Method for manufacturing rebaudioside A in high yield by recycling by-products produced from manufacturing process for rebaudioside A

A technology of stevioside and by-products, applied in the field of manufacturing stevioside A, can solve problems such as failure to provide purity level and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

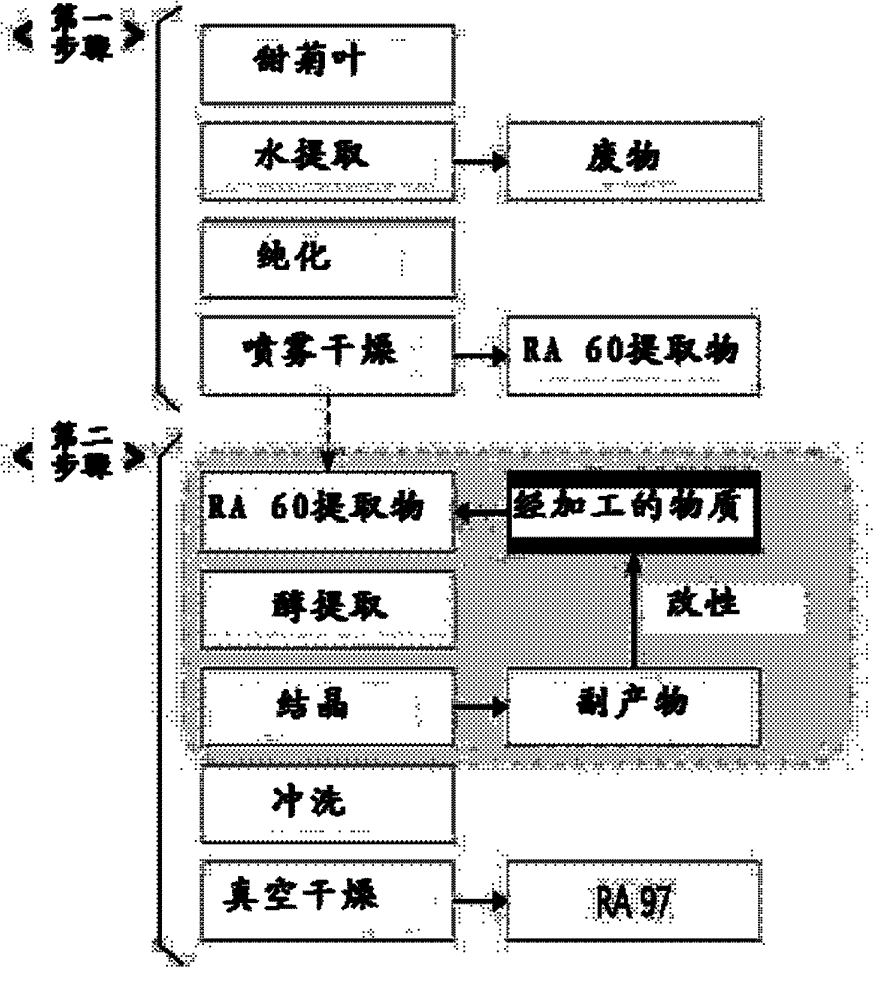

Method used

Image

Examples

example 1

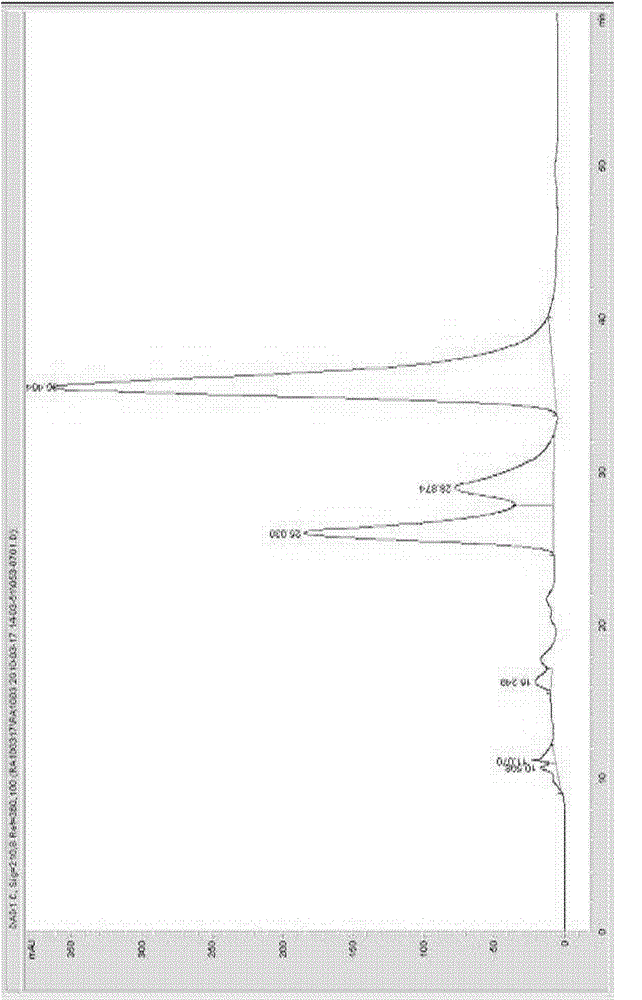

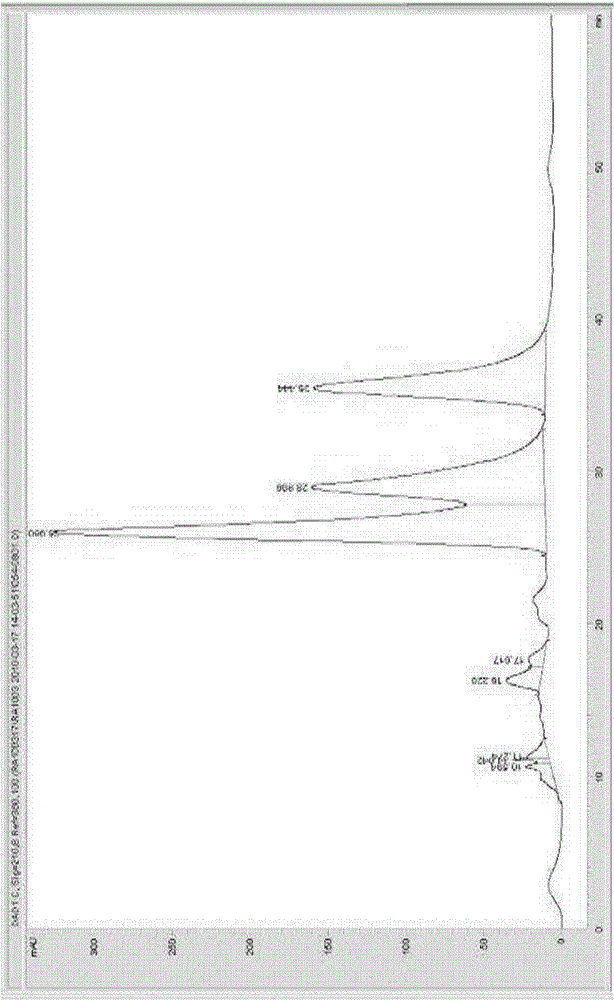

[0038] Example 1. Analysis of steviol glycoside content and ash content in conventional RA 60 product and in residual by-products generated from conventional rebaudioside A, especially as mother liquor from the fractional crystallization process

[0039] HPLC analysis was performed to determine the content of steviol glycosides. To this end, 1 g of each sample and 1000 ml of distilled water were loaded into a 1000 ml large-capacity cylinder and mixed uniformly, and then filtered through a 0.45 μm aqueous filter. An HPLC (Agilent 1200 series) apparatus was used and loaded with 20 μl of each sample. Analysis conditions were set: the flow rate was 0.5 mL / min and the wavelength was 210 nm. Such as figure 2 and image 3 As indicated in , the content of stevioside, rebaudioside A and rebaudioside C was measured.

[0040] As a result of the analysis, the conventional RA60 product included 23.3% stevioside, 61.4% rebaudioside A, and 12.7% rebaudioside C, while by-products include...

example 2

[0045] Example 2. Purification of by-products

