Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "2,4-Dichlorophenol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

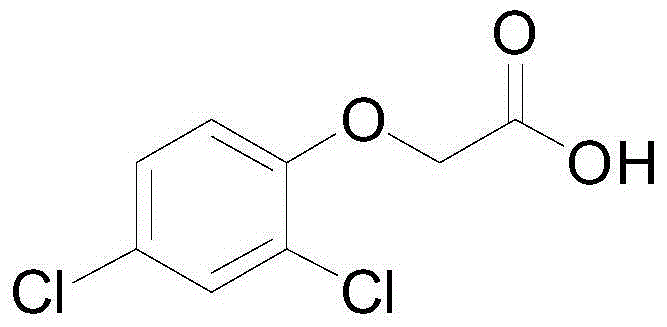

Inventor

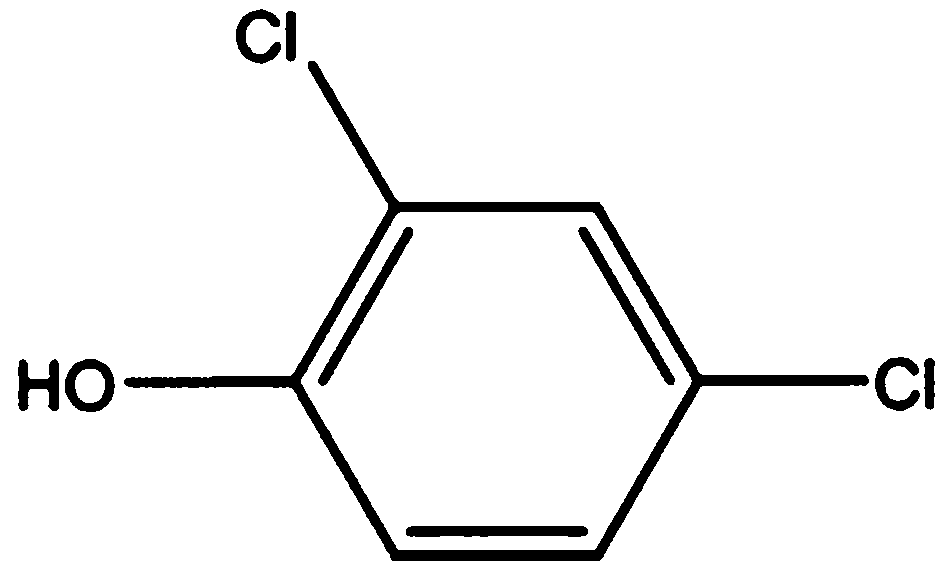

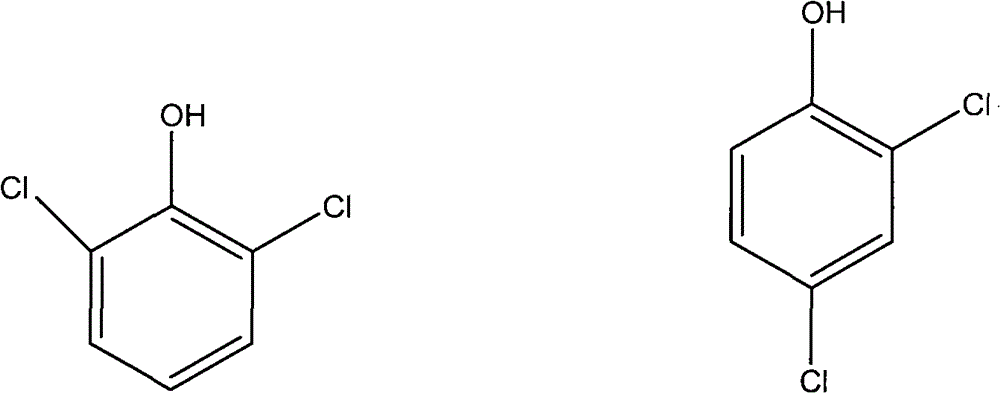

2,4-Dichlorophenol (2,4-DCP) is a chlorinated derivative of phenol with the molecular formula Cl₂C₆H₃OH. It is a white solid that is mildly acidic (pKₐ = 7.9). It is produced on a large scale as a precursor to the herbicide 2,4-dichlorophenoxyacetic acid (2,4-D).

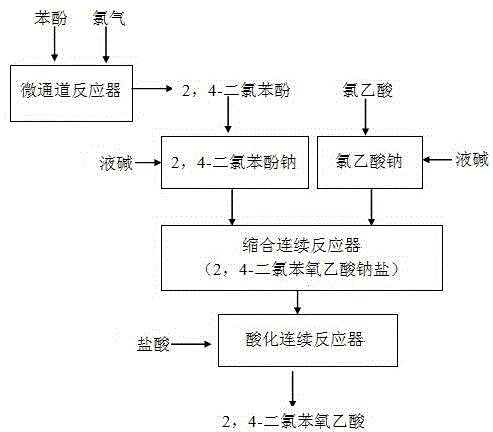

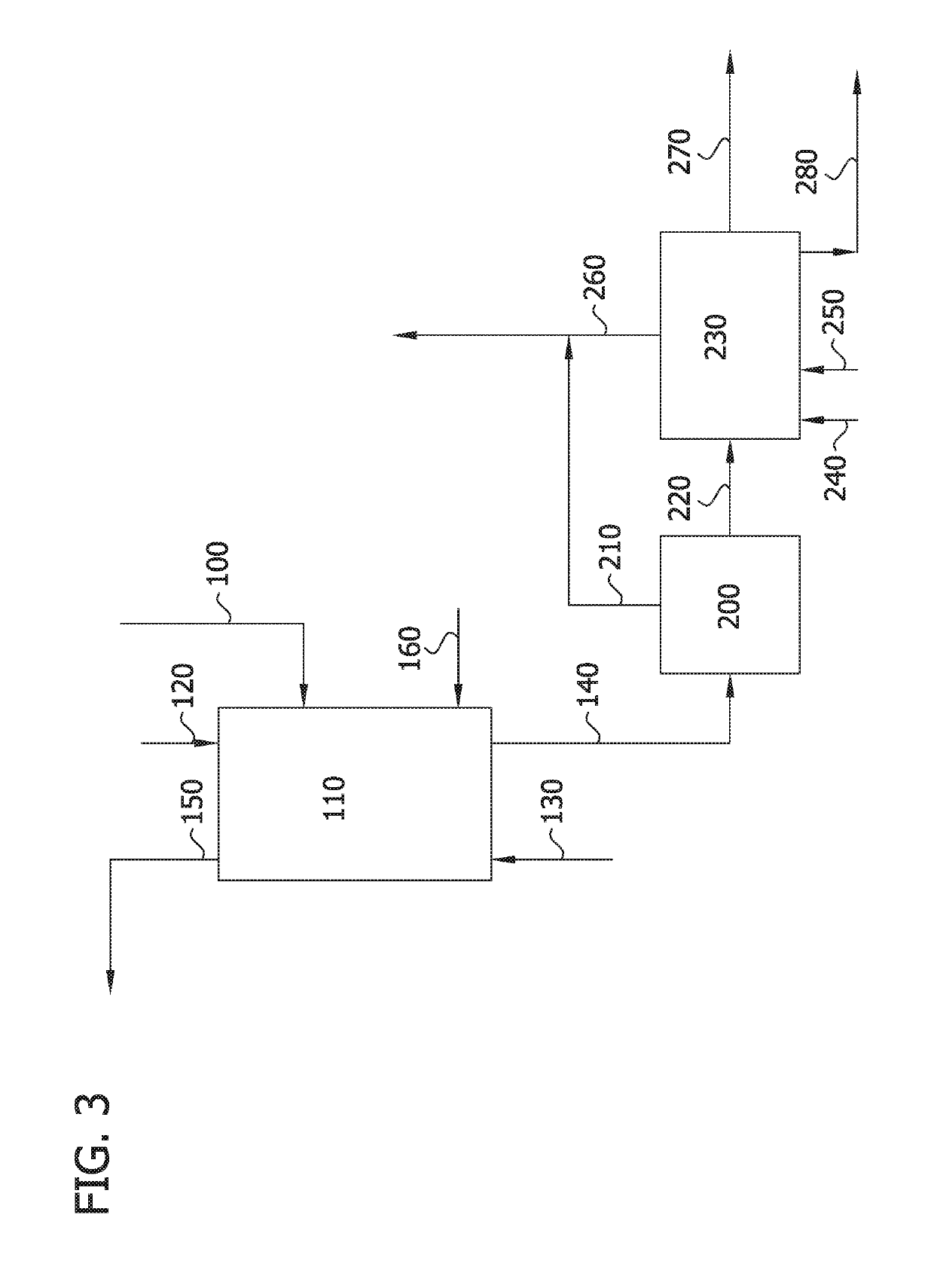

Method for continuously producing herbicide 2,4-dichlorophenoxyacetic acid

ActiveCN104529757AEmission reductionSafe and efficient productionPreparation from carboxylic acid saltsOrganic compound preparationPhenol2,4-Dichlorophenol

