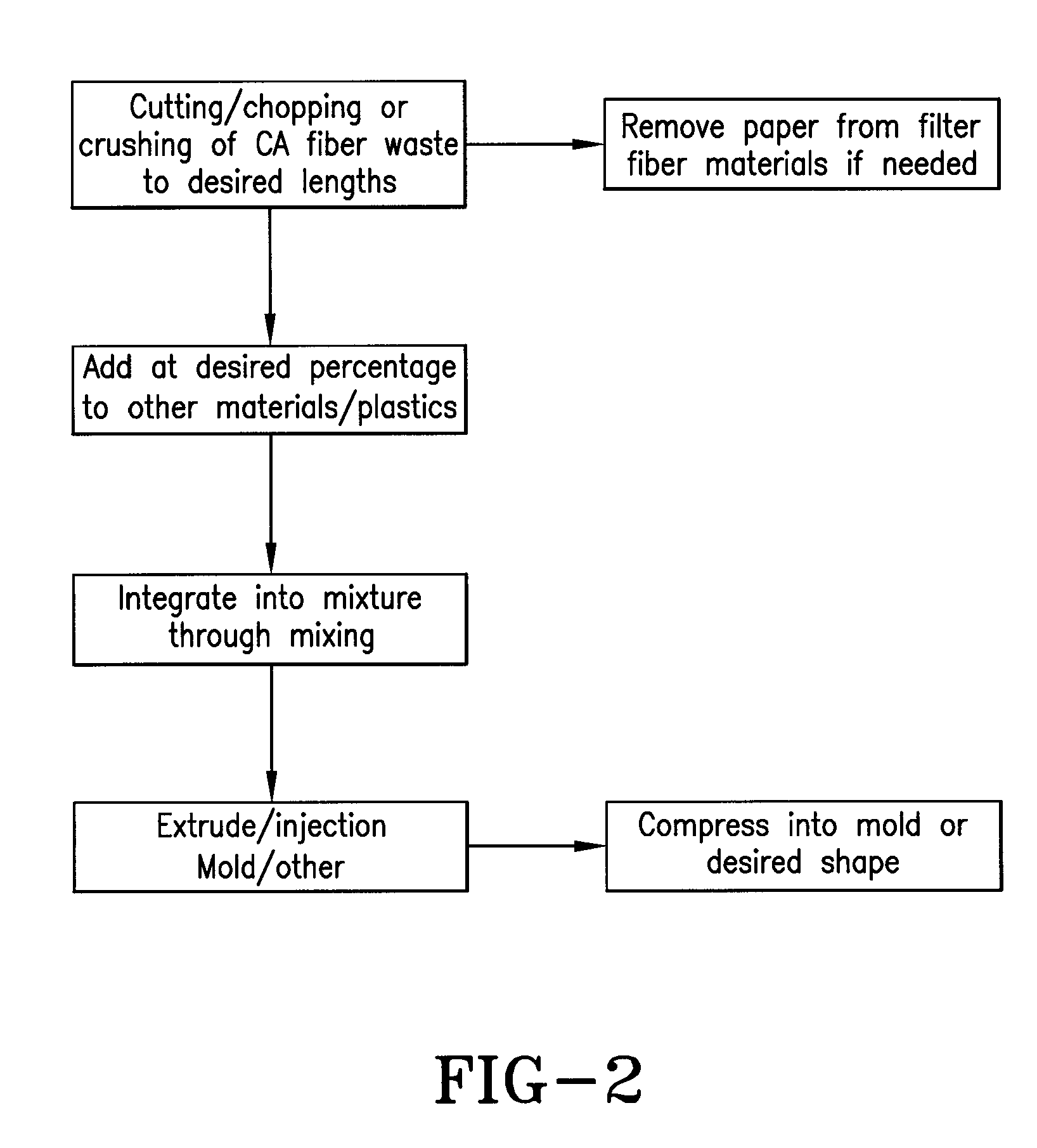

Process and Method for Cellulose Acetate Manufacturing Waste Product Recycling

InactiveUS20140287144A1Eliminate weightIncrease fuel consumptionPlastic recyclingPretreated surfacesCigarette buttCellulose acetate

The present invention is directed to processes and methods for recycling the waste products from the manufacture of cellulose acetate materials, using the example of cigarette butt manufacturing, in this case, but also applies to cellulose acetate production for other materials. Once the cellulose acetate containing materials are processed, they may be acceptable for use in a multitude of applications from insulation to reinforcements and decorative pieces.

Owner:BURICH BLAKE +1

Technique for recycling reject magnetic materials

InactiveCN102751066AIncrease production value and profitSimple manufacturing processInorganic material magnetismInductances/transformers/magnets manufactureSpray GranulationMetallurgy

The invention discloses a technique for recycling reject magnetic materials. The technique comprises the steps: conducting classification, impurity removal and grinding treatments on the reject magnetic materials, thus obtaining magnetic core fine powder with average particle size of no more than 2mum; adding raw magnetic materials with10-30% of total weight of magnetic core fine powder contained in a stirring pond, as well as PVA glue with 8-12% of total weight of magnetic core fine powder and the raw magnetic materials, regulating the formula of mixture of the magnetic core fine powder and the raw magnetic materials according to the properties of the needed magnetic material products, and evenly stirring, and conducting spray granulation into granulated powder with granularity of 40-160 meshes; conditioning to obtain finished granulated powder with moisture content of 0.3-0.5% and flowing angel smaller than 30 degrees, pressing into the needed magnetic material products, and conducting low-temperature sintering treatment under conditions of temperature of 1200-1280 DEG C. The technique has the advantages of being capable of realizing energy resources and being good in environment friendliness and economic benefit.

Owner:JIANGSUSR MAGNETIC MATERIAL & DEVICE ENG TECH RES

Preparation technology of furfural

InactiveCN106146441AHigh flow channel volume ratioExtended stayOrganic compound preparationChemical/physical/physico-chemical stationary reactorsAcetic acidFurfural

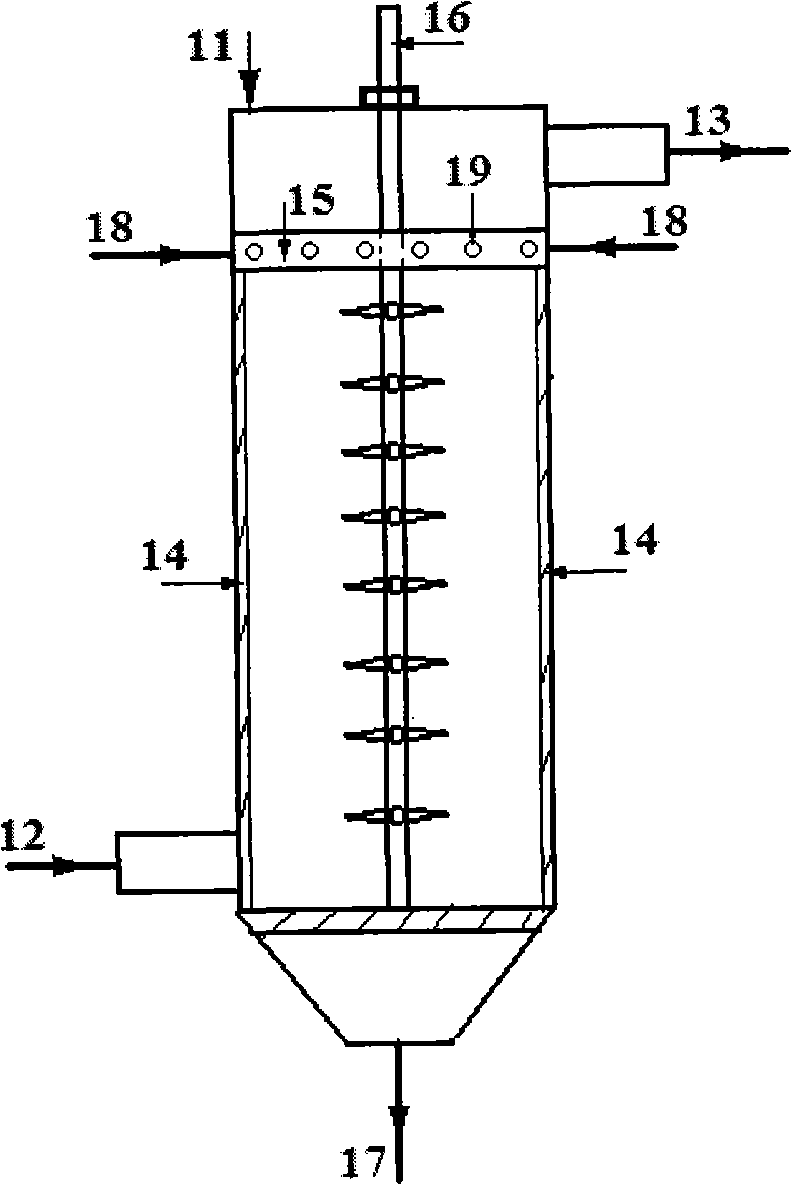

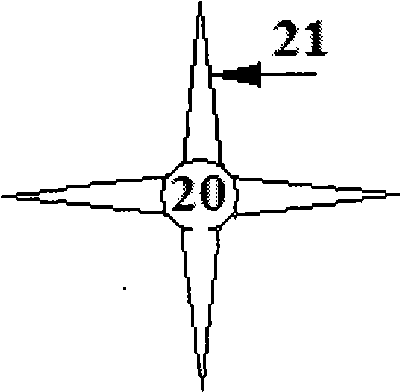

The invention discloses a novel technology for efficiently producing furfural and simultaneously recycling by-products including methanoic acid and acetic acid. An impinging stream reactor which is especially suitable for the technology is adopted, fluid mixing is achieved through multiple times of impinging, a good micromixing effect is achieved, mixed liquid flows outside an impinging area in a plug-flow mode, sufficient staying time is provided for materials, cascaded reacting is achieved, and the target conversion rate is achieved through flow channel and liquid flow rate design. According to the technology, the defect that an existing impinging stream reactor cannot achieve the high conversion rate through a single reactor is overcome, the technology procedures are simplified, production cost and equipment investment are reduced, and long-period running of equipment is guaranteed; no waste liquid is drained in the production process, and a green and environment-friendly technology method is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

