Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47 results about "Nanodot array" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

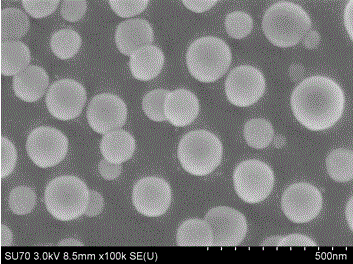

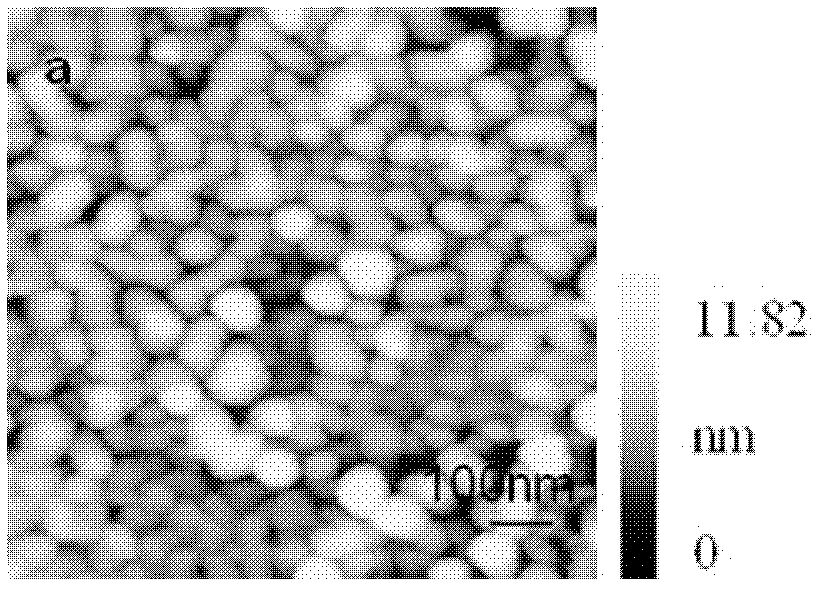

Metal nanodot array surface enhancing Raman active base and preparation method thereof

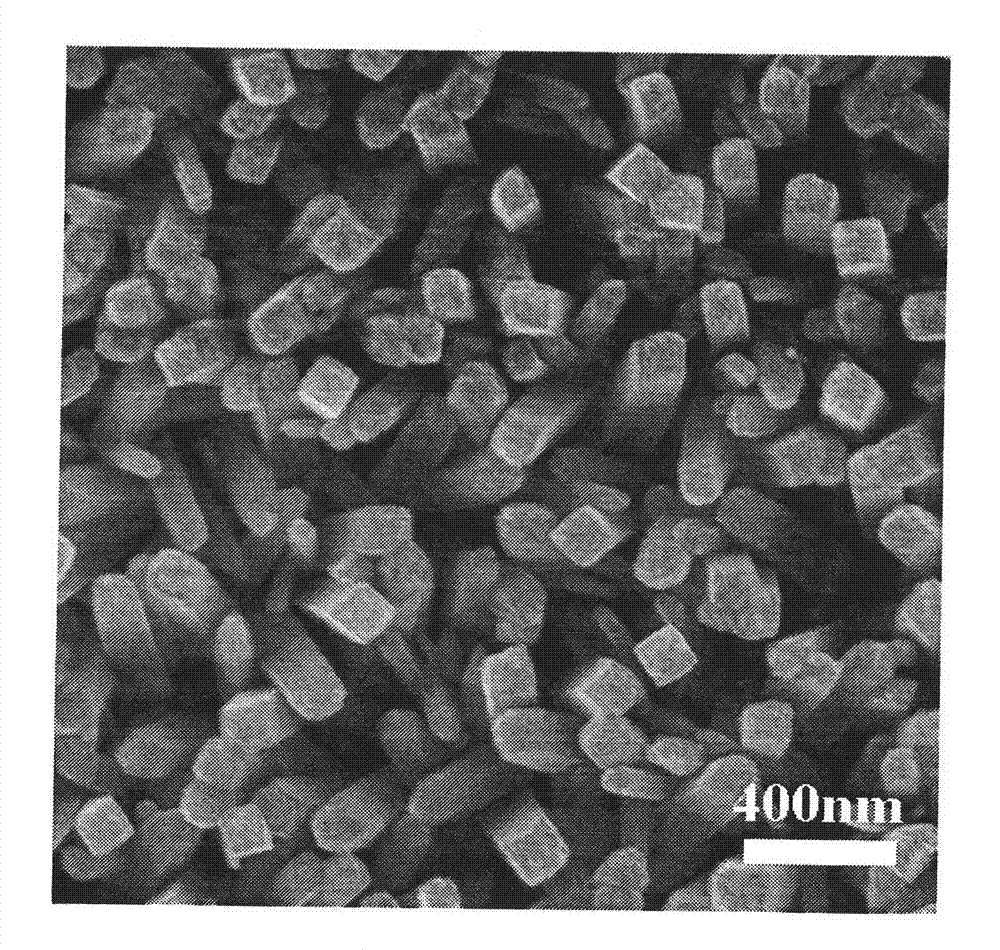

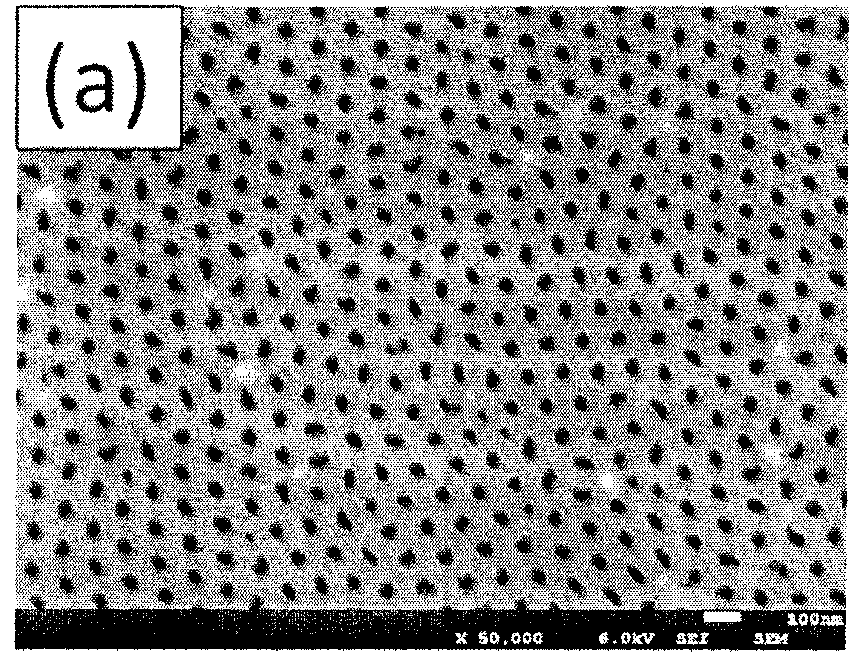

InactiveCN102621126AUniform shapeOptimal Control StructureVacuum evaporation coatingSurface reaction electrolytic coatingAnalyteArray data structure

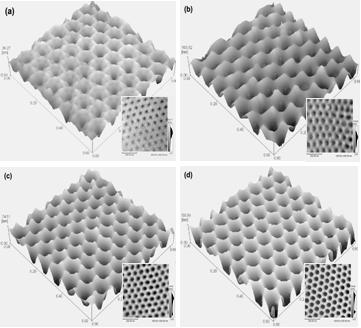

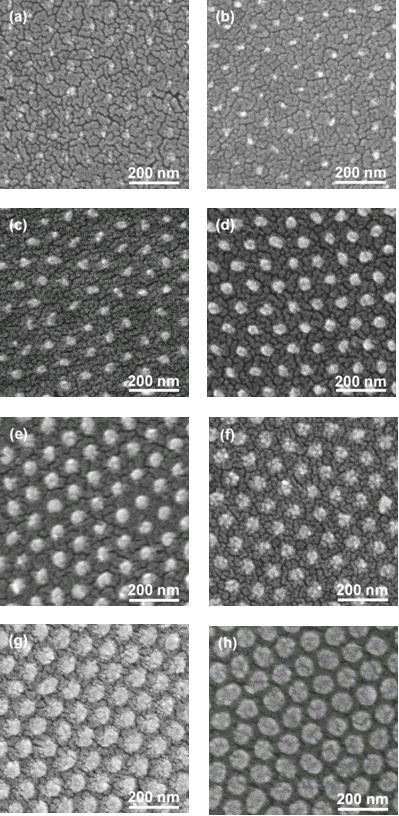

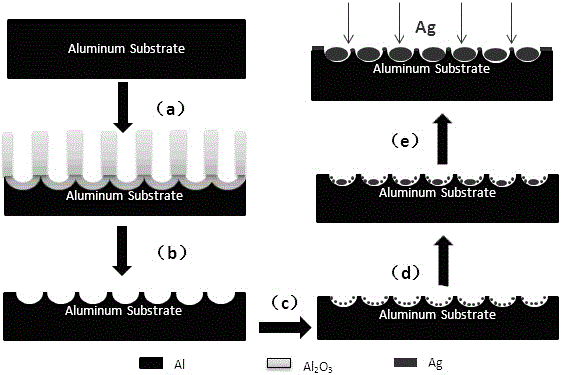

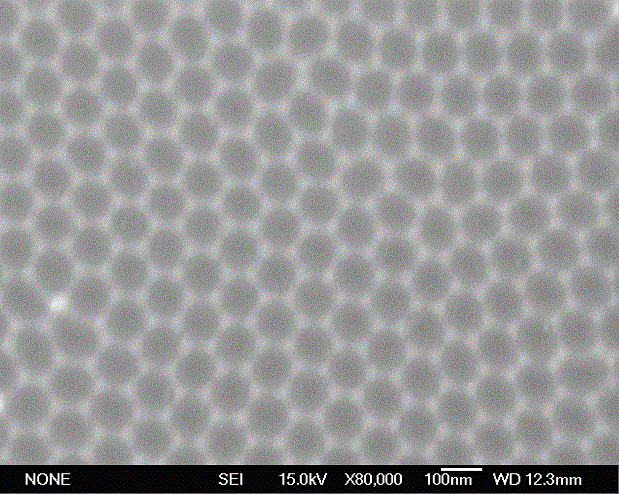

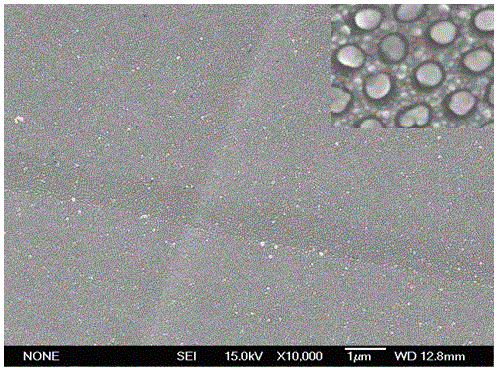

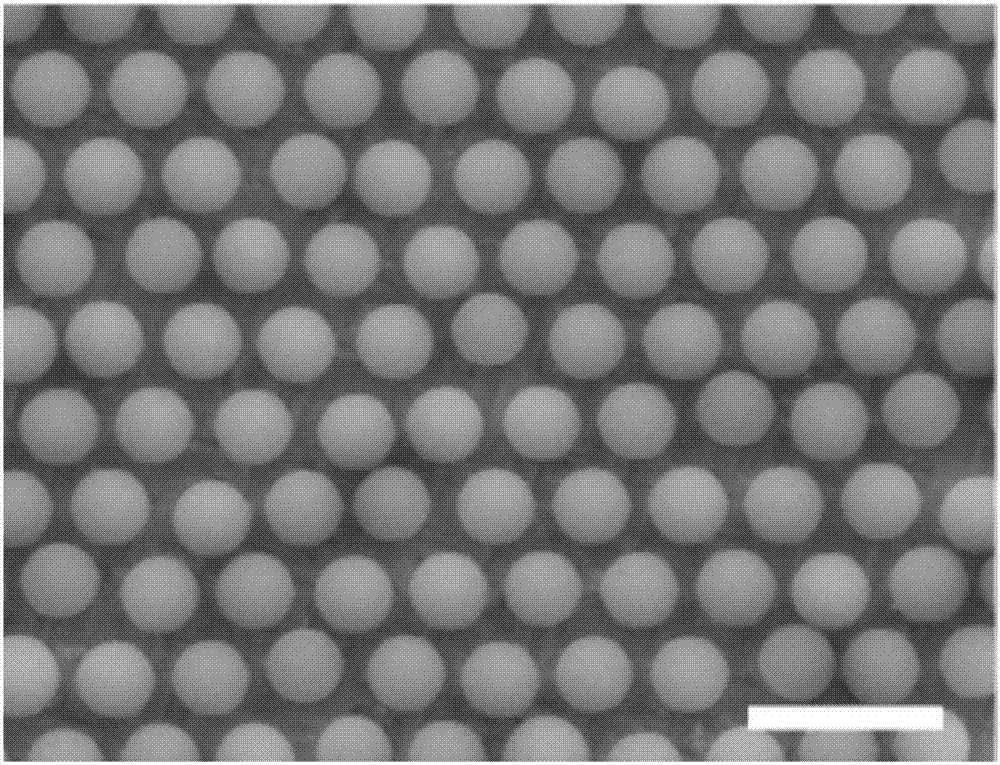

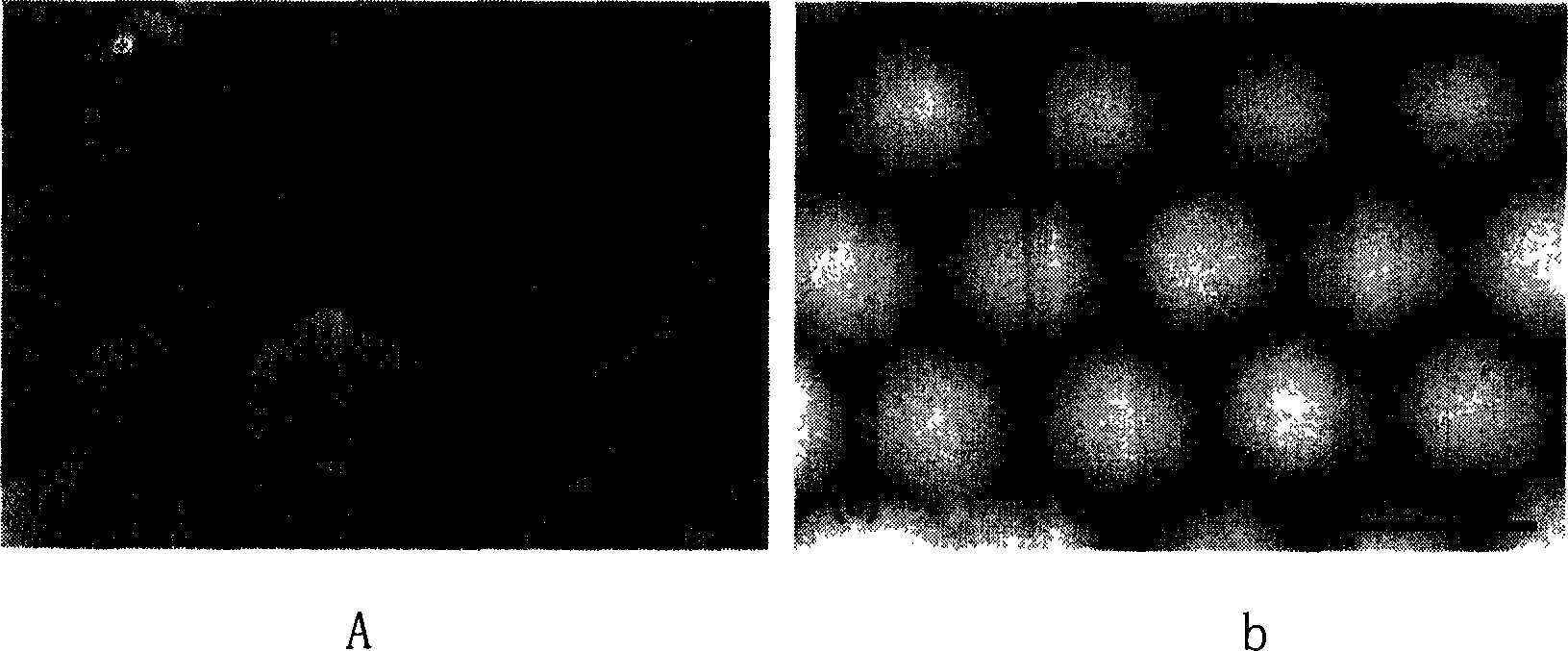

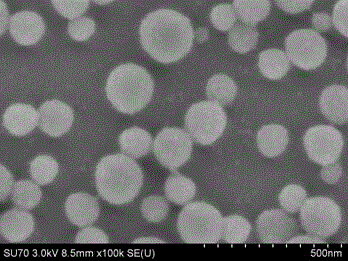

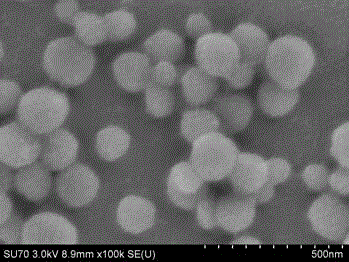

The invention discloses a metal nanodot array surface enhancing Raman active base and a preparation method thereof. The base takes silicon single crystals as the substrate, and metal nano particles forming an array structure are deposited on the surface of silicon; and further, the particle sizes of the metal nano particles range from 16 to 85nm, and the center distances of the particles range from 99 to 111nm. The metal nanodot array surface enhancing Raman active base provided by the invention is uniform in morphology, is controllable in structure, has a remarkable surface Raman enhancing effect on analytes of different concentration, and has a uniform and stable enhancing signal. Through the method provided by the invention, structural parameters and morphology of the metal nanodot array can be adjusted according to structural parameter of an ultrathin aluminum oxide template, and different influences on the Raman surface enhancing effect by different metal nanodot array bases can be realized; and further, the base and method have the advantages of simplicity for operation, low cost and easiness for industrial production.

Owner:SHANGHAI UNIV

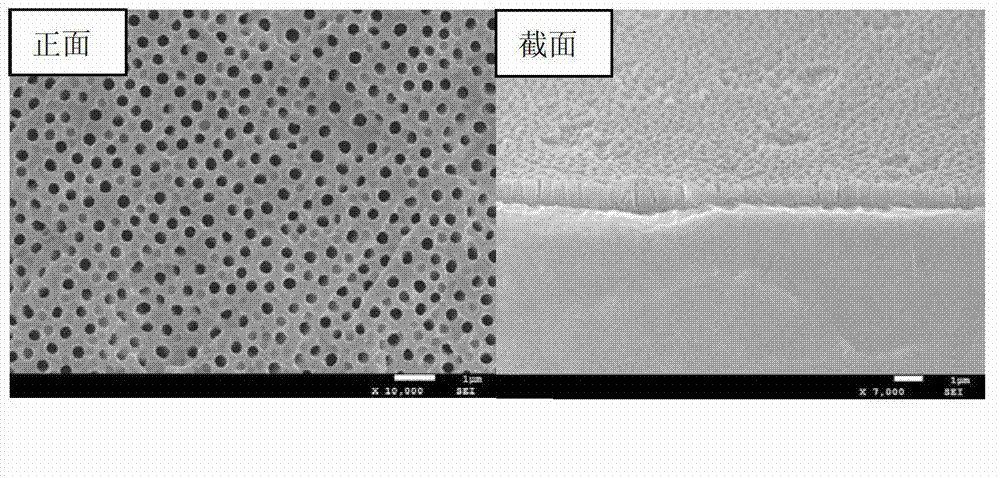

Embedded type nano dot array surface enhanced Raman active substrate and preparation method thereof

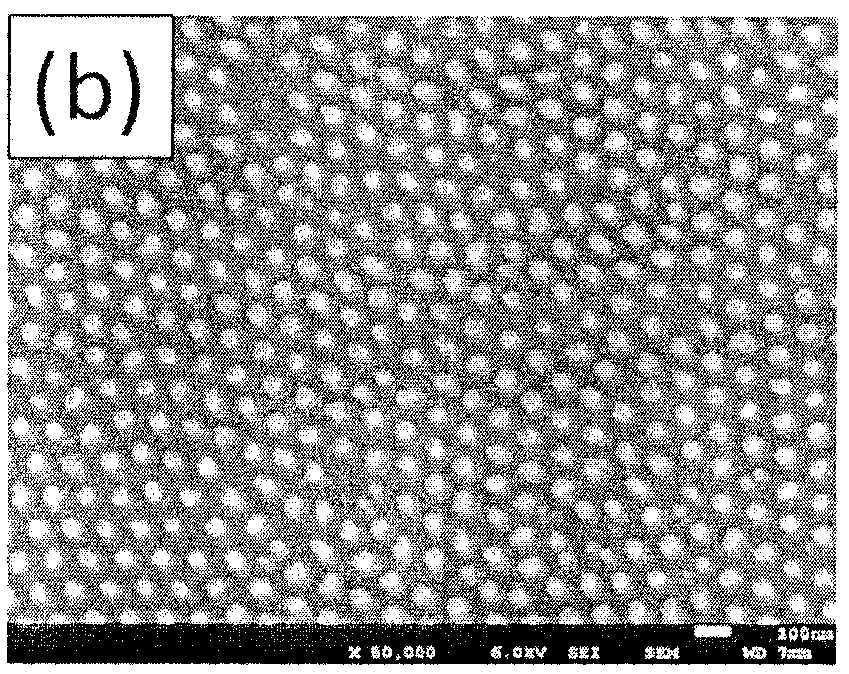

InactiveCN104949957ASignificant surface Raman enhancement effectEasy to makeMaterial nanotechnologyVacuum evaporation coatingAnalyteNanometre

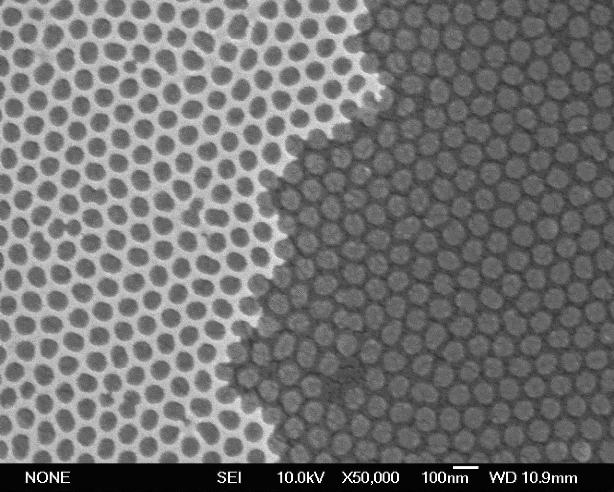

The invention discloses a preparation method of a novel embedded type nano dot array structure surface enhanced Raman active substrate. The substrate takes an aluminum sheet with an ordered concave pit array structure on the surface as a template and materials with SERS (Surface Enhanced Raman Scattering) performances are deposited to obtain a large-area and highly-ordered nano dot array structure embedded into a groove on the concave pit substrate. The nano dot array provided by the invention can be used for adjusting structure parameters and shapes of the embedded type nano dot array according to the size of the concave pit array, so that different influences on the Raman surface enhancing effect by different embedded type metal nano array substrates are realized. The preparation method has the advantages of simplicity in operation, no need of transferring, low cost and easiness for industrial production; the shape of the substrate is highly ordered and the Raman activity is high; and the substrate has the remarkable Raman surface enhancing effect on analytes with different concentrations and has very high detection limit.