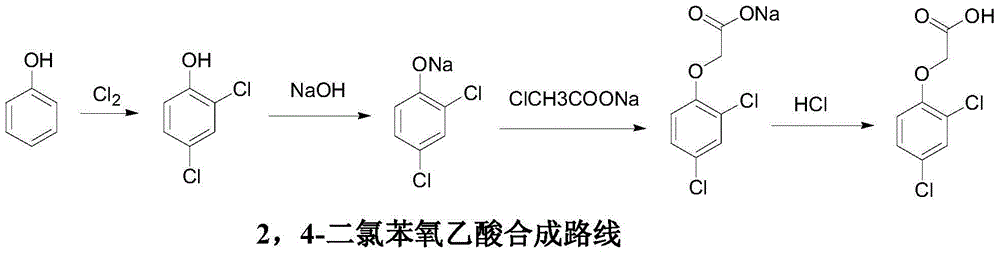

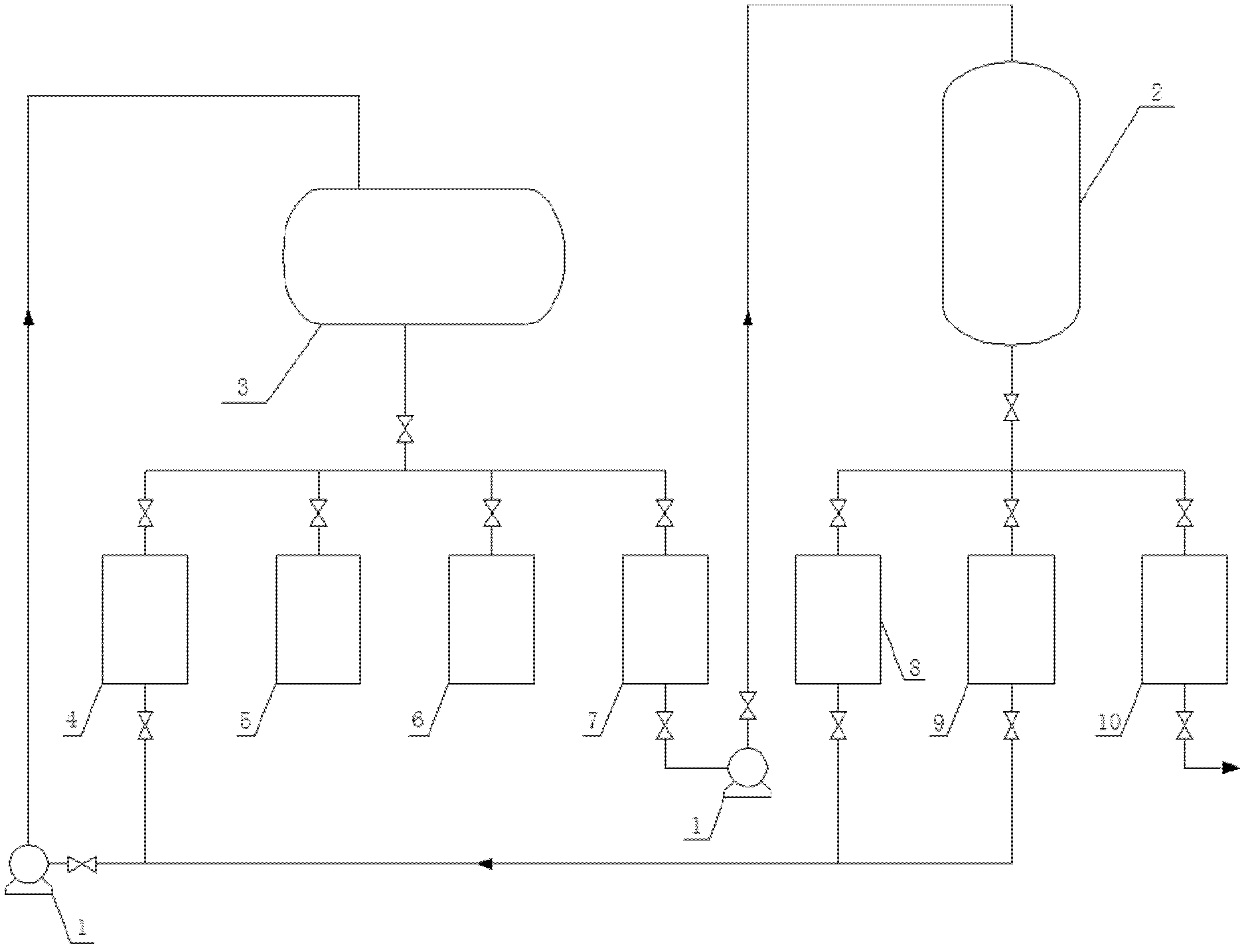

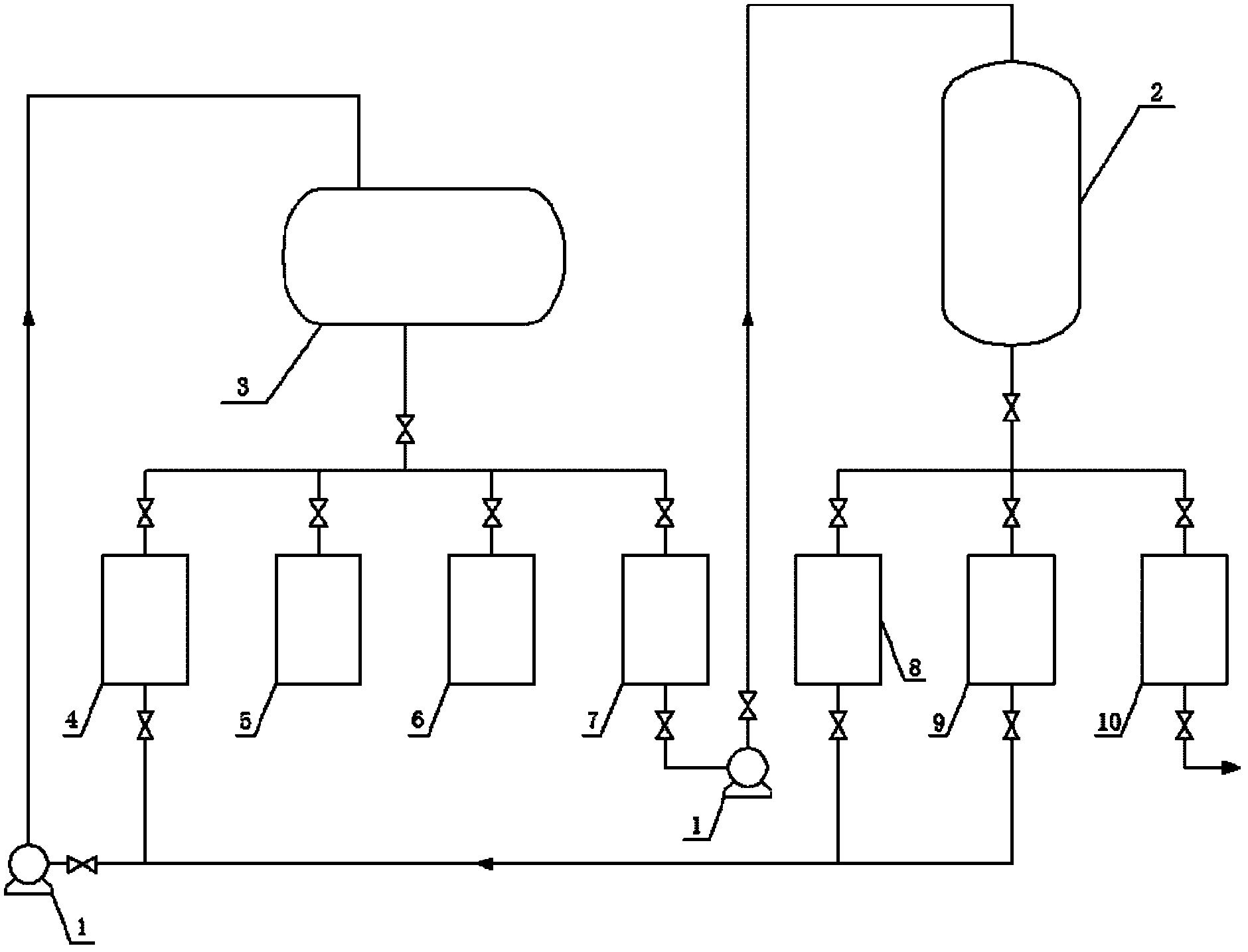

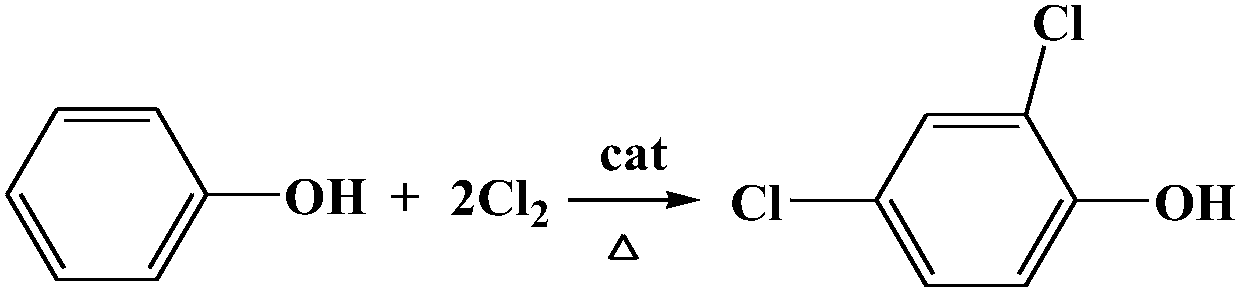

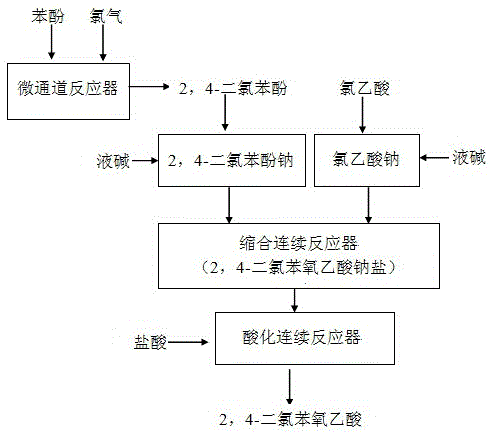

The invention discloses a method for continuously producing herbicide 2,4-dichlorophenoxyacetic acid. According to the method, phenol and chlorine gas are used as raw materials; a continuous chlorination reaction is conducted through a micro-channel reactor to prepare 2,4-dichlorophenol, a condensation reaction is conducted through a tandem condensation reaction kettle to prepare 2,4-dichlorphenoxyacetic acid sodium salt, and then a continuous acidification reaction is conducted through a tandem acidification reaction kettle to prepare the 2,4-dichlorphenoxyacetic acid. Since continuous operation is realized in all the three reactions, the technological process is efficient, environmentally friendly, sustainable and suitable for industrial production; the method has the advantages that energy is saved, consumption is lowered, and emission of pollutants is reduced, and therefore safe and continuous industrial production is achieved.

Owner:台州煜农生物科技有限公司

Method for removing 2, 4-dichlorophenol in water by using polyurethane sponge fixed white rot fungi

InactiveCN101734801AAvoid inactivationHigh removal rateWater contaminantsNature of treatment waterPorosityBiological reaction

The invention discloses a method for removing 2,4-dichlorophenol in water by using polyurethane sponge fixed white rot fungi, belonging to the field of environmental microbiology. The method comprises the following steps: preprocessing a carrier, preparing fixed white rot fungi and removing 2, 4-dichlorophenol in water. The carrier has the characteristics of porosity, hydrophily and good adsorbability, enjoys stable chemical property and hydrolytic resistance, high organism bearing capacity and mass transfer rate and is not soluble in acid / alkaline water solution; while the fixed carrier can effectively absorb and fix white rot fungi, improve capacity of fixed white rot fungi in removing 2,4-dichlorophenol in water and leads the fixed white rot fungi to be easily separated from the product, thus being applicable to execute biological reaction processing on multiple sewages.

Owner:BEIJING NORMAL UNIVERSITY

Continuous preparation method of herbicide intermediate of 2, 4-dichlorophenol

InactiveCN102659530AReduce labor intensityEmission reductionOrganic chemistryOrganic compound preparationDichlorophenol2,4-Dichlorophenol

The invention provides a continuous preparation method of an herbicide intermediate of 2, 4-dichlorophenol. The method includes the steps of continuously and reversely feeding phenol and chlorine gas in a mass ratio of 1: (1.4-1.5), subjecting fed materials to continuous chlorination reaction through a multistage chlorination tower, enabling reacted liquid materials to flow into a 2, 4-dichlorophenol receiving tank, and recycling the gas with water through a tail gas absorption tower. The continuous preparation method replaces existing batch type mode to prepare the intermediate 2, 4-dichlorophenol of 2, 4-D acid, operation is simple, safety of preparation is controllable, discharge of three wastes is reduced, power consumption is reduced, and unit time output is increased. Simultaneously, the preparation can further improve yield of products, and recycle by-product acid with concentration of 30.5% during the reaction.