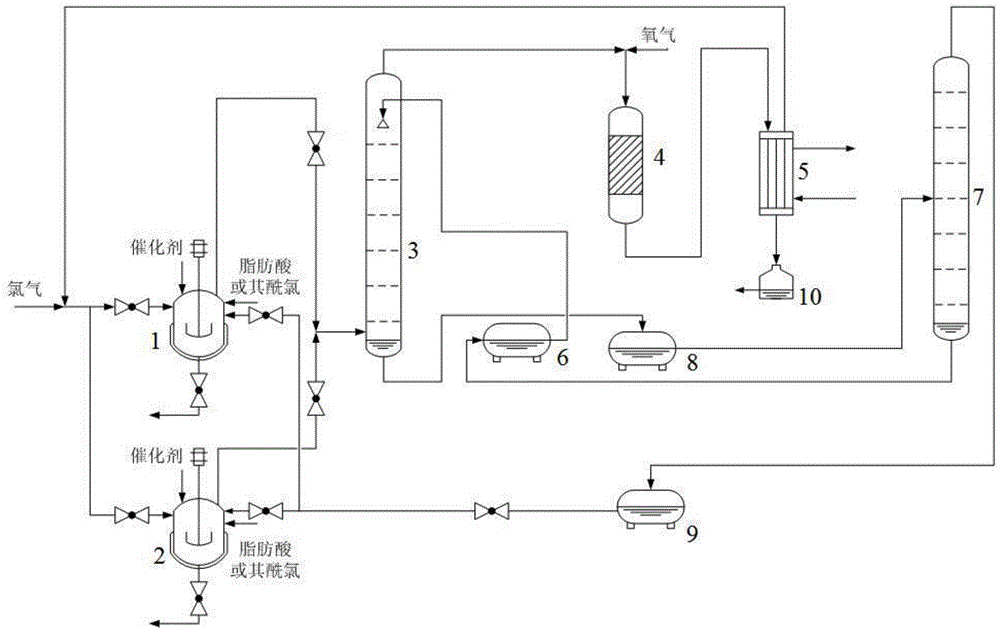

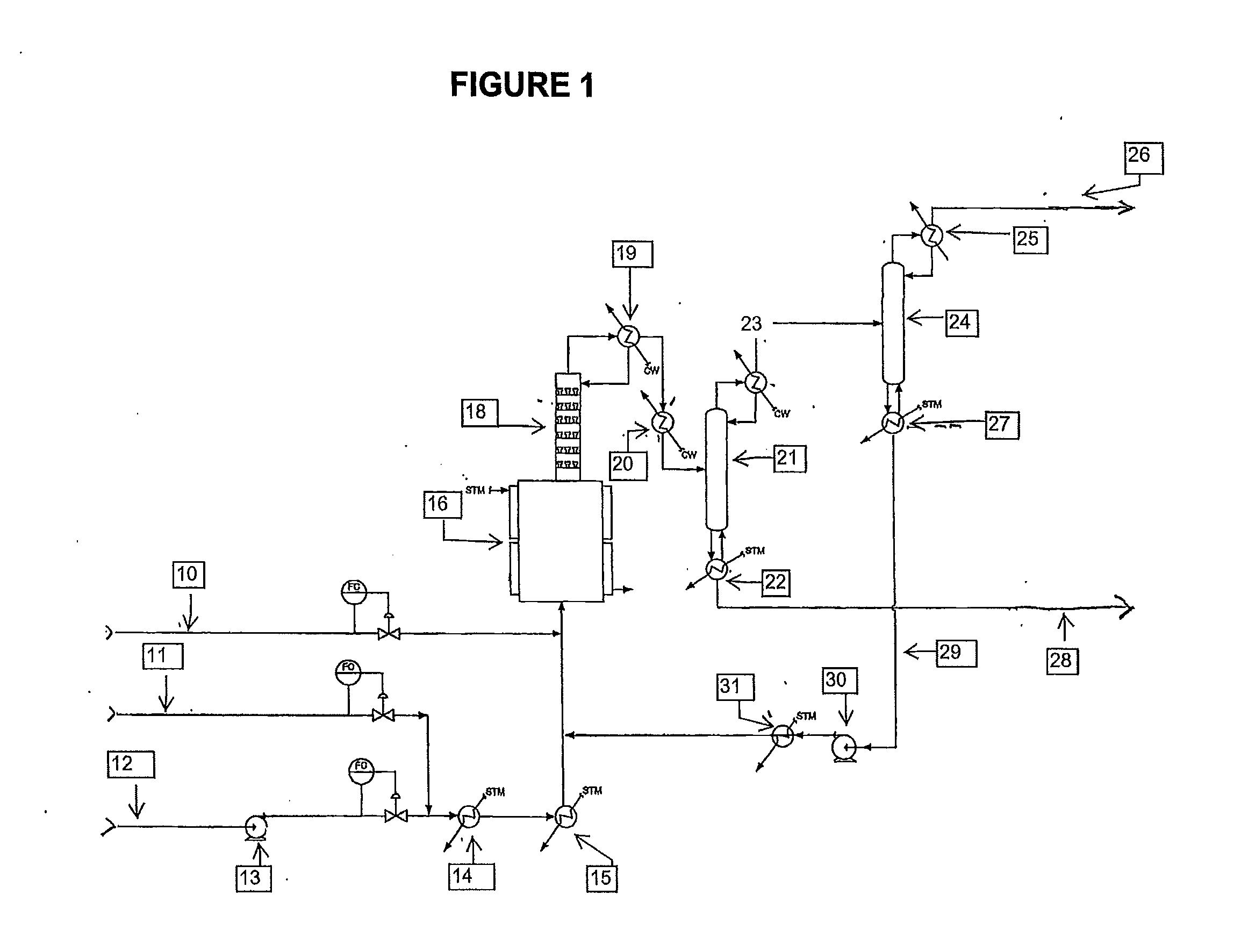

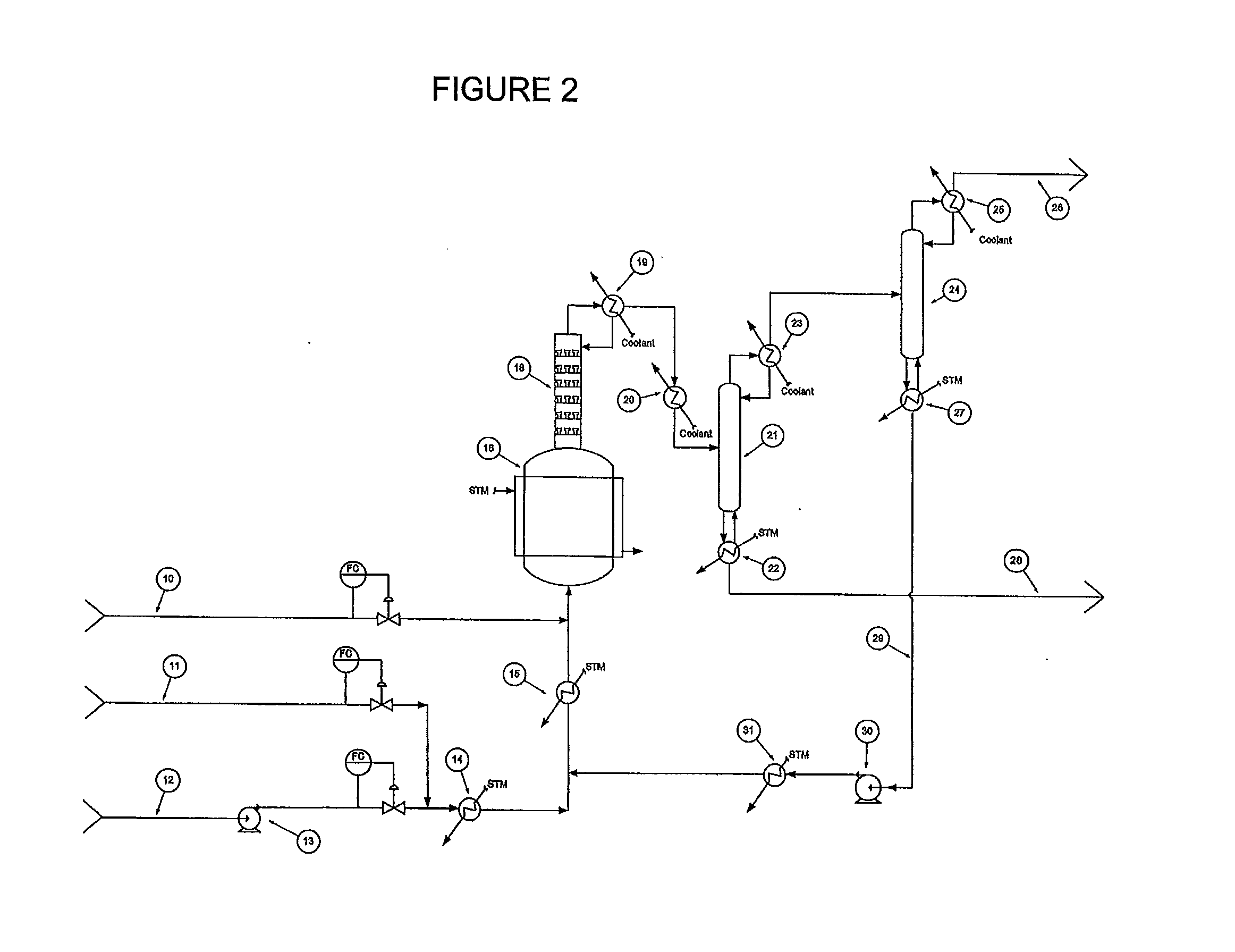

Method and system for recycling by-product hydrogen chloride in fatty acid or fatty acyl chloride chlorination production process

ActiveCN105480948AEliminate cumbersome proceduresSimple process routeChlorine/hydrogen-chloride purificationOrganic compound preparationCatalytic oxidationOxygen

The invention discloses a method for recycling the by-product hydrogen chloride in the fatty acid or fatty acyl chloride chlorination production process. The method includes the steps that the by-product hydrogen chloride waste gas generated in a chlorination reaction of fatty acid or acyl chloride thereof is introduced into a hydrogen chloride purification tower from the lower portion of the hydrogen chloride purification tower and makes countercurrent contact with absorption liquid in the hydrogen chloride purification tower, and organic impurities in the hydrogen chloride waste gas are adsorbed and removed with the absorption liquid; the hydrogen chloride waste gas obtained after absorption purification and oxygen are subjected to a catalytic oxidation reaction under the action of an oxidation catalyst; mixed gas obtained after the oxidation reaction of hydrogen chloride passes through chilled brine, and the mixed gas obtained after chilled dehydration is subjected to catalytic chlorination with fresh chlorine and fatty acid or acyl chloride thereof directly so as to produce chlorinated aromatic hydrocarbons; the hydrogen chloride waste gas containing organic impurities enters the hydrogen chloride purification tower from the lower portion of the hydrogen chloride purification tower to be subjected to absorption purification again. By means of the method, the tedious processes of conducting compression chilling and the like for separating oxygen after hydrogen chloride is oxidized are omitted, the technological route is shortened, and the equipment investment cost can be greatly reduced.

Owner:NANTONG TIANSHI CHEM

Method for recycling by-product 2-ethylacraldehyde from reaction process of preparing trimethylolpropane by condensing and hydrogenating method

InactiveCN102304022AHigh economic utilizationSimple methodOrganic compound preparationHydroxy compound preparationTrimethylolpropaneRecycling by product

The invention discloses a method for recycling a by-product 2-ethylacraldehyde from a reaction process of preparing trimethylolpropane by a condensing and hydrogenating method. The method comprises the following steps of: taking the main by-product 2-ethylacraldehyde (EA) generated at a condensation stage of aldol in trimethylolpropane prepared by condensing and hydrogenating method as the raw material; separating and reacting the raw material with formaldehyde under the alkaline condition; and finally, obtaining trimethylolpropane (TMP). According to the invention, more than 90% of the EA can be basically transformed and the selectivity of the generated TMP is more than 90%; the method improves the economic utilization of the raw material and the reaction cost is reduced as well. The method provided by the invention also can directly utilize the commercial grade EA and formaldehyde to react under the alkaline condition so that the EA can be transformed into TMP.

Owner:SHANGHAI HUAYI GRP CO

PROCESS TO MANUFACTURE 2-CHLORO-1,1,1,2-TETRAFLUOROPROPANE (HCFC-244bb)

ActiveUS20150225317A1Well mixedIncrease pressurePreparation by dehalogenationPreparation by hydrogen halide split-offBoiling pointEthyl Chloride

The invention relates to a process to produce HCFC-244bb from HCFO-1233xf wherein, in one embodiment, one or more co-feed species having a normal boiling point of between about −80° C. to about 0° C., such as HFC-245cb, is added to the reaction at a pressure of at least about 100 psig; and in another embodiment it is added to maintain a mole ratio of HFC-245cb to HCFO-1233xf of between about 0.005:1 to about 1:1. The HFC-245cb may be added as recycled by-product of the reaction and / or added as fresh feed. The HFC-245cb provides elevated pressures to the reaction thereby facilitating reactor operation, mixing and HCFC-244bb product removal. Other co-feed species are also disclosed.