[0046] In order to process the residual by-products (i.e., by-products produced as mother liquor from crystallization) produced after the manufacture of conventional RA60 products to a reusable level, the decolorized and purified by-products were analyzed in the same manner as in Example 1. The content pattern of steviol glycosides in the product to determine the content of stevioside, rebaudioside A and rebaudioside C.

[0047] After purification of the by-products, the ash content of stevioside, rebaudioside A and rebaudioside C from each process was analyzed.

example 3

[0048] Example 3. Enzyme transfer process

[0049] As in Example 2, the by-product produced by the fractional crystallization process as a mother liquor was processed to a reusable level, and the stevioside in the by-product was used as an acceptor and transferred in β-1,3-glucosyl Enzyme, β-1,3-glucosyl oligosaccharide compound and β-1,3-glucanase for decomposing β-1,3 glucose contained in β-1,3 glucosyl oligosaccharide compound Rebaudioside A was produced by reacting at a temperature of 50° C. for 5 hours in the presence of .

[0050] The content pattern of newly formed steviol glycosides was analyzed in the same manner as in Example 1 to determine the content of stevioside, rebaudioside A and rebaudioside C.

[0051] As apparent from the above description, according to the method of the exemplary embodiments, by-products (ie, residual by-products) generated when purifying and crystallizing extracted rebaudioside A (RA) are recycled as raw materials to increase productivity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com