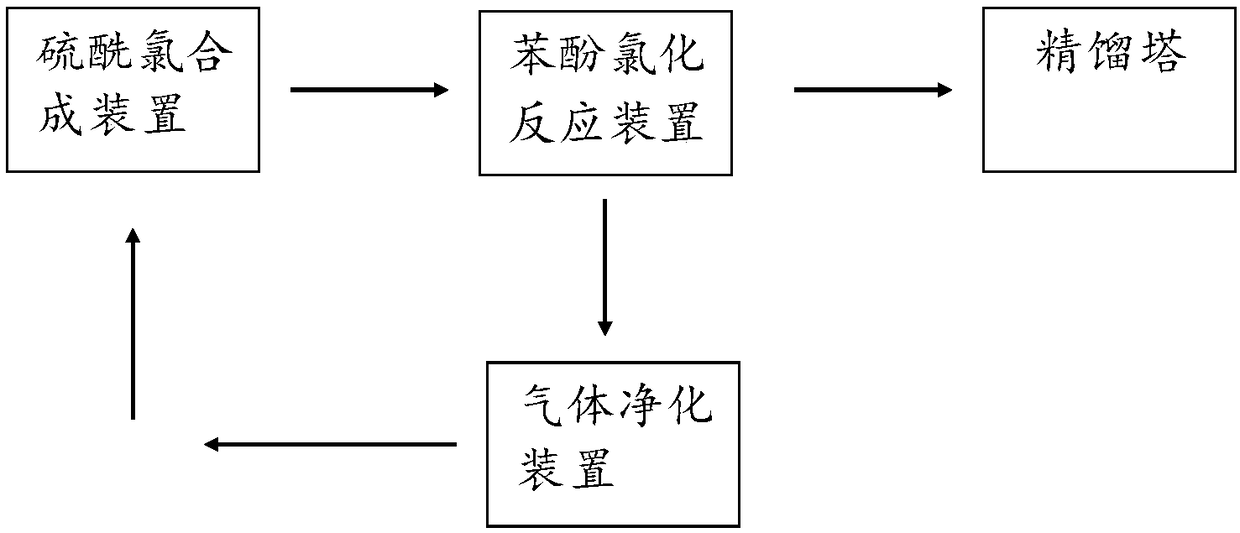

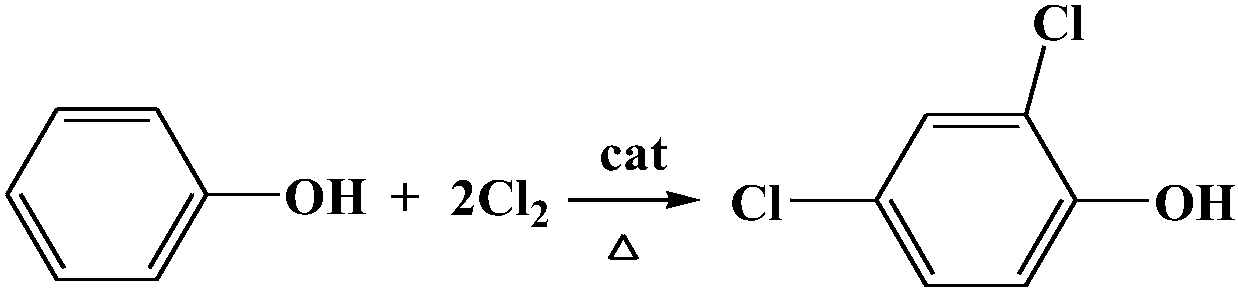

Production method and production system for 2,4-dichlorophenol

A production method and technology of dichlorophenol, which is applied in the field of 2,4-dichlorophenol production method and production system, can solve problems such as affecting use and poor product appearance, and achieve simple process, low cost and high selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Add 4000kg of phenol to the 8000L chlorination kettle of the tail gas recycling device supporting phenol recovery and drying, start stirring, then add 0.4kg of dimethyl sulfide, 8kg of ferric chloride, after complete dissolution, keep the temperature at 40°C, start 100 kg of sulfuryl chloride was added dropwise as an initiator, and no fresh sulfuryl chloride was used subsequently. When sulfuryl chloride is added dropwise, tail gas containing sulfur dioxide and hydrogen chloride will overflow. After passing through the tail gas purification and recovery device, the purified mixed gas of sulfur dioxide and hydrogen chloride has a molar ratio of sulfur dioxide to hydrogen chloride of 1:1. After being measured by a flow meter, it is sent to the sulfuryl chloride synthesis process.

[0055] In the sulfuryl chloride synthesis unit, according to the molar amount of tail gas measured by the flow rate, it enters the sulfuryl chloride synthesis reactor at a molar ratio of 1:1 bet...

Embodiment 2

[0060] Add 4000kg of phenol to the 8000L chlorination kettle of the tail gas recycling device supporting phenol recovery and drying, start stirring, then add 1kg of phenylene sulfide and 8kg of ferric chloride, after complete dissolution, keep the temperature at 50°C, and start adding dropwise 150 kg of sulfuryl chloride was used as an initiator, and fresh sulfuryl chloride was no longer used in the follow-up. When sulfuryl chloride is added dropwise, tail gas containing sulfur dioxide and hydrogen chloride will overflow. After passing through the tail gas purification and recovery device, the purified mixed gas of sulfur dioxide and hydrogen chloride has a molar ratio of sulfur dioxide to hydrogen chloride of 1:1. After being measured by a flow meter, it is sent to the sulfuryl chloride synthesis process.

[0061] In the sulfuryl chloride synthesis unit, according to the molar amount of tail gas measured by the flow rate, the molar ratio of chlorine gas to mixed gas is 1.05:1...

Embodiment 3

[0066] Add 4000kg of phenol to the 8000L chlorination kettle of the tail gas recycling device supporting phenol recovery and drying, start stirring, then add 0.6kg of phenylene sulfide and 7kg of titanium tetrachloride. Add 100 kg of sulfuryl chloride as an initiator, and no fresh sulfuryl chloride will be used later. When sulfuryl chloride is added dropwise, tail gas containing sulfur dioxide and hydrogen chloride will overflow. After passing through the tail gas purification and recovery device, the purified mixed gas of sulfur dioxide and hydrogen chloride has a molar ratio of sulfur dioxide to hydrogen chloride of 1:1. After being measured by a flow meter, it is sent to the sulfuryl chloride synthesis process.

[0067] In the sulfuryl chloride synthesis unit, according to the molar amount of tail gas measured by the flow rate, it enters the sulfuryl chloride synthesis reactor at a molar ratio of 1.1:1 between chlorine gas and mixed gas for sulfuryl chloride synthesis, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com