Owner:HONEYWELL INT INC

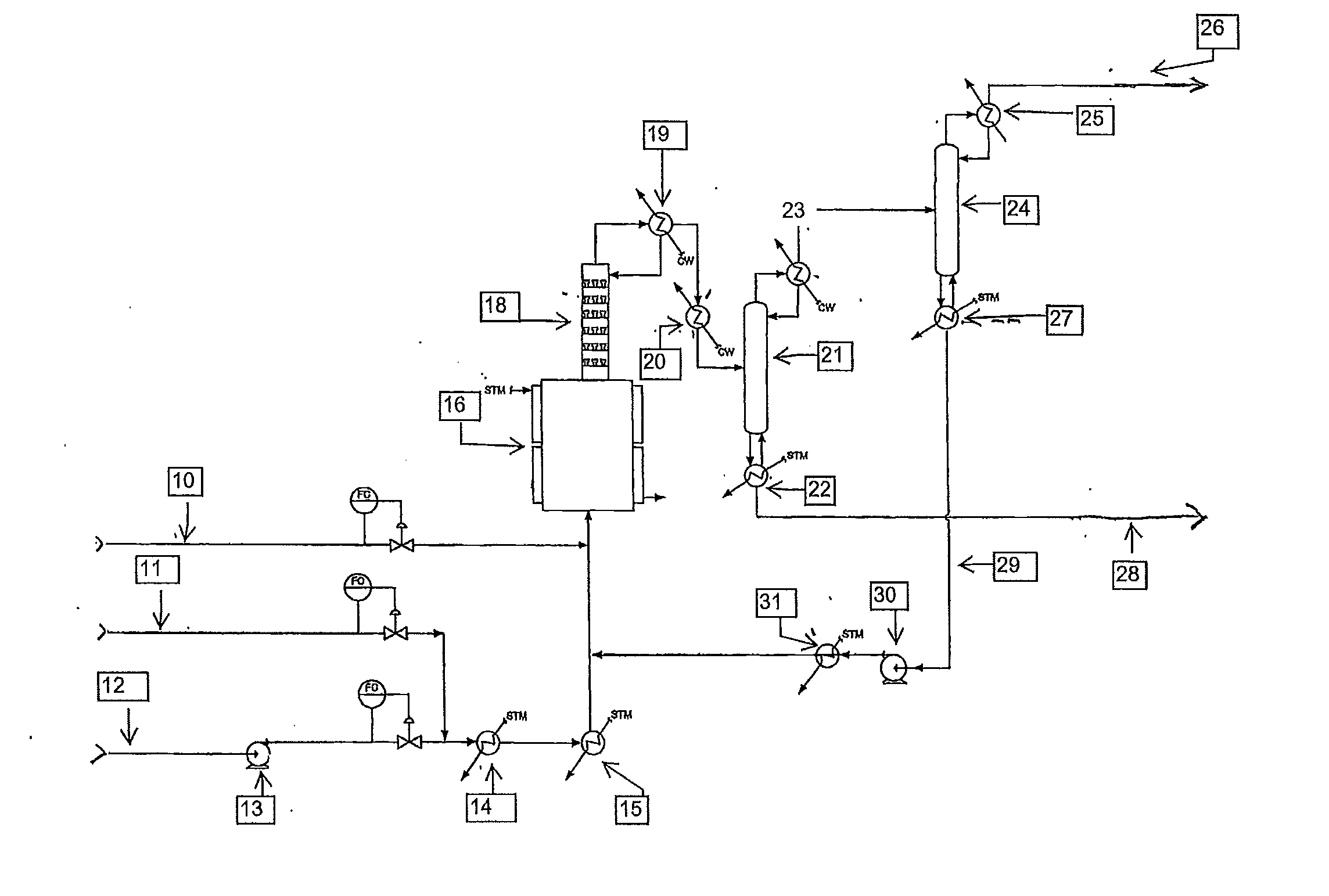

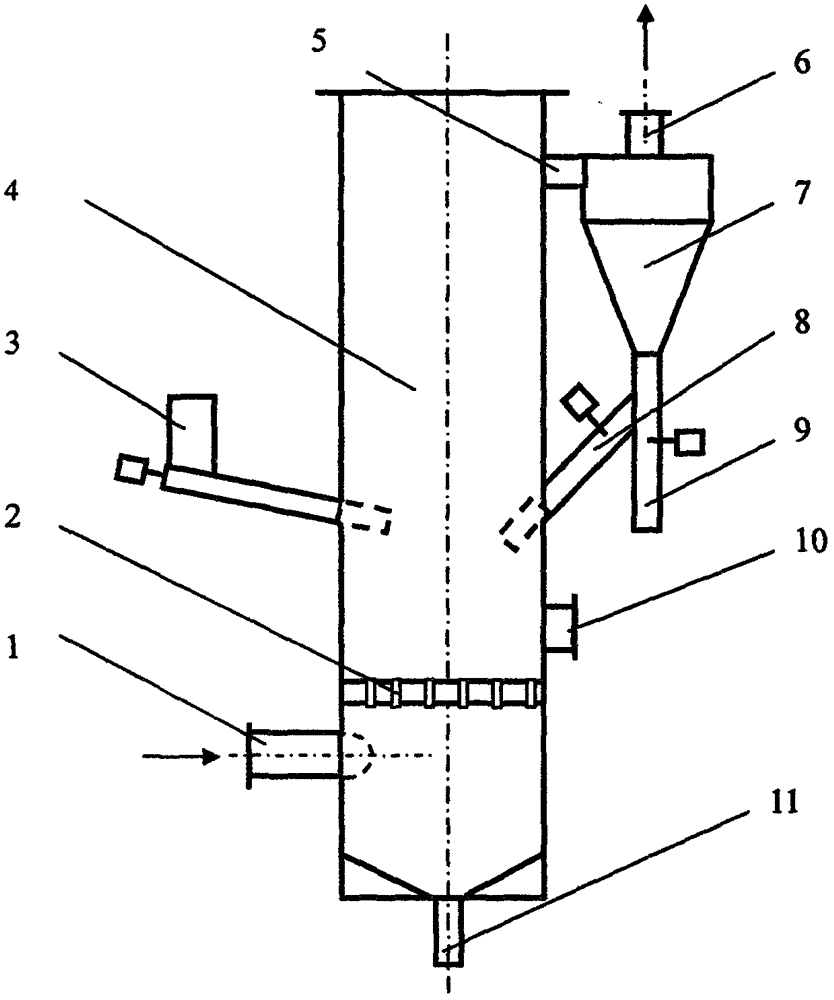

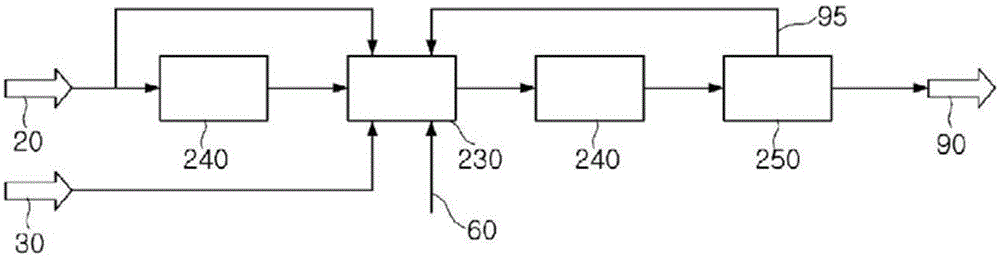

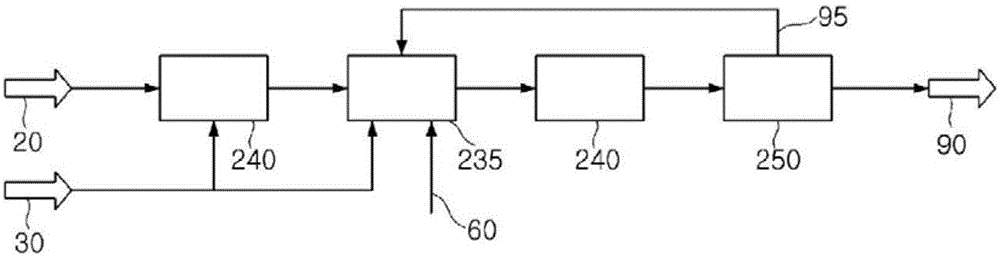

A Heat Pump Evaporation Process for Recycling and Utilizing Byproducts of Flue Gas Purification

ActiveCN104496101BReduce consumptionSave raw steamHeat recovery systemsEnergy inputCirculator pumpEvaporation

The invention provides a heat pump evaporation process for recycling flue gas cleaning byproducts. The process is characterized by comprising the following steps: feeding waste liquor subjected to wet cleaning into a reactor to have reaction with ammonium bicarbonate; after the reaction is finished, carrying out solid-liquid separation on feed liquid, cooling and crystallizing liquid to obtain clear liquid serving as raw material liquid, pumping the raw material liquid into a preheater, feeding the preheated raw material liquid into a heat exchanger, heating the raw material liquid by using shell pass steam in a tube pass of the heat exchanger so that the temperature of the raw material liquid is increased; pushing the raw material liquid into a crystal separator by using a forced circulation pump, performing flash evaporation in the crystal separator so that the raw material liquid is supersaturated and crystallized to obtain ammonium salt crystals which can be recycled; compressing secondary steam (generated by flash evaporation) by a compressor and feeding the compressed secondary steam serving