Degradation method capable of adsorbing 2,4-dichlorophenol in organic halide

An organic halide, dichlorophenol technology, applied in chemical instruments and methods, water pollutants, oxidized water/sewage treatment, etc., can solve the problems of catalyst waste, reduce catalytic efficiency, etc., achieve reagent saving, good degradation effect, The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take 20mL of the 1.0g / L 2,4-dichlorophenol (2,4-DCP) pollutant stock solution and place it in a 1L beaker. Pipette 10mL, 25mL, 50mL, and 100mL of the stock solution into the beaker, then add deionized water to dilute to nearly 1 liter, the concentration of Fe(Ⅲ)-EDDS complex in the mixed solution is 0.02mmol / L, 0.05mmol / L, 0.1mmol / L, 0.2mmol / L, after fully mixing, adjust the pH value to 7.0±0.1, then quickly add 100μL hydrogen peroxide solution (concentration of hydrogen peroxide solution is 30%, density 1.13g / mL) , set the volume in a 1000mL volumetric flask, and the concentration of hydrogen peroxide in the mixed solution is 1.0mmol / L; then pour it into a xenon lamp catalytic reactor, adopt internal illumination type light irradiation and adopt a xenon lamp light source, irradiate and start Timing, at 0min, 5min, 10min, 20min, 30min, 45min, 60min, 90min, 120min, take 1.0mL water sample with a pipette gun for measurement. The result is as figure 1 shown.

[0027] I...

Embodiment 2

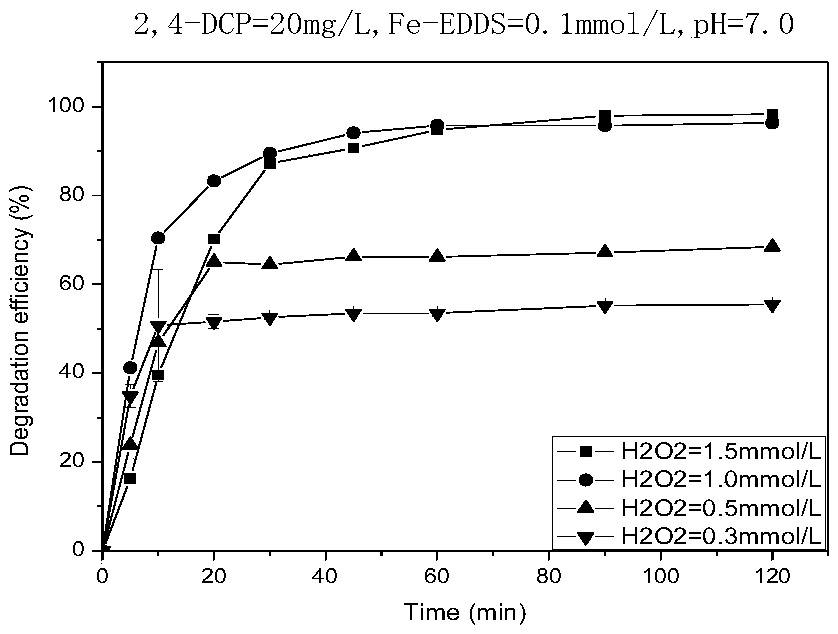

[0029] Take 20mL of 1.0g / L 2,4-dichlorophenol (2,4-DCP) stock solution and place it in a 1L beaker. From 2.0mmol / L Fe(Ⅲ)-EDDS complex stock solution Pipette 50mL solution into a beaker, add deionized water to dilute to nearly 1 liter, the concentration of Fe(Ⅲ)-EDDS complex is 0.1mmol / L, after fully mixing, adjust the pH value to 7.0±0.1, and then rapidly Add 30 μL, 50 μL, 100 μL, and 150 μL of hydrogen peroxide solution (30% hydrogen peroxide solution, density 1.13 g / mL), set the volume in a 1000 mL volumetric flask, and the concentration of hydrogen peroxide in the mixture reaches 0.3 mmol / L, 0.5mmol / L, 1.0mmol / L, 1.5mmol / L, and then pour it into a xenon light catalytic reactor, use internal light irradiation and xenon light source, irradiate and start timing, at 0min, 5min, 10min, 20min , 30min, 45min, 60min, 90min, 120min Take 1.0mL water sample with a pipette gun for determination. The result is as figure 2 shown.

[0030] In this example, as the concentration of hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com