Owner:荆州沙隆达控股有限公司

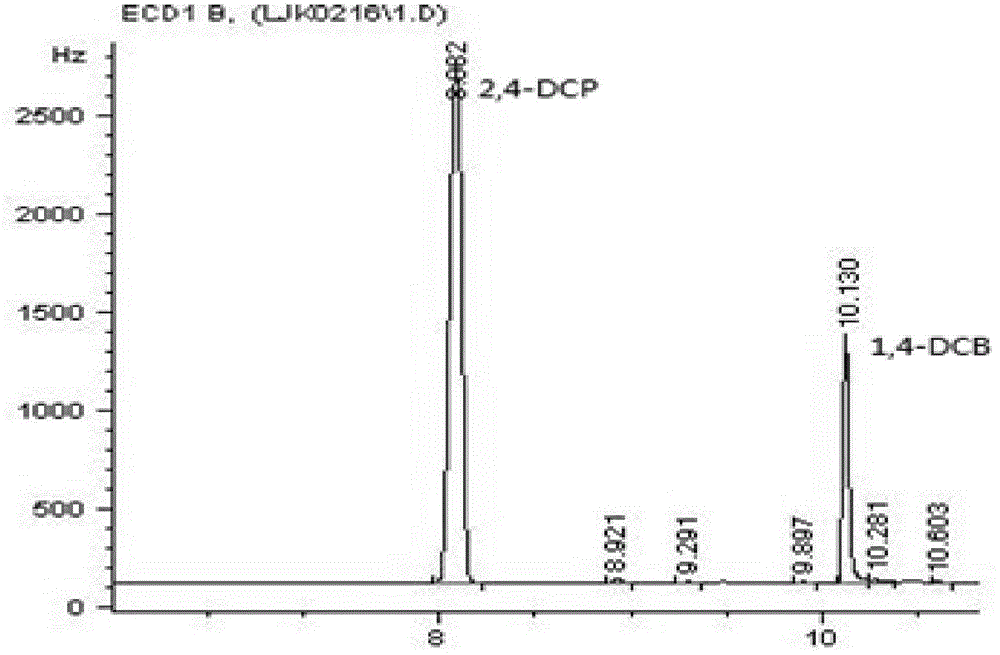

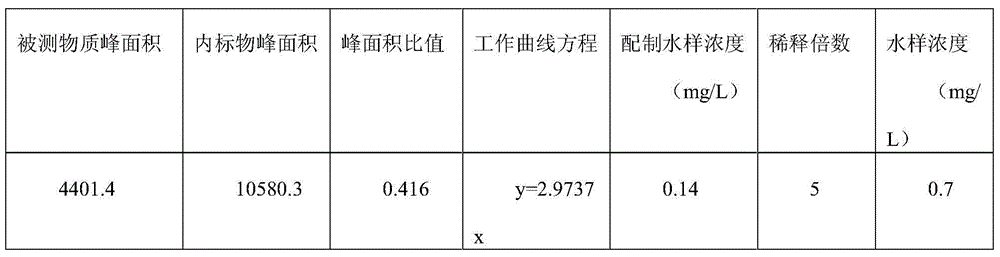

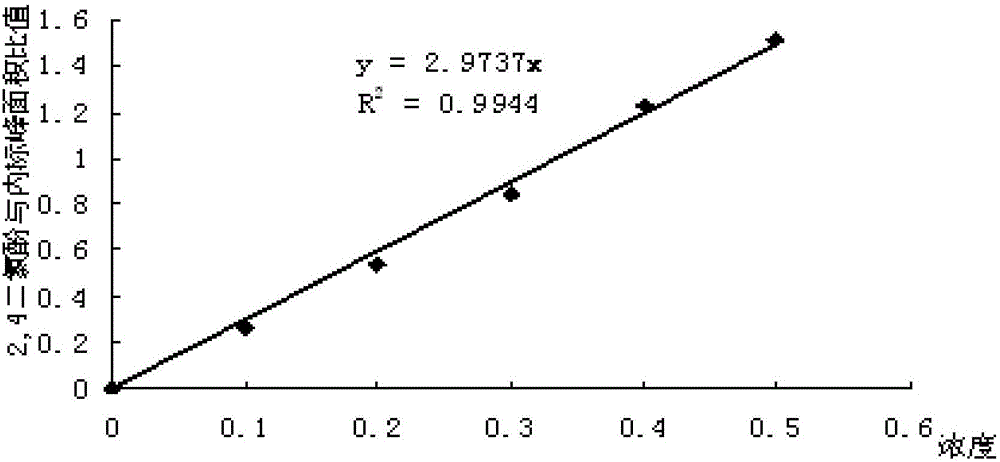

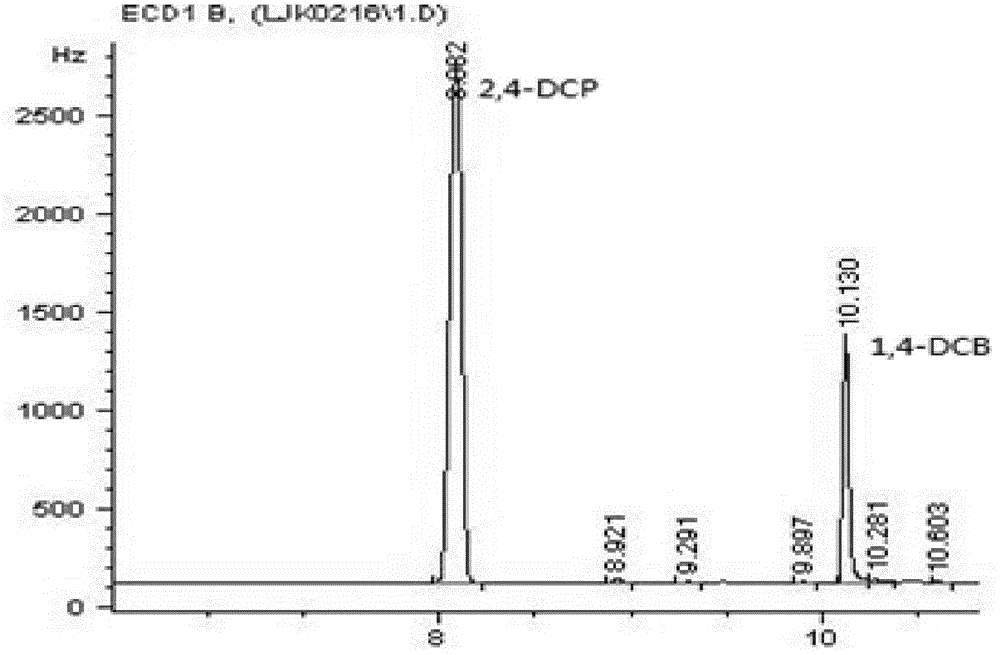

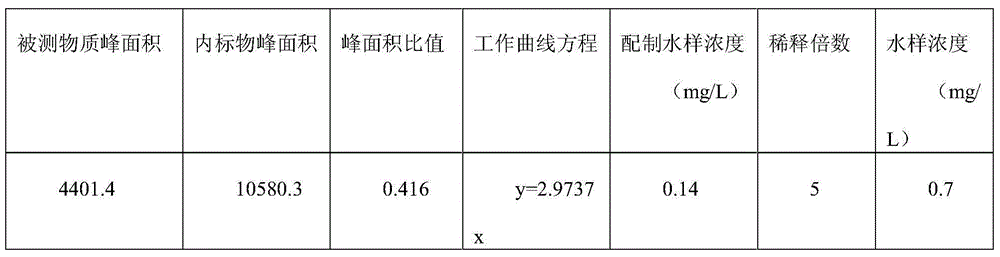

Method for quantitatively detecting 2, 4-dichlorophenol in water

ActiveCN103604883ALess solventLess interfering substancesComponent separationEnvironmental resistanceGas phase

The invention relates to a method for quantitatively detecting 2, 4-dichlorophenol in water, belonging to the field of analysis and detection of a compound. The invention provides a method for detecting 2, 4-dichlorophen in water through a head space solid phase microextraction-gas chromatography. The extracting head of the solid phase microextraction has the effect of gathering volatilizing components and can detect trace 2, 4-dichlorophen in water. The method can be used as a standard method for detecting the concentration of 2, 4-dichlorophen in water, the pretreatment is simple and rapid, and only needs heating and extracting for 30 minutes, no solvent is needed, the method is safe and environment-friendly, the dosage of the sample is less, the method has good linear adding standard recovery, and the detection sensitivity can reach 6.54mu g / L.

Owner:BEIJING UNIV OF TECH

Method for separating 2,4-Dichlorophenol and 2,6-Dichlorophenol

ActiveCN101781175AEasy to separateEasy to operateOrganic chemistryOrganic compound preparationMorpholineEthyl acetate

The invention discloses a method for separating 2,4-Dichlorophenol and 2,6-Dichlorophenol, comprising the following steps: dissolving the mixture of the 2,4-Dichlorophenol and the 2,6-Dichlorophenol in an organic solvent, adding alkalic organism, stirring and reacting at the temperature of 40-80 DEG C until the reaction liquid is clear, cooling the reaction liquid after the reaction is finished, standing and precipitating crystals, filtering to obtain a filter cake A and a filtrate A, and retaining the 2,4-Dichlorophenol in the filtrate A, wherein the filter cake A is a crude product of the 2,6-Dichlorophenol; the alkalic organism is triethylene diamine, morpholine, piperazidine, ethylpiperazine or methyl piperazine; and the organic solvent is ethanol, methanol, acetone or ethyl acetate. The invention has higher separation efficiency and only need crystallization for one time; the total yield of the 2,4-Dichlorophenol is 90-95%, and the purity thereof is 96-99%; the total yield of the 2,6-Dichlorophenol is 77-89%, and the purity thereof is 90-99%; and the invention has the advantages of simple operation, good repeatability and low implementation cost, and is favor of industrialized scale-up.

Owner:ZHEJIANG UNIV OF TECH

Method for separating dichlorophenol mixture by cross-current dissociation extraction

InactiveCN101863744AReduce dosageHigh purityOrganic chemistryOrganic compound preparationOrganic solventOrganic layer

The invention discloses a method for separating dichlorophenol mixture by cross-current dissociation extraction. The method includes the following steps that: the dichlorophenol mixture as a material is dissolved in organic solvent to prepare mixed dichlorophenol solution, aqueous inorganic alkali solution is adopted as an extracting agent, and after cross-current dissociation extraction, the organic layer is distilled, so that 2, 4-dichlorophenol is obtained. Since the method adopts cross-current dissociation extraction to separate the dichlorophenol mixture, the technique and equipment are simple, the usages of the organic solvent and the alkali is small, the consumption of material and energy is reduced, 98 percent of 2, 4-dichlorophenol can be obtained, meanwhile, the recovery rate of2, 4-dichlorophenol is more than 95 percent, and the recovery rate of the organic solvent exceeds 99 percent.

Owner:NANJING NORMAL UNIVERSITY

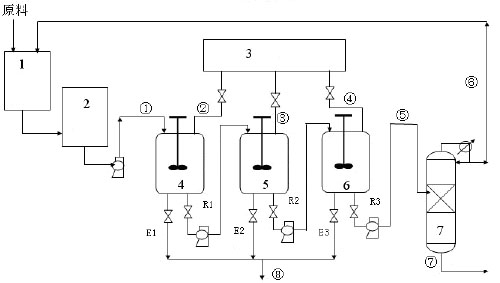

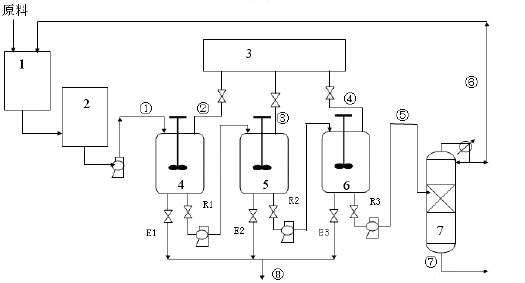

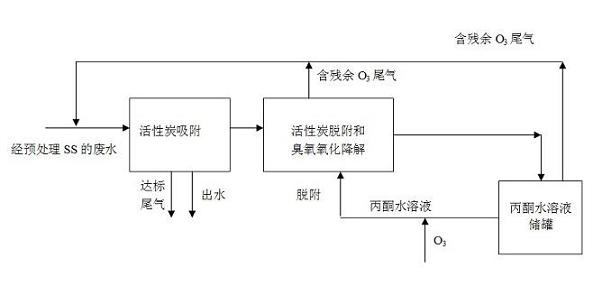

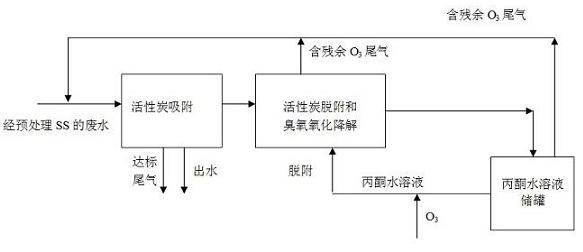

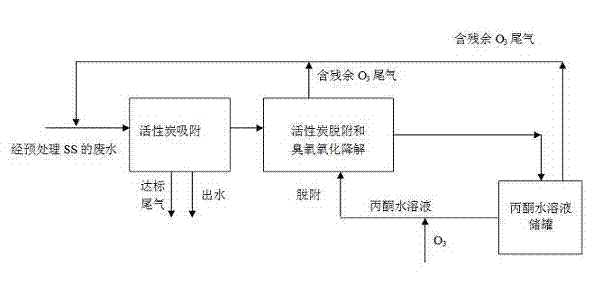

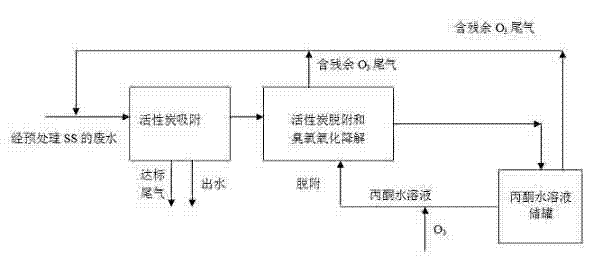

Method for treating 2,4-dichlorophenol wastewater by ozone oxidation in organic solvent

ActiveCN102134133AReduce dosageShort reaction timeMultistage water/sewage treatmentWater/sewage treatment by sorptionAqueous acetoneAtmospheric air

The invention discloses a method for treating 2,4-dichlorophenol wastewater by ozone oxidation in an organic solvent, and belongs to the field of organic wastewater treatment. Active carbon is used as an adsorbent in an adsorption column; extraction and enrichment are performed on the 2,4-dichlorophenol wastewater with concentration of less than 500mg / L; after the active carbon is adsorbed and saturated, natural gravity drainage is performed; and outer circulation desorption-ozone oxidation treatment is performed by adopting aqueous solution of acetone. The residual zone containing tail gas enters the active carbon column in adsorption treatment and is subjected to adsorption-decomposition treatment and then emitted to the atmosphere. The aqueous solution of the acetone and the active carbon can be recycled; and under the same conditions, compared with a traditional reaction system, the adding amount of ozone is reduced by over 1 / 2, the reaction time is shortened by over 2 / 3, the total removal rate of the 2,4-dichlorophenol reaches over 90 percent, and the quality of the discharged water is stable. The method has the advantage of efficient low-consumption treatment, and is convenient for operation in actual projects, easy to control and easy to realize industrialized production.