Owner:SHANGHAI UNIV

Method for preparing density-adjustable TiO2 nanorod array

InactiveCN101973582AChange densityControlled surface wettabilityNanostructure manufactureTitanium dioxideAlcoholDensity distribution

The invention discloses a method for preparing a density-adjustable TiO2 nanorod array. The diameter of TiO2 nanorods is 10-200 nm, and the density distribution range of the TiO2 nanorods is 9.4*10<2> / cm<-2> to 8.3*10<13> / m<-2>. The preparation method comprises the following steps of: (1) dissolving tetrabutyl titanate, water and acetylacetone into alcohol, and adding polyvinylpyrrolidone to form titanium dioxide precursor sol; (2) quickly spin-coating the titanium dioxide precursor sol on a substrate to form a titanium dioxide precursor nano lattice array sol film on the substrate, and putting the substrate into a muffle furnace for thermal treatment; and (3) putting the thermally treated substrate into a titanate and acid mixed water solution for hydro-thermal treatment to obtain the TiO2 nanorod array on the substrate. The preparation method is simple, and the surface wettability, the photocatalytic property and the photoelectric properties of the prepared TiO2 nanorod array can be controlled according to different diameters and densities.

Owner:ZHEJIANG UNIV

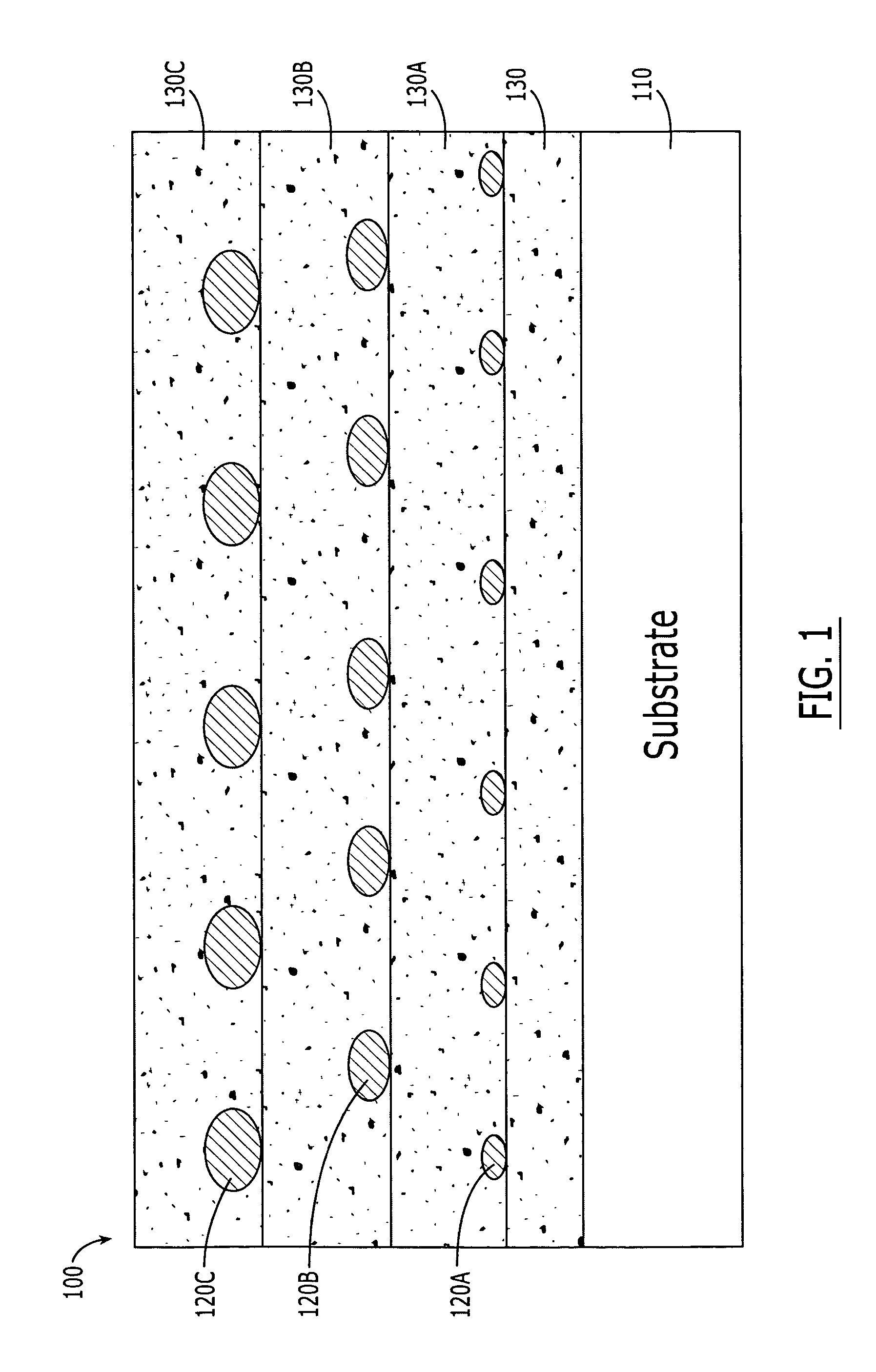

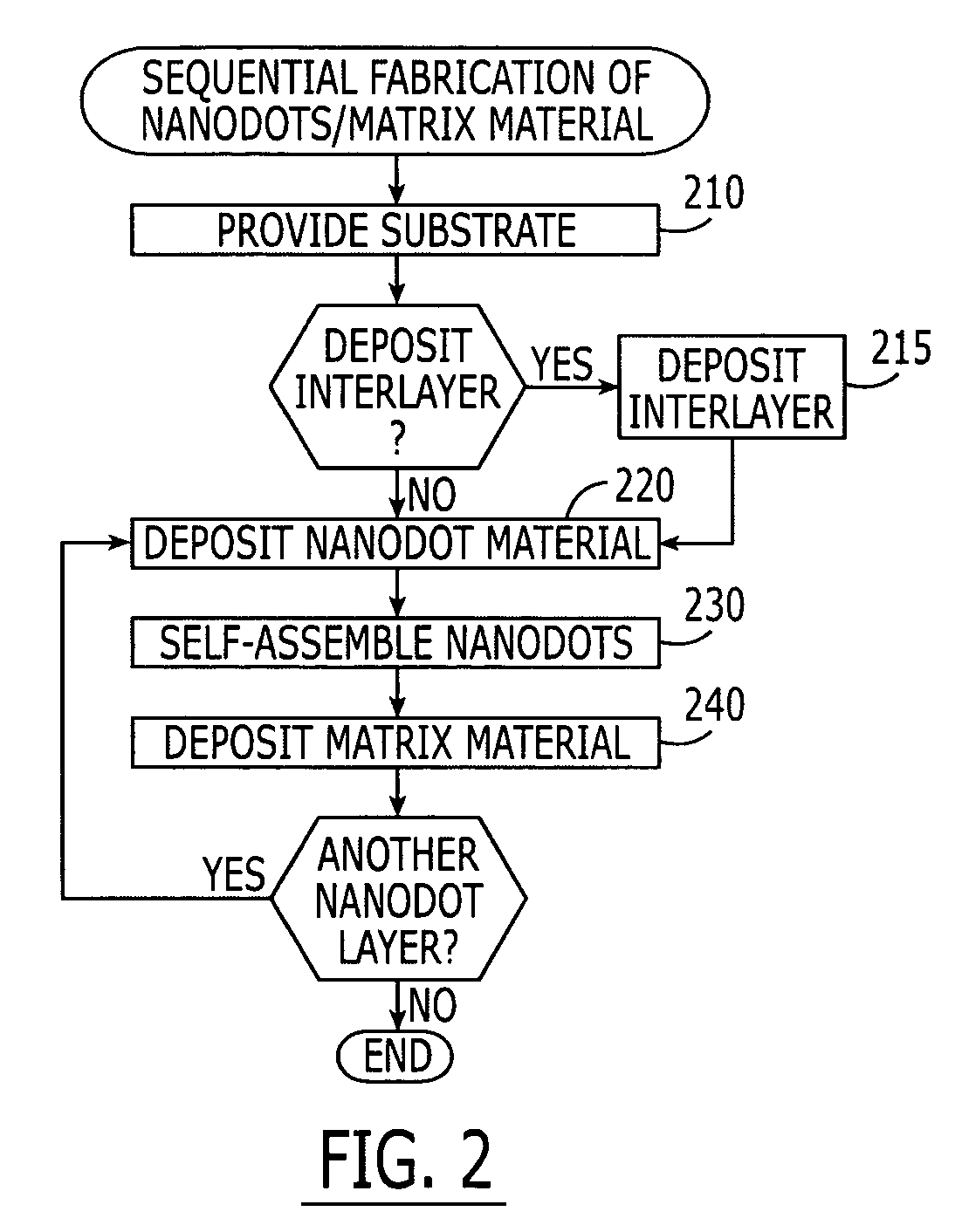

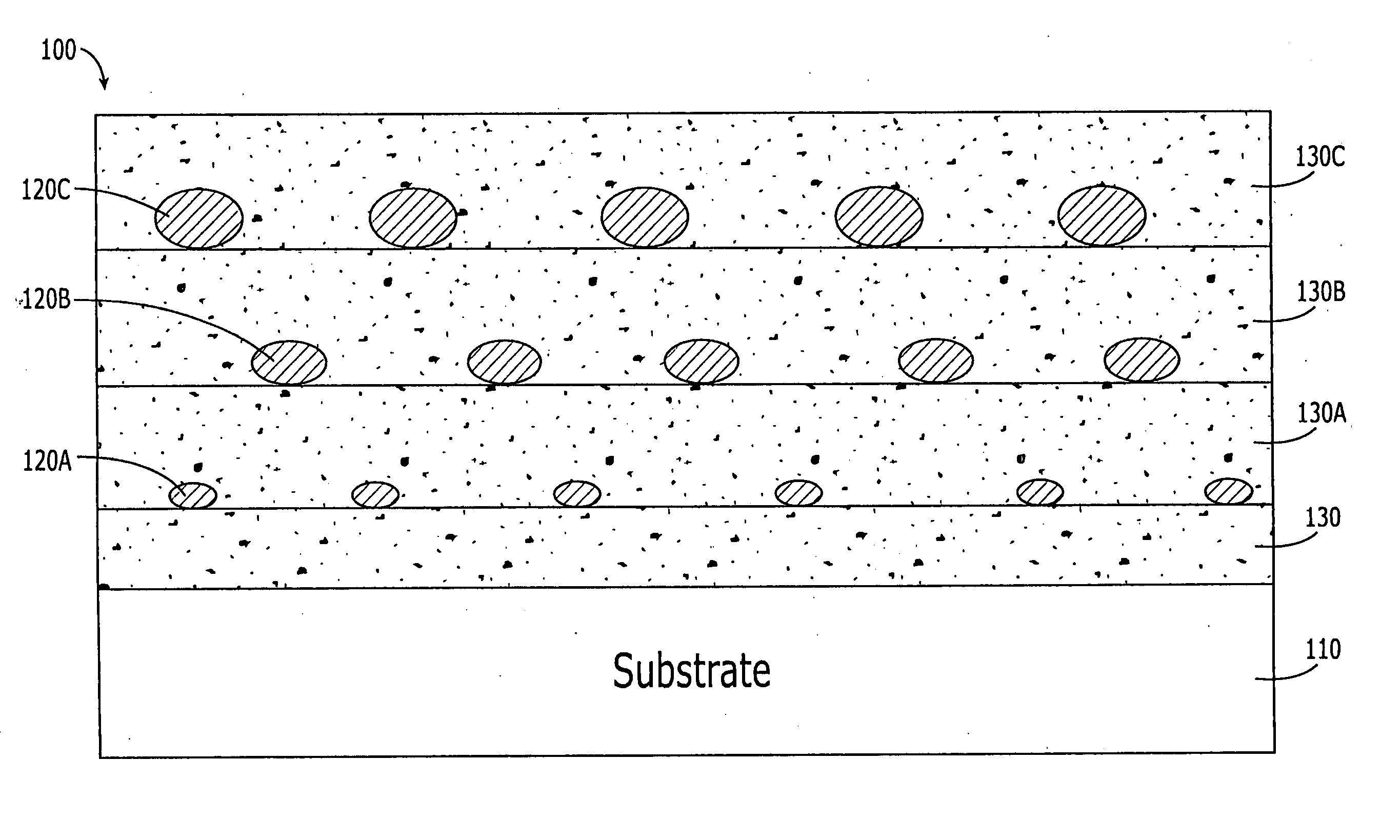

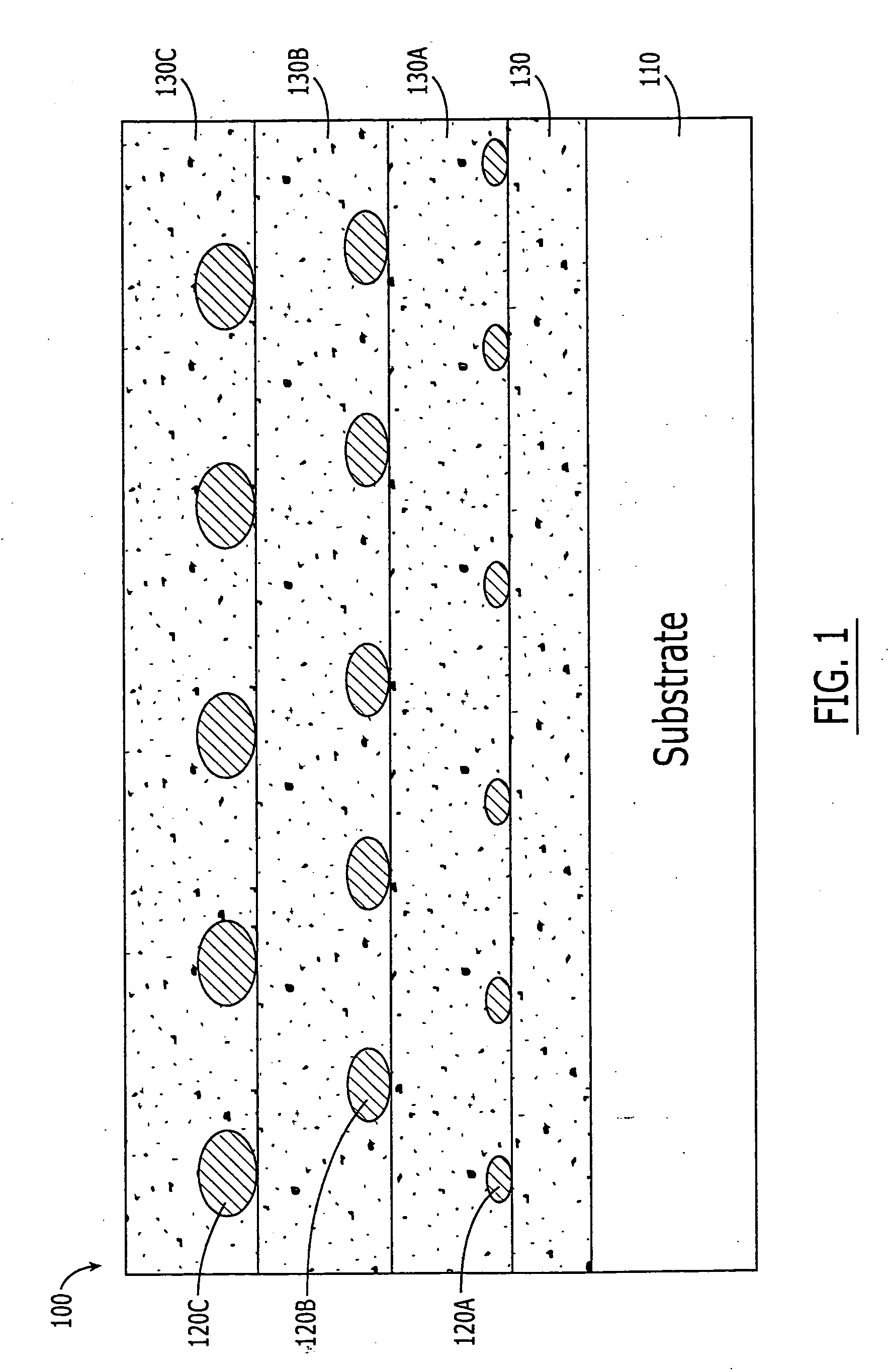

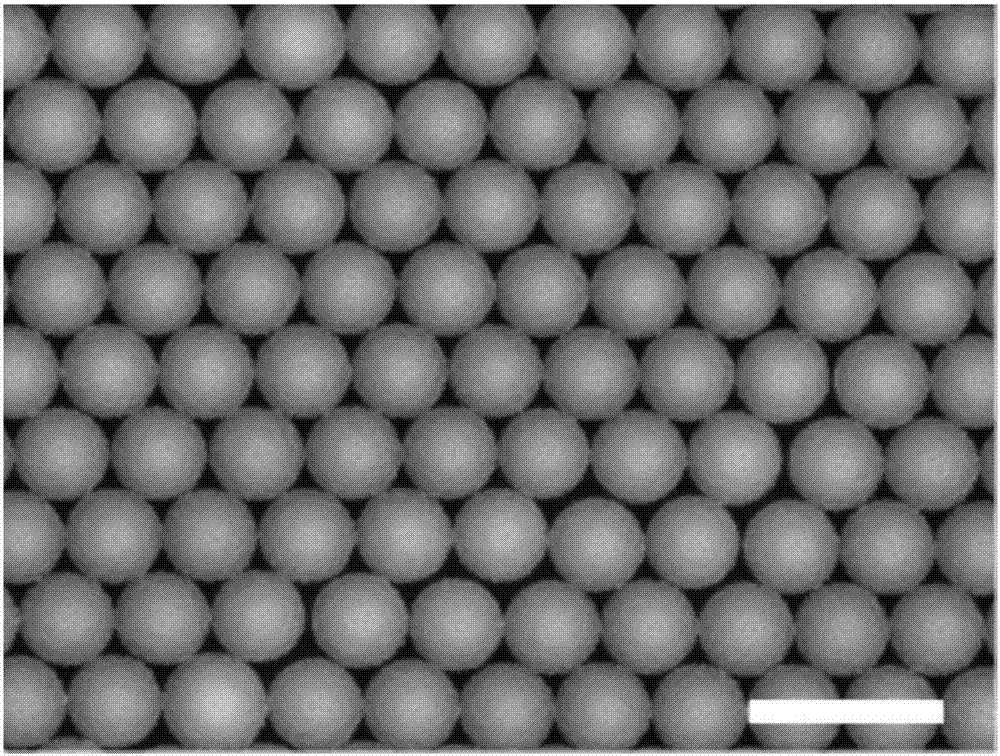

Methods of forming three-dimensional nanodot arrays in a matrix

ActiveUS7105118B2Rapid productionImprove magnetic propertiesNanostructure applicationNanomagnetismNanodotFree energies

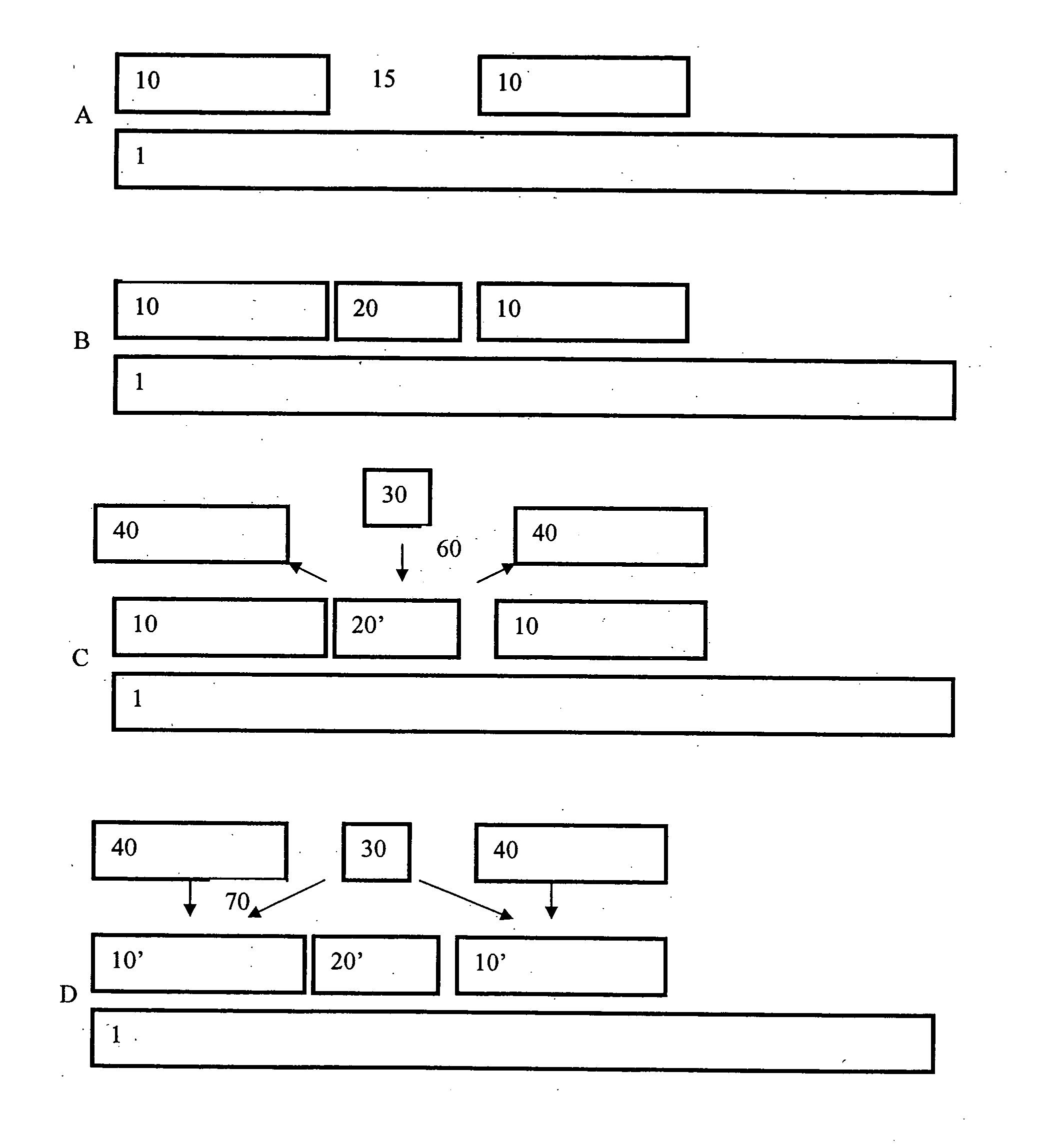

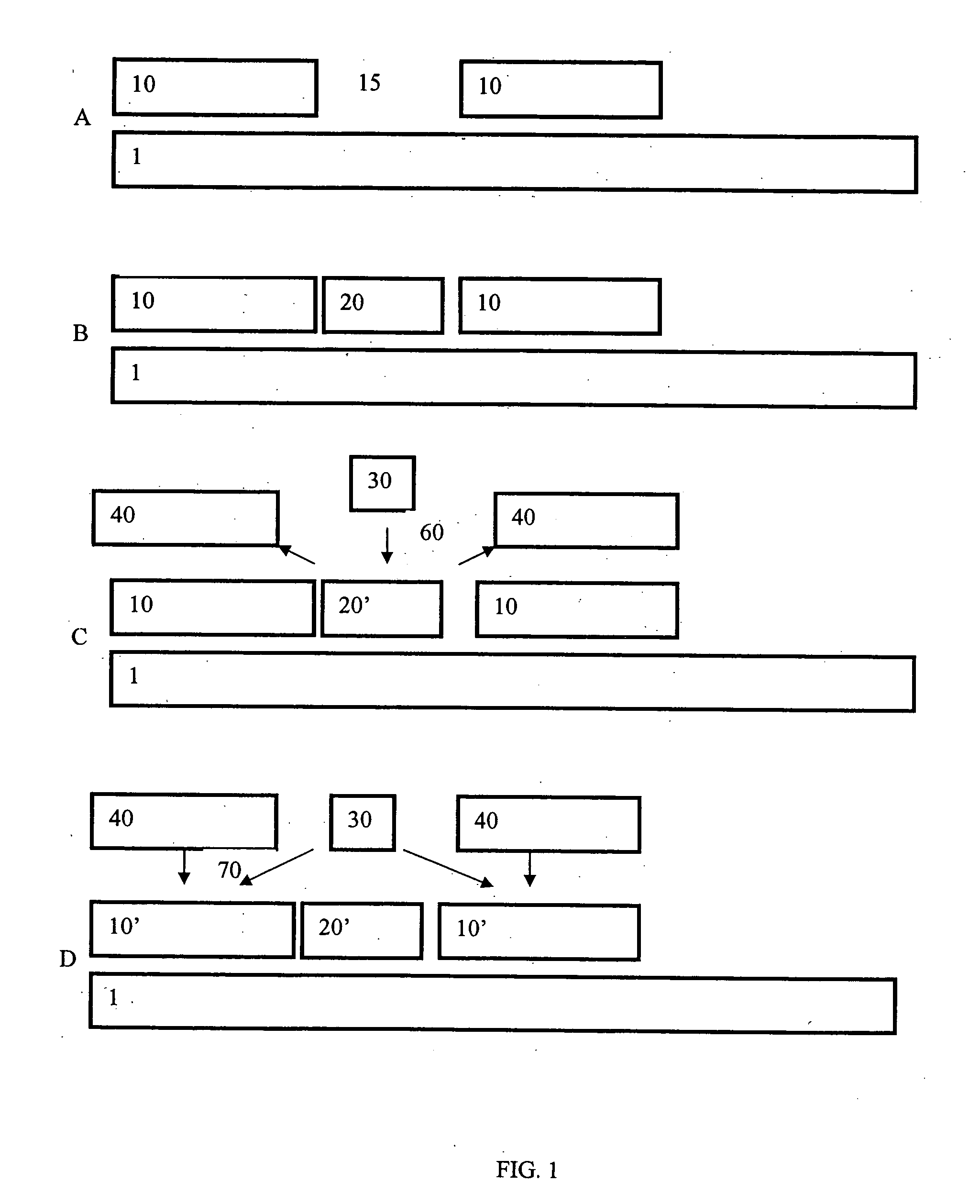

Nanostructures and methods of making nanostructures having self-assembled nanodot arrays wherein nanodots are self-assembled in a matrix material due to the free energies of the nanodot material and / or differences in the Gibb's free energy of the nanodot materials and matrix materials.

