Method for preparing paint raw material from paint waste residue

A paint waste and paint slag technology, applied in plastic recycling, polyester coatings, epoxy resin coatings, etc., can solve the problems of high organic solvent content, difficult to be accepted by manufacturers, and high operating costs, and achieve low organic solvent content and low disposal costs. The effect of reducing and reducing the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

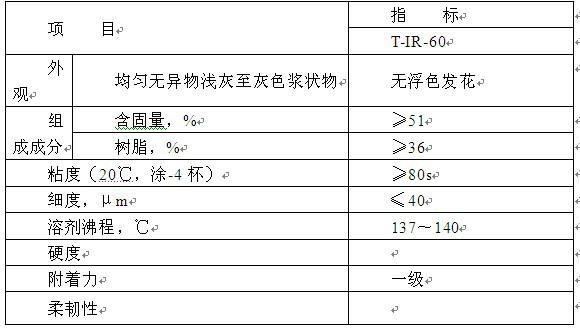

Image

Examples

Embodiment 1

[0037] The invention discloses a method for preparing paint waste slag into paint raw materials, which comprises the steps of primary selection of paint slag, homogeneous dispersion, separation and modification, solvent separation, product packaging and the like. refer to figure 1 , the specific process is as follows:

[0038] The paint slag is pre-treated to classify it, remove foreign matter, add additives and protective agents, and disperse evenly; the pre-treated paint slag is sent to the organic waste recycling system, and it is processed after setting the appropriate temperature, speed, and pressure. Separation and modification; the solid part is recycled and packaged as a modified resin in the form of viscous cement; the mixed vapor of solvent and water is collected by gas and then condensed to separate gas and liquid, and the gas part is purified by tail gas Discharge up to the standard, the liquid part enters the oil-water separation, so that the water and the solven...

Embodiment 2

[0040] The more optimal technical scheme of the present invention is:

[0041] A method for preparing paint raw materials from paint waste, characterized in that it comprises the steps of:

[0042] a. Primary selection of paint slag: classify paint slag and remove foreign matter;

[0043] b. Homogeneous dispersion:

[0044] According to the type of paint residue and the temperature resistance of paint residue, add liquid paraffin or phthalate as an additive, the mass ratio of paint residue to additive is 100: (1-25), and then mix and stir evenly;

[0045] According to the different types of paint slag and resin components in paint slag, add organic sulfonic acid agent, organic base or metal compound as protective agent, the mass ratio of paint slag to organic sulfonic acid agent is 100:10, the ratio of paint slag to organic base The mass ratio is 100:(1~20), the mass ratio of paint slag to metal compound is 100:(1~5);

[0046]c. Separation modification:

[0047] Put the pa...

Embodiment approach

[0050] The best implementation mode of the present invention is:

[0051] 1. Preliminary selection of paint slag: classify the paint slag, and remove foreign objects such as metal and cloth;

[0052] 2. Homogeneous dispersion:

[0053] 2.1 Choose different additives according to the type of paint residue and the temperature resistance of paint residue.

[0054] 2.1.1 For low-temperature resistant paint residues, such as furniture factory paints, it is mainly composed of polyurethane paint (PU), polyester paint (PE) and nitro paint (NC). Its paint slag chooses liquid paraffin as an additive.

[0055] 2.1.2 For high-temperature-resistant paint residues, such as paints in the automotive coating industry, generally between 100°C and 1800°C, phthalate plasticizers are selected as additives for paint residues.

[0056] 2.1.3 Regardless of the type of paint slag, the addition ratio is based on the mass ratio of paint slag: additive = 100: (1 ~ 25), mixing and stirring evenly; addi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com