Owner:常熟紫金知识产权服务有限公司

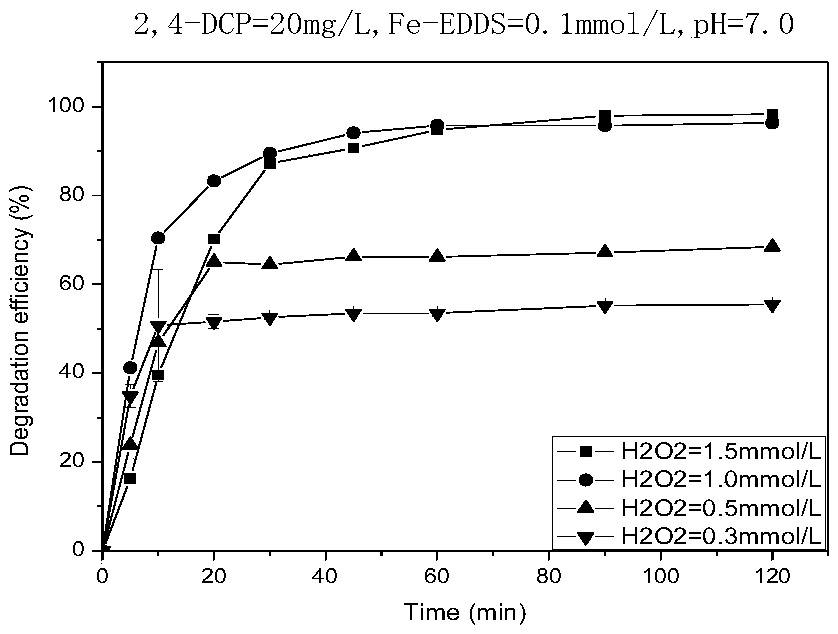

Degradation method capable of adsorbing 2,4-dichlorophenol in organic halide

InactiveCN109319917AAccelerate the redox cycleReduce usageWater contaminantsWater/sewage treatment by oxidationPhotocatalytic reactionSludge

The invention discloses a degradation method capable of adsorbing 2,4-dichlorophenol in an organic halide. The degradation method comprises the following steps: (1) putting a pollutant containing the2,4-dichlorophenol into a beaker; (2) mixing carboxylic acid and Fe(III) and adding water to prepare a carboxylic acid-Fe(III) complex compound; (3) adding the complex compound obtained in step (2) into the beaker of step (1) to enable the concentration of the 2,4-dichlorophenol in the pollutant to be 20 mg / L and the concentration of the carboxylic acid-Fe(III) complex compound to be 0.02 to 0.2 mmol / L; (4) regulating the pH (Potential of Hydrogen) value of a mixed solution of step (3) to be 7+ / -0.1; then adding hydrogen peroxide and carrying out oxidization reaction; (5) finally, pouring intoa photocatalytic reactor and utilizing light irradiation to degrade the 2,4-dichlorophenol until degradation reaction is finished. The method disclosed by the invention is applied to degradation of AOX (Absorbable Organic Halide) in wastewater; carboxylic acid is introduced into traditional photo-Fenton and the disadvantages of a traditional Fenton oxidization technology that the yield of iron sludge is great and an applicable pH range is narrow can be overcome; the dosage of an oxidant hydrogen peroxide is reduced; the degradation method has good economical efficiency and a very good application prospect.

Owner:GUANGXI UNIV

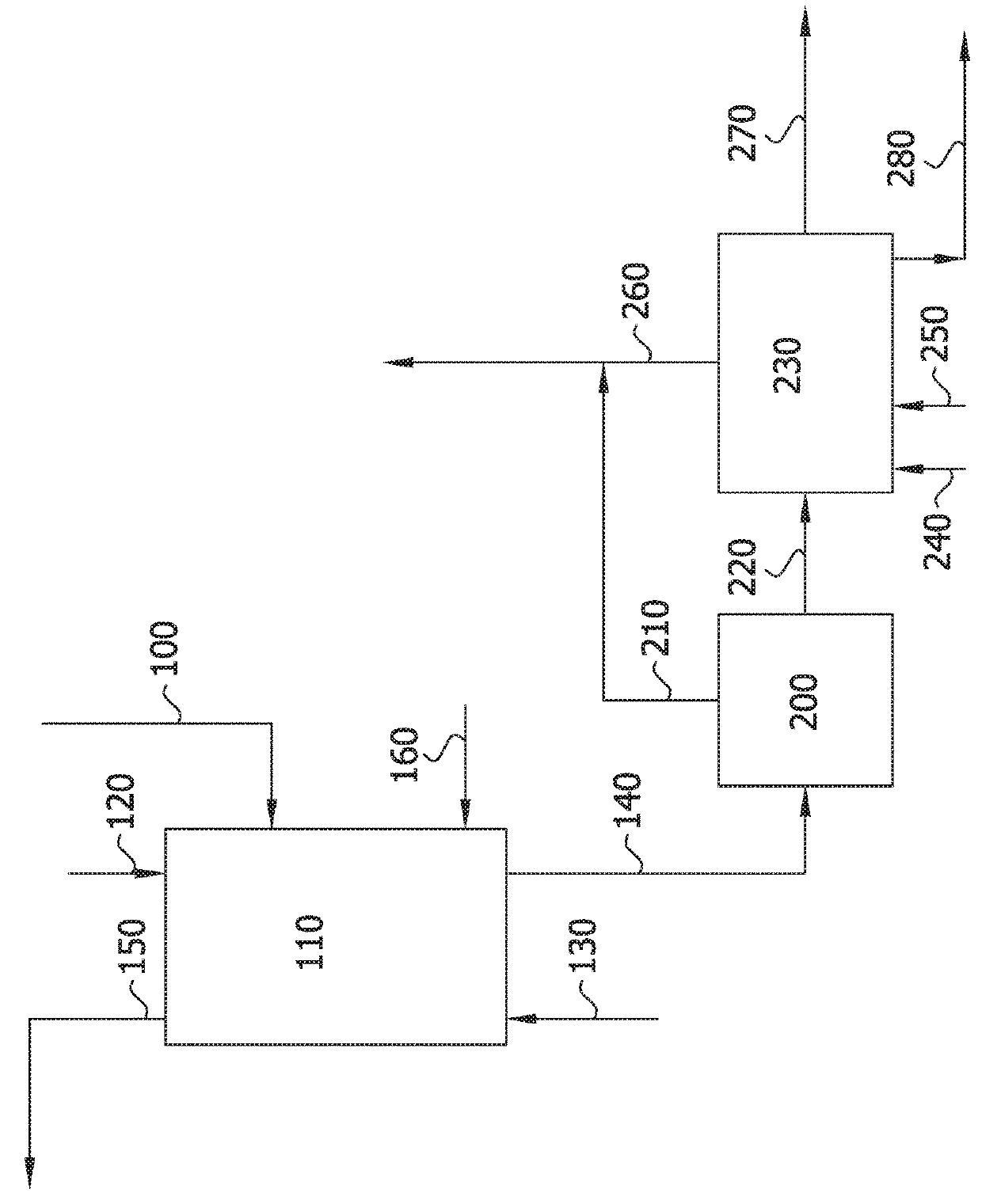

Separation of dichlorophenols

ActiveUS20180179132A1Organic compound preparationWater contaminants2-methoxybenzoic acidDichlorophenol

Various processes for the separation of a mixture containing dichlorophenols are described. In various aspects, the present invention relates to separation processes that produce an extract enriched in 2,4-dichlorophenol content and an extract enriched in 2,5-dichlorophenol content. The present invention further relates to various processes that integrate with these separation processes, such as a process for producing 3,6-dichloro-2-methoxybenzoic acid (dicamba) or salt or ester thereof or a process for producing 2,4-dichlorophenoxyacetic acid (2,4-D) or salt or ester thereof.

Owner:MONSANTO TECH LLC

Method and device for purifying 2,4-dichlorophenol

InactiveCN102659529ASimple distillationEasy to operateOrganic chemistryOrganic compound preparationOrganic solventHigh energy

The invention provides a method for purifying 2,4-dichlorophenol. The method comprises the following steps of cooling crude 2,4-dichlorophenol to 10 to 20 DEG C, stopping crystallization to obtain crystals, discharging mother liquor, heating the crystals and sweating at the temperature of between 30 and 50 DEG C, and discharging sweat to obtain the purified 2,4-dichlorophenol. According to the method, rectification is simple and easy to operate, the defects of high energy consumption and high production cost, damage to the health of operators and environment pollution due to the use of organic solvents and the like are overcome by fractional crystallization, and the requirements of industrialized production are met. The purity of the purified 2,4-dichlorophenol is over 98 percent, and requirements for preparing other products by using the purified 2,4-dichlorophenol are met.