Owner:NORTH CAROLINA STATE UNIV

Methods of forming three-dimensional nanodot arrays in a matrix

InactiveUS20060266442A1Rapid productionMaterial nanotechnologyMolten spray coatingNanodotFree energies

Nanostructures and methods of making nanostructures having self-assembled nanodot arrays wherein nanodots are self-assembled in a matrix material due to the free energies of the nanodot material and / or differences in the Gibb's free energy of the nanodot materials and matrix materials.

Owner:NARAYAN JAGDISH +1

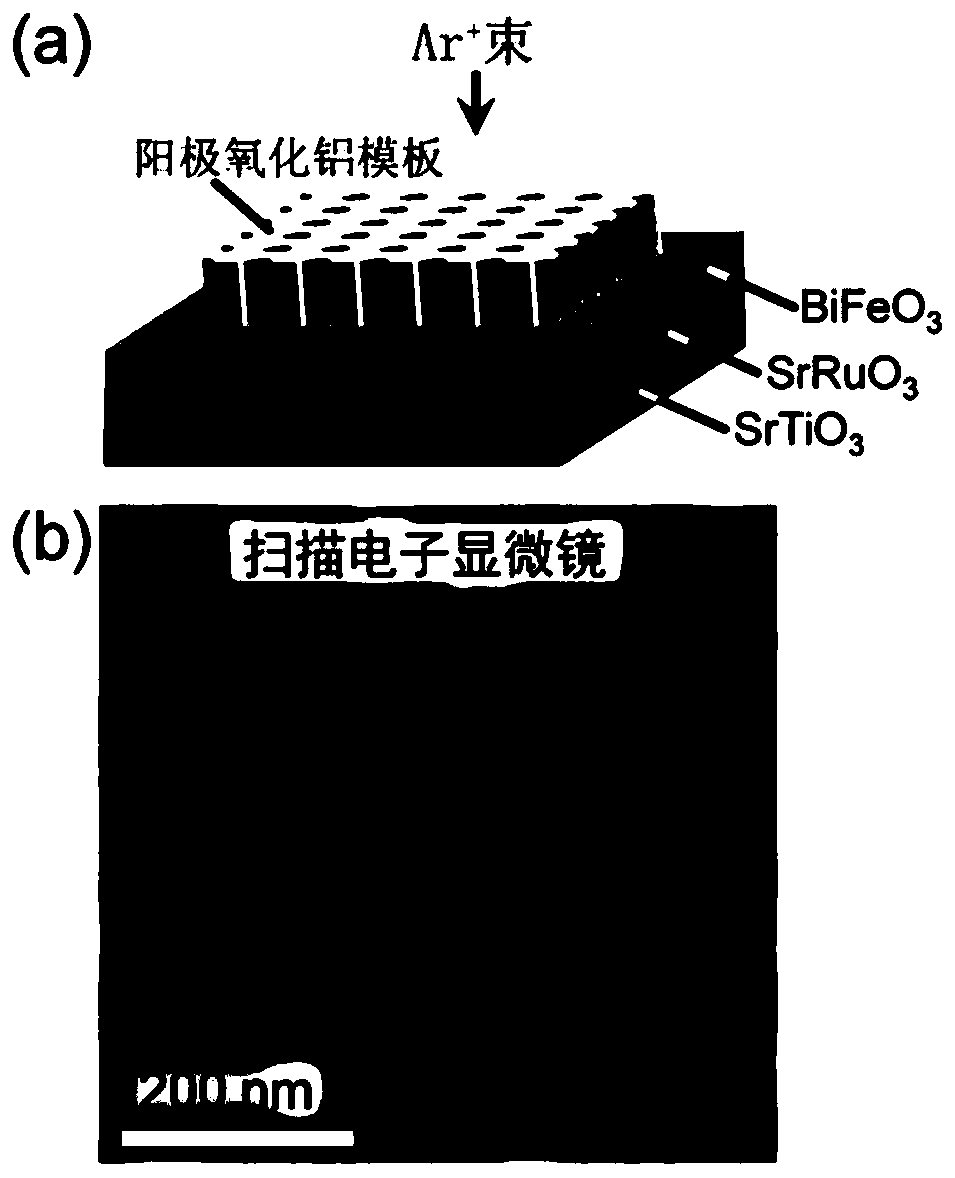

Method using one-step template method to prepare ordered ferroelectric nanodot array

InactiveCN107244649AImprove securityEasy to extendSpecific nanostructure formationOxygen plasma etchingPulsed laser deposition

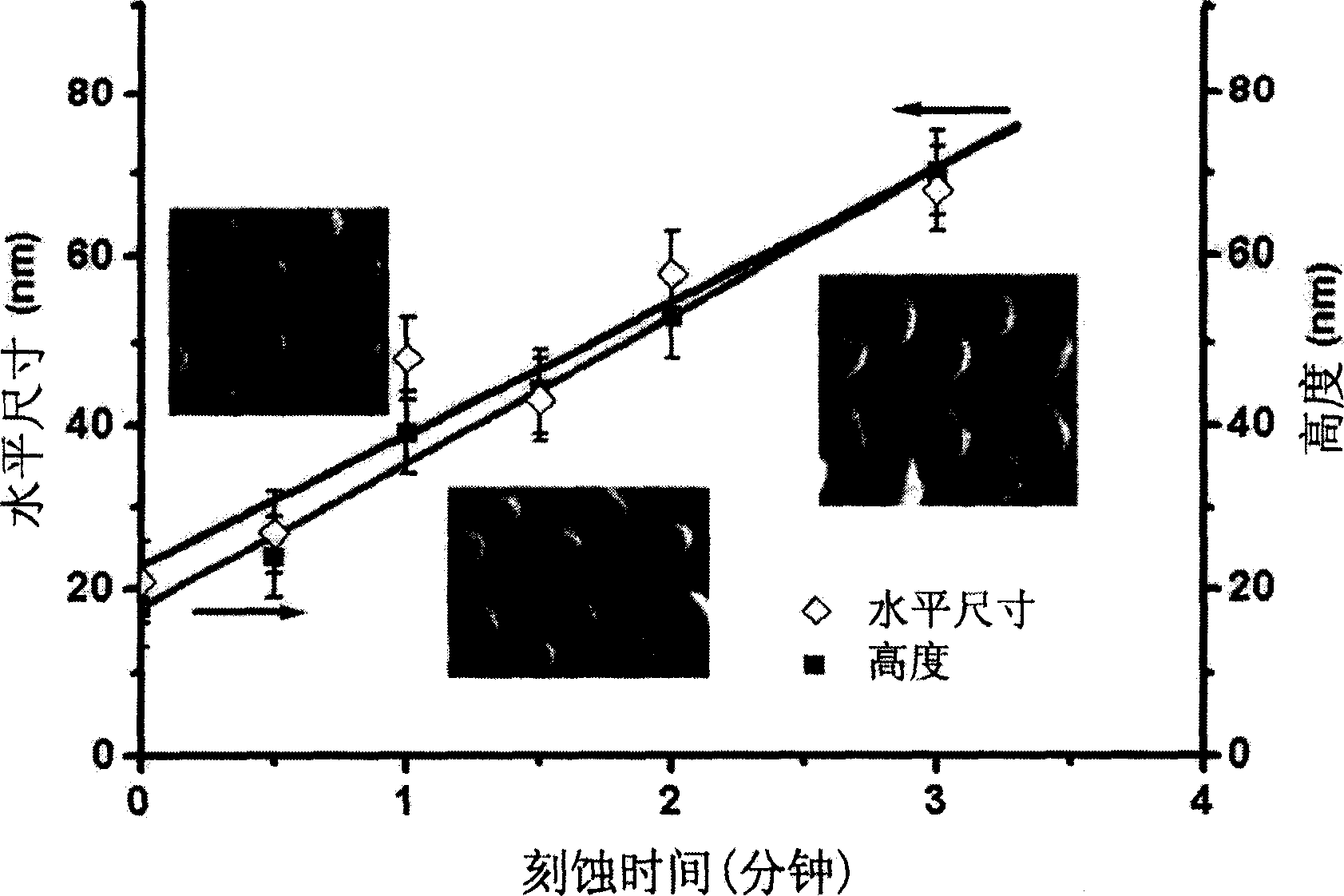

The invention relates to a method using a one-step template method to prepare an ordered ferroelectric nanodot array. The method includes the steps of S1, using a pulsed laser deposition method to deposit a high-performance epitaxy ferroelectric film on a substrate; S2, transferring single-layer PS small spheres to the surface of the ferroelectric film to serve as the mask plate; S3, performing oxygen plasma etching on the substrate with the mask plate to obtain a to-be-etched sample; S4, etching the to-be-etched sample in an ion beam etching machine; S5, removing the residual mask plate to obtain the ordered ferroelectric nanodot array. The method has the advantages that the method is simple, convenient in template removing and suitable for large-scale preparation, and the prepared ferroelectric nanodot array keeps the excellent epitaxy and ferroelectric performance of the ferroelectric film.

Owner:SOUTH CHINA NORMAL UNIVERSITY

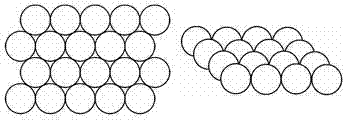

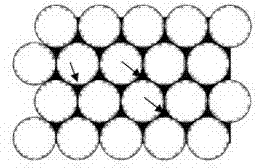

Method for preparing nano dot array of controllable unit size using nano ball template

InactiveCN1588236AControllable expansionSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusNanolithographyUnit size

This invention disclose a method of availing of micro millimeter ball template prepares micro millimeter lattice array of controlled cell size, the method belongs to micro millimeter photo etching technique field. It makes use of plasma ion etching to control size of sedimentation access of micro millimeter ball template, combines with filming step and cleaning step in micro millimeter photo etching technique, thereby acquires micro millimeter lattice array of controlled cell size. The density of micro millimeter lattice array in the lecture experiment is 42G / in2, and it controls cell size in 26-100nm. This method builds directly upon the control of sedimentation access of template, it applies to lattice array of all kinds of stuff. By means of conjoining thin film technique of disparity stuff, micro millimeter ball photo etching technique which is modified by this method could prepare high density micro millimeter lattice array of disparity stuff and controlled cell size. It could use for device based on micro millimeter lattice array, for instance, magnetic store, preparation of transducer and performance optimization of device based on controlled cell size.

Owner:TSINGHUA UNIV

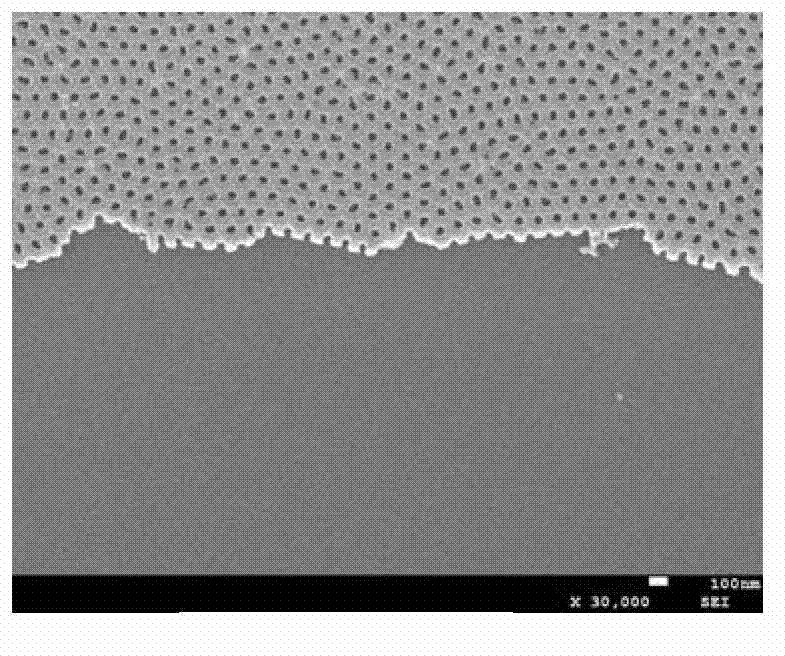

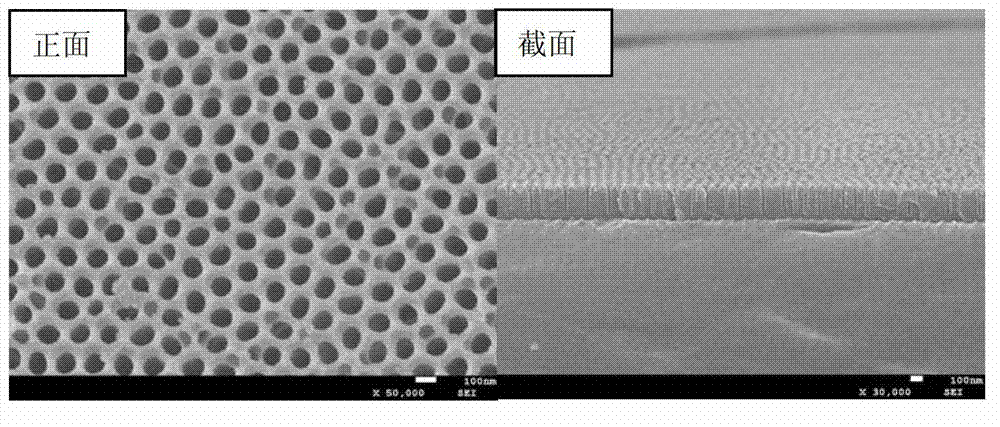

Transfer method of ultrathin porous aluminum oxide template

The invention discloses a transfer method of an ultrathin porous aluminum oxide template. The transfer method comprises the following steps of: 1, placing an aluminum sheet in an electrolyte for first-time oxidization; 2, removing a porous aluminum oxide layer on the aluminum sheet subjected to first-time oxidization, then placing in the electrolyte for second-oxidization to obtain a porous aluminum oxide template; 3, spinning protection glue on the front surface of the porous aluminum oxide template; 4, placing the porous aluminum oxide template in a corrosive liquid for removing an aluminum base; 5, transferring the porous aluminum oxide template obtained in the step 4 to a soaking solution by using filter paper or a mesh to remove a baffle layer; and 6, transferring the porous aluminum oxide layer template obtained in the step 5 to a substrate so that the transfer of the porous aluminum oxide template is completed. The transfer method of the ultrathin porous aluminum oxide template is combined with other physical sputtering methods so that nano lattice array structures made of various materials can be prepared at low price, and the size and the spacing of nano units can be changed through regulating the pore diameter and the pore spacing of the template, and thus the property of the nano material is improved.

