Method for recycling iron-containing by-products discharged from coal-based ironmaking process, system used therefor, and direct-reduced iron agglomeration system

A by-product, reduced iron technology, applied in the direction of process efficiency improvement, furnace type, furnace, etc., can solve the problems of reduced recycling effect, increased energy consumption and manufacturing cost, etc., to achieve no decrease in permeability, prevention of losses, The effect of preventing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

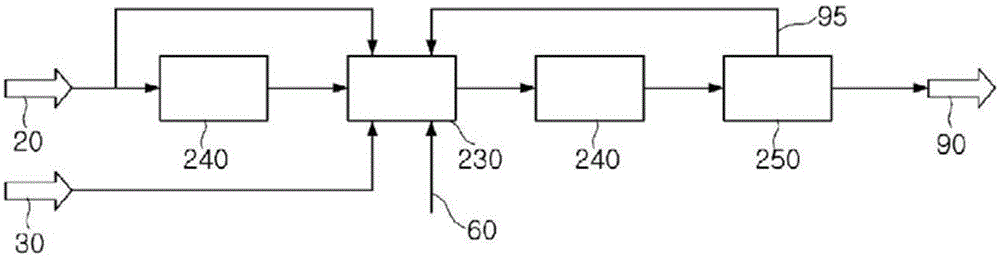

[0137] In Example 1, sludge and dust generated from the FINEX process for producing molten iron (Molten Iron Production FINEX Process) were passed through figure 1 The by-product agglomeration process shown in to agglomerate.

[0138] Specifically, sludge 20 having a water content of about 40 wt % and dust 30 having a water content of about 15 wt % as by-products discharged from the molten iron production FINEX process were prepared in a weight ratio of 7:3.

[0139] Half of the sludge 20 is fed to a sludge dryer (rotary kiln) 240 in which the half of the sludge 20 is heated to remove water.

[0140] Then, the heat-dried half of the sludge 20 is supplied to a by-product agglomeration device 230 which is an agitating mixer, and the other half of the sludge 20 which is not dried is directly supplied to the agitating mixer so that The undried half of sludge in sludge 20 is mixed with the dried half of sludge in sludge 20 . In addition, the dust 30 is supplied to an agitating mi...

Embodiment 2

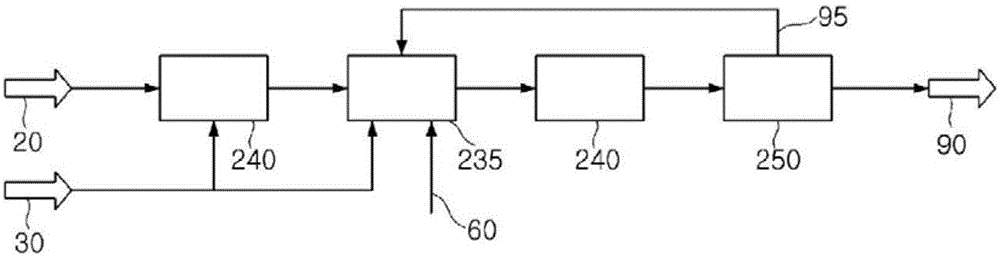

[0146] In Example 2, the sludge and dust generated from the FINEX process of molten iron production were passed through figure 2 The by-product agglomeration process shown in to agglomerate.

[0147] The same by-products as used in Example 1 were produced according to the FINEX process for the production of molten iron.

[0148] All the sludge 20 is supplied to a sludge dryer (rotary kiln) 240, and the sludge 20 is heated in the sludge dryer 240 to remove water.

[0149] The dried sludge 20 is fed to an agglomerating device 30 which is a pelletizer, and dust 30 is also fed to the pelletizer. The by-products (sludge 20 and dust 30 ) mixed in the pelletizer had a water content of about 5 wt% based on the total weight of the by-products.

[0150] Water was supplied into the pelletizer to adjust the water content of the by-product to 8 wt%, and then, the by-product was agglomerated into pellets using the pelletizer.

[0151] Thereafter, the pellets are transferred from the pel...

Embodiment 3

[0154] Equal weights of sludge and dust produced from the FINEX process for producing molten iron and having the composition shown in Table 1 were mixed with each other for about 3 minutes using an Eirich mixer. In this way, pellets with an average particle size of 2 mm were obtained.

[0155] The pellets were dried in a box dryer at 105°C for 24 hours to sufficiently remove water from the pellets.

[0156] Thereafter, the pellets were mixed with reduced iron at a weight ratio of 2:8 to form a mixture sample, and 100 g of the mixture sample was agglomerated at 600 °C while applying a pressure of 150 MPa to the mixture sample to form a disc-shaped compact. Subsequently, the compressive strength of the disc-shaped compact (sample) was measured.

[0157] After excluding outliers, the average of 10 measurements was calculated. The average compressive strengths are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com