Method and device for recycling by-product hydrochloric acid in methane fluorine compound production

A technology for by-produced hydrochloric acid and recovery method, applied in chemical instruments and methods, halogen/halogen acid, halogenated hydrocarbon disproportionation separation/purification, etc., can solve the increase of difluoromethane production cost, environmental pollution, increase of equipment and energy consumption and other problems, to achieve the effects of low energy consumption, environmental pollution reduction, and economical efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to the drawings and embodiments. The following embodiments are for explaining the present invention and the present invention is not limited to the following embodiments.

[0023] A method for recovering by-product hydrochloric acid in the production of methane fluoride, which is characterized in that it comprises the following steps:

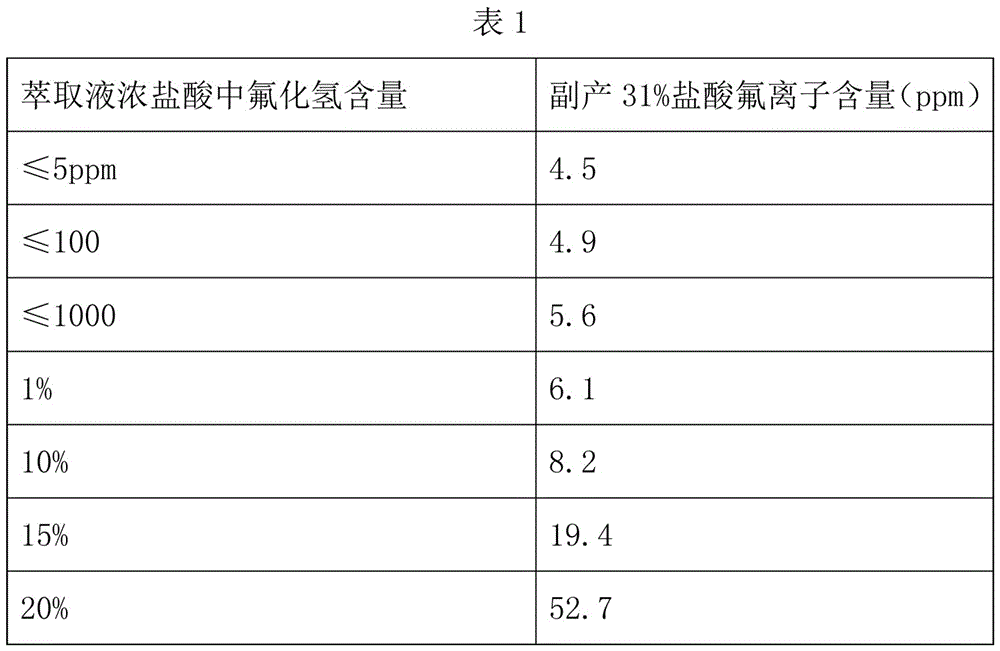

[0024] Step 1: Use concentrated hydrochloric acid with a mass concentration of 30-35% to extract HF in the fluorination reaction mixed gas; the mass concentration of concentrated hydrochloric acid is preferably 31%, the extraction temperature is controlled at 5-30℃, and the best control is at 5℃~20 ℃, the pressure of the bubble column separation process is controlled at 10kPa-100kPa, and the content of hydrogen fluoride after 31% concentrated hydrochloric acid absorbs hydrogen fluoride is controlled within 15wt%.

[0025] Step 2: The extracted mixed gas is passed thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com