Method for generating polycrystalline silicon by recycling by-products

A by-product, polysilicon technology, applied in the direction of silicon, etc., can solve the problems of dry recycling polluting the production cycle system, polysilicon is difficult to achieve high purity, etc., to reduce equipment investment, improve quality, and improve economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

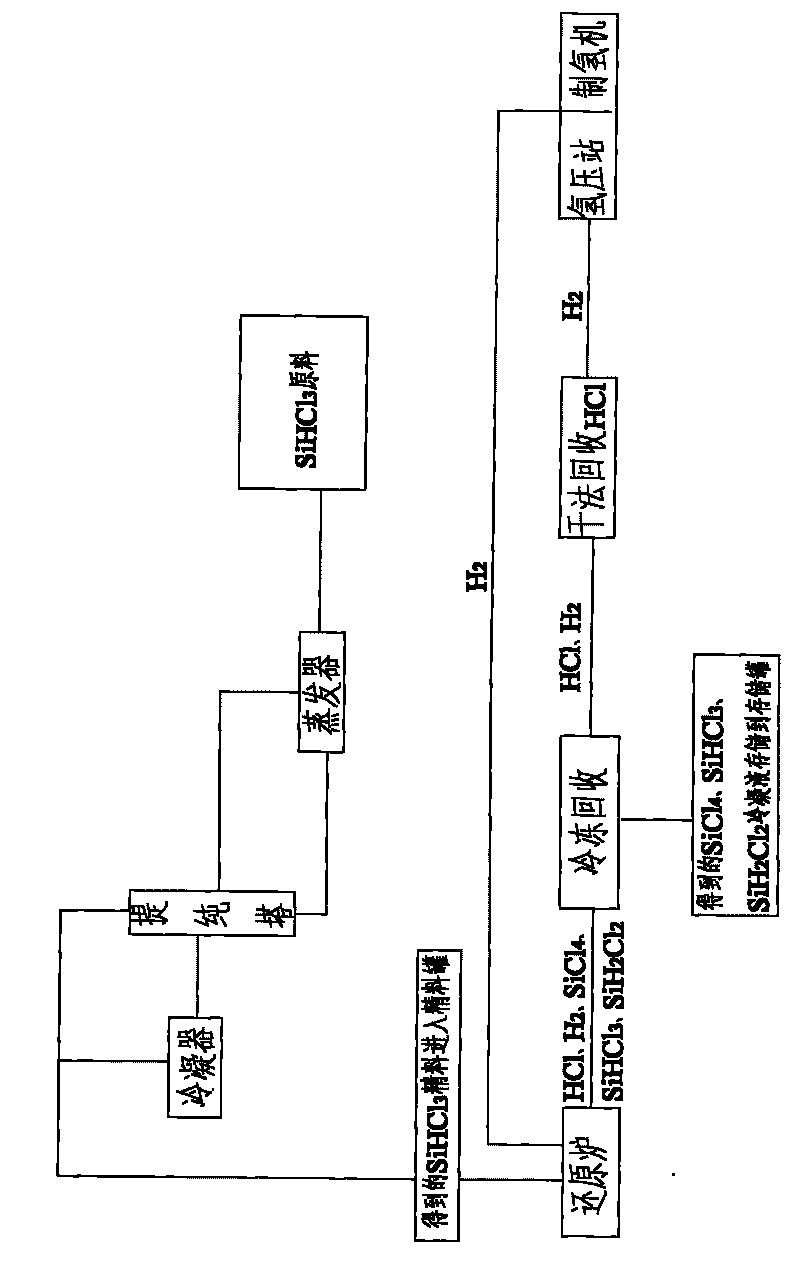

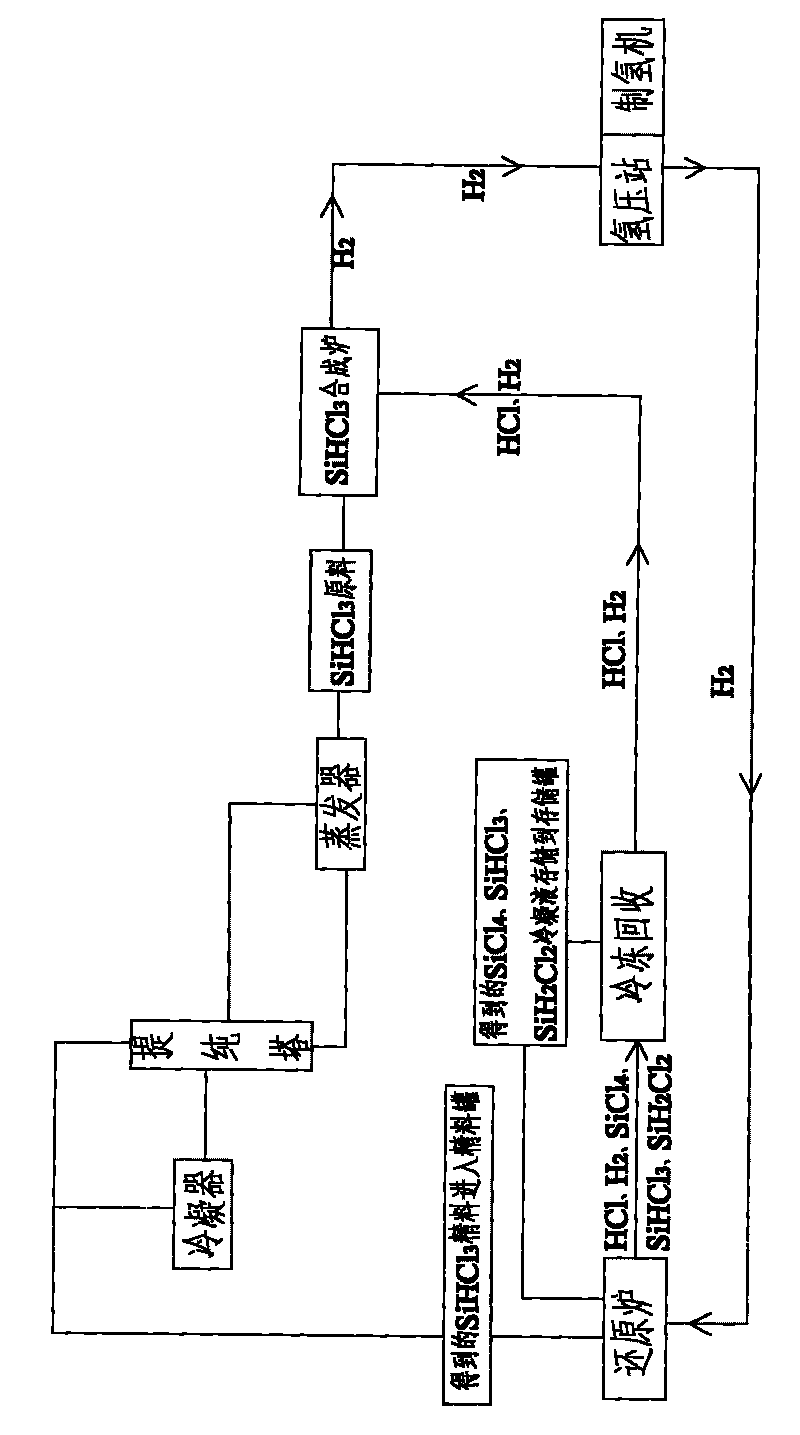

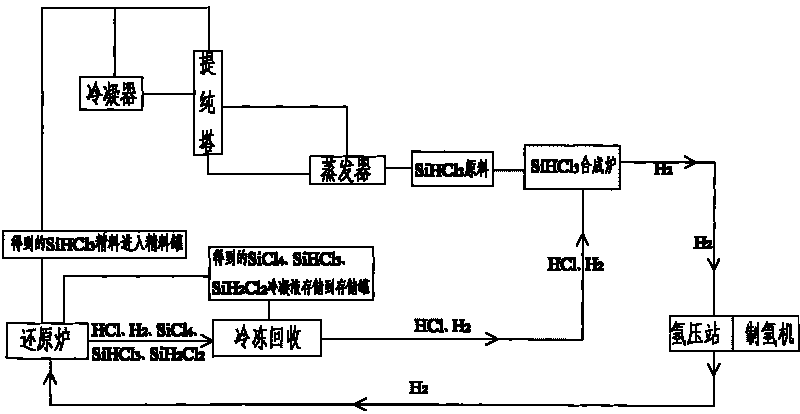

[0015] Such as figure 2 As shown, the method of recycling by-products to produce polysilicon is: purify SiHCl through evaporator, purification tower and condenser 3 Raw material, generating SiHCl 3 Concentrate, SiHCl 3 The fine material is subjected to H in the reduction furnace 2 Reduction reaction, the reaction temperature is 1200 ° C, polysilicon is generated, and HCl, H 2 、SiCl 4 , SiHCl 3 、SiH 2 Cl 2 Composed of by-products, the by-products are recovered by freezing to obtain SiCl 4 , SiHCl 3 、SiH 2 Cl 2 Condensate composed of HCl, H 2 Composed of gas, the condensate is circulated into the reduction furnace to continue to participate in the H 2 Reduction reaction, from HCl, H 2 The composition of the gas is passed through SiHCl 3 Synthetic furnace, react with silicon powder at 350°C to generate SiHCl 3 as SiHCl 3 Raw materials used, residual H 2 H produced by the hydrogen generator 2 are transported to the reduction furnace through the hydrogen pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com