Owner:荆州沙隆达控股有限公司

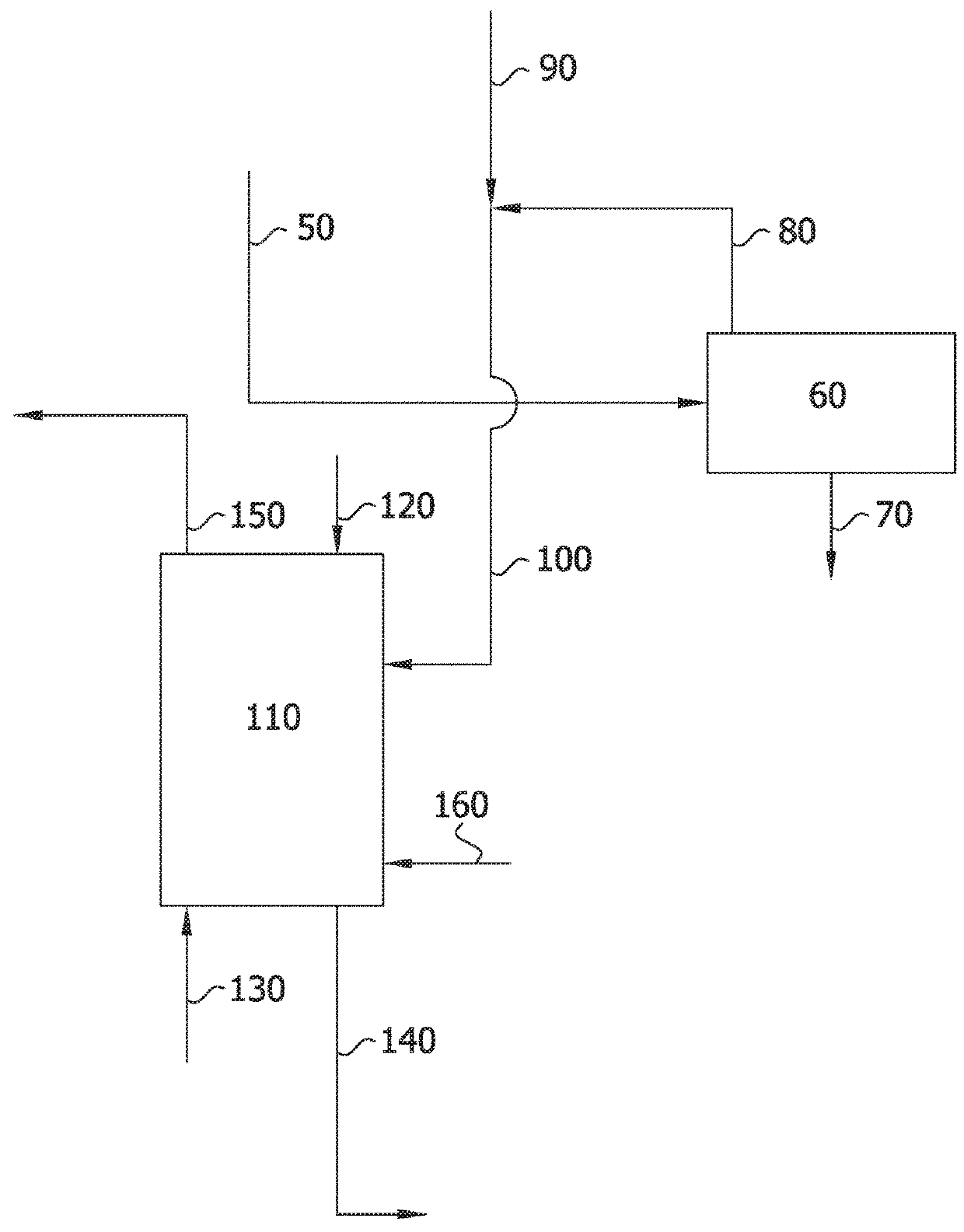

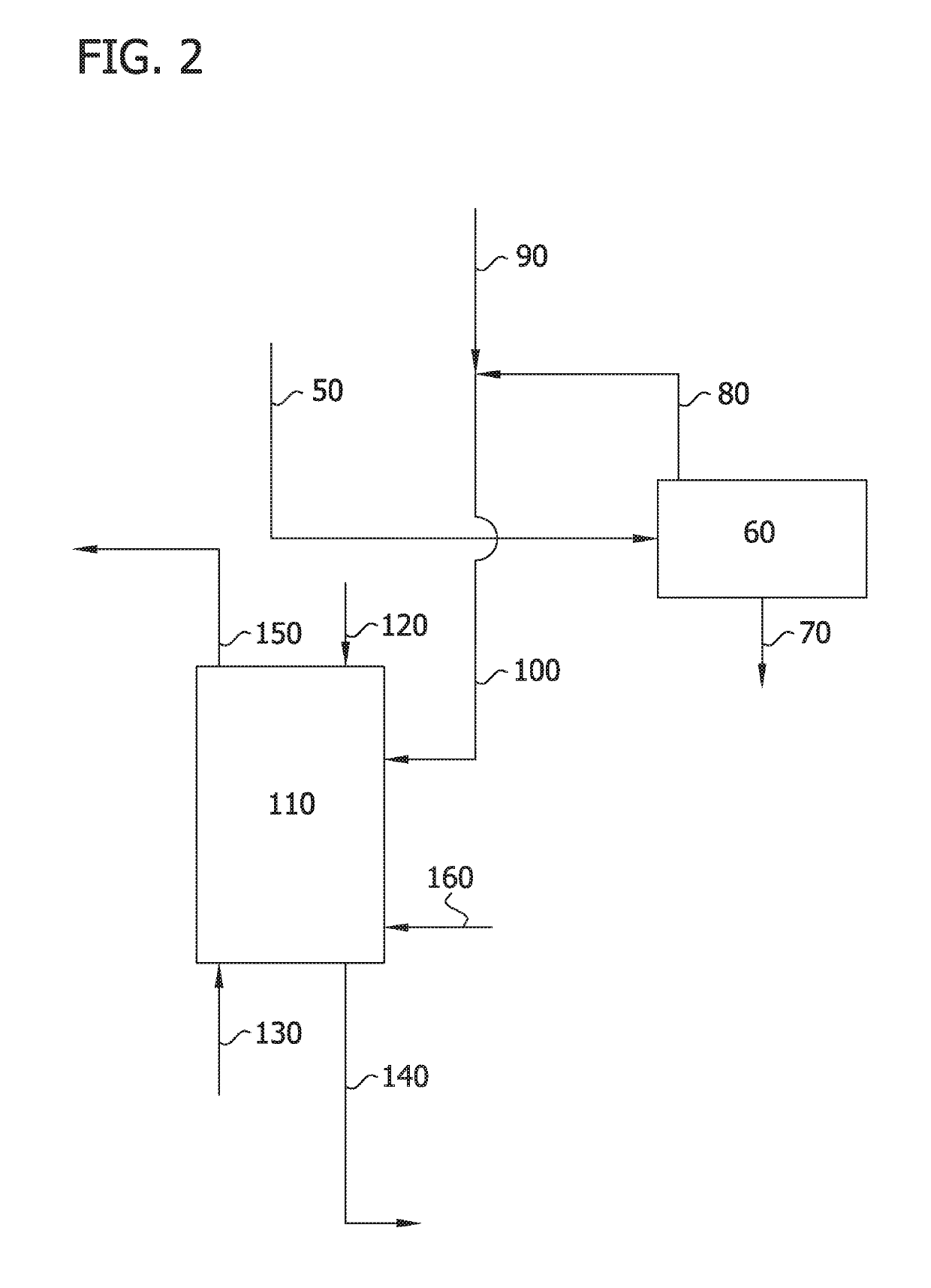

Production method and production system for 2,4-dichlorophenol

InactiveCN108424355ALess impuritiesEasy to separate and purifyOrganic chemistryOrganic compound preparationContinuous useMetal catalyst

The invention provides a production system for 2,4-dichlorophenol. The production system comprises a fixed-bed reactor, which comprises a phenol feeding port, a sulfuryl chloride feeding port and a discharge outlet, and is provided with a supported metal salt catalyst; a deacidification tower, which comprises a feed inlet, a gas discharge outlet and a liquid discharge outlet, wherein the feed inlet of the deacidification tower communicates with the discharge outlet of the fixed-bed reactor; and a rectifying tower, wherein the feed inlet of the rectifying tower communicates with the liquid discharge outlet of the deacidification tower. Compared with the prior art, the production system provided by the invention has the following advantages: the supported metal salt catalyst is fixed in thefixed-bed reactor for continuous usage and is not in a same system with phenol and a metal catalyst, so impurities in a reaction solution used in a chlorination reaction are reduced, the reaction solution can be easily separated and purified, a finally rectified substance has no solid residue, and a reaction route is clean and environment-friendly.

Owner:SHANDONG RUNBO BIOTECH CO LTD

Method for continuous production of herbicide 2,4-dichlorophenoxyacetic acid

ActiveCN104529757BEmission reductionSafe and efficient productionPreparation from carboxylic acid saltsOrganic compound preparationPhenol2,4-Dichlorophenol

The invention discloses a method for continuously producing herbicide 2,4-dichlorophenoxyacetic acid. According to the method, phenol and chlorine gas are used as raw materials; a continuous chlorination reaction is conducted through a micro-channel reactor to prepare 2,4-dichlorophenol, a condensation reaction is conducted through a tandem condensation reaction kettle to prepare 2,4-dichlorphenoxyacetic acid sodium salt, and then a continuous acidification reaction is conducted through a tandem acidification reaction kettle to prepare the 2,4-dichlorphenoxyacetic acid. Since continuous operation is realized in all the three reactions, the technological process is efficient, environmentally friendly, sustainable and suitable for industrial production; the method has the advantages that energy is saved, consumption is lowered, and emission of pollutants is reduced, and therefore safe and continuous industrial production is achieved.

Owner:台州煜农生物科技有限公司

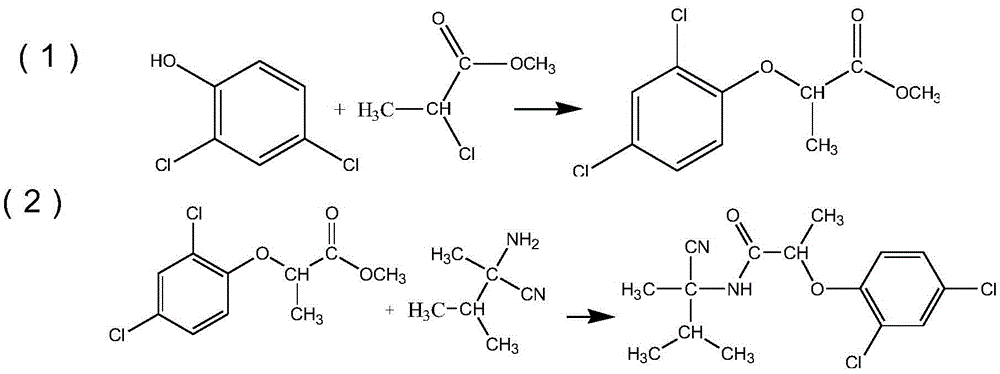

Method for synthesizing fenoxanil

ActiveCN104496847AReduce typesLow costCarboxylic acid nitrile preparationOrganic compound preparationSodium bicarbonateDistillation

The invention relates to a novel method for synthesizing fenoxanil serving as a systemic fungicide. The novel method for synthesizing fenoxanil serving as the systemic fungicide comprises the following steps: adding 2,4-dichlorophenol, sodium hydroxide and 2-methyl chloropropionate into a methyl benzene solvent, controlling reaction temperature at 30-70 DEG C, washing methyl benzene phase by using water after the reaction is ended, and carrying out reduced pressure distillation on a solvent of the washed methyl benzene phase to obtain dichlorprop methyl ester; and adding the obtained dichlorprop methyl ester into a methyl benzene solution with dissolved 2-amino-2,3-dimethyl butyronitrile and sodium bicarbonate, reacting by controlling the reaction temperature at 0-30 DEG C, washing the methyl benzene phase by using water after the reaction is ended, carrying out reduced pressure distillation on a solvent of the washed methyl benzene phase, recrystallizing by using a mixed solvent of water and ethyl alcohol, reducing the temperature to the room temperature, and filtering to obtain the fenoxanil. According to the synthesis method, 2-chloropropionic acid is replaced by 2-methyl chloropropionate; dipropionyl chloride is replaced by the generated dichlorprop methyl ester; one-step acylation reaction is eliminated; the process route is simplified; the reaction period is shortened; the method has great development in the industrial production.

Owner:JINGBO AGROCHEM TECH CO LTD

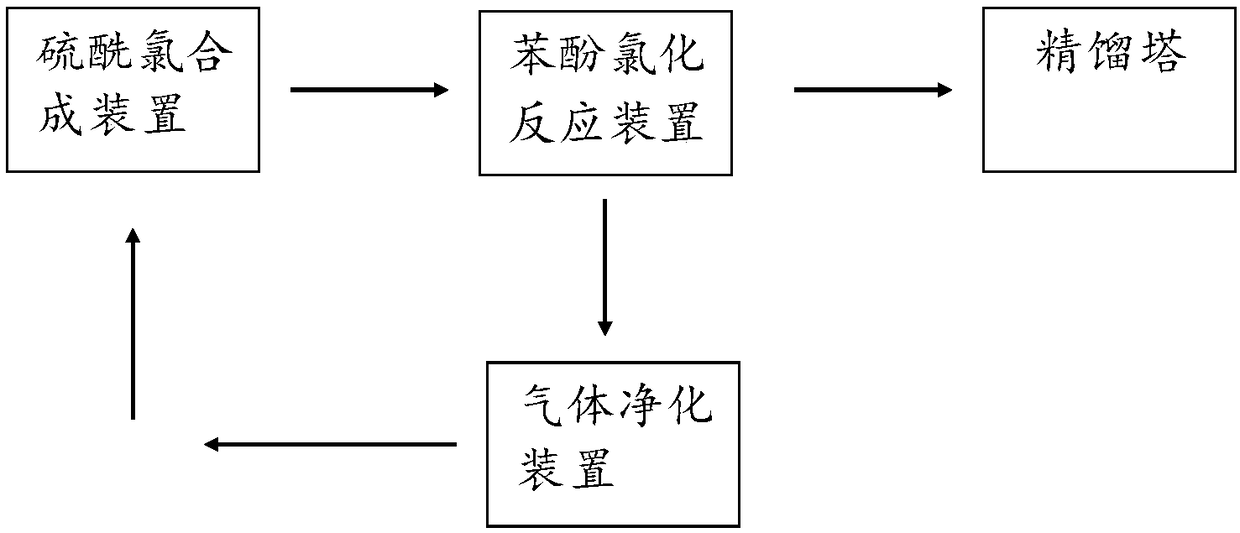

Production method and production system for 2,4-dichlorophenol

InactiveCN108424356AHigh selectivityHigh yieldOrganic chemistryOrganic compound preparationPhenolHigh selectivity

The invention provides a production method for 2,4-dichlorophenol. The production method comprises the following steps: S1) mixing an initiator, phenol and a catalyst and carrying out a reaction to obtain the chlorination tail gas of phenol and a reaction solution, wherein the initiator is sulfuryl chloride; S2) mixing the chlorination tail gas of phenol with chlorine gas for a reaction to obtainsulfuryl chloride; and S3) mixing the sulfuryl chloride with the reaction solution and carrying out a reaction to obtain the chlorination tail gas of phenol and 2,4-dichlorophenol. Compared with the prior art, the invention has the following advantages: chlorine gas is used as an initial chlorination raw material and continuously produces sulfuryl chloride through a reaction with sulfur dioxide inthe chlorination tail gas of phenol, and then the sulfuryl chloride is continuously added into the reaction solution to finally prepare 2,4-dichlorophenol; continuous reaction and tail gas recyclingflow are adopted in the invention, so high-selectivity low-cost high-yield preparation of 2,4-dichlorophenol is realized; moreover, the production method is simple in process flow and applicable to industrial production, and has great economic value and social benefits.

Owner:SHANDONG RUNBO BIOTECH CO LTD

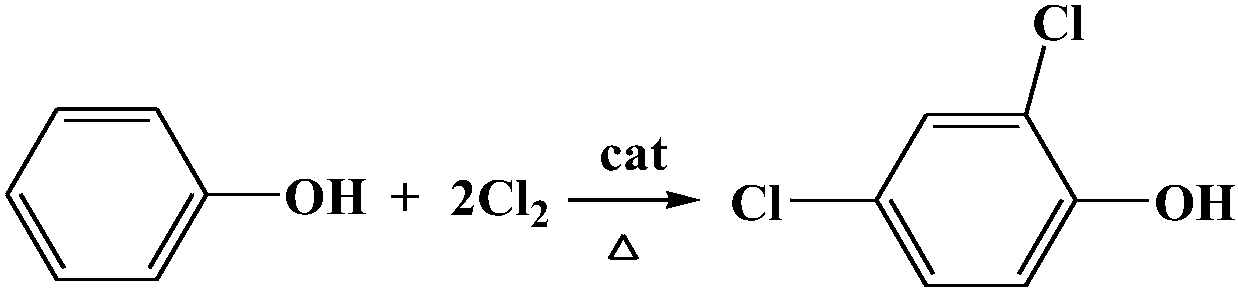

Method for preparing 2,4-dichlorophenol by catalytic chlorination of phenol

ActiveCN110452094ASimple and fast operationHigh yieldOrganic chemistryOrganic compound preparationPhenolPhenothiazine

The invention belongs to the field of preparation of fine chemical intermediate 2,4-dichlorophenol, and particularly relates to a method for preparing 2,4-dichlorophenol by catalytic chlorination of phenol. According to the method, phenol and chlorine are used as raw materials, Fe powder or FeCl3 is added as a catalyst, p-toluenethiol or o-aminobenzenethiol or phenothiazine is added as a cocatalyst, and the phenol is chlorinated to prepare 2,4-dichlorophenol. The method is simple and convenient to operate, the conversion rate of phenol is 100%, and the yield is high. The prepared 2,4-dichlorophenol can be directly used as a raw material of a 2,4-D raw drug, and in addition, the content of impurities such as by-product 2,6-dichlorophenol, 2,4,6-trichlorophenol and the like is low.