as a heat source into the shell pass of the heat exchanger. The process is particularly suitable for processing sodion waste liquid generated after flue gas desulfurization and denitration and the aims of changing waste material into things of value is achieved and steam consumption is reduced.

Owner:CHENGDU HUAXITANG INVESTMENT

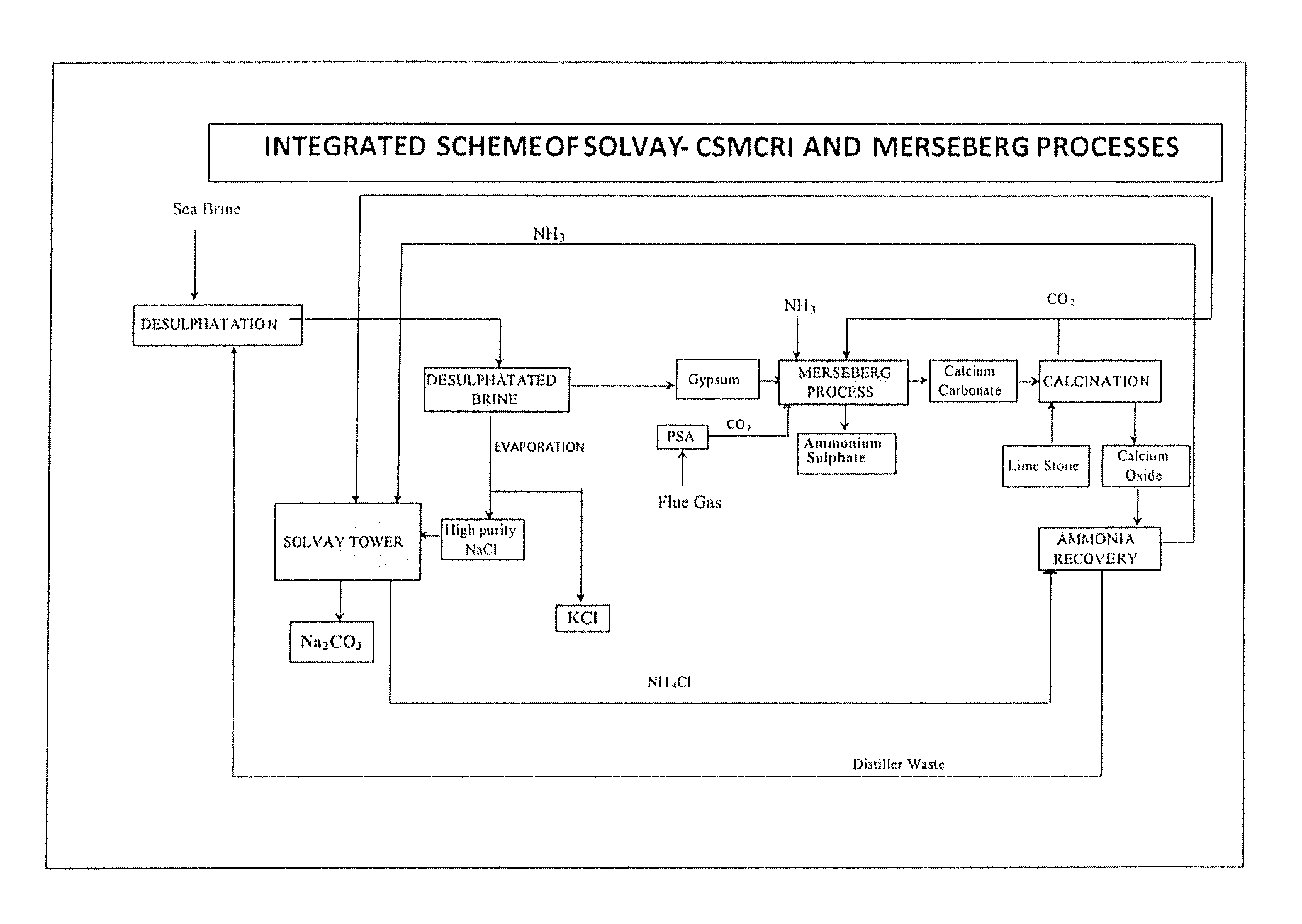

Method of recycling of by-products for the production of soda ash and ammonium sulphate

InactiveUS9193601B2Lower requirementEasy dischargeAmmonium sulfatesCarbonate preparationSolvay processCalcination

A method of producing soda ash and ammonium sulphate by recycling by-products of Merseberg and Solvay processes includes treating brine with soda ash distiller waste for desulphatation of the brine to obtain gypsum, recovering pure salt from the desulphated brine and utilizing it in manufacture of soda ash in a Solvay process, washing the gypsum and reacting it with liquor ammonia and carbon dioxide to obtain CaCO3 and ammonium sulphate, separating the CaCO3 from the ammonium sulphate solution and recovering solid ammonium sulphate, washing the CaCO3 followed by calcination to generate CO2 and lime, recycling the CO2 in the Solvay process to obtain soda ash, recycling the lime with ammonium chloride generated in the Solvay process to recover ammonia and obtain distiller waste containing CaCl2 as a by-product, recycling the by-product distiller waste for the desulphatation of the brine, and recycling the ammonia recovered.