Owner:山西师范大学

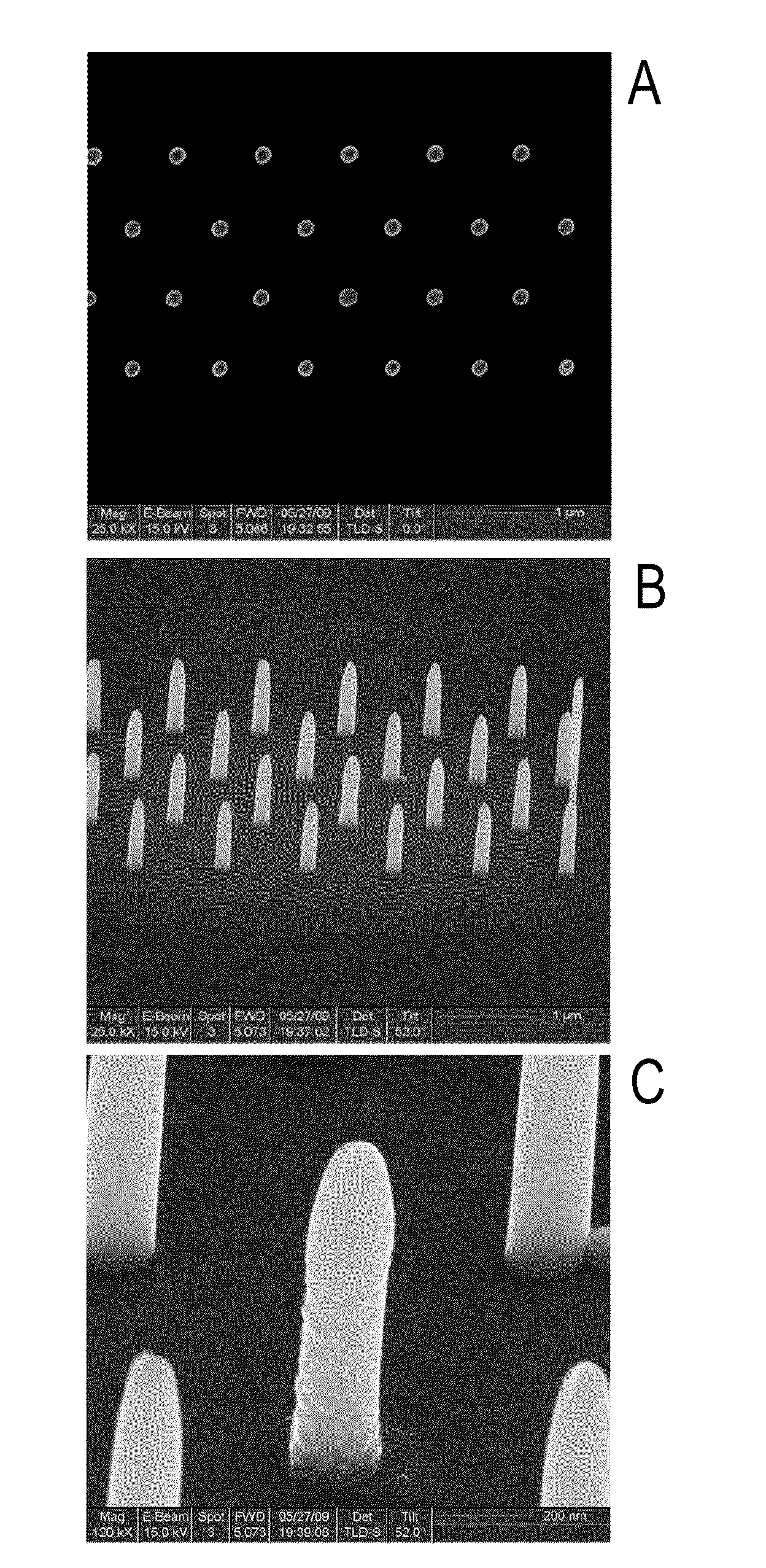

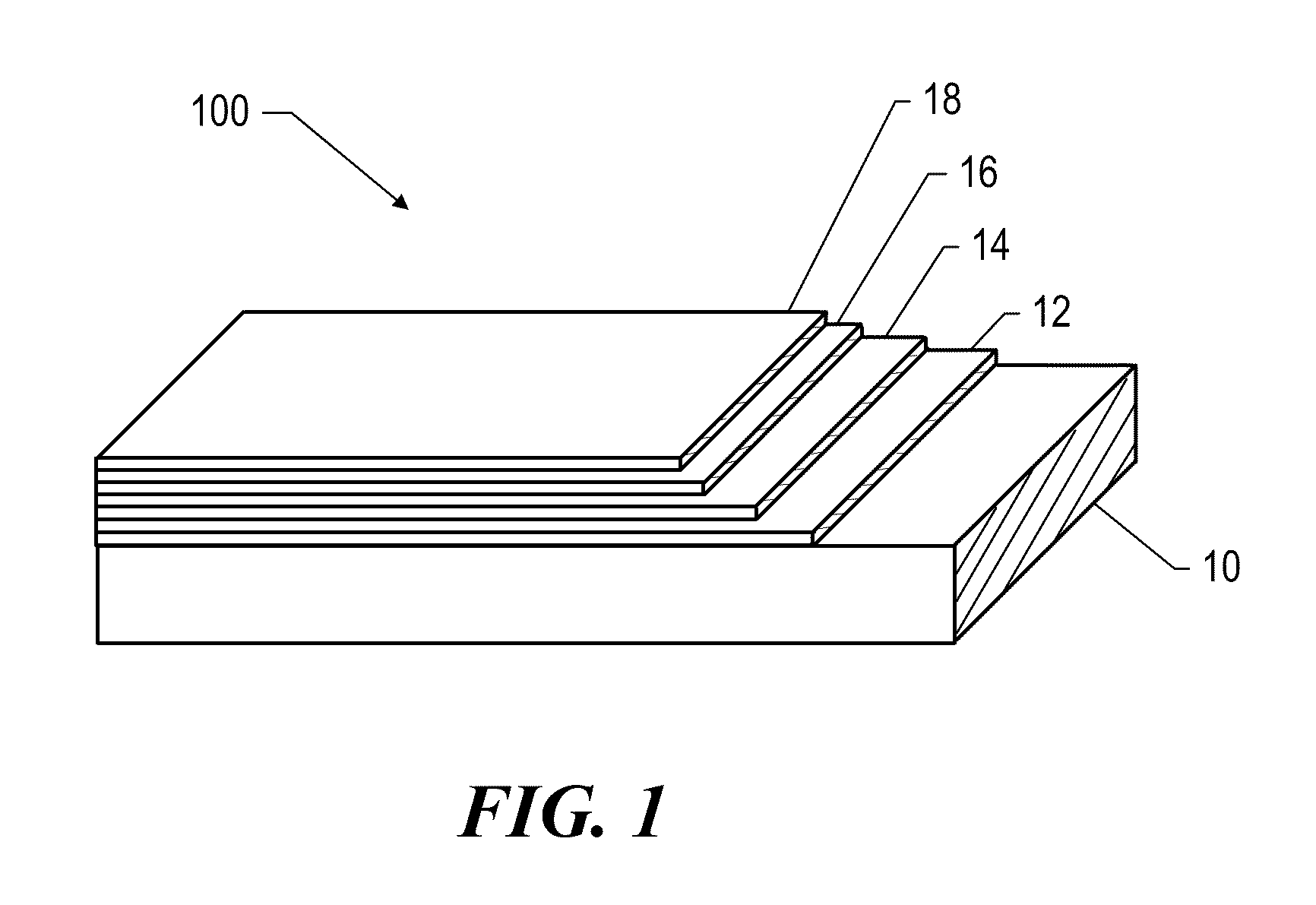

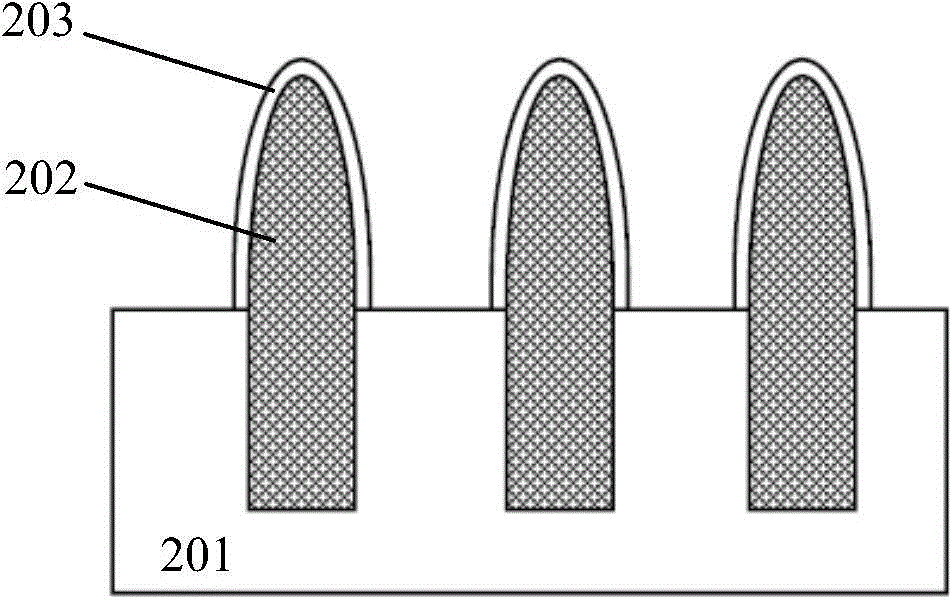

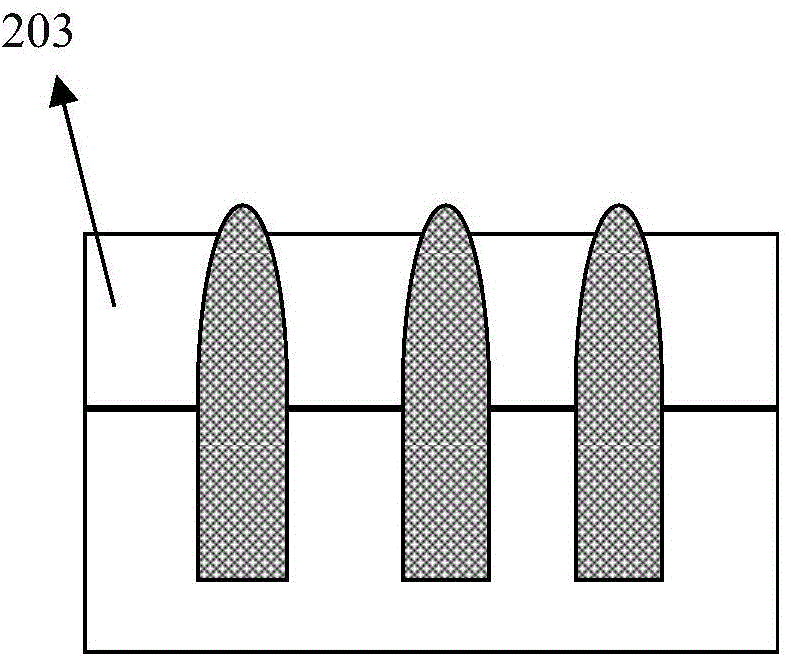

Superconductive Article with Prefabricated Nanostructure for Improved Flux Pinning

ActiveUS20110028328A1Material nanotechnologyNanostructure manufactureFlux pinningHigh-temperature superconductivity

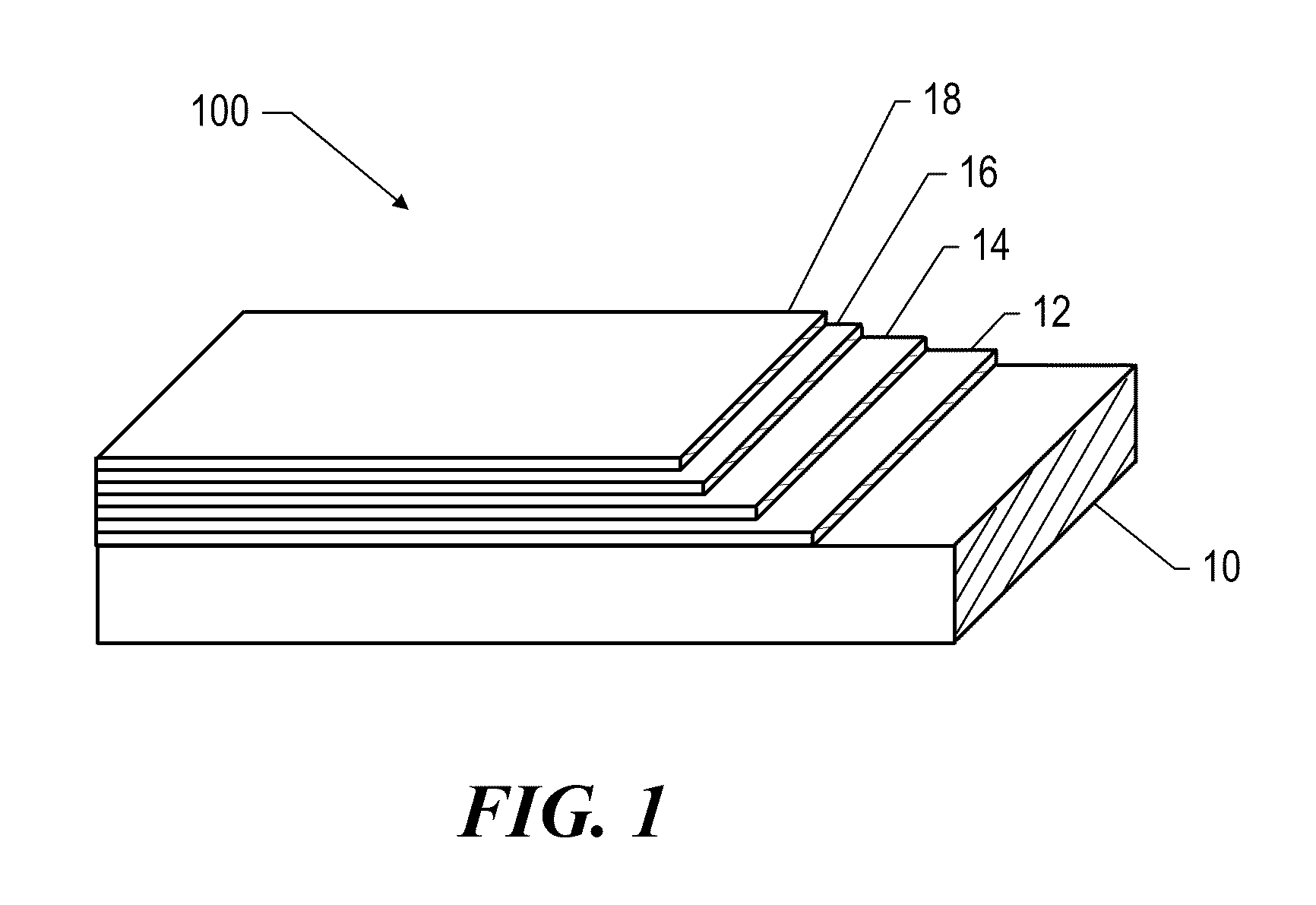

A superconducting article comprises a substrate, a buffer layer overlying the substrate, and a high-temperature superconducting (HTS) layer overlying the buffer layer. The HTS layer includes a plurality of nanorods. A method of forming a superconducting article comprises providing a substrate, depositing a buffer layer overlying the substrate; forming a nanodot array overlying the buffer layer; depositing an array of nanorods nucleated on the nanodot array; and depositing a high-temperature superconducting (HTS) layer around the array of nanorods and overlying the buffer layer.

Owner:SUPERPOWER INC

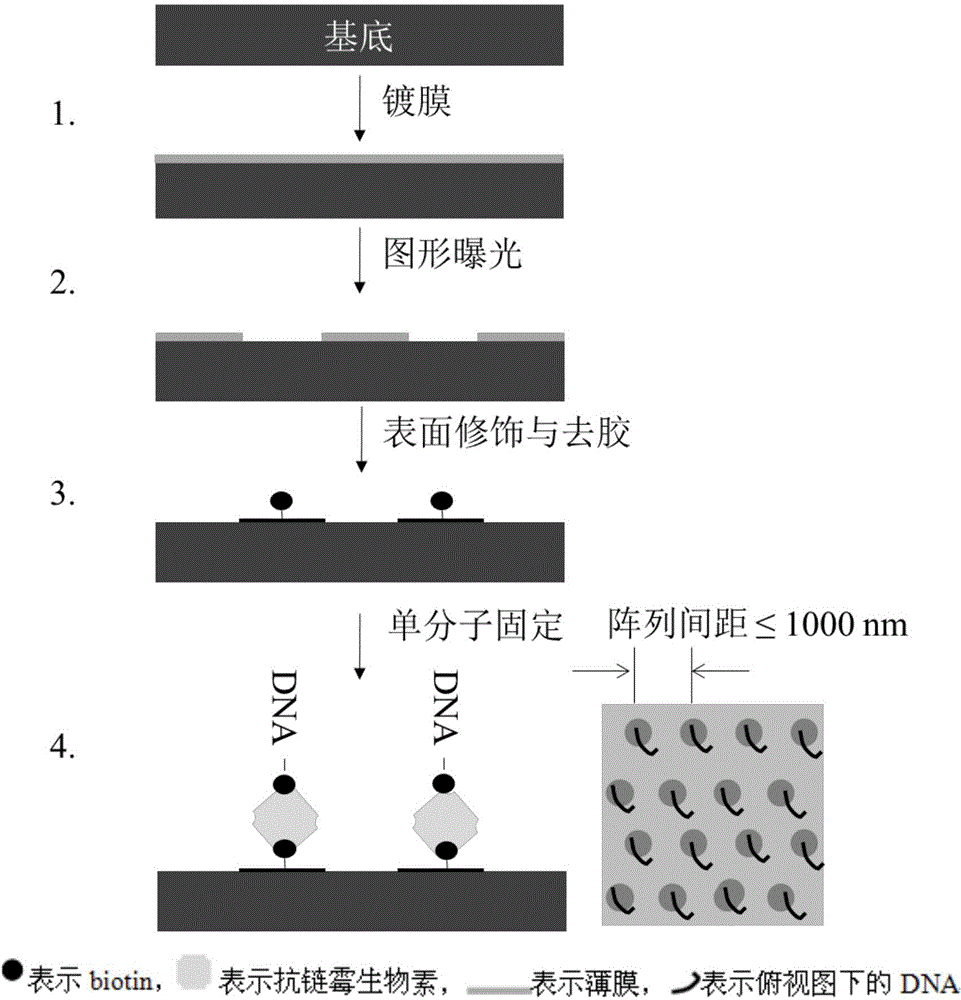

Method for preparing bio-macromolecular monomolecular chips by virtue of high-density nano-dot arrays

ActiveCN104531853ASimple preparation processSample spacing controllablePeptide librariesNucleotide librariesSubstrate modificationO2 plasma

The invention discloses a method for preparing bio-macromolecular monomolecular chips by virtue of high-density nano-dot arrays. The method comprises the following steps: firstly, laying a layer of thin films on a substrate, then preparing nano-hollow arrays on the thin films, performing further substrate modification (performing hydroxylation on the substrate which is subjected to O2 plasma treatment, and then modifying the substrate to be biotinylated), and removing the thin films to form active nano-dot arrays which can be connected with bio-macromolecules, wherein only one bio-macromolecule can be connected with each nano-dot because the nano-dots are small enough; and finally cleaning the substrate to obtain high-density monomolecular biological chips. Objective biological chips obtained by using the method disclosed by the invention are mainly characterized in that the objective biological chips are monomolecular, have high throughput and multiple functions, and can be applied to the fields of ultra-sensitive monomolecular enzyme-linked immunosorbent assay, hybridization based DNA variation detection, monomolecular DNA synthesis and connection sequencing, single-cell RNA sequencing and the like.

Owner:SHANGHAI BEION MEDICAL TECH CO LTD

Quantum dot/titanium dioxide composite nanodot array having visible-light response and preparation method of quantum dot/titanium dioxide composite nanodot array

ActiveCN104449698AAdjustable responsivenessAdjustable utilizationMaterial nanotechnologyNanoopticsNanodotLight response

The invention discloses a quantum dot / titanium dioxide composite nanodot array having visible-light response. On the surface of a substrate, each nanodot in the composite nanodot array is composed of titanium dioxide covered visible-light response quantum dots; the dimension of the composite nanodots ranges from 50-200nm and the density of the composite nanodots ranges from 0.31*10<10> to the power of 10 to 3.01*10<10> to the power of 10 cm<-2>. The preparation process is a one-step method and specifically comprises the following steps: adding the quantum dots while preparing a spin-coating solution, applying the spin-coating solution to the surface of the substrate by use of a sol-gel spin-coating method, and preparing the quantum dot / titanium dioxide composite nanodot array by use of a hydrothermal method or direct annealing; the process is simple and easy to implement. The response and the utilization rate of the composite nanodot array to light can be regulated by regulating the types of the quantum dots and the excitation waveforms of the quantum dots; besides, the hydrophobicity and the hydrophilicity of the surface of the material can be changed by use of visible light different in wavelength, and therefore, later cell detachment is realized and the visible light can be possibly used for cell detachment.

Owner:ZHEJIANG UNIV

Superconductive article with prefabricated nanostructure for improved flux pinning

ActiveUS8926868B2Material nanotechnologyNanostructure manufactureHigh temperature superconductingOptoelectronics

A superconducting article comprises a substrate, a buffer layer overlying the substrate, and a high-temperature superconducting (HTS) layer overlying the buffer layer. The HTS layer includes a plurality of nanorods. A method of forming a superconducting article comprises providing a substrate, depositing a buffer layer overlying the substrate; forming a nanodot array overlying the buffer layer; depositing an array of nanorods nucleated on the nanodot array; and depositing a high-temperature superconducting (HTS) layer around the array of nanorods and overlying the buffer layer.