Owner:SOUTHEAST UNIV

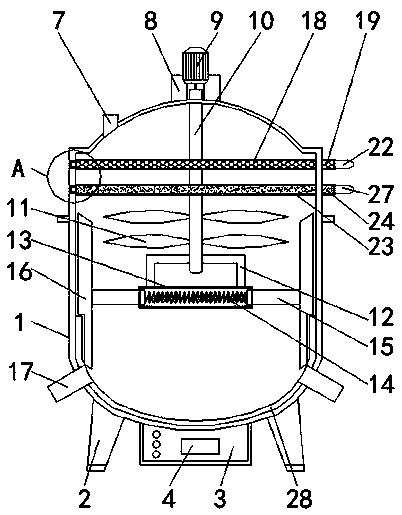

2,4-dichlorophenol concentrating crystallization device with impurity-removing effect and convenient to operate

InactiveCN108671578AWith impurity removal effectEasy to operateOrganic chemistryOrganic compound preparationMotor driveDichlorophenol

The invention relates to the technical field of concentrating crystallization, and discloses a 2,4-dichlorophenol concentrating crystallization device with an impurity-removing effect and convenient to operate. The 2,4-dichlorophenol concentrating crystallization device comprises a device body, wherein footstands are fixedly connected to the left and right sides of the bottom of the device body; two footstands are provided; a heater positioned on one side where the two footstands are opposite to each other is fixedly connected to the bottom of the device body; a control panel is fixedly connected to the front surface of the heater. According to the 2,4-dichlorophenol concentrating crystallization device with the impurity-removing effect and convenient to operate, through arrangement of a motor, a rotating rod, stirring wheels and blades, after the motor works normally, the motor drives the rotating rod to rotate, the rotating rod drives the stirring wheels to rotate therewith so as touniformly stir a material inside the device body, and the rotating rod drives the blades to rotate therewith so as to scrape off the material on the inner wall of the device body; because of differentthicknesses, a buffer effect is achieved through a spring, so that the effect of stirring the material uniformly is achieved, and thus the effect of convenient operation is achieved.

Owner:JIANGSU DINGYE PHARMA CO LTD

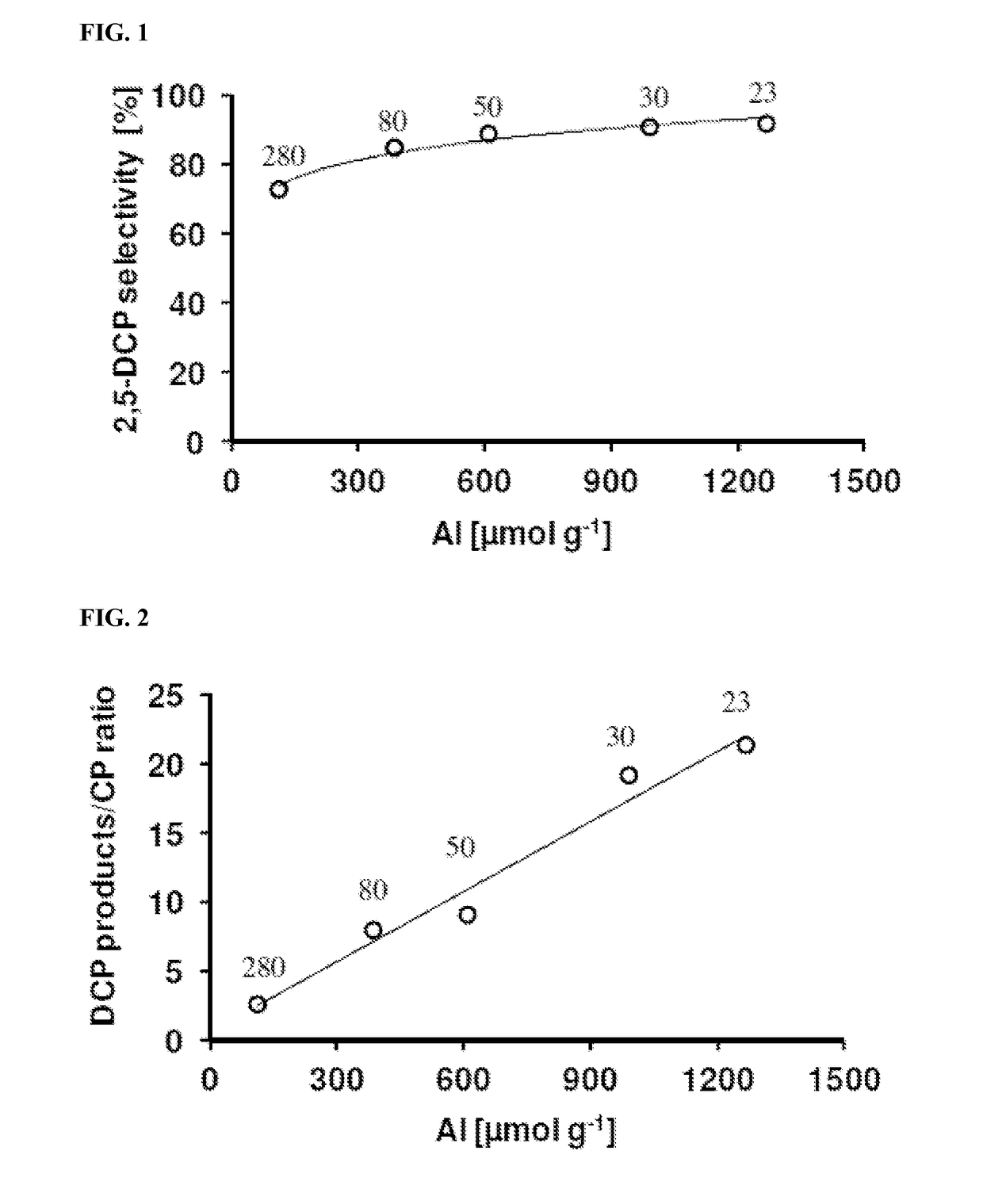

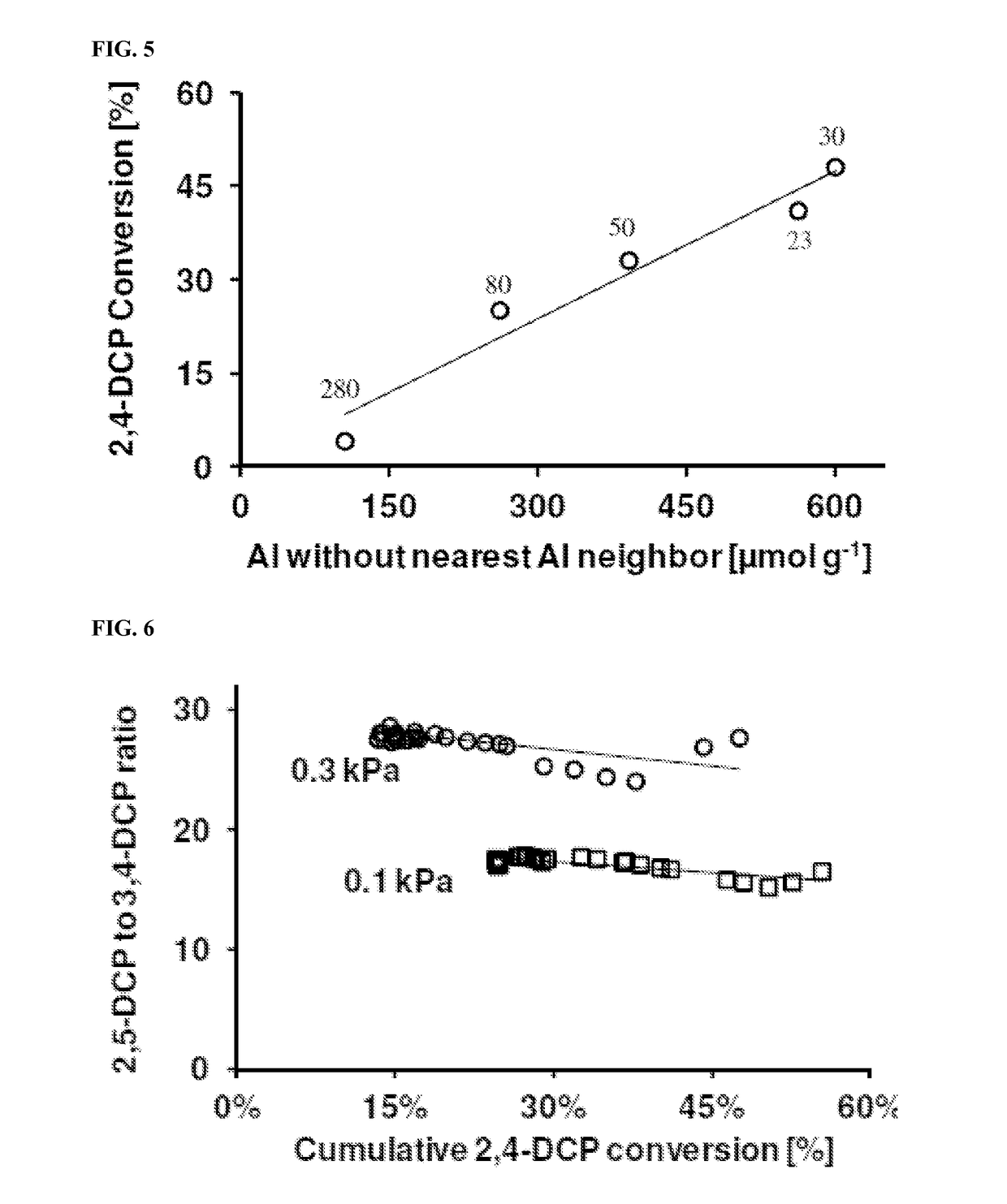

Processes for preparing 2,5-dichlorophenol

ActiveUS20170247310A1Molecular sieve catalystsOrganic compound preparation2-methoxybenzoic acidDichlorophenol

Processes for producing 2,5-dichlorophenol and 3,6-dichloro-2-methoxybenzoic acid are described. Various processes for isomerizing 2,4-dichlorophenol over a zeolite catalyst to form 2,5-dichlorophenol are provided. Processes for preparing 2,5-dichlorophenol including hydroxylating 1,4-dichlorobenzene are also described. The present invention also relates to processes for producing 3,6-dichloro-2-methoxybenzoic acid.

Owner:MONSANTO TECH LLC

Method for separating 2,5-dichlorophenol and 2,4-dichlorophenol

InactiveCN105801380AReduce processing costsSimple operation processOrganic chemistryOrganic compound preparationDissolutionDichlorophenol

The invention discloses a method for separating 2,5-dichlorophenol and 2,4-dichlorophenol, belonging to the technical field of fine chemical industry. According to the method, the 2,5-dichlorophenol is separated out by a urea addition process, and then the less 2,5-dichlorophenol is separated from the 2,4-dichlorophenol by steps of ammonia water dissolution, crystallization and the like, so that the 2,5-dichlorophenol is thoroughly separated from the 2,4-dichlorophenol. Compared with the prior art, the method has the advantages of being low in cost, simple in operation technology and less in energy consumption.

Owner:SICHUAN FOURSTAR BIOTECH RANDD CORP

Method for separating 2,5-dichlorophenol from 2,4-dichlorophenol

ActiveCN105801379AReduce solubilityLow costOrganic chemistryOrganic compound preparationDichlorophenol2,4-Dichlorophenol

The invention discloses a method for separating 2,5-dichlorophenol from 2,4-dichlorophenol, and belongs to the technical field of fine chemical engineering. According to the method disclosed by the invention, after the 2,5-dichlorophenol is separated through steps of dissociation, extraction, dewatering, sedimentation, filter and the like, the 2,4-dichlorophenol is separated through steps of forming salt by ammonia water, recrystallizing and the like, and the purpose of completely separating the 2,5-dichlorophenol from the 2,4-dichlorophenol is realized through setting specific parameters of each working procedure; the method has the advantages that the operation is simple and convenient, and the cost is low.