Owner:COUNCIL OF SCI & IND RES

Processing method of dried shrimp meat floss with low allergy

The invention provides a hypoallergenic processing method of dried shrimp floss, which comprises the following steps: the first step is to remove the shrimp shells to collect the shrimp meat, soak the shrimp meat in seasoning liquid, take it out after 30 to 40 minutes and place it in a water-proof steamer. In the pot, spray a layer of seasoning liquid on the surface of the shrimp meat, heat until the water boils and cook for 30-40 minutes to obtain cooked shrimp meat, and spray the seasoning liquid on the surface of the shrimp meat every 10 minutes during the cooking period; the second step is to cook the shrimp meat. The prepared shrimp meat is baked in an oven until 50% dry, taken out and naturally cooled to room temperature, and then shredded along the texture of the meat to obtain minced shrimp meat. Put the minced shrimp meat, minced mushrooms, minced garlic, and minced onion on the Grinding in a cooking machine to obtain a pulverized product; in the third step, putting the pulverized product in a frying pan and frying it dry on low heat to obtain the hypoallergenic shrimp floss. The invention recycles the by-products of pork skin and hoof tendons to make minced skin, which is used as an additive of the meat floss, thereby greatly improving the quality of the meat floss.

Owner:颜强

Method and device for removing harmful gas

InactiveCN105944554ATo achieve the purpose of purificationLow costDispersed particle separationChemical reactionAcyl group

The invention discloses a method and device for removing harmful gas, and belongs to the technical field of air pollution control and environmental protection. Volatile organic matters such as alcohol, amine, acyl matters, ketone, aldehyde and ester in airflow and inorganic maters including hydrogen sulfide, ammonia and the like are removed. The method comprises the processing steps that airflow containing harmful gas is introduced into a gas-solid reactor, calcium chloride solid particles at the certain temperature are introduced into the gas-solid reactor, the certain gas-solid reaction temperature is controlled, harmful gas in the airflow is subjected to a gas-solid adsorption chemical reaction with a calcium chloride in the gas-solid reactor, and a solid product is generated, so that the purpose of purifying gas is achieved, and the solid product is heated and regenerated. The invention further discloses a special device, and has the advantages of being low in investment cost and operation cost, capable of recycling by-products, easy to operate, and high in processing efficiency.

Owner:黄立维

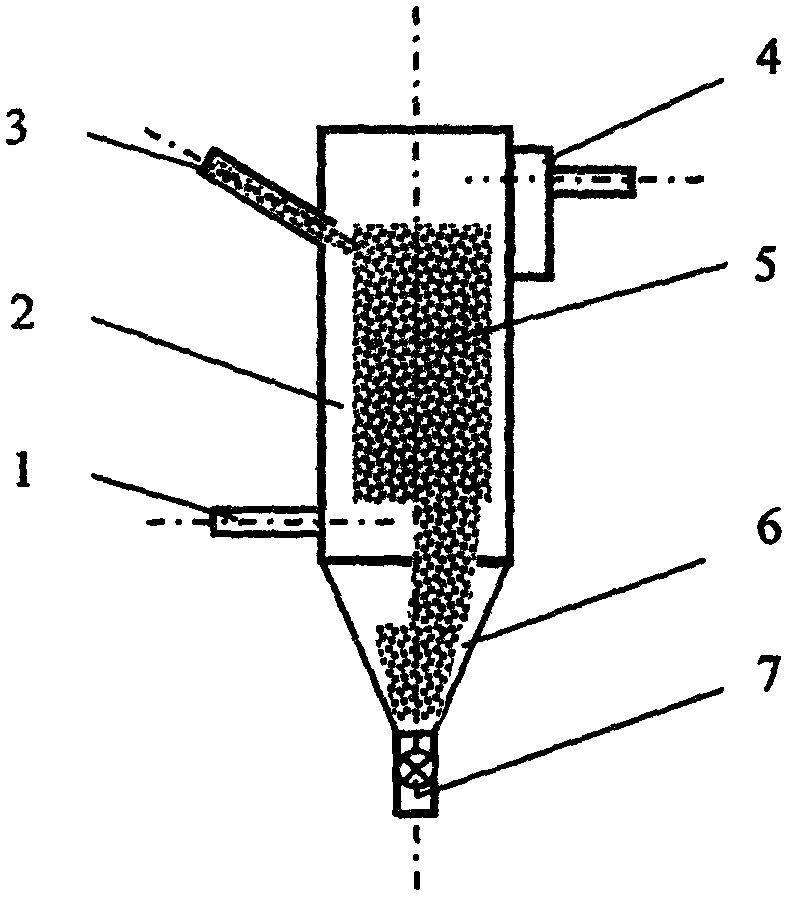

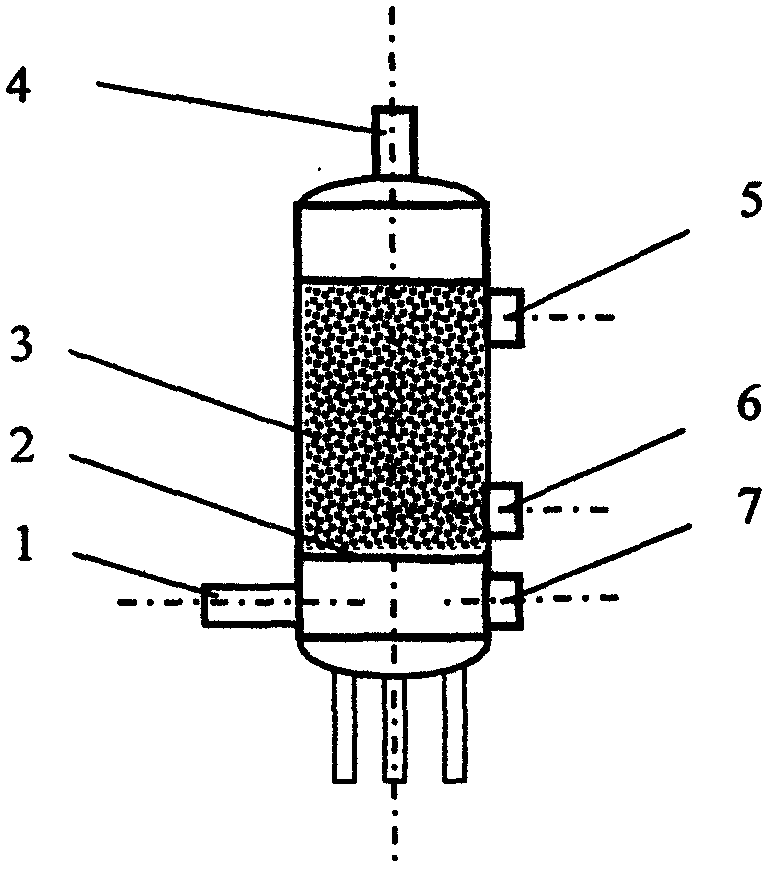

Method for recycling iron-containing by-products discharged from coal-based molten ironmaking process, system therefor, and reduced iron agglomeration system

ActiveUS20160024611A1Effectively agglomeratedReduced ironFluidised-bed furnacesProcess efficiency improvementSludgeFerric

There is provided a method and system for recycling by-products containing large amounts of useful components and discharged in the form of dust and sludge from a coal-based molten iron making process to reuse the by-products in a reduced iron agglomeration process. The system includes: a fluidized reduction furnace reducing fine iron ore; a reduced iron tank connected to the fluidized reduction furnace through a reduced iron discharge pipe for storing the reduced iron and supplying the reduced iron in an agglomeration system; an agglomeration system agglomerating the reduced iron transferred from the reduced iron tank; and a transfer unit transferring compactions of by-products discharged from a molten iron making process through a by-product supply pipe. The compactions of the by-products are supplied to at least one selected from the group consisting of the fluidized reduction furnace, the reduced iron supply pipe, and the reduced iron tank.