Owner:SUPERPOWER INC

Extended deposition range by hot spots

Owner:ASM INTERNATIONAL

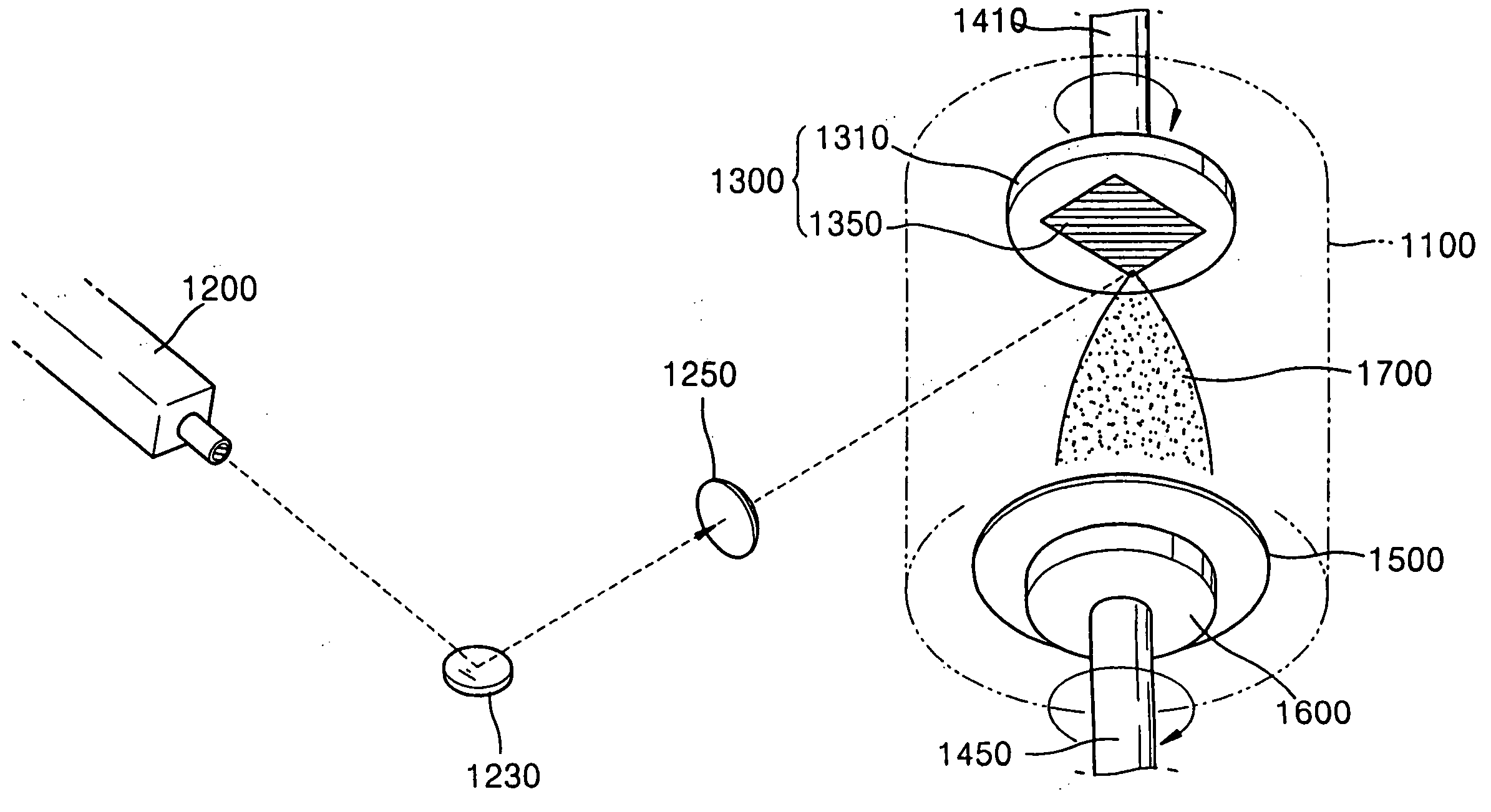

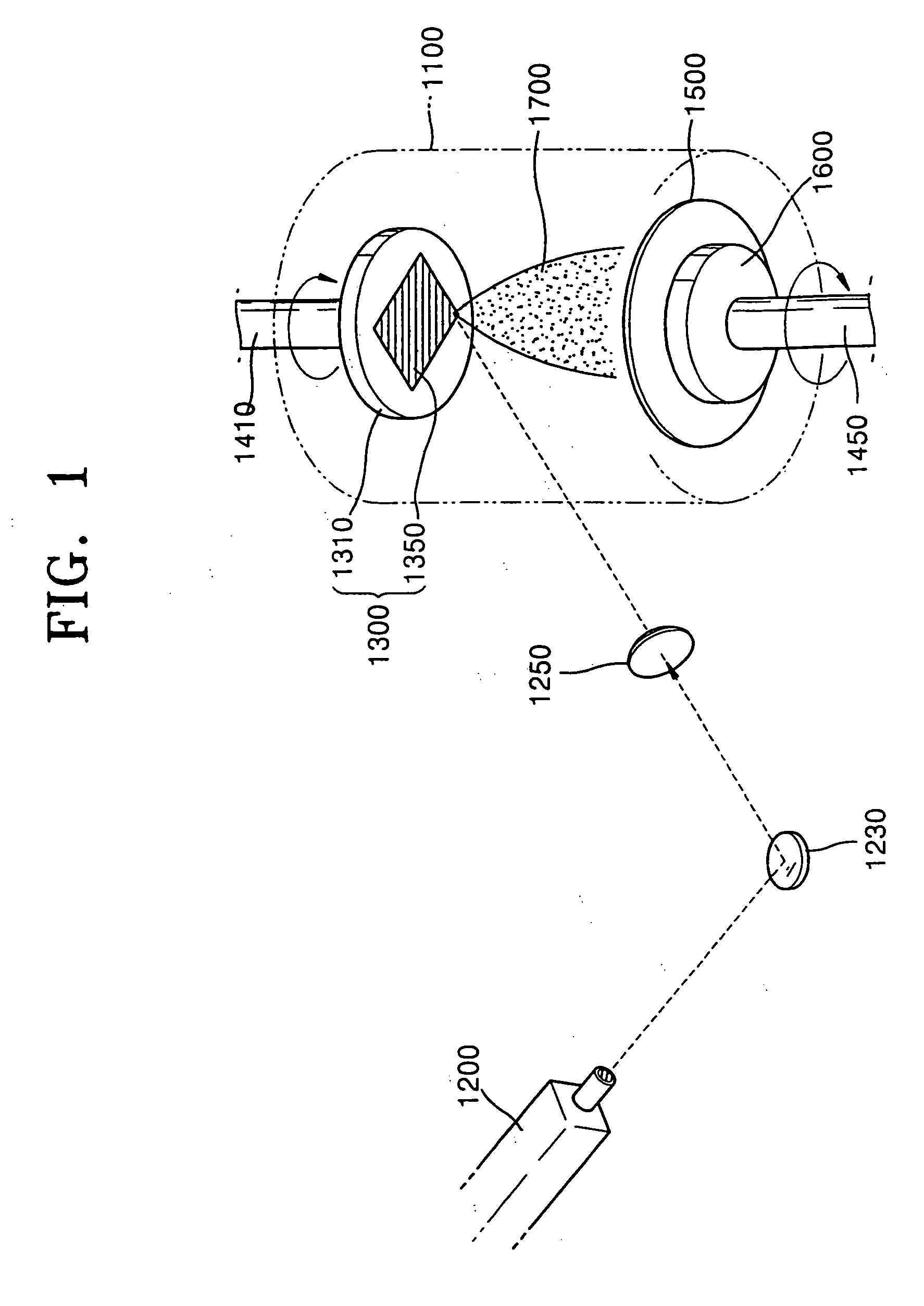

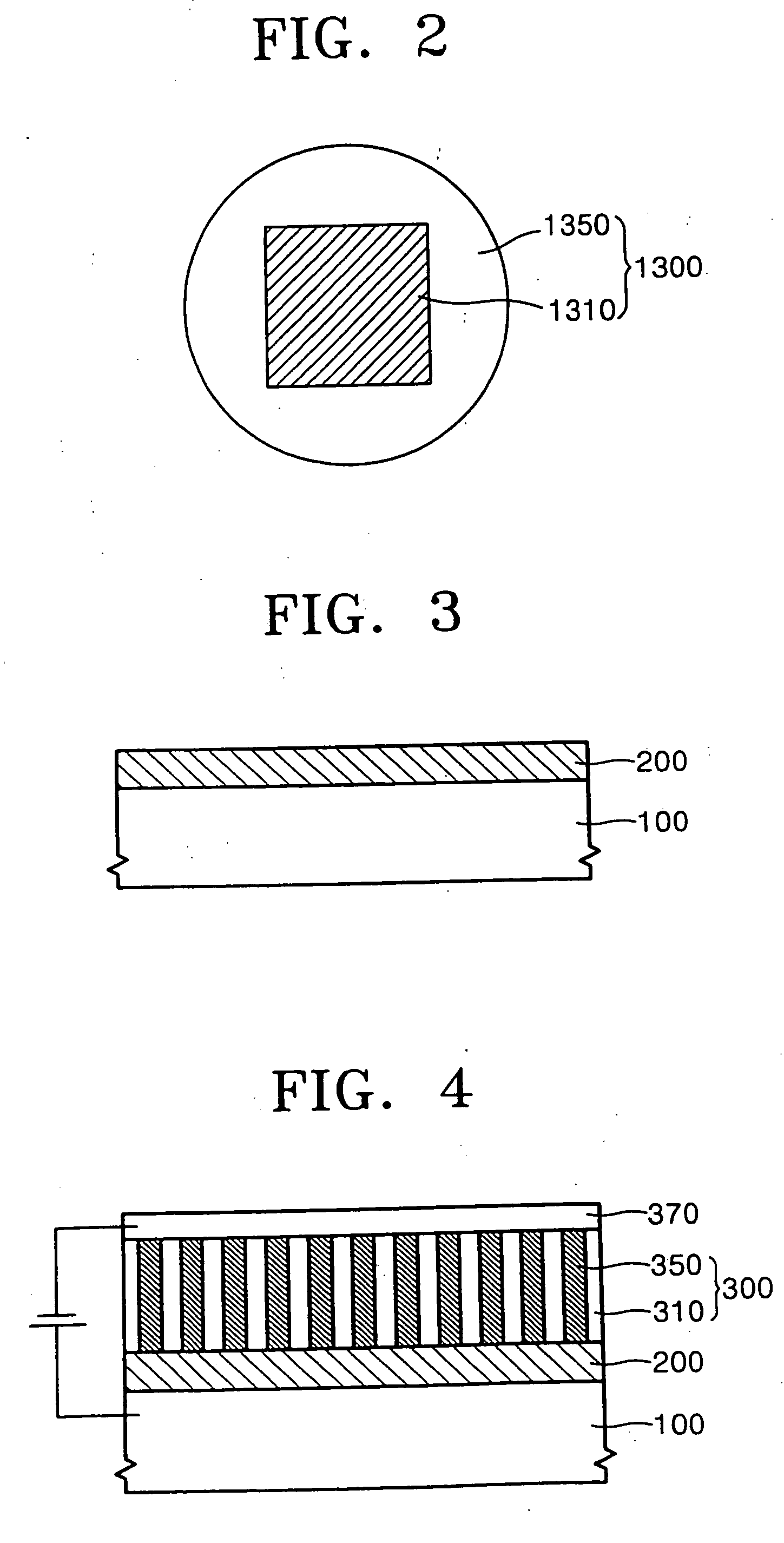

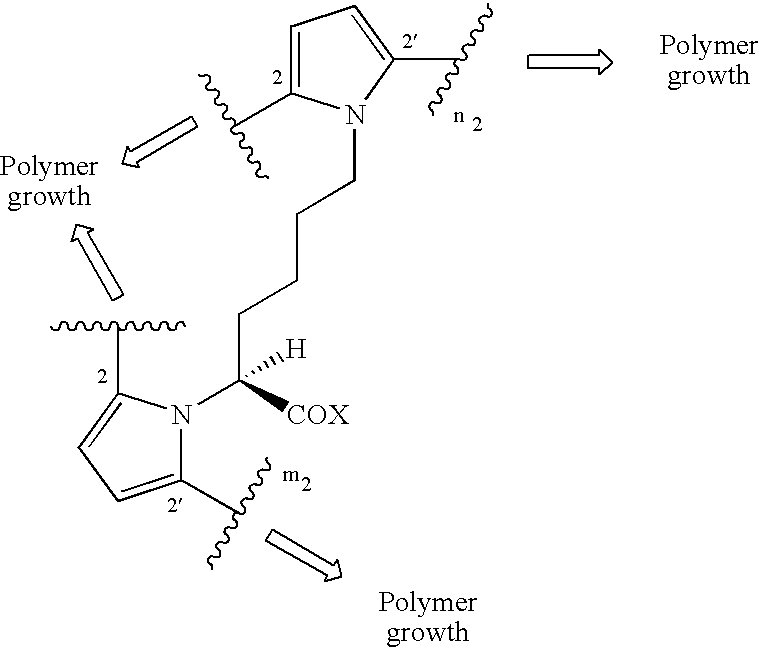

Method of manufacturing Er-doped silicon nano-dot array and laser ablation apparatus used therein

InactiveUS20050061235A1High purityAvoid pollutionAfter-treatment apparatusLaser detailsLaser lightNanodot array

Owner:HA JEONG SOOK +3

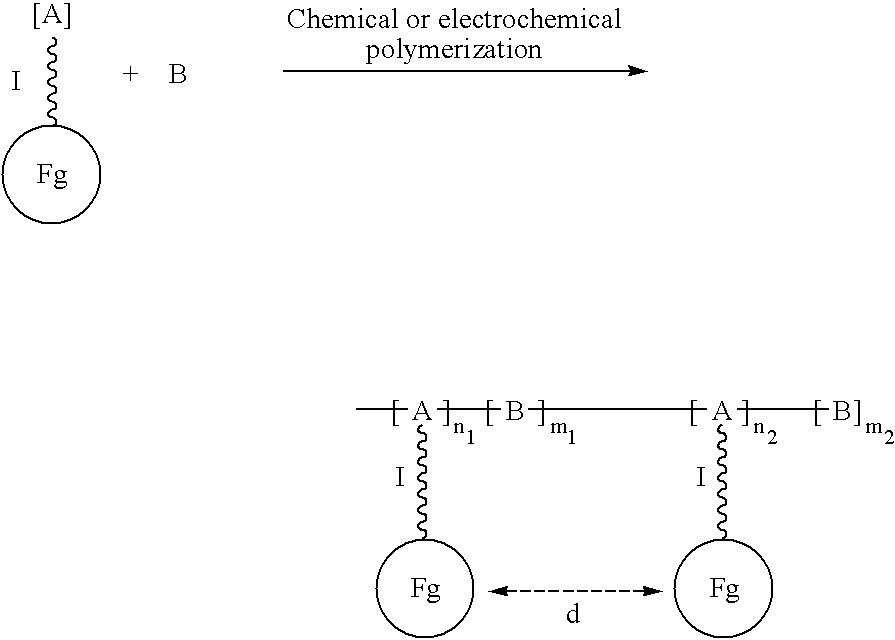

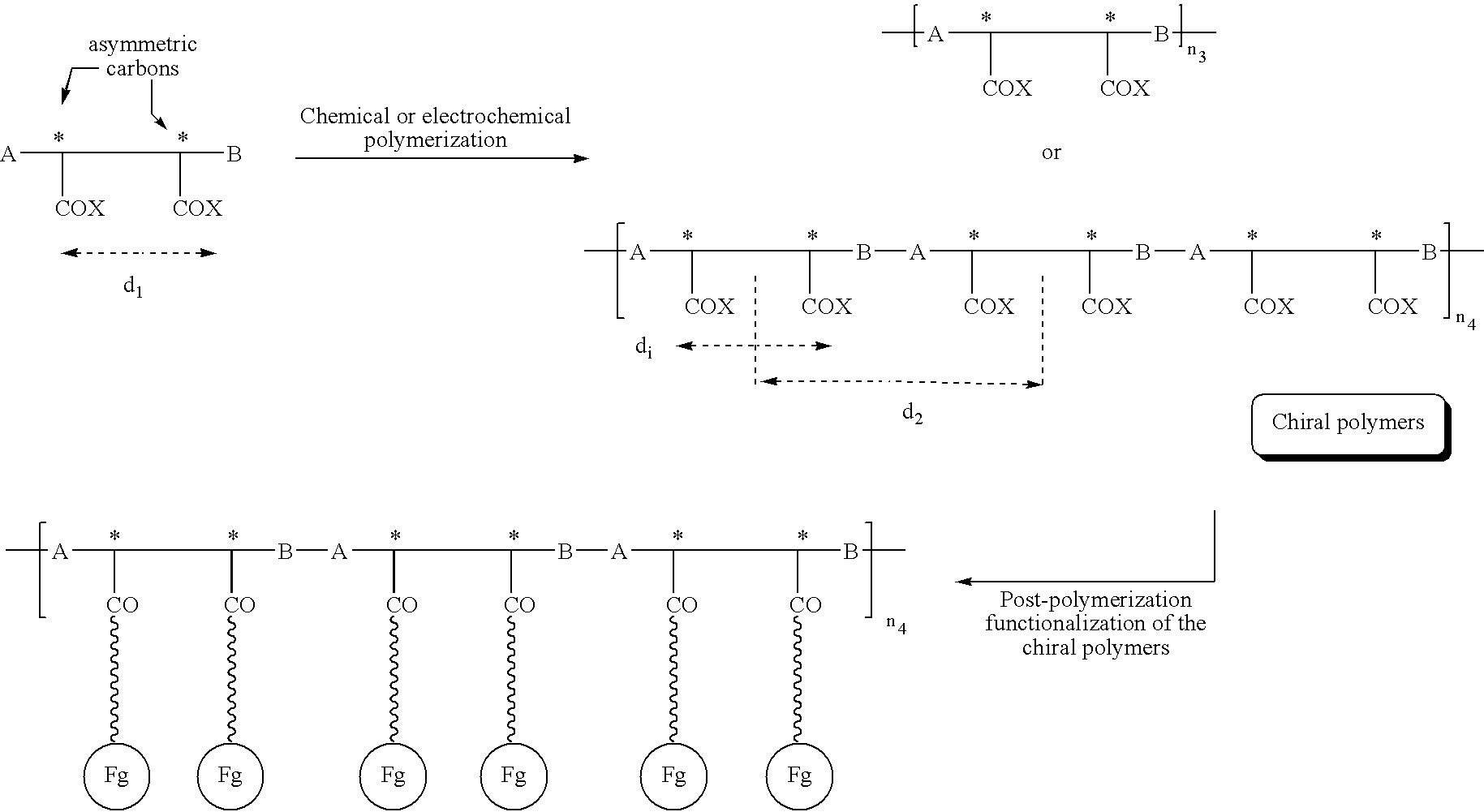

Electroconductive polymers

Provided are novel polymerizable monomers allowing preparation of exceptionally useful surface coatings by polymerization. Embodiments include highly reticulated chiral nanoparticles useful, for example, for covalently grating biological ligands, epitaxial growth of conductive polymers onto surface modified indium tin oxide (ITO) electrodes and arrays of gold nanodots and electroconductive polymers.