Owner:SICHUAN FOURSTAR BIOTECH RANDD CORP

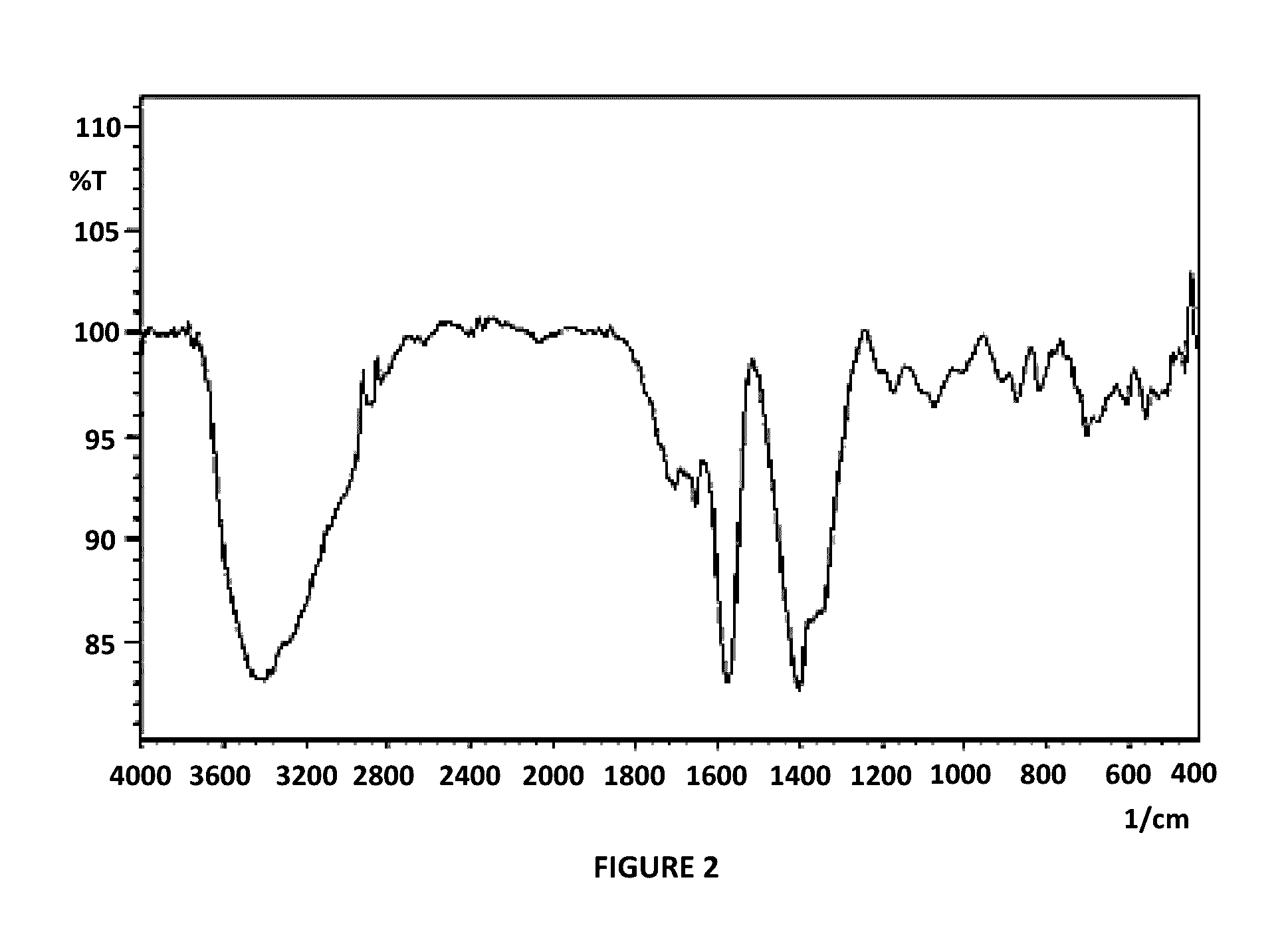

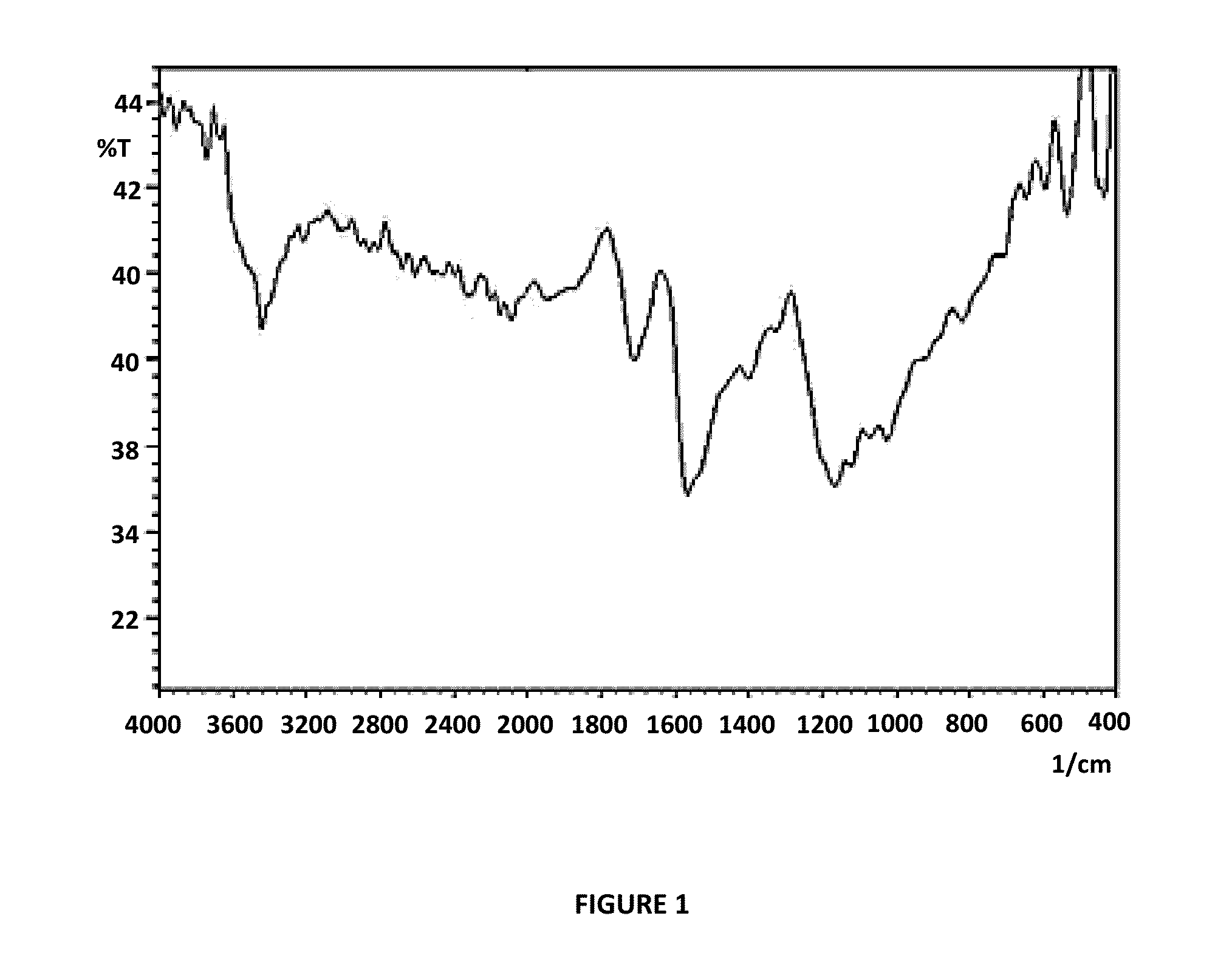

Methodology for the formation of an extractive agent of polymerized carbon nanotubes encapsulating phenol nanoparticles used for DNA extraction and purification, and product thereof

A method for synthesis of nanocomposites using polymerized carbon nanotubes and phenolic compounds, such as 2,4-dichlorophenol, 4-nitrophenol, 2-nitrophenol, 4-chlorophenol, 2,4,6-trinitrophenol and phenol, in aqueous media, as well as the application of one of such nanocomposites, namely MWCNT-g-PCA-Phenol, as a DNA extraction agent. The aforementioned nanocomposites enable the isolation of genomic DNA of plant samples. Pursuant to the present invention, the toxicity of free phenols used in DNA extraction is decreased since very low concentrations of phenol are required in the method, as compared to conventional techniques which employ saturated phenol solutions. This remarkable advantage is due to the encapsulation of the phenol nanoparticles into the polymerized carbon nanotubes.

Owner:SARLAK NAHID +1

Method for treating 2,4-dichlorophenol wastewater by ozone oxidation in organic solvent

ActiveCN102134133BReduce dosageShort reaction timeMultistage water/sewage treatmentWater/sewage treatment by sorptionAqueous acetoneAtmospheric air

Owner:常熟紫金知识产权服务有限公司

Method for separating 2,4-Dichlorophenol and 2,6-Dichlorophenol

ActiveCN101781175BImprove separation efficiencyEasy to operateOrganic chemistryOrganic compound preparationMorpholineEthyl acetate

The invention discloses a method for separating 2,4-Dichlorophenol and 2,6-Dichlorophenol, comprising the following steps: dissolving the mixture of the 2,4-Dichlorophenol and the 2,6-Dichlorophenol in an organic solvent, adding alkalic organism, stirring and reacting at the temperature of 40-80 DEG C until the reaction liquid is clear, cooling the reaction liquid after the reaction is finished, standing and precipitating crystals, filtering to obtain a filter cake A and a filtrate A, and retaining the 2,4-Dichlorophenol in the filtrate A, wherein the filter cake A is a crude product of the 2,6-Dichlorophenol; the alkalic organism is triethylene diamine, morpholine, piperazidine, ethylpiperazine or methyl piperazine; and the organic solvent is ethanol, methanol, acetone or ethyl acetate. The invention has higher separation efficiency and only need crystallization for one time; the total yield of the 2,4-Dichlorophenol is 90-95%, and the purity thereof is 96-99%; the total yield of the 2,6-Dichlorophenol is 77-89%, and the purity thereof is 90-99%; and the invention has the advantages of simple operation, good repeatability and low implementation cost, and is favor of industrialized scale-up.

Owner:ZHEJIANG UNIV OF TECH

Preparation method for 2,4-dichlorophenol, and preparation method for 2,4-dichlorophenolate

InactiveCN108424357AHigh selectivityGuaranteed reaction rateOrganic chemistryOrganic compound preparationOrganic solventReaction rate

The invention provides a preparation method for 2,4-dichlorophenol. The preparation method comprises the following steps: S) adding phenol, a promoter and sulfuryl chloride into an organic solvent andcarrying out chlorination under low temperature conditions to obtain 2,4-dichlorophenol, wherein the promoter is one or more selected from the group consisting of dimethyl sulfide, phenyl sulfide andisopropyl ether. Compared with the prior art, the preparation method provided by the invention has the advantage that selectivity is improved due to the reaction under low temperature conditions; andthe promoter is added at the same time to ensure a reaction rate.

Owner:SHANDONG RUNBO BIOTECH CO LTD

Methodology for the formation of an extractive agent of polymerized carbon nanotubes encapsulating phenol nanoparticles used for DNA extraction and purification, and product thereof

A method for synthesis of nanocomposites using polymerized carbon nanotubes and phenolic compounds, such as 2,4-dichlorophenol, 4-nitrophenol, 2-nitrophenol, 4-chlorophenol, 2,4,6-trinitrophenol and phenol, in aqueous media, as well as the application of one of such nanocomposites, namely MWCNT-g-PCA-Phenol, as a DNA extraction agent. The aforementioned nanocomposites enable the isolation of genomic DNA of plant samples. Pursuant to the present invention, the toxicity of free phenols used in DNA extraction is decreased since very low concentrations of phenol are required in the method, as compared to conventional techniques which employ saturated phenol solutions. This remarkable advantage is due to the encapsulation of the phenol nanoparticles into the polymerized carbon nanotubes.