Owner:POHANG IRON & STEEL CO LTD

Method for preparing paint raw material from paint waste residue

ActiveCN102558938BReduce contentReduce mass ratioPlastic recyclingPolyurea/polyurethane coatingsSolid componentOrganic solvent

The invention discloses a method for preparing a paint raw material from a paint waste residue, and the method comprises the following steps of: preprocessing the paint waste residue, classifying, removing impurities, then adding an additive and a protecting agent, and uniformly dispersing; sending the preprocessed paint waste residue to an organic waste recycling system, setting a proper temperature and then carrying out separation modification; recycling solid components to form thick plaster-shaped modified resin and packaging; collecting mixed steam of a solvent and water through gas and then condensing so as to separate gas from liquid, carrying out tail gas purification on the gas part and discharging the gas part when the gas part reaches the standard, carrying out oil-water separation on the liquid part to ensure that water is separated from the solvent, collecting the solvent for concentrated utilization, and carrying out wastewater treatment on the water and then discharging when the gas part reaches the standard. A large quantity of organic solvent is not adopted in the method, water can be well separated from the paint waste residue, and the prepared paint raw material has the advantages of lower organic solvent content, lower danger and the like, thus the paint raw material can be safely used in various medium- and low-end coating raw materials.

Owner:NANJING ENVIRO TECH ENVIRONMENTAL TECH & DEV

Method for preparing iron oxalate

InactiveCN101717331ASolve intractableHigh economic valueCarboxylic acid salt preparationSulfateDissolution

The invention relates to a method for preparing iron oxalate, belonging to the field of chemical engineering. The method for preparing iron oxalate can recycle by-product of copperas generated when preparing titanium pigment with titanium concentrate. The method for preparing iron oxalate takes the by-product of copperas generated when preparing the titanium pigment with the titanium concentrate as raw materials, and comprises the following steps of: a. adding water to the copperas for dissolution to obtain a ferrous sulfate solution, adjusting pH value to be 5.6 to 6.5 by utilizing ammonia, filtering the solution; b. extracting the filtrate by utilizing P2O4, separating the filtrate to obtain an organic phase and a water phase; c. and adding a solution containing F to the water phase so as to deposit Mg<2+>, filtering the solution, adding an oxalic acid solution to the filtrate, and filtering the solution to obtain iron oxalate crystallization. The invention not only solves the problem of stacking the copperas, but also enhances the economic value of the copperas, provides a new choice for treating the by-product of copperas generated when preparing titanium pigment with a sulfuric acid method, and has wide application prospect.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

Process to manufacture 2-chloro-1,1,1,2-tetrafluoropropane (HCFC-244bb)

ActiveUS9233895B2Well mixedLittle or no unwantedPreparation by dehalogenationPreparation by hydrogen halide split-offBoiling pointEthyl Chloride

The invention relates to a process to produce HCFC-244bb from HCFO-1233xf wherein, in one embodiment, one or more co-feed species having a normal boiling point of between about −80° C. to about 0° C., such as HFC-245cb, is added to the reaction at a pressure of at least about 100 psig; and in another embodiment it is added to maintain a mole ratio of HFC-245cb to HCFO-1233xf of between about 0.005:1 to about 1:1. The HFC-245cb may be added as recycled by-product of the reaction and / or added as fresh feed. The HFC-245cb provides elevated pressures to the reaction thereby facilitating reactor operation, mixing and HCFC-244bb product removal. Other co-feed species are also disclosed.

Owner:HONEYWELL INT INC

Method and device for recycling by-product hydrochloric acid in methane fluorine compound production

InactiveCN106672905AImprove qualityReduce pollutionChlorine/hydrogen-chloride purificationHalogenated hydrocarbon separation/purificationEnergy consumptionMixed gas

The invention discloses a method for recycling by-product hydrochloric acid in methane fluorine compound production. The method comprises the following steps: step one, extracting HF in mixed gas in fluoridation by using concentrated hydrochloric acid of which the mass concentration is 30 to 35 percent; step two, absorbing HCl in the extracted mixed gas through a falling film absorber, thus preparing the by-product hydrochloric acid; step three, carrying out water washing and alkali washing treatment on residual gas, and entering follow-up equipment, thus obtaining a methane fluorine compound. The method disclosed by the invention can be executed under normal temperature and normal pressure, the energy consumption is small, economy and effectiveness are realized, and the purity of the recycled hydrochloric acid is high.

Owner:JIANGSU SANMEI CHEM

Method for preparing byproduct N-benzylphthalimide during preparation of mono-propargylamine

InactiveCN101597232AReduce pollutionHigh yieldChemical recyclingAmino preparation by functional substitutionSolventBenzylamine

The invention provides a method for preparing byproduct N-benzylphthalimide during the preparation of mono-propargylamine. The method comprises the following steps: reacting N-propinyl-phthalimide with high boiling amine at 160-180 DEG C by using amine salt as catalyst, collecting the fraction at 80-85 DEG C, namely, propargylamine, recycling benzylamine from the reaction solution, and then recycling byproduct N-benzylphthalimide from the obtained solution by recrystallisation. The beneficial effect of the invention is as follows: solvent is not used; the yield is high; and compared with existing methods, the method for recycling by-product N-benzylphthalimide through recrystallisation reduces the cost greatly and decreases the environmental pollution.