Owner:BAR ILAN UNIV

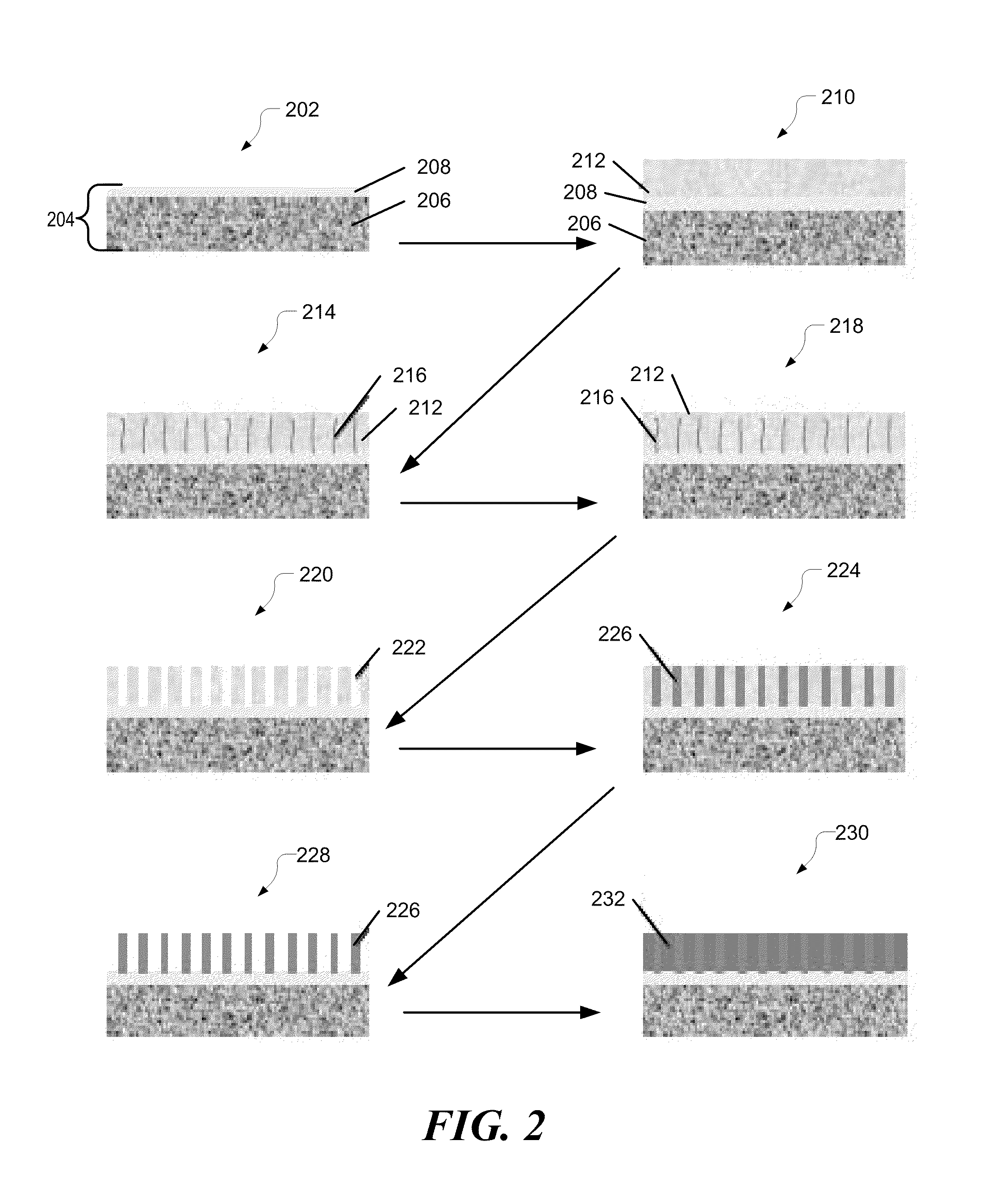

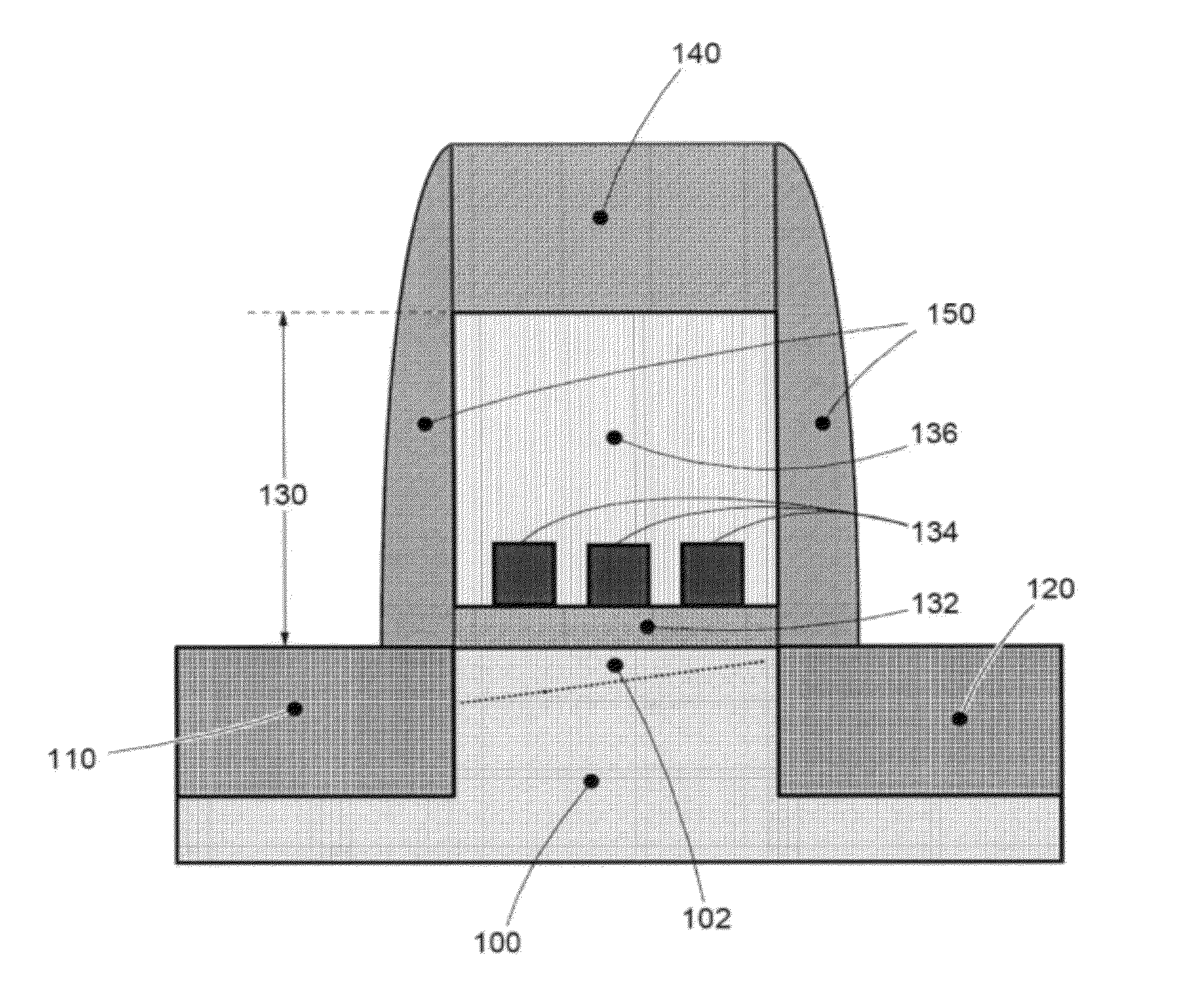

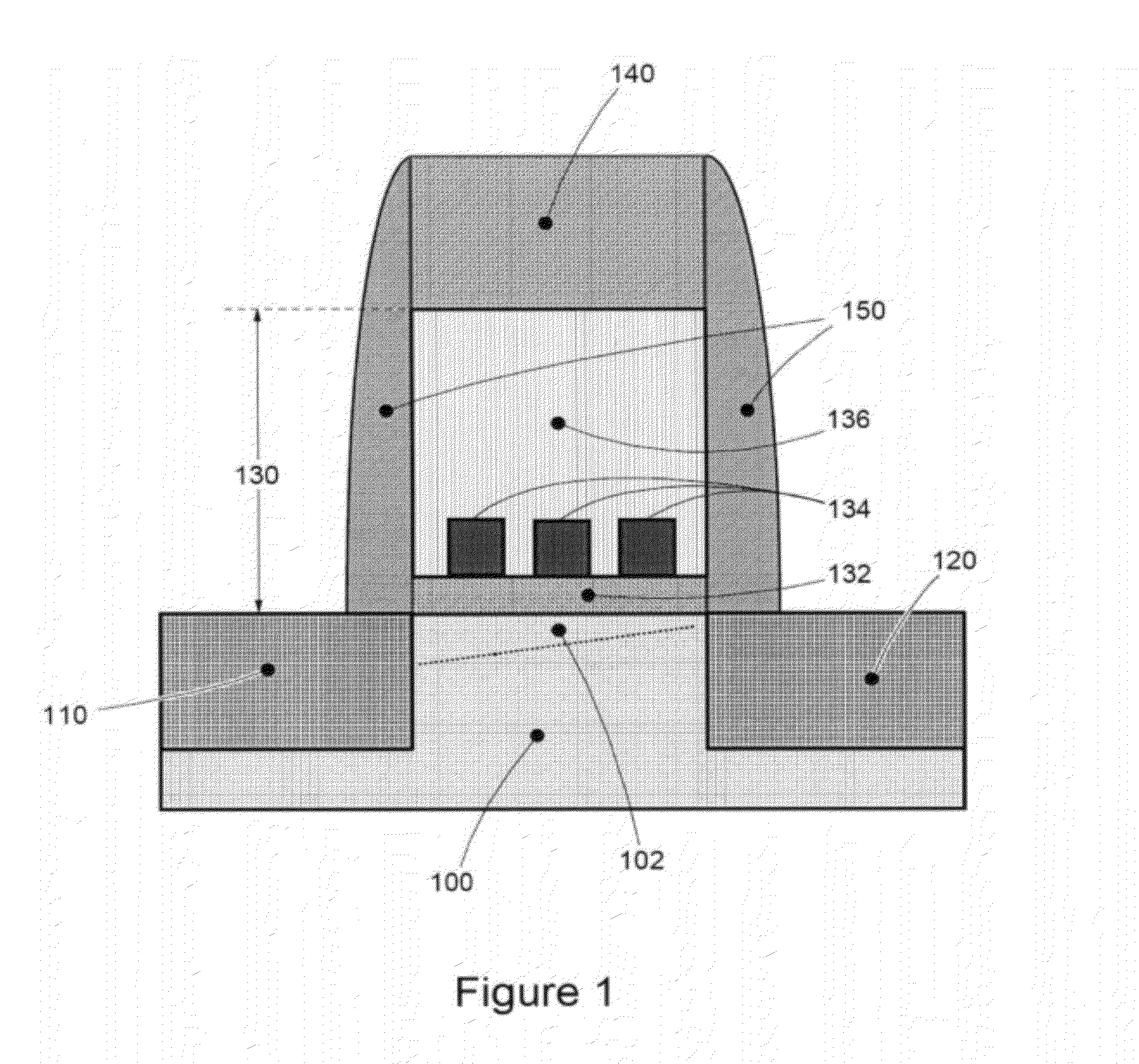

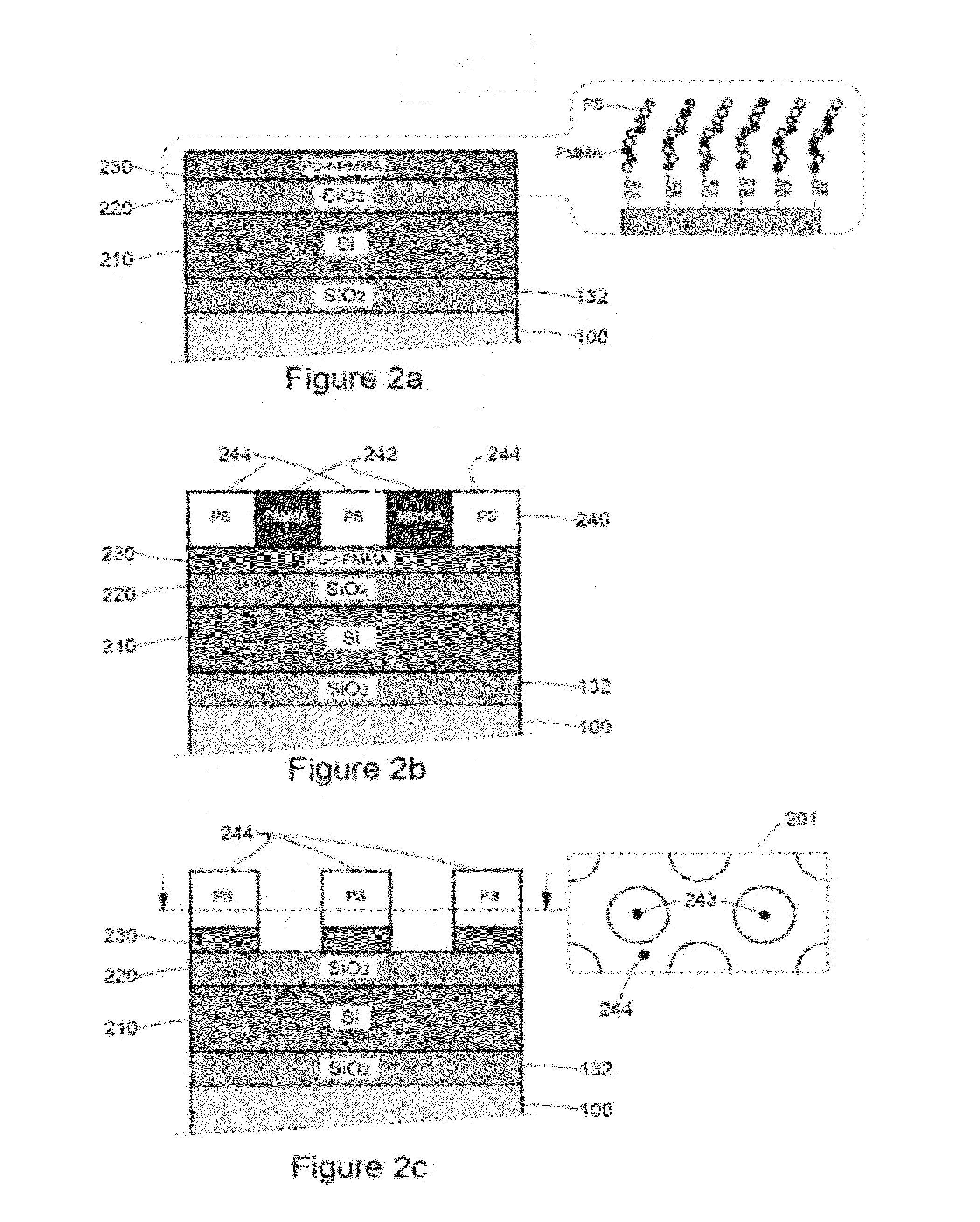

Process for obtaining an array of nanodots

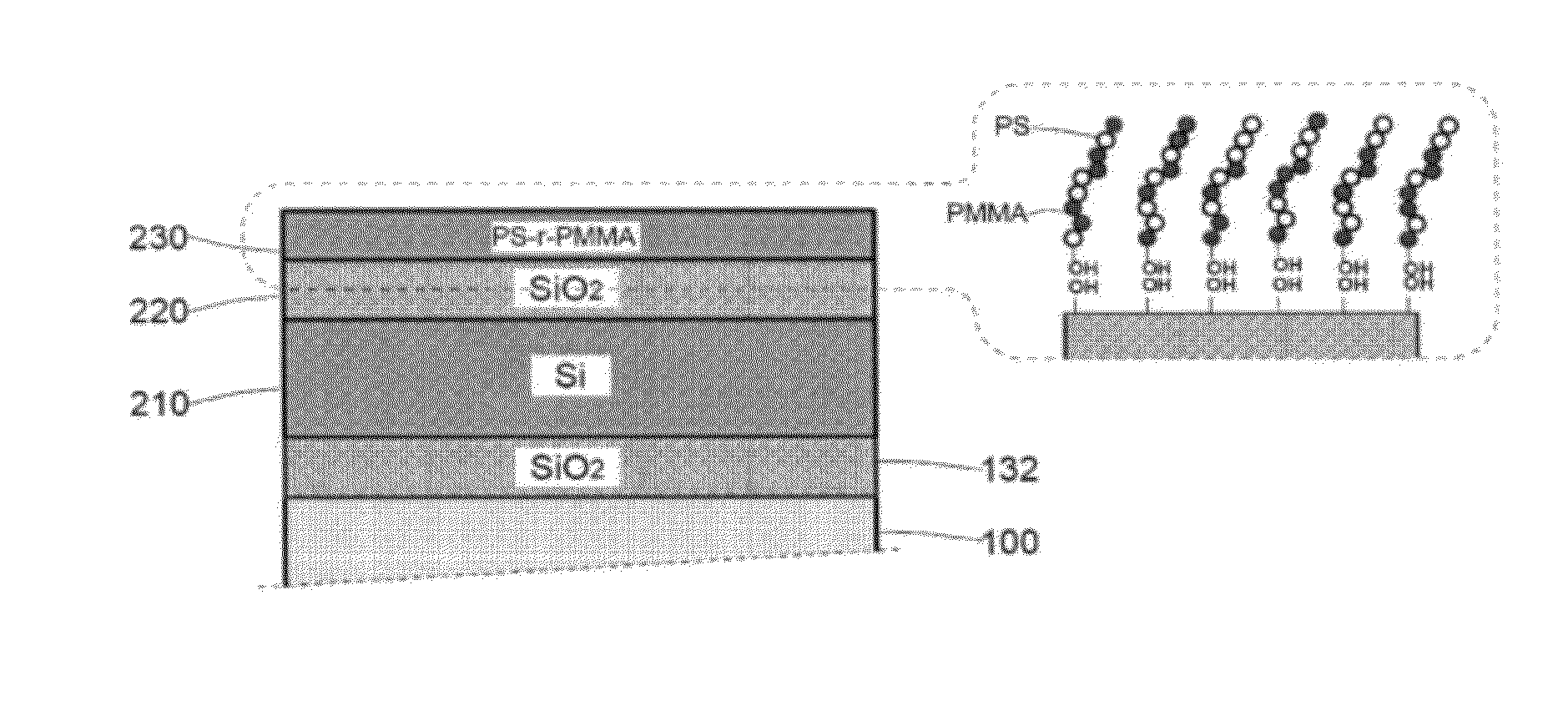

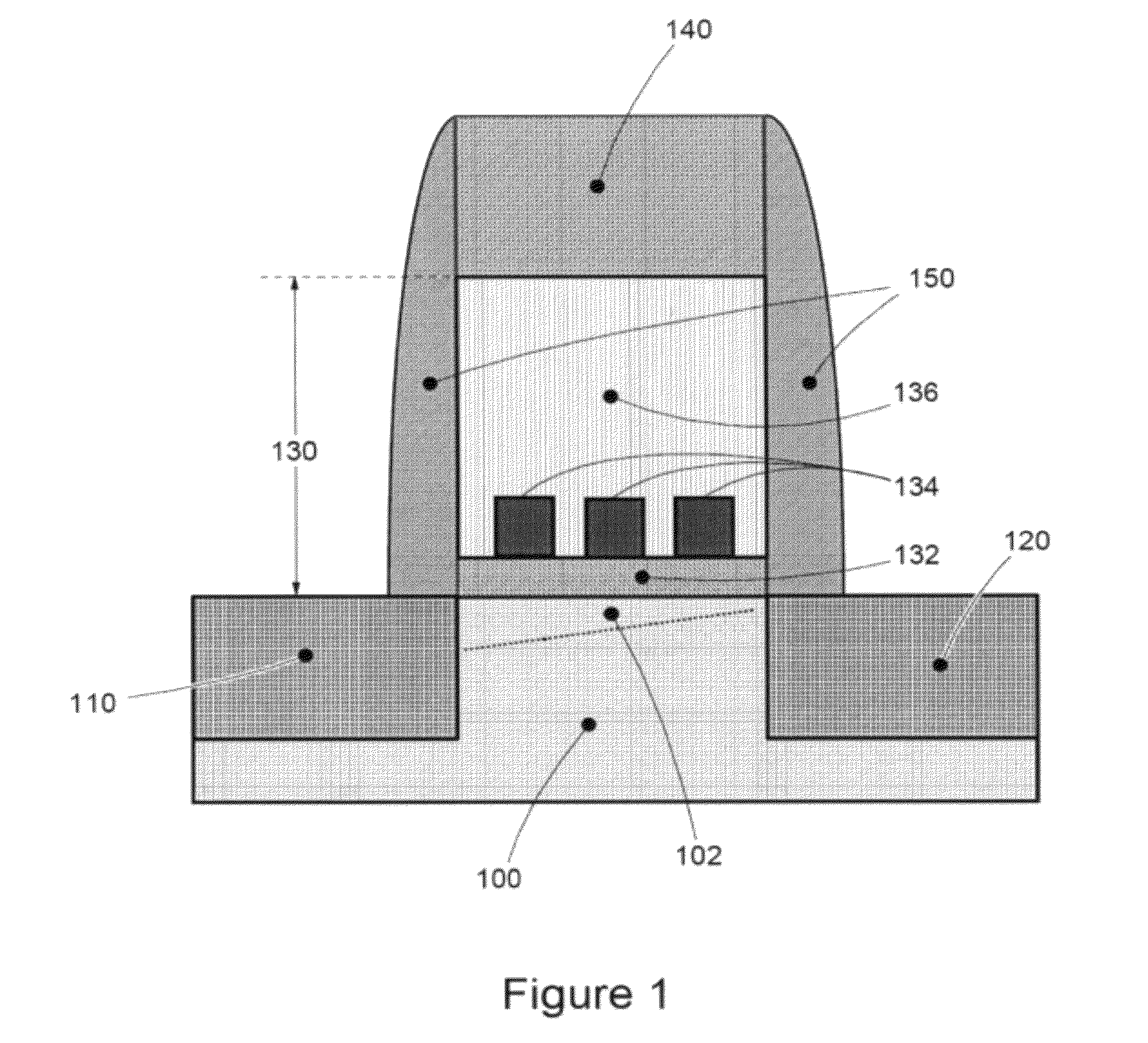

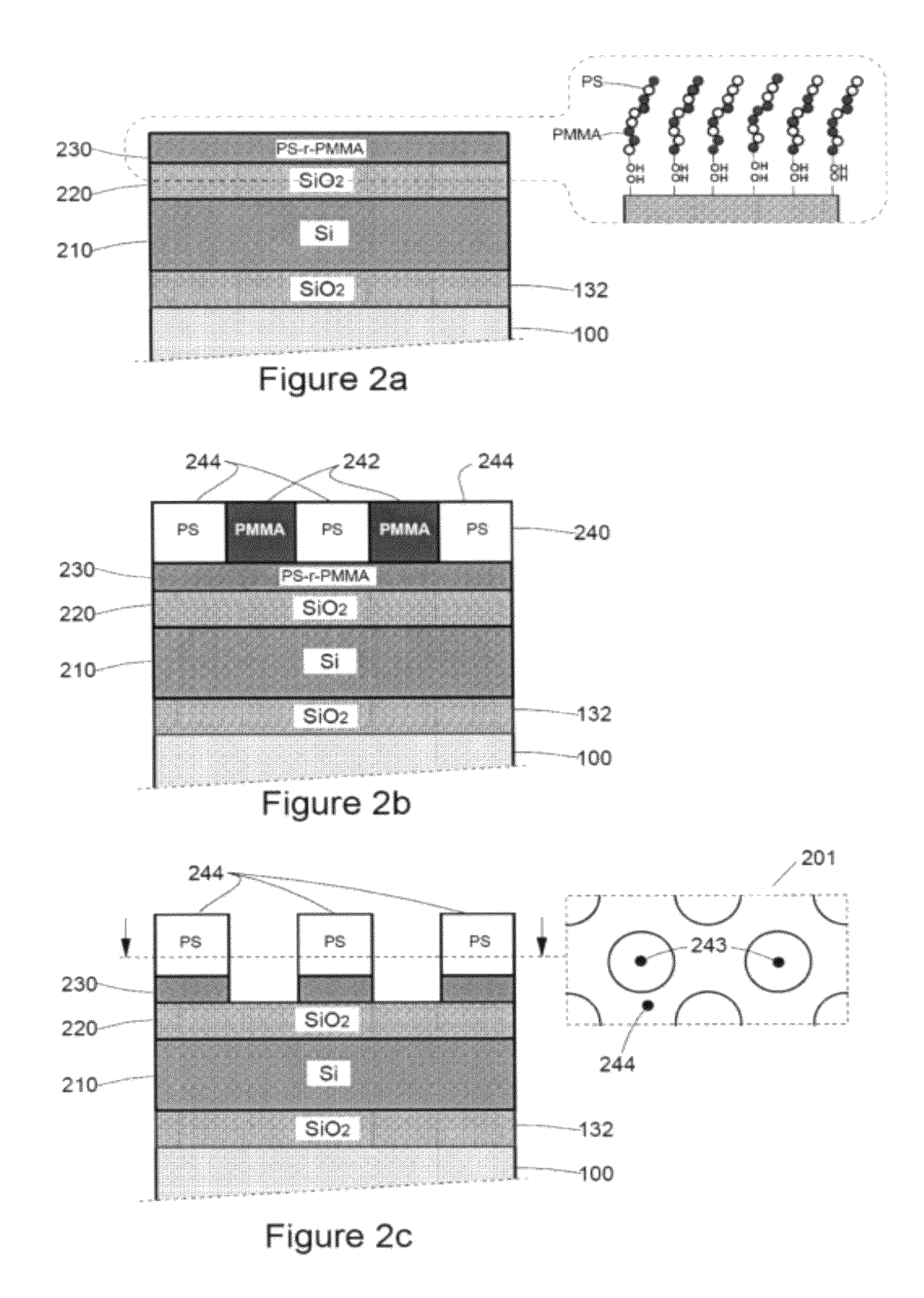

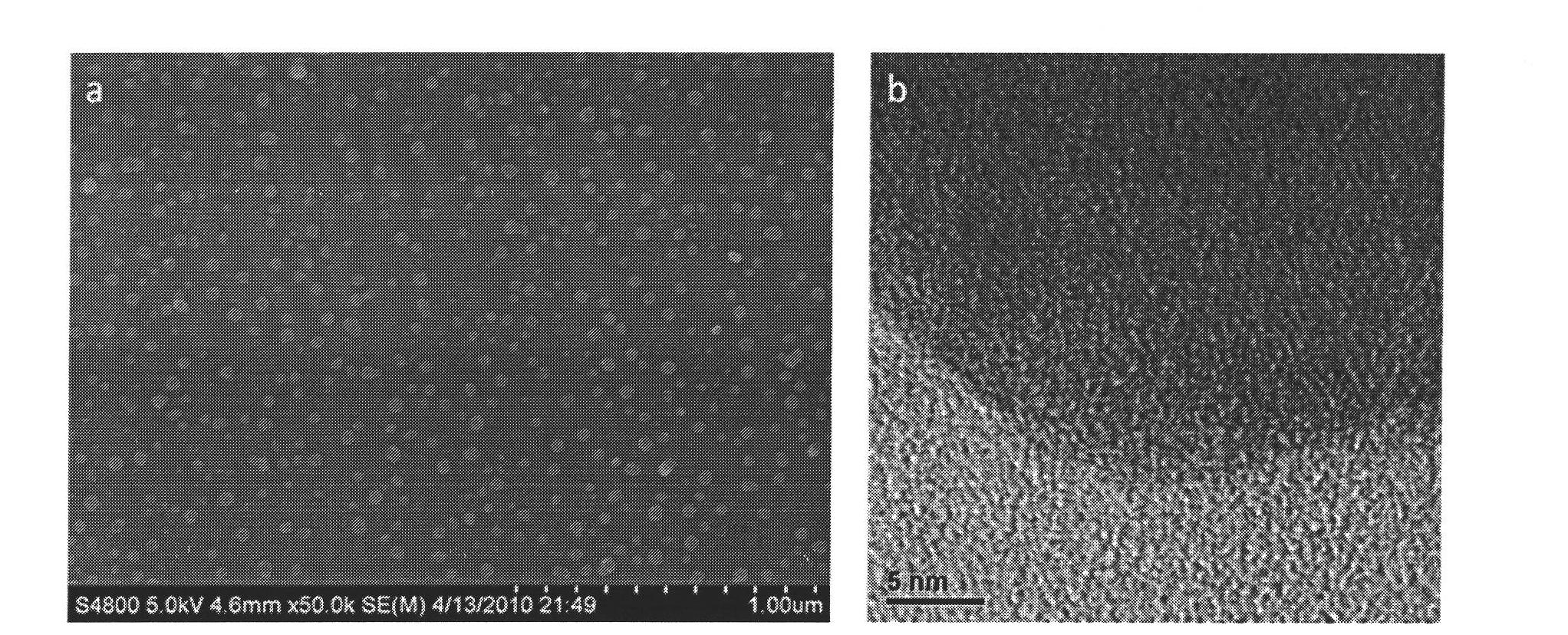

InactiveUS20120217565A1Easy to controlImprove performanceTransistorSemiconductor/solid-state device manufacturingNanodotNanodot array

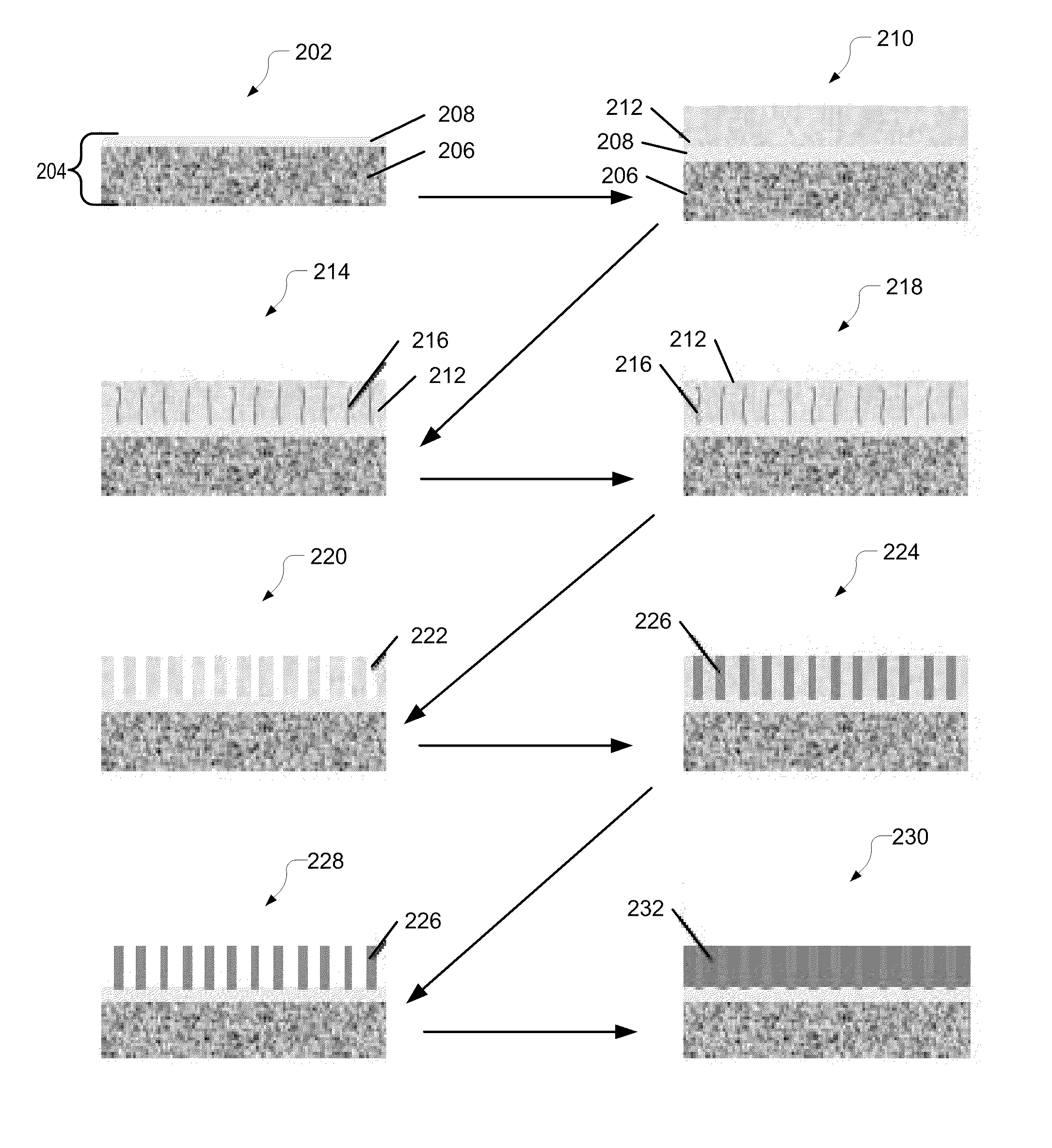

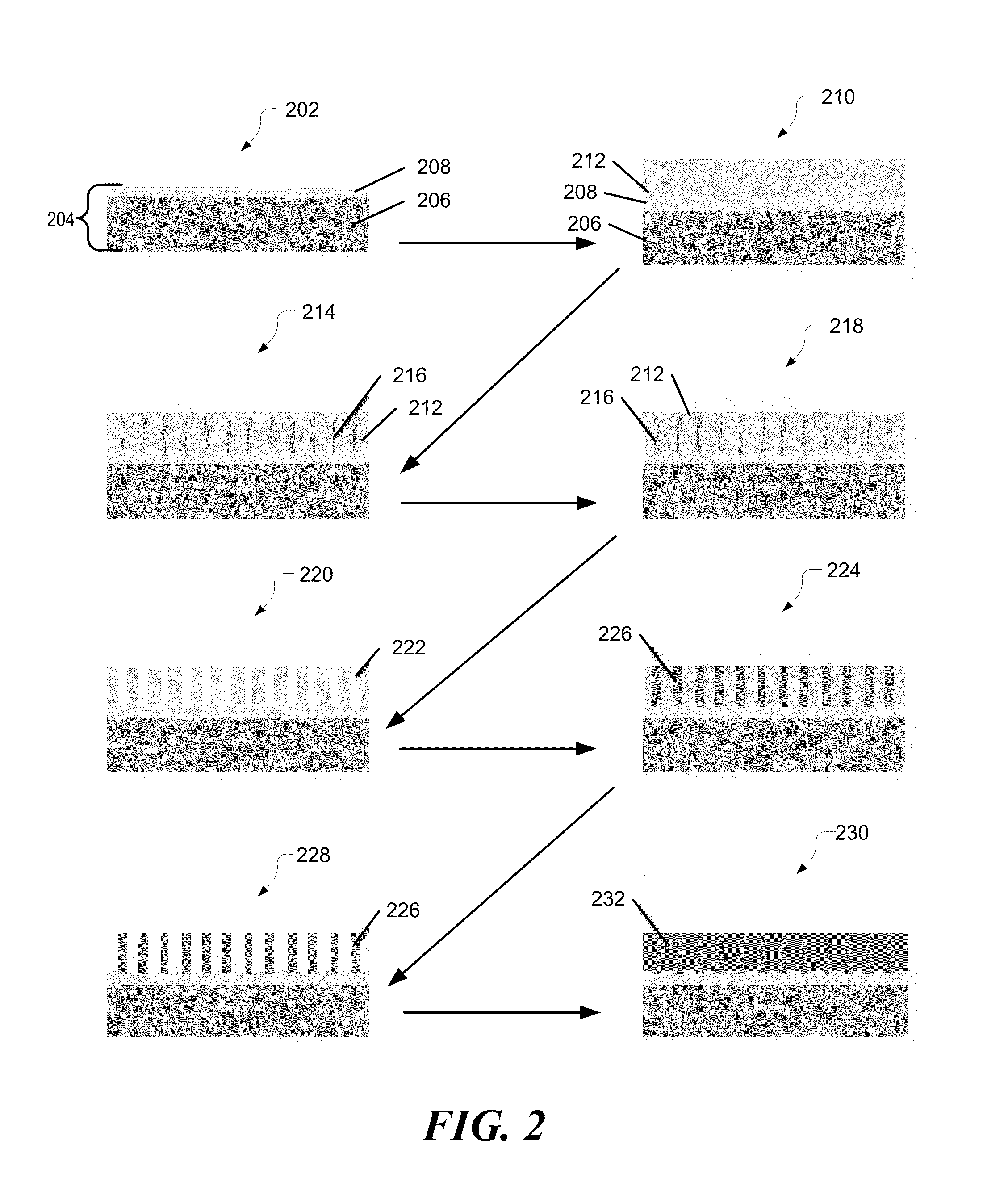

A process for obtaining an array of nanodots (212) for microelectronic devices, characterized in that it comprises the following steps:deposition of a silicon layer (210) on a substrate (100, 132),formation, above the silicon layer (210), of a layer (240) of a material capable of self-organizing, in which at least one polymer substantially forms cylinders (242) organized into an array within a matrix (244),formation of patterns (243) in the layer (240) of a material capable of self-organizing by elimination of the said cylinders (242),formation of a hard mask (312) by transfer of the said patterns (243),production of silicon dots (212) in the silicon layer (210) by engraving through the hard mask (312),silicidation of the silicon dots (212), comprising deposition of a metal layer (510).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +2

Process for obtaining an array of nanodots

InactiveUS8940623B2Improve behaviorBehavior of the dots obtained according to the invention therefore remains stableTransistorSemiconductor/solid-state device manufacturingNanodotArray data structure

A process for obtaining an array of nanodots (212) for microelectronic devices, characterized in that it comprises the following steps:deposition of a silicon layer (210) on a substrate (100, 132),formation, above the silicon layer (210), of a layer (240) of a material capable of self-organizing, in which at least one polymer substantially forms cylinders (242) organized into an array within a matrix (244),formation of patterns (243) in the layer (240) of a material capable of self-organizing by elimination of the said cylinders (242),formation of a hard mask (312) by transfer of the said patterns (243),production of silicon dots (212) in the silicon layer (210) by engraving through the hard mask (312),silicidation of the silicon dots (212), comprising deposition of a metal layer (510).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +2

Amorphous titanium dioxide nano dot array and preparation method thereof

The invention discloses an amorphous titanium dioxide nano dot array. The titanium dioxide of the array has an amorphous structure, the diameter of titanium dioxide nano dots is 10 to 250 nanometers, and the distribution density of the titanium dioxide nano dots is 1.0-10.0*1,010 cm<2>. A preparation method for the amorphous titanium dioxide nano dot array comprises the following steps of: dissolving titanate, water and acetylacetone into alcohol, adding polyvinylpyrrolidone into the mixture to form titanium dioxide precursor sol; and spinning the titanium dioxide precursor sol on a substrateto form a titanium dioxide precursor nano dot array sol film, and obtaining the amorphous titanium dioxide nano dot array on the substrate by ageing and hydrothermal process. The preparation method solves the problem of preparing the amorphous titanium dioxide nano dot array on the surface of the substrate; and the preparation method is simple, feasible and convenient to operate, and can be applied in the fields of surface function modification of non high-temperature resistant materials, photo-catalysis and the like.

