Method for treating 2,4-dichlorophenol wastewater by ozone oxidation in organic solvent

A dichlorophenol and ozone oxidation technology, which is applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of lack of selective oxidation, low ozone utilization rate, and many intermediate products , to achieve the effect of large promotion and application value, low processing cost and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

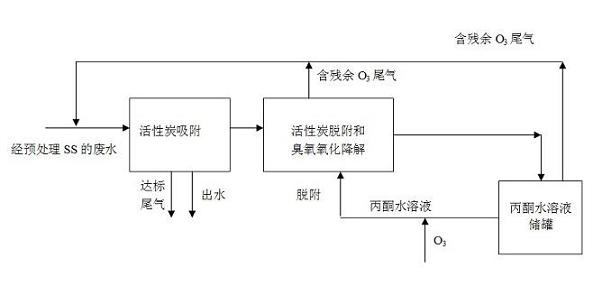

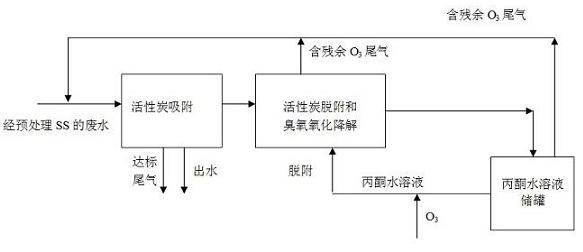

[0023] A commonly used activated carbon adsorption column (or tower) is used, and its device is connected to a solvent desorption system. The treated organic wastewater is 2,4-dichlorophenol wastewater, and the water volume is less than 20m 3 / d, the concentration is below 10mg / L, and the ozone generator is 3.0g / h. The wastewater containing 2,4-dichlorophenol is adsorbed in the activated carbon adsorption column, and the saturated activated carbon is desorbed / ozonated intermittently. After the saturated activated carbon is naturally drained by gravity, the acetone aqueous solution (containing less than 50% acetone, volume ratio) is used for external circulation desorption / ozone oxidation at the same time. Returning to the liquid storage tank, the tail gas containing residual ozone is fed into the activated carbon column being adsorbed through the pump, and is discharged into the atmosphere after complete adsorption-decomposition. Acetone aqueous solution and activated carbon...

Embodiment 2

[0025] A commonly used activated carbon adsorption column (or tower) is used, and its device is connected to a solvent desorption system. The treated organic wastewater is 2,4-dichlorophenol wastewater, and the water volume is less than 20m 3 / d, the concentration is below 100mg / L, and the ozone generator is 5.0g / h. The wastewater containing 2,4-dichlorophenol is adsorbed in the activated carbon adsorption column, and the saturated activated carbon is desorbed / ozonated intermittently. After the saturated activated carbon is naturally drained by gravity, the acetone aqueous solution (containing less than 50% acetone, volume ratio) is used for external circulation desorption / ozone oxidation at the same time. Returning to the liquid storage tank, the tail gas containing residual ozone is fed into the activated carbon column being adsorbed through the pump, and is discharged into the atmosphere after complete adsorption-decomposition. Acetone aqueous solution and activated carbon...

Embodiment 3

[0027] Use an ordinary activated carbon adsorption column (or tower), and its device is connected to a solvent desorption system. The organic wastewater to be treated is 2,4-dichlorophenol wastewater, and the water volume is greater than 20m 3 / d, the concentration is below 100mg / L, and the ozone generator is 8.0g / h. The wastewater containing 2,4-dichlorophenol is adsorbed in the activated carbon adsorption column, and the wastewater containing 2,4-dichlorophenol is continuously adsorbed by replacing the activated carbon column, and the saturated activated carbon is desorbed / ozone intermittently oxidation. After the saturated activated carbon is naturally drained by gravity, the acetone aqueous solution (containing less than 50% acetone, volume ratio) is used for external circulation desorption / ozone oxidation at the same time. Returning to the liquid storage tank, the tail gas containing residual ozone is fed into the activated carbon column being adsorbed through the pump,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com