Owner:夏成才

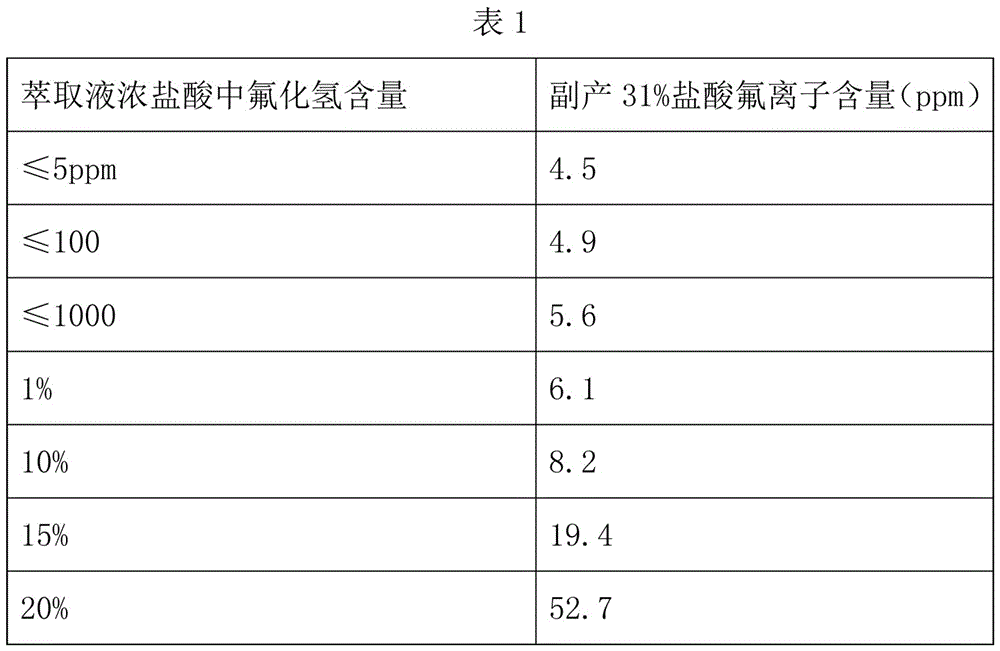

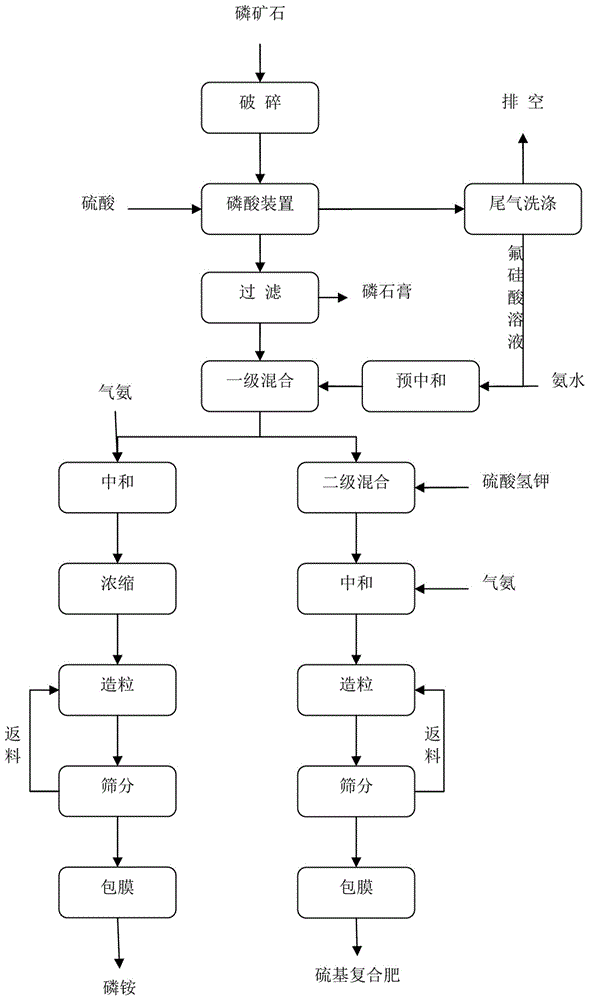

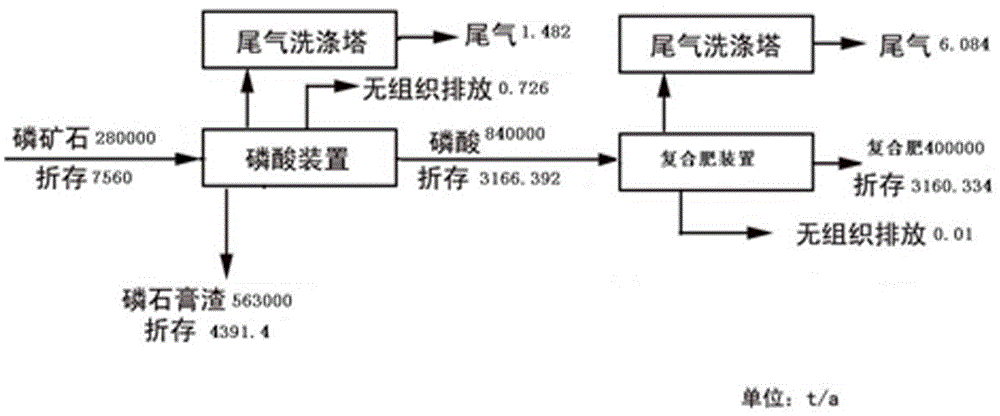

Technology for recycling by-product fluosilicic acid of wet process phosphoric acid

InactiveCN107522519ALess corrosiveReduce volatilityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersEcological environmentHydrogen Sulfate

The invention relates to a technology for recycling a by-product fluosilicic acid of wet process phosphoric acid. The technology comprises the following steps: washing and absorbing fluorine-containing gas produced in a production process of the wet process phosphoric acid so as to form a fluosilicic acid solution, and then enabling the fluosilicic acid solution and ammonia water to be subjected to a preneutralization reaction so as to generate an ammonium fluosilicate solution; primarily mixing the ammonium fluosilicate solution with the wet process phosphoric acid to obtain mixed acid liquor; then, secondarily mixing the mixed acid liquor with potassium hydrogen sulfate to obtain compound fertilizer mixed acid slurry; enabling the compound fertilizer mixed acid slurry and gaseous ammonia to be subjected to a neutralization reaction to obtain compound fertilizer neutralized slurry; or enabling the mixed acid liquor and the gaseous ammonia to be subjected to a neutralization reaction to obtain ammonium phosphate neutralized slurry, and concentrating the ammonium phosphate neutralized slurry to obtain concentrated slurry; carrying out slurry-spraying granulation on the compound fertilizer neutralized slurry or the concentrated slurry, drying, screening and enveloping to obtain sulfur-based compound fertilizer or ammonium phosphate. The technology reduces the volatilization of the fluorine-containing gas of the fluosilicic acid solution, reduces the corrosivity of the solution, reduces pollutant emission and improves the ecological environment.

Owner:YICHANG EZHONG CHEM

PROCESS TO MANUFACTURE 2-CHLORO-1,1,1,2-TETRAFLUOROPROPANE (HCFC-244bb)

ActiveUS20140343331A1Well mixedLittle or no unwantedPreparation by dehalogenationPreparation by hydrogen halide split-offMole ratioRecycling by product

The invention relates to a process to produce HCFC-244bb from HCFO-1233xf wherein, in one embodiment, co-feed species HFC-245cb is added to the reaction at a pressure of at least about 100 psig; and in another embodiment it is added to maintain a mole ratio of HFC-245cb to HCFO-1233xf of between about 0.005:1 to about 1:1. The HFC-245cb may be added as recycled by-product of the reaction and / or added as fresh feed. The HFC-245cb provides elevated pressures to the reaction thereby facilitating reactor operation, mixing and HCFC-244bb product removal. Other co-feed species are also disclosed.

Owner:HONEYWELL INT INC

Method for recycling iron-containing by-products discharged from coal-based ironmaking process, system used therefor, and direct-reduced iron agglomeration system

InactiveCN105102642AEffective agglomerationAvoid breakingRecovering materialsFluidised-bed furnacesSludgeIron storage

The present invention relates to a method for recycling by-products, produced in the form of dust or sludge from a coal-based ironmaking process and containing a large amount of valuable components, in a process of manufacturing agglomerated reduced iron and to an agglomeration system. The present invention provides a direct-reduced iron agglomeration system and a corresponding agglomeration method, the direct-reduced iron agglomeration system comprising: a fluidized reduction furnace for reducing fine iron ore into reduced iron; a reduced iron storage tank for storing the reduced iron and feeding the stored reduced iron to an agglomeration apparatus, the reduced iron storage tank being connected to the fluidized reduction furnace through a reduced iron discharge pipe; the agglomeration apparatus for agglomerating the reduced iron fed from the reduced iron storage tank; and an conveying means for conveying agglomerates of the by-products produced from the ironmaking process through a by-product feed pipeline, wherein the by-product feed pipeline feeds the agglomerates of the by-products to at least one selected from the fluidized reduction furnace, the reduced iron discharge pipe, and the reduced iron storage tank.

