Microporous film filter for processing heavy metal wastewater

A microporous film and heavy metal technology, which is applied in fixed filter element filters, filtration and separation, chemical instruments and methods, etc., can solve the problem of high operating costs per ton of water, high requirements for precipitation reaction conditions, and secondary pollution in chemical flocculation and sedimentation methods. The threat can not be ignored and other issues, to achieve the effect of good chemical stability, novel appearance, low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in detail: present embodiment implements under the premise of the technical scheme of the present invention, has provided detailed implementation and working process, but protection scope of the present invention is not limited to following Example.

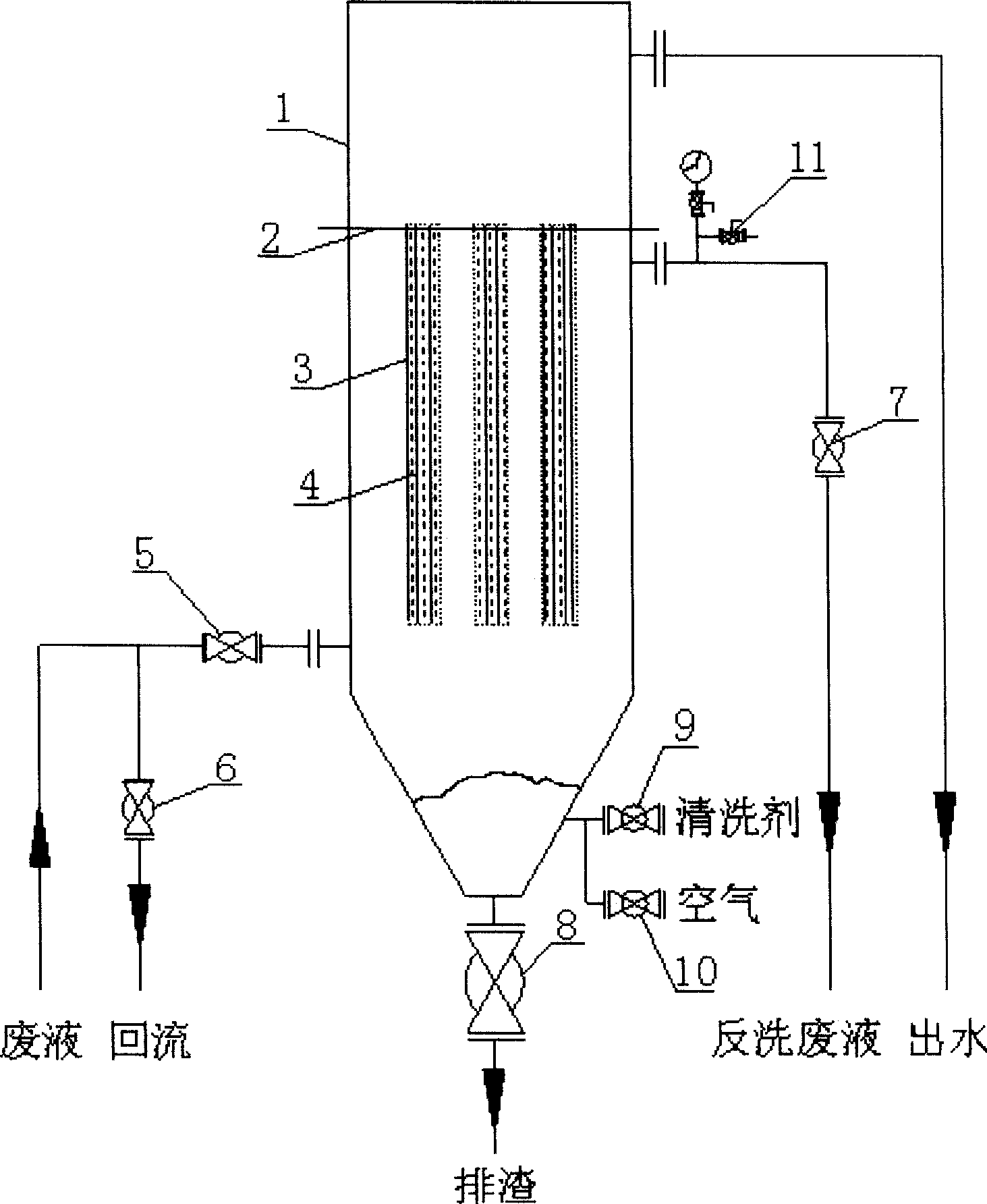

[0040] Such as figure 1 As shown, the microporous membrane filter of this embodiment mainly includes: tank body 1, stainless steel flower plate 2, expanded polytetrafluoroethylene film filter bag 3, filter bag support cage 4, acid inlet flexible valve 5, return flow flexible valve Sex valve 6, backwash flexible valve 7, mud discharge flexible valve 8, cleaning agent liquid inlet valve 9, air solenoid valve 10, exhaust solenoid valve 11. The expanded polytetrafluoroethylene film filter bag 3 is set on the filter bag supporting cage 4, and then all the filter bag supporting cages 4 are fixed on the stainless steel flower pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com