Owner:ZHEJIANG UNIV

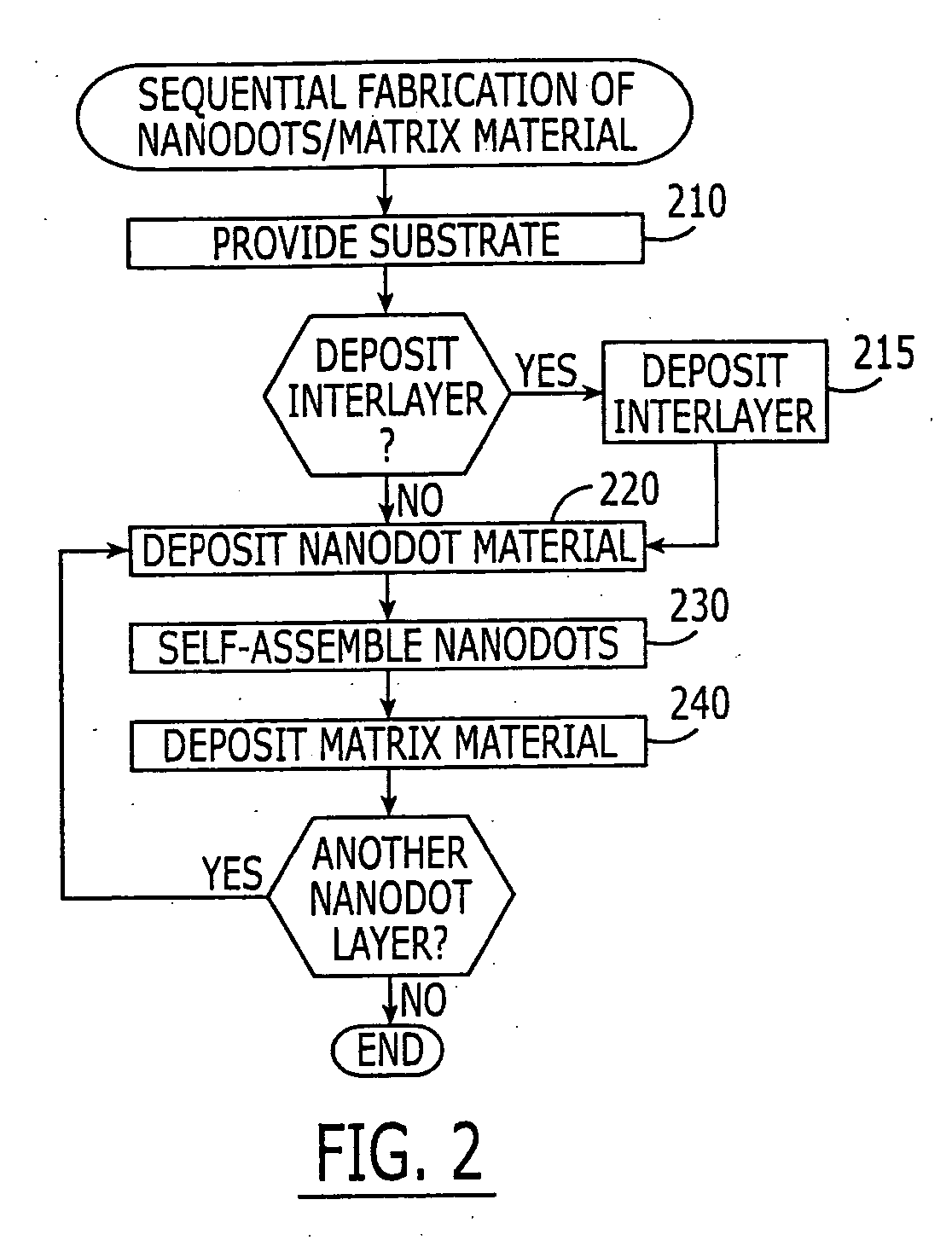

Manufacture method of nano point array with perpendicular magnetic anisotropy

InactiveCN102543107AWith perpendicular magnetic anisotropyVarying Deposition ThicknessRecord carriers manufactureNano structuringPerpendicular anisotropy

The invention relates to a manufacture method of a nano structure material capable of being applied to high-density magnetic storage, and in particular relates to a manufacture method of a nano point array with perpendicular magnetic anisotropy. The manufacture method comprises the following steps of: 1, manufacturing a substrate: manufacturing a single-layer hexagonal close-packed colloid array spherical substrate by adopting a self-assembly technology; and 2, depositing a two-layer film: depositing a Co / Pt multilayer film on the colloid array spherical substrate manufactured in the step 1 by adopting a sputtering technology to ensure that a thickness of a film of a sphere gap is only 2 / 3 of that of a film on the top of a sphere, so as to obtain a nano point with the perpendicular magnetic anisotropy. The nano point array manufactured by adopting the manufacture method has a complete edge structure, good storage property and strong perpendicular magnetic anisotropy.

Owner:JILIN NORMAL UNIV

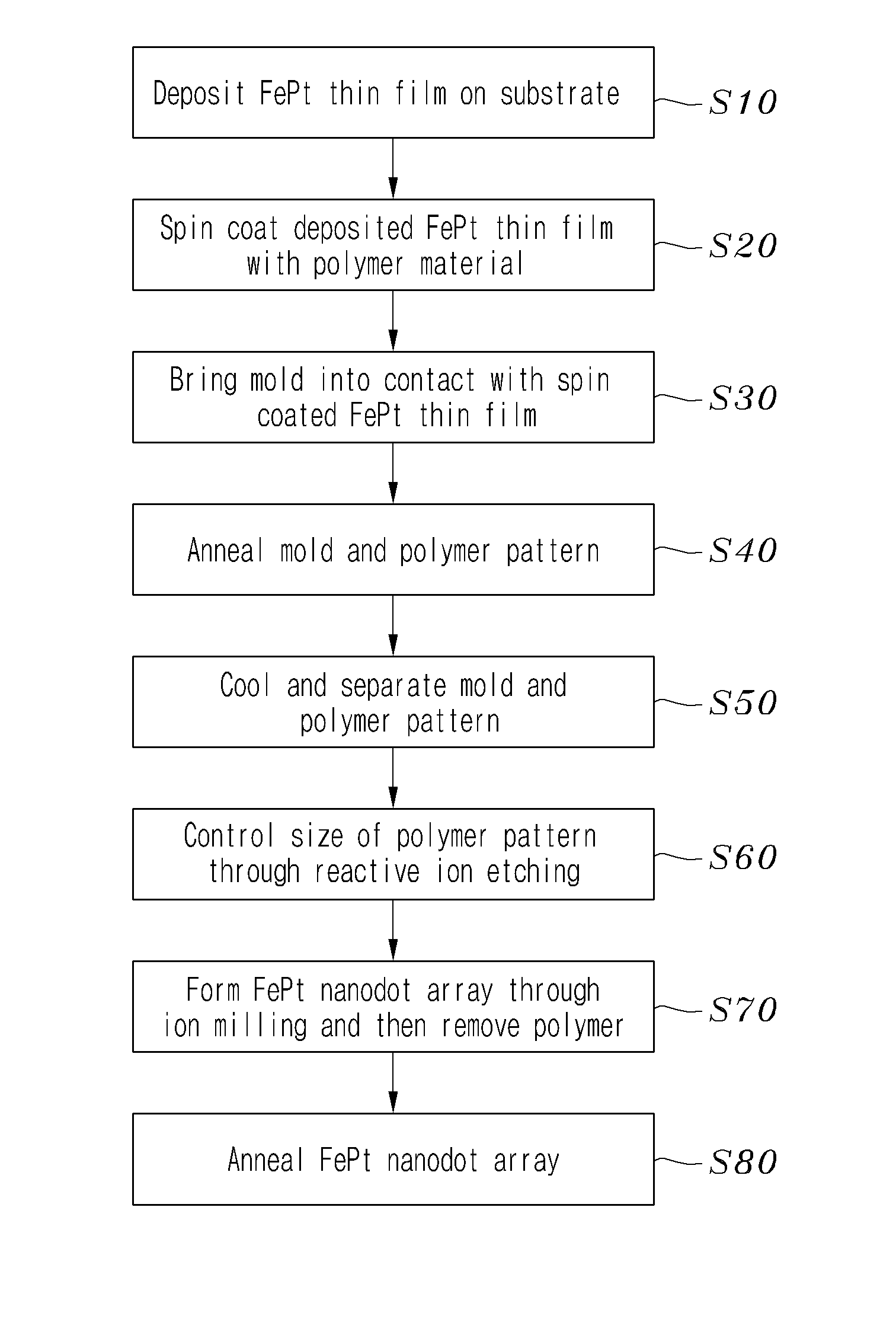

L10-ORDERED FePt NANODOT ARRAY, METHOD OF MANUFACTURING THE SAME AND HIGH DENSITY MAGNETIC RECORDING MEDIUM USING THE SAME

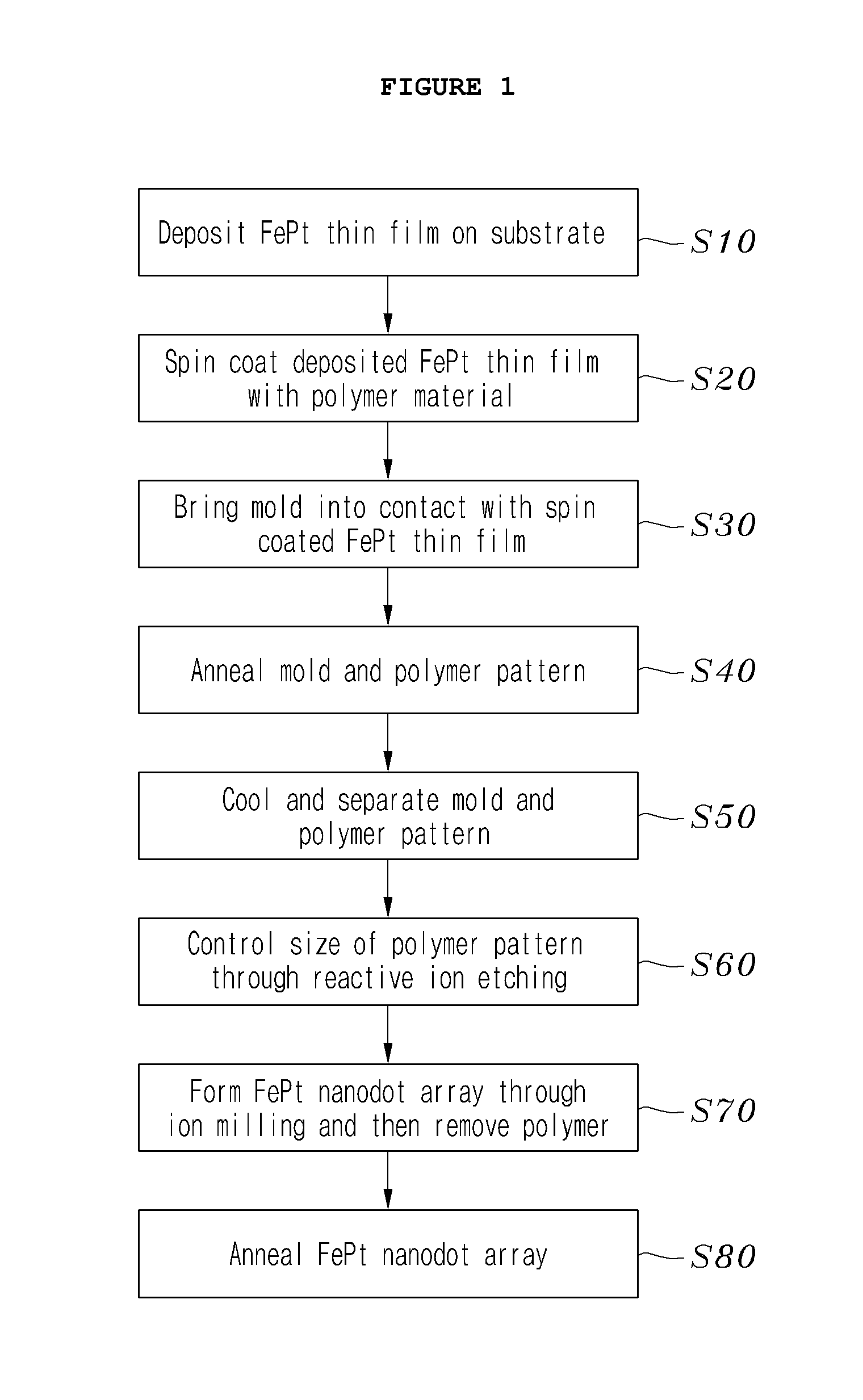

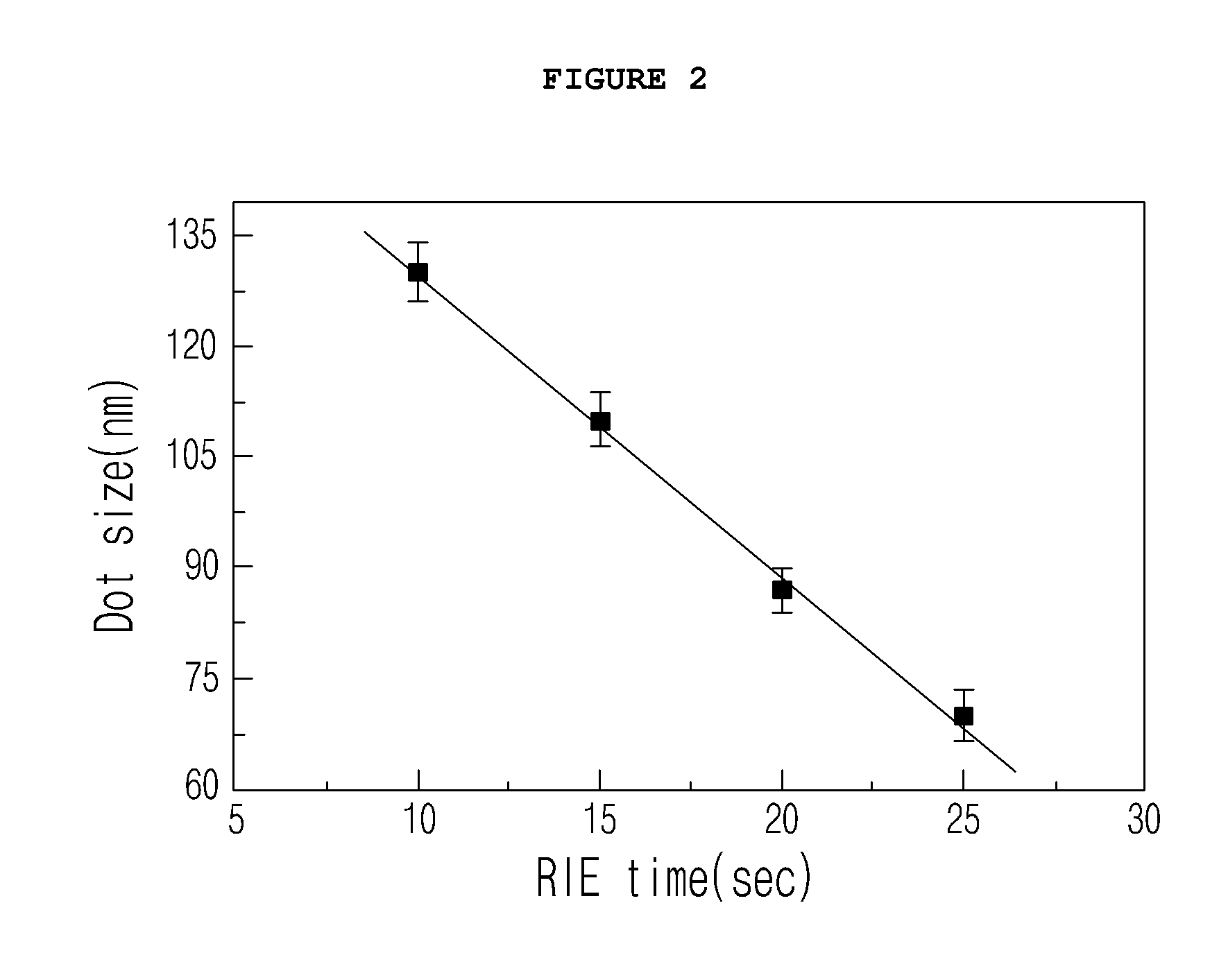

This invention relates to a L10-ordered FePt nanodot array which is manufactured using capillary force lithography, to a method of manufacturing the L10-ordered FePt nanodot array and to a high density magnetic recording medium using the L10-ordered FePt nanodot array. This method includes depositing a FePt thin film on a MgO substrate, forming a thin film made of a polymer material on the deposited FePt thin film using spin coating, bringing a mold into contact with the spin coated FePt thin film, annealing the mold and a polymer pattern which are in contact with each other, cooling and separating the mold and the polymer pattern which are annealed, controlling a size of the polymer pattern through reactive ion etching, ion milling a portion of the FePt thin film uncovered with the polymer pattern thus forming a FePt nanodot array and then removing a remaining polymer layer, and annealing the FePt nanodot array.

Owner:KOREA ADVANCED INST OF SCI & TECH

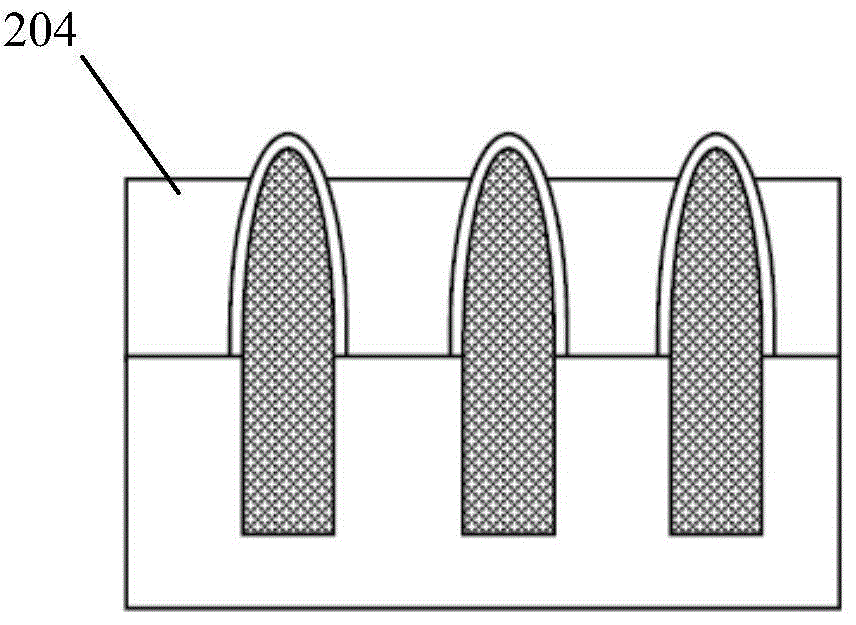

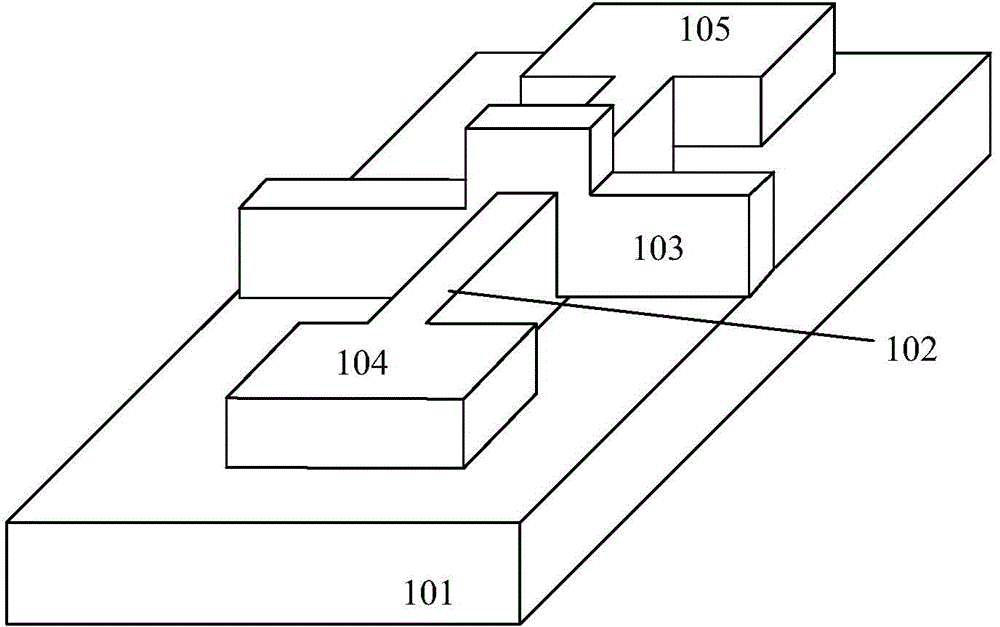

Method for manufacturing transistor based on metal nano-dot trench, and prepared product

ActiveCN105448716ASmall feature sizeReduce power consumptionSemiconductor/solid-state device manufacturingNanotechnologyNanodot arrayGap filling

The invention discloses a method for manufacturing a transistor based on a metal nano-dot trench, and a prepared product. The method can manufacture a trench with a metal nano dot, thereby obtaining a transistor which is prepared without a semiconductor. The method comprises the steps: forming fin-shaped structures on a substrate; forming insulating layers on the surfaces of the fin-shaped structures; filling a gap between the fin-shaped structures with gap filling materials; exposing the tops of the fin-shaped structures; forming a metal nano dot array at the tops of the gap filling materials and the fin-shaped structures; and removing the gap filling materials and the metal nano dots on the gap filling materials, so as to form a structure which is only provided with the metal nano dots at the tops of the fin-shaped structures.