Owner:POHANG IRON & STEEL CO LTD

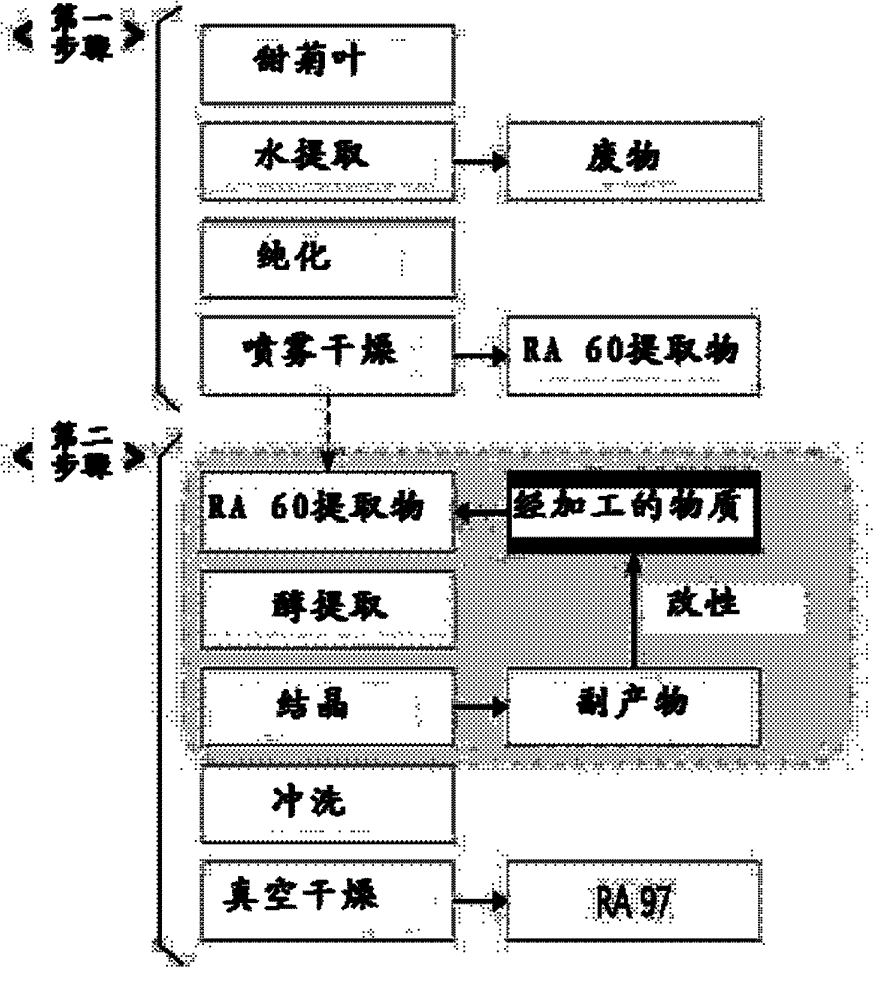

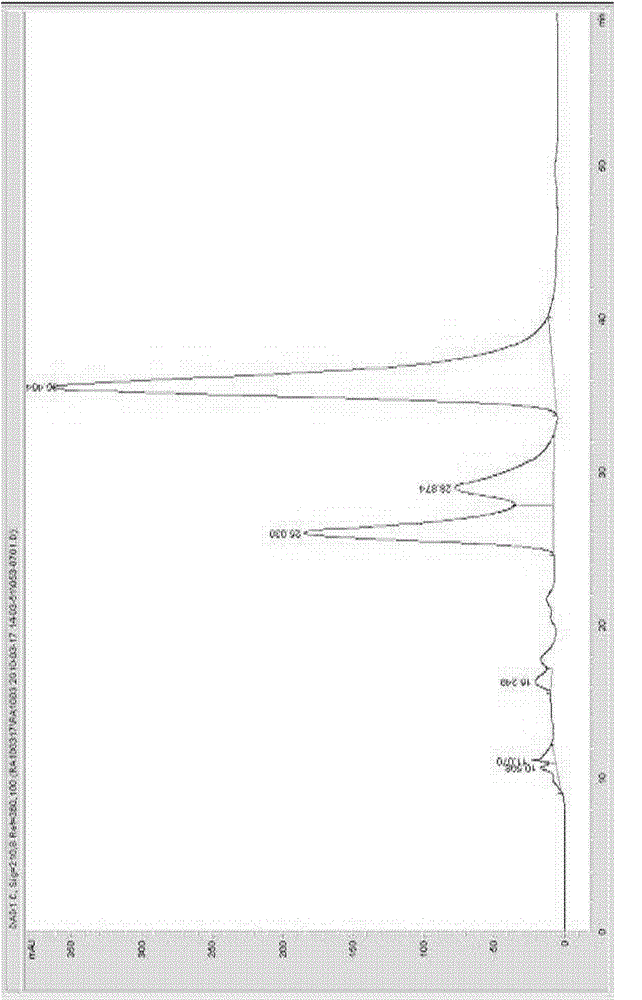

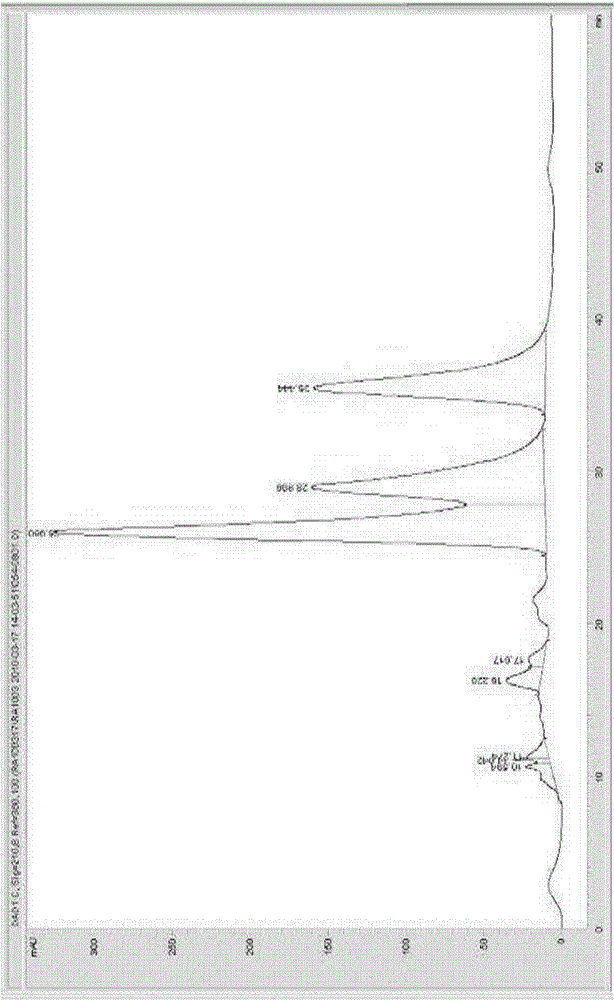

Method for manufacturing rebaudioside A in high yield by recycling by-products produced from manufacturing process for rebaudioside A

The present invention relates to a method of producing Rebaudioside A in a high yield by recycling by-products produced when Rebaudioside A is produced from leaves of Stevia Rebaudiana Bertoni containing a sweetening material.

Owner:CJ CHEILJEDANG CORP

Method for preparing iron oxalate

InactiveCN101717331BSolve intractableHigh economic valueCarboxylic acid salt preparationSulfateDissolution

The invention relates to a method for preparing iron oxalate, belonging to the field of chemical engineering. The method for preparing iron oxalate can recycle by-product of copperas generated when preparing titanium pigment with titanium concentrate. The method for preparing iron oxalate takes the by-product of copperas generated when preparing the titanium pigment with the titanium concentrate as raw materials, and comprises the following steps of: a. adding water to the copperas for dissolution to obtain a ferrous sulfate solution, adjusting pH value to be 5.6 to 6.5 by utilizing ammonia, filtering the solution; b. extracting the filtrate by utilizing P2O4, separating the filtrate to obtain an organic phase and a water phase; c. and adding a solution containing F to the water phase so as to deposit Mg<2+>, filtering the solution, adding an oxalic acid solution to the filtrate, and filtering the solution to obtain iron oxalate crystallization. The invention not only solves the problem of stacking the copperas, but also enhances the economic value of the copperas, provides a new choice for treating the by-product of copperas generated when preparing titanium pigment with a sulfuric acid method, and has wide application prospect.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

Method for recycling iron-containing by-products discharged from coal-based molten ironmaking process, system therefor, and reduced iron agglomeration system

ActiveUS9994928B2Effectively agglomeratedReduced ironRecovering materialsFluidised-bed furnacesSludgeFerric

There is provided a method and system for recycling by-products containing large amounts of useful components and discharged in the form of dust and sludge from a coal-based molten iron making process to reuse the by-products in a reduced iron agglomeration process. The system includes: a fluidized reduction furnace reducing fine iron ore; a reduced iron tank connected to the fluidized reduction furnace through a reduced iron discharge pipe for storing the reduced iron and supplying the reduced iron in an agglomeration system; an agglomeration system agglomerating the reduced iron transferred from the reduced iron tank; and a transfer unit transferring compactions of by-products discharged from a molten iron making process through a by-product supply pipe. The compactions of the by-products are supplied to at least one selected from the group consisting of the fluidized reduction furnace, the reduced iron supply pipe, and the reduced iron tank.

Owner:POHANG IRON & STEEL CO LTD

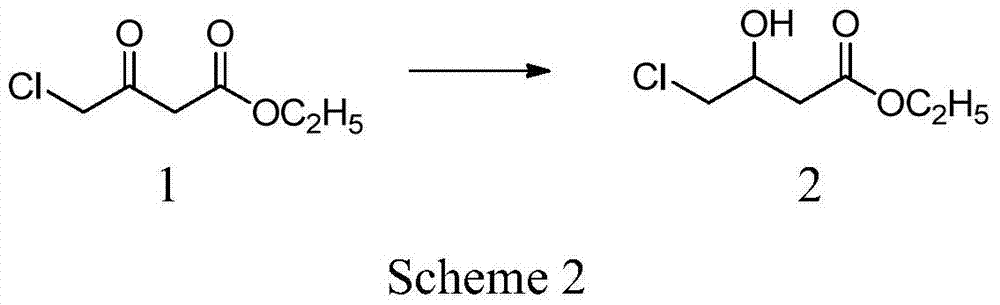

A kind of preparation method of highly optically pure l-carnitine

ActiveCN103497978BHigh optical purityEasy to buyOrganic compound preparationAmino-carboxyl compound preparationEthyl acetateHydrolysis

The invention provides a preparation method of highly optically pure L-carnitine, comprising step 1): taking ethyl 4-chloroacetoacetate as a raw material, and obtaining ethyl 4-chloro-3-hydroxybutyrate through hydroboration reduction reaction; Step 2): Using ethyl 4-chloro-3-hydroxybutyrate obtained in step 1) as the reaction starting material, under the catalysis of immobilized lipase, carry out asymmetric esterification reaction with acyl donor to obtain (R )‑4‑chloro‑3‑hydroxybutyrate ethyl ester and (S)‑4‑chloro‑3‑hydroxybutyrate ethyl ester; step 3): (R)‑4‑chloro‑3‑hydroxybutyrate obtained in step 2) 3-Hydroxybutyrate ethyl ester is the reaction starting material, and after condensation with trimethylamine, the hydrolysis reaction is carried out to obtain L-carnitine. In the preparation method provided by the invention, the reaction raw materials are easy to obtain, the product yield is high, the optical purity is high, by-products can be recycled, and the method is suitable for industrial production.

Owner:BENGBU BBCA MEDICINE SCI DEV

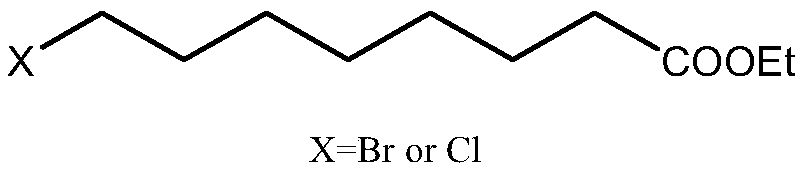

Method for recycling by-product in preparation process of ethyl 8-halooctanoate

InactiveCN110105211ASimple and fast operationMild conditionsOrganic compound preparationCarboxylic acid esters preparationHydrogen halideReaction temperature

The invention discloses a method for recycling a by-product in a preparation process of ethyl 8-halooctanoate. The method comprises the steps of introducing hydrogen halide gas into ethyl 8-halooctanoate containing the by-product ethyl 8-ethoxyoctanoate and stirring the gas for a reaction at the temperature of 100-160 DEG C. According to the method, hydrogen halide, halogen acid, ethyl 8-ethoxyoctanoate and ethyl 8-halooctanoate are adopted for the reaction, so that the ethyl 8-ethoxyoctanoate is converted into the ethyl 8-halooctanoate, the conditions are mild, and the operation is simple andconvenient. Therefore, the method is suitable for industrial production.

Owner:启东东岳药业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com