Method and device for removing harmful gas

A technology for harmful gas and gas import, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation. Low cost and operating expenses, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

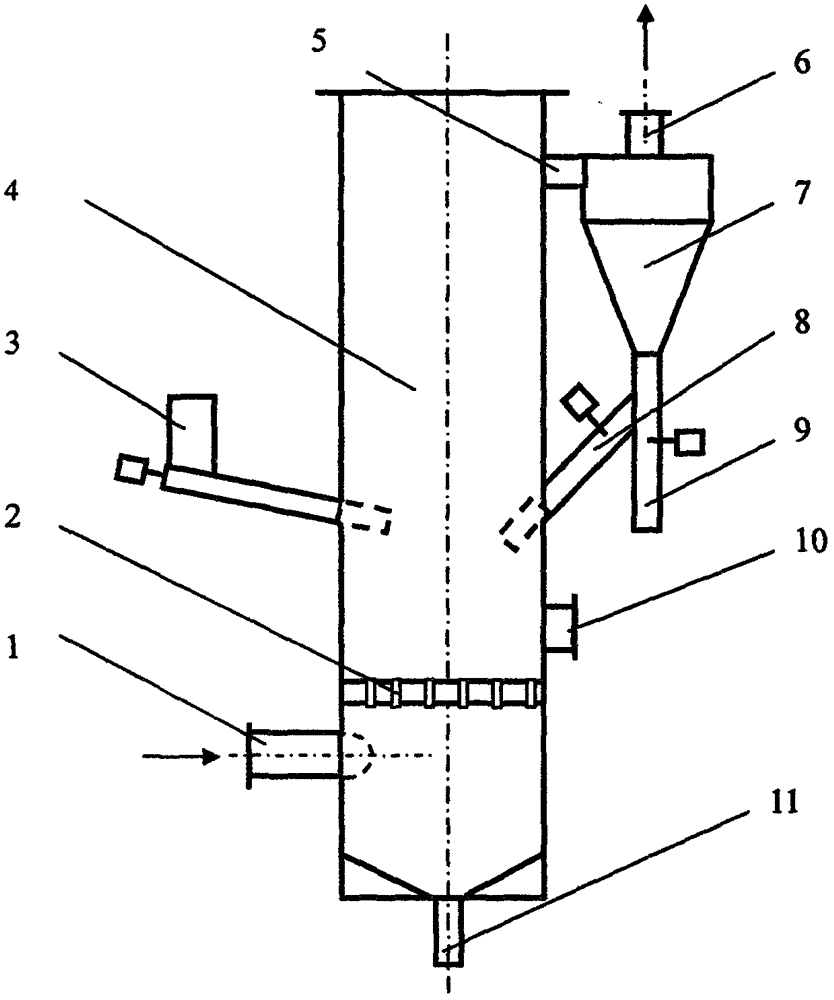

[0018] Embodiment 1: a kind of circulating fluidized bed gas-solid reactor device that removes harmful gas from the gas stream such as figure 1 shown. The circulating fluidized bed gas-solid reactor has a diameter of Φ60mm and a height of 2500mm, of which the effective height is about 1600mm, and the material is stainless steel. The experimental conditions are: the carrier gas is air, the flow rate is about 3m 3 / h, the gas temperature is about 25°C, the relative humidity of the gas is about 70%, the calcium chloride is commercially available industrial grade powder particles, the purity is above 98%, and the average particle size is about 0.1mm. The calcium chloride is first heated by an electric heater After reaching about 40°C-50°C, put it into the reactor, the temperature of the reactor is about 30°C, and the gas-solid contact time in the reactor is about 3-5s. The molar ratio of harmful substances to calcium chloride is about 1:15. After the reaction, the solid particl...

Embodiment 2

[0022] Embodiment 2: 20% (volume) of quartz sand with a particle size of about 1.5 mm is mixed in the material. Other conditions are with embodiment 1. The experimental results are shown in Table 2.

[0023] Table 2 Harmful substance removal effect

[0024]

Embodiment 3

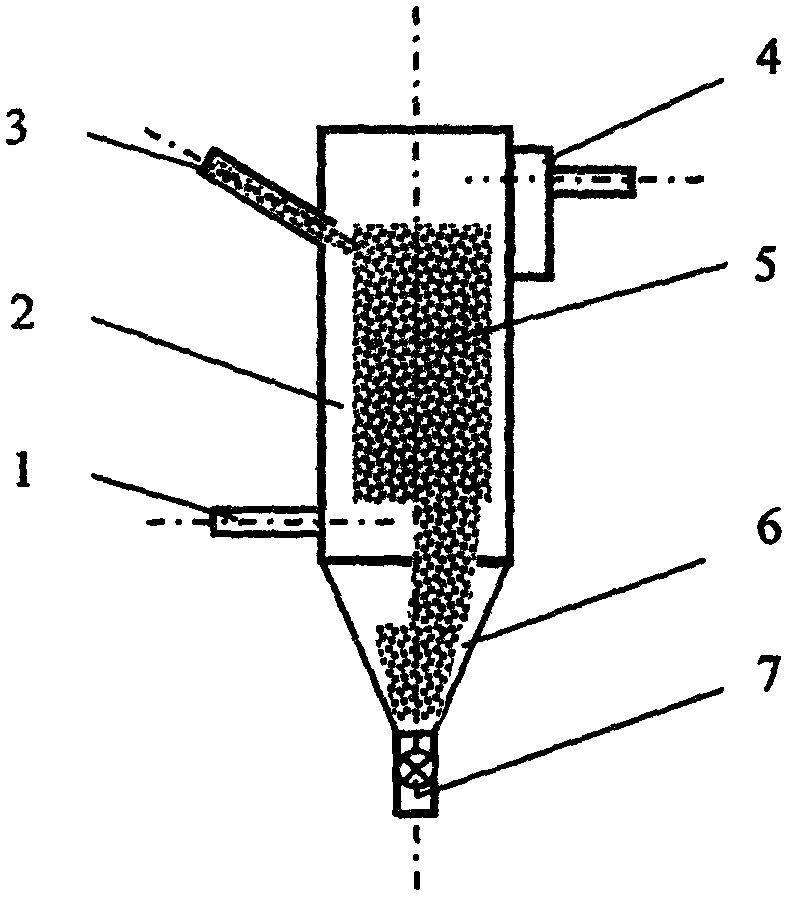

[0025] Embodiment 3: a kind of gas-solid countercurrent contact reactor device that removes harmful gas such as figure 2shown. Its treatment process is that the harmful gas to be treated enters the gas-solid reactor tower body (2) from the gas inlet (1) and the calcium chloride powder added from the solid particle inlet (3) in the gas-solid reaction zone ( 5) A chemical adsorption reaction occurs, the purified gas flow is discharged from the gas outlet (4), and the solid particles after the reaction pass through the solid particle recovery area (6) and then are discharged through the solid particle discharge port (7). The diameter of the reactor is Φ60mm , the height is 1500mm, the material is stainless steel, and the effective height of the gas-solid reaction zone is about 1000mm. The molar ratio of harmful substances to calcium chloride dosage is about 1:30. The carrier gas is air, the flow rate is about 1m 3 / h, the gas-solid contact time in the reactor is about 10-15s....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com