Owner:SEMICON MFG INT (SHANGHAI) CORP

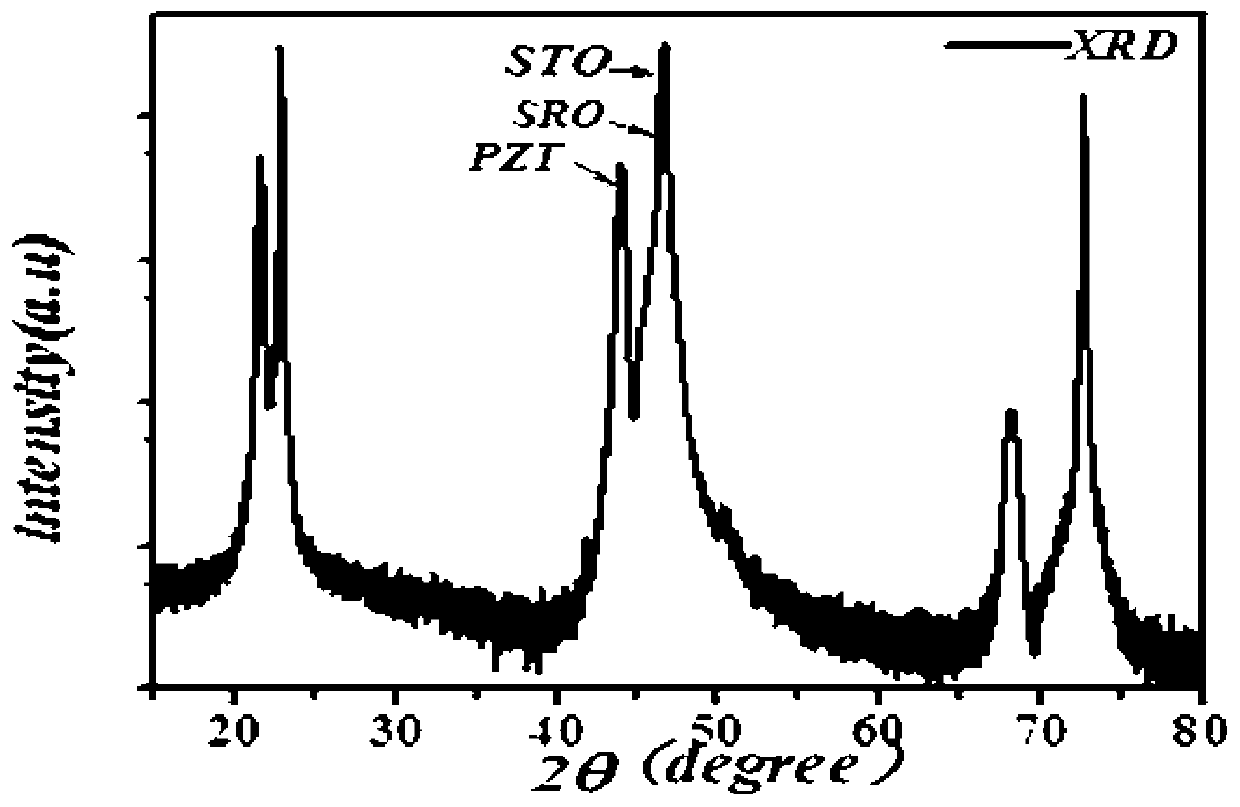

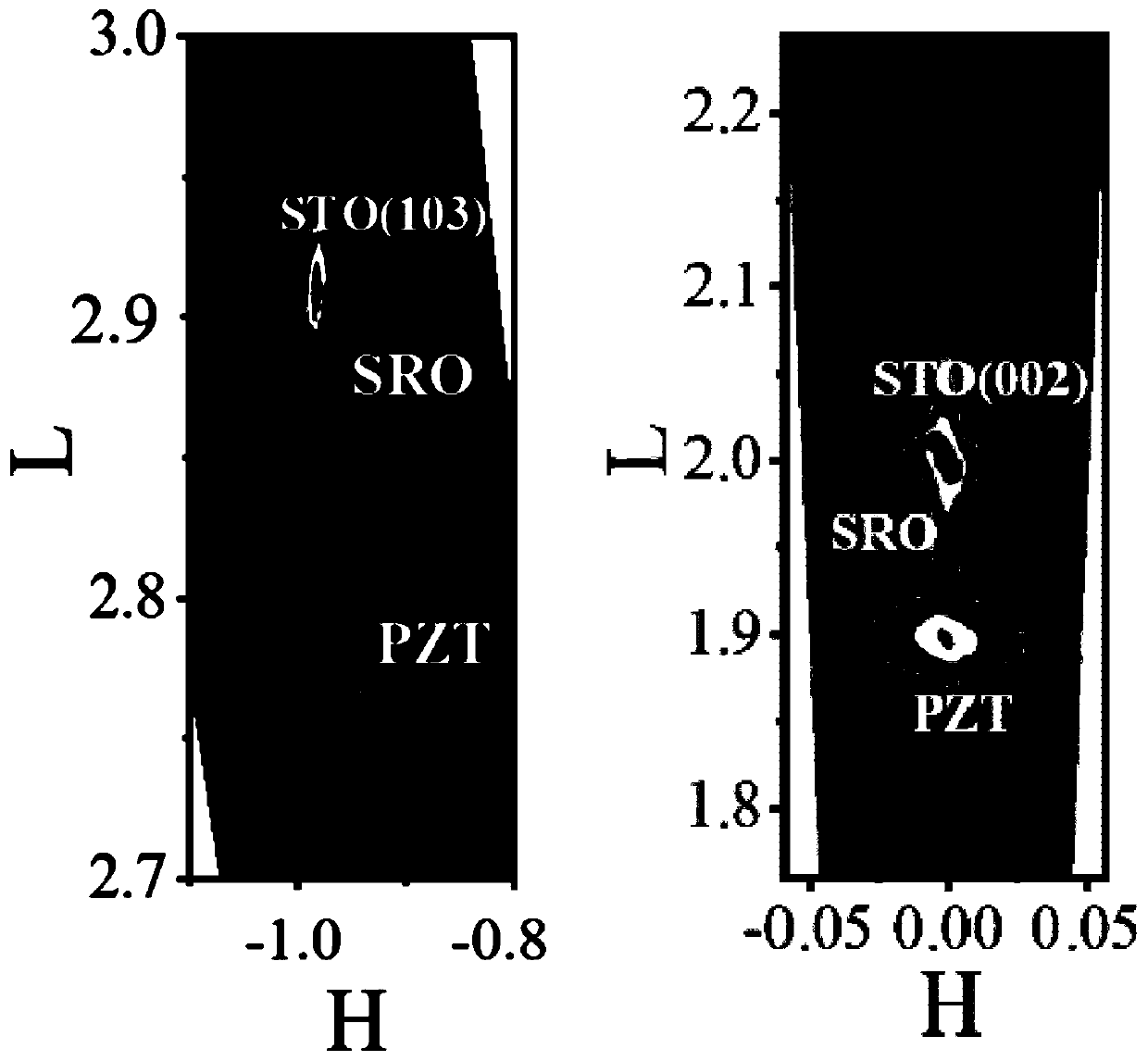

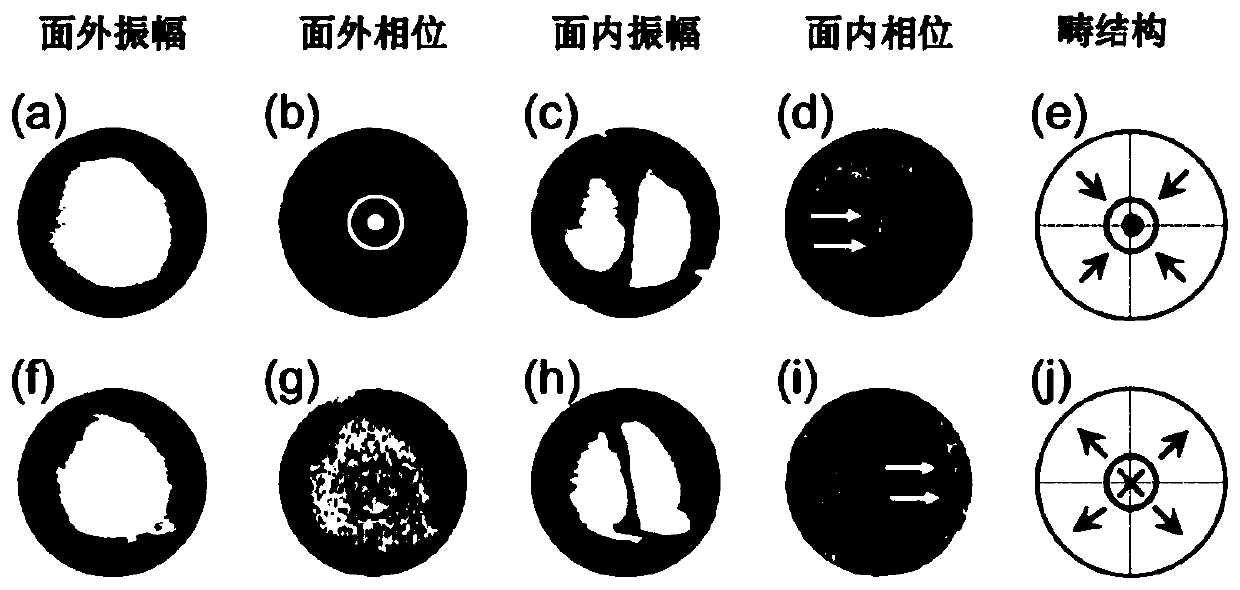

Preparation method of ordered ferroelectric topological domain structure array

ActiveCN110473873ARealize independent controlSolid-state devicesNanotechnologySingle crystalNanodot array

The invention relates to a preparation method of an ordered ferroelectric topological domain structure array. The preparation method comprises the following steps of: S1, depositing an SRO conductivelayer as a bottom electrode on an STO single crystal substrate in a (001) direction by adopting a pulse laser deposition method; S2, selecting a PZT target material with a Zr:Ti ratio being equal to 7:3, depositing a layer of diamond-phase PZT film on the SRO conductive layer by adopting the pulse laser deposition method; and S3, transferring the single-layer PS spheres to the surface of the PZT film to serve as a mask plate, then performing etching treatment by using oxygen plasma, then placing the mask plate in an ion beam etching machine for etching, and finally removing the residual mask plate of the single-layer PS spheres to obtain an ordered rhombic-phase PZT nano dot array which is a central topological domain structure. The ordered ferroelectric topological domain structure arrayprepared by the method reaches the nanoscale, and is a high-density ordered nano dot array structure. Ferroelectric topological domain structures are independent to each other, can be regulated and controlled by an external electric field, and have good thermal stability.

Owner:SOUTH CHINA NORMAL UNIVERSITY

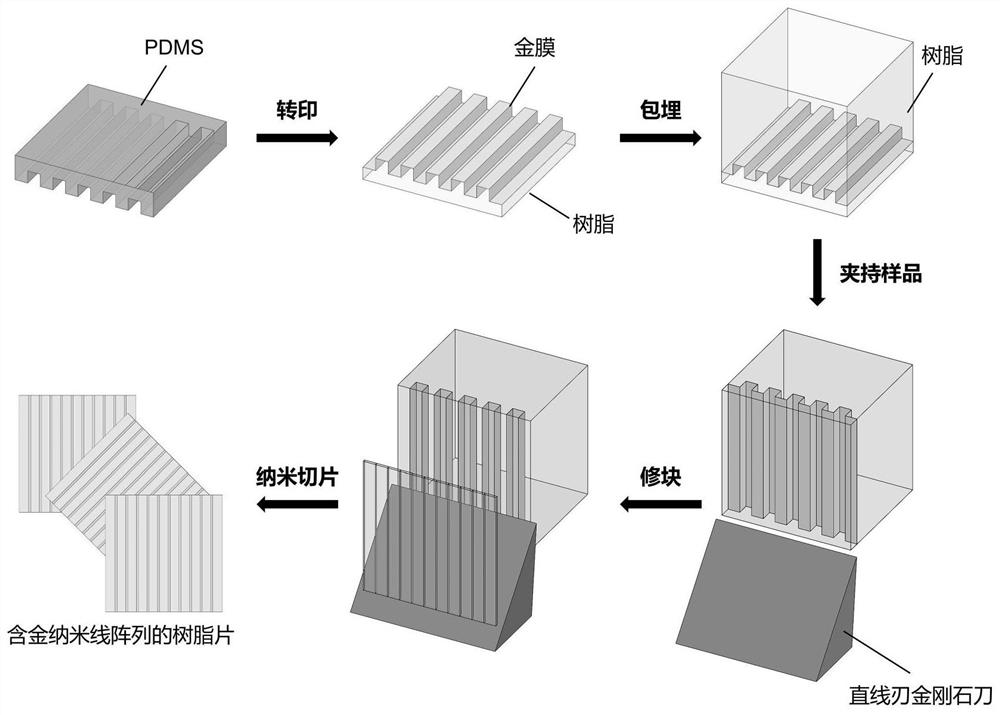

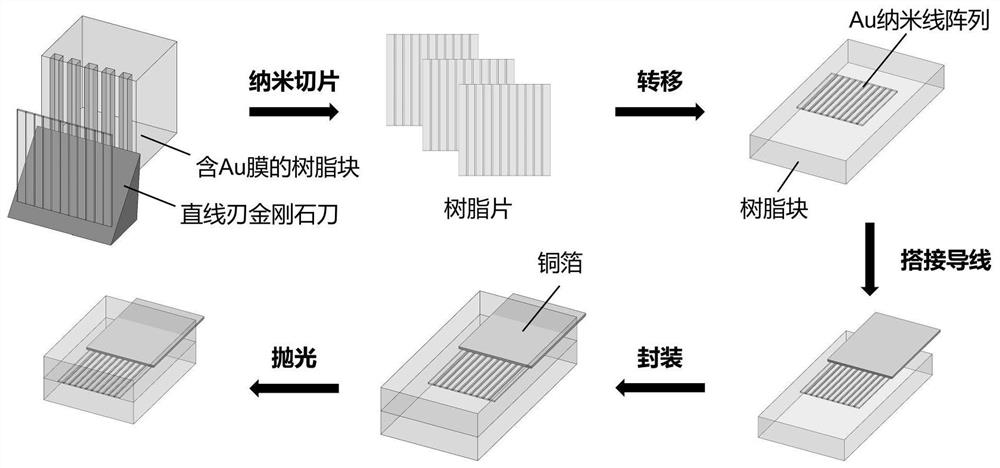

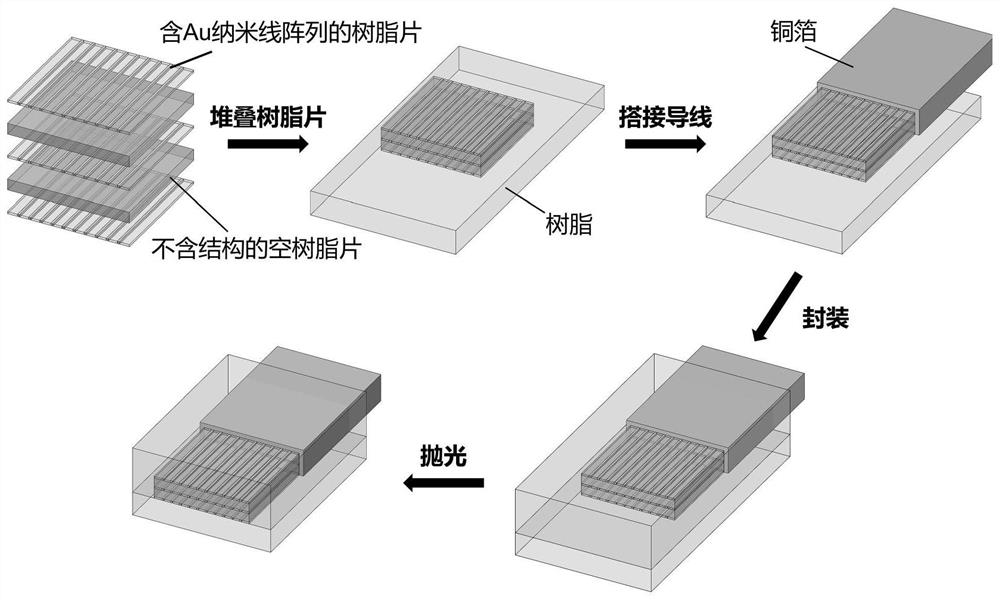

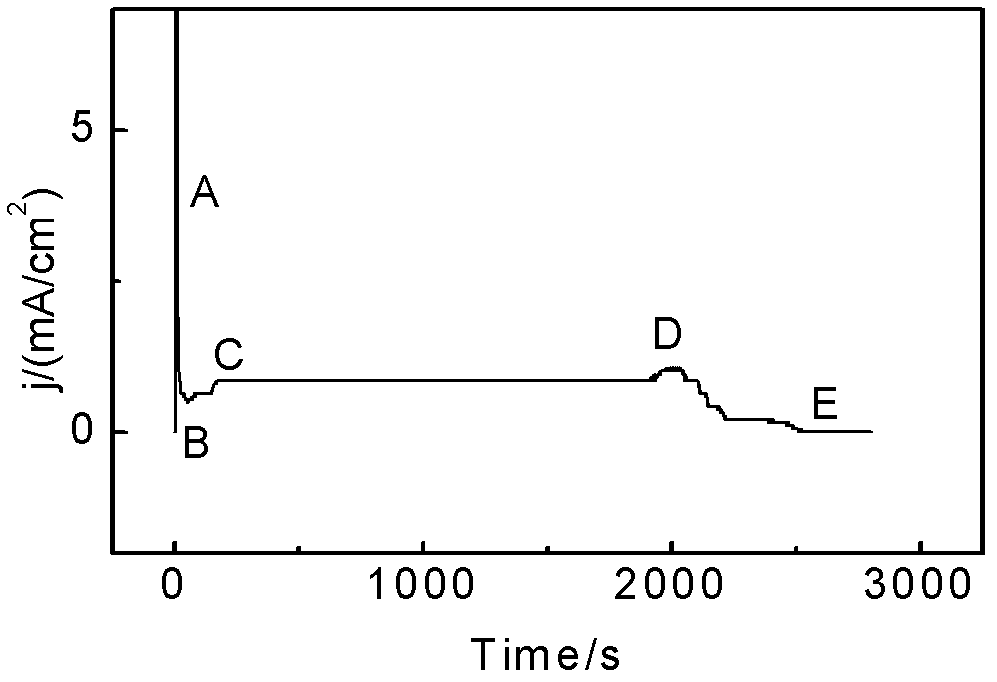

Method for preparing electrochemical nano dot array electrode by using ultra-long nanowire

ActiveCN111948267AEasy to operateReduce processing costsNanosensorsMaterial electrochemical variablesCapacitanceResin embedding

The invention relates to a method for preparing an electrochemical nano dot array electrode by using an ultra-long nanowire, and belongs to the technical field of nano electrode preparation. In orderto simply, efficiently and repeatedly prepare a nano dot array electrode, the method includes: pouring PDMS on a silicon template containing a micron groove array; pouring resin on the cured PDMS moldto obtain a resin block with a micron groove array; and depositing a layer of metal film on the resin block, performing embedding with resin, carrying out nano slicing, transferring a single resin sheet containing the nanowire array or a plurality of resin sheets containing the nanowire array alternately stacked with the hollow resin sheets to the substrate, lapping and fixing the lead on the surface of the nanowire array, adding resin for packaging, and trimming and polishing one end of the non-lapped wire to obtain the nano-dot array electrode. According to the invention, the overlapping ofthe capacitance and the diffusion layer of the adjacent electrode is avoided, and the new clean nano dot array can be obtained by re-trimming and polishing the end surface of the nanowire, so that the long-term repeated use of the nano dot array electrode is facilitated.

Owner:HARBIN INST OF TECH

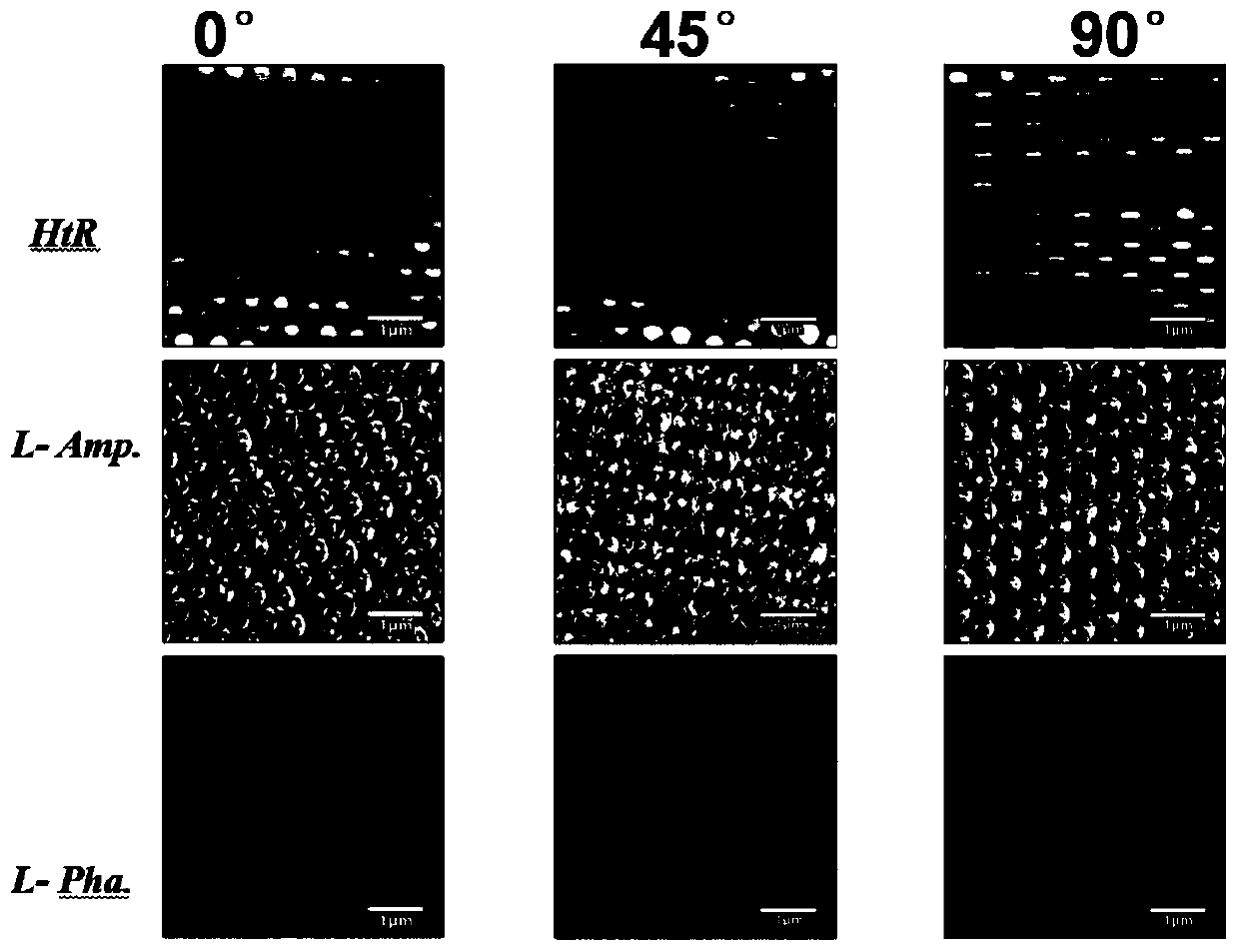