Owner:SARLAK NAHID +1

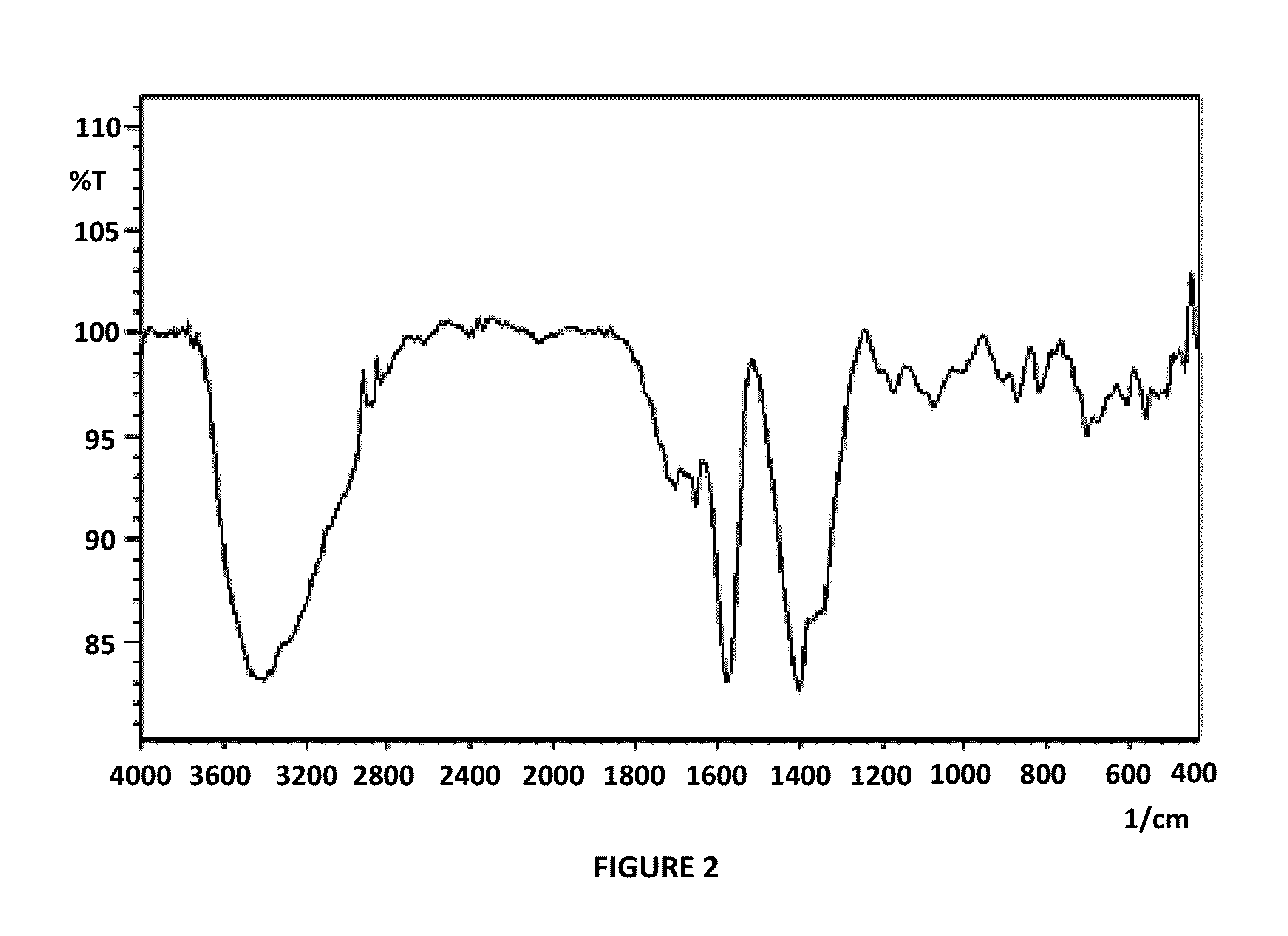

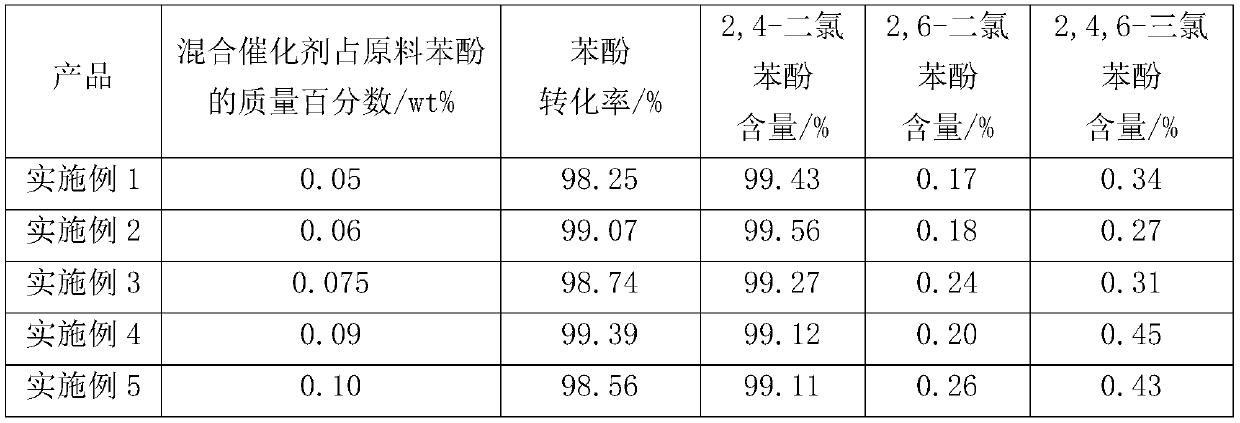

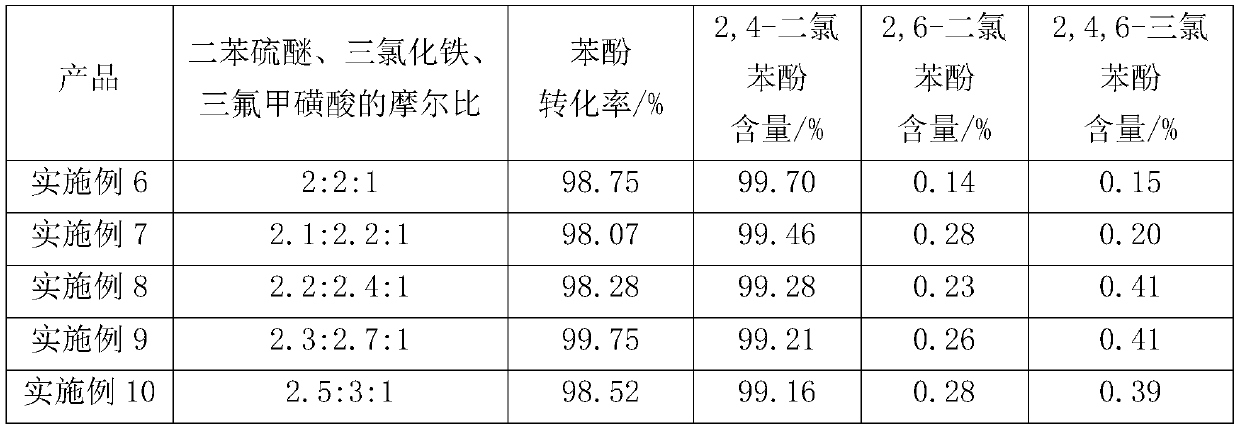

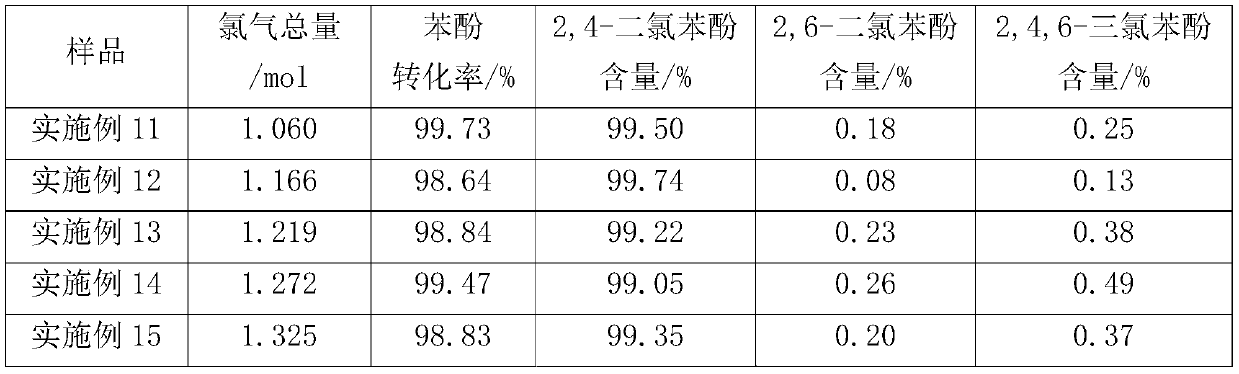

Method for producing high-purity 2,4-dichlorophenol

ActiveCN109851481AImprove conversion rateReduce dosageOrganic chemistryOrganic compound preparationTriflic acidEthyl Chloride

The invention provides a method for producing high-purity 2,4-dichlorophenol. The method comprises the following steps: (1) performing heating melting on a raw material, and adding a mixed catalyst into the raw material, wherein the raw material is at least one selected from phenol, o-chlorophenol or p-chlorophenol, and the mixed catalyst is a mixture of diphenyl sulfide, ferric chloride and trifluoromethanesulfonic acid; (2) maintaining the temperature of the material at 40-100 DEG C, introducing a chlorinating agent into the material, and performing a chlorination catalytic reaction to obtain crude 2,4-dichlorophenol,wherein the chlorinating agent is at least one selected from chlorine gas and sulfuryl chloride; and (3) performing melt crystallization on the crude 2,4-dichlorophenol to obtain the 2,4-dichlorophenol product. According to the method provided by the invention, the chlorinating agent used in the method can be the sulfuryl chloride or the chlorine gas, and when the sulfuryl chloride or the chlorine gas is used, a higher conversion rate of the raw material can be achieved; the crude product obtained by the catalytic chlorination reaction in the method does not need rectification, and the 2,4-dichlorophenol product with purity of 99% can be obtained only by the melt crystallization.

Owner:QINGDAO UNIV OF SCI & TECH

Method for preparing 2,4-dichlorophenol by microreactor

InactiveCN108863729AHigh purityShort reaction timeOrganic chemistryOrganic compound preparationMixed materialsSolvent

The invention relates to a method for preparing 2,4-dichlorophenol by a microreactor. Phenol is dissolved into a solvent, and is pumped into a miniature mixer to be mixed with introduced chlorine gas;the mixed material is then introduced into a micro passage reaction tube for continuous reaction to obtain a reaction mixture; tail gas is absorbed by water to prepare diluted hydrochloric acid. Thesolvent in the reaction mixture is distilled and recovered to obtain a reaction product. The method has the advantages that the advantages of the miniature reactor in an aspect of heat transfer and mass transfer are utilized; the catalyst addition is not needed; the continuous preparation of 2,4-dichlorophenol can be realized in short time; the advantages of low device cost, continuous and controllable process, high product purity, easy realization of industrialization and the like are realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of method of synthesizing blastamide

ActiveCN104496847BReduce typesLow costCarboxylic acid nitrile preparationOrganic compound preparationSodium bicarbonateSynthesis methods

The invention relates to a novel method for synthesizing fenoxanil serving as a systemic fungicide. The novel method for synthesizing fenoxanil serving as the systemic fungicide comprises the following steps: adding 2,4-dichlorophenol, sodium hydroxide and 2-methyl chloropropionate into a methyl benzene solvent, controlling reaction temperature at 30-70 DEG C, washing methyl benzene phase by using water after the reaction is ended, and carrying out reduced pressure distillation on a solvent of the washed methyl benzene phase to obtain dichlorprop methyl ester; and adding the obtained dichlorprop methyl ester into a methyl benzene solution with dissolved 2-amino-2,3-dimethyl butyronitrile and sodium bicarbonate, reacting by controlling the reaction temperature at 0-30 DEG C, washing the methyl benzene phase by using water after the reaction is ended, carrying out reduced pressure distillation on a solvent of the washed methyl benzene phase, recrystallizing by using a mixed solvent of water and ethyl alcohol, reducing the temperature to the room temperature, and filtering to obtain the fenoxanil. According to the synthesis method, 2-chloropropionic acid is replaced by 2-methyl chloropropionate; dipropionyl chloride is replaced by the generated dichlorprop methyl ester; one-step acylation reaction is eliminated; the process route is simplified; the reaction period is shortened; the method has great development in the industrial production.

Owner:JINGBO AGROCHEM TECH CO LTD

Separation method of 2,4-dichlorophenol and 2,5-dichlorophenol mixture

ActiveCN101412664BHigh purityHigh yieldOrganic chemistryOrganic compound preparationFencholSpatial structure

The invention provides a method for separating a mixture of 2, 4-dichlorophenol and 2, 5-dichlorophenol. Based on the fundamental principle of supramolecular assembly, the method uses topology match between subjective molecules and objective molecules, and separates 2, 4 / 2, 5-mixed dichlorophenol by identifying molecules. Because of different molecular spatial structures of the 2, 4-dichlorophenol and the 2, 5-dichlorophenol and certain difference on polarities, specific different identifying capability among the subjective molecules exists, while difficulty or ease of intermolecular actions among the subjective molecules and other heterocyclic compound is different, therefore, the aim of separation can be achieved through identifying the molecules. The product obtained from the 2, 4 / 2, 5-mixed dichlorophenol by the method has high purity, and can be directly used after being separated, but does not need to be recrystallized to improve purity; and the method has high yield, is simple and practical, and is easy to industrialize.

Owner:ZHEJIANG UNIV OF TECH

Separation of dichlorophenols

Various processes for the separation of a mixture containing dichlorophenols are described. In various aspects, the present invention relates to separation processes that produce an extract enriched in 2,4-dichlorophenol content and an extract enriched in 2,5-dichlorophenol content. The present invention further relates to various processes that integrate with these separation processes, such as a process for producing 3,6-dichloro-2-methoxybenzoic acid (dicamba) or salt or ester thereof or a process for producing 2,4-dichlorophenoxyacetic acid (2,4-D) or salt or ester thereof.

Owner:MONSANTO TECH LLC

Method for quantitatively detecting 2, 4-dichlorophenol in water

ActiveCN103604883BLess solventLess interfering substancesComponent separationEnvironmental resistanceSolid-phase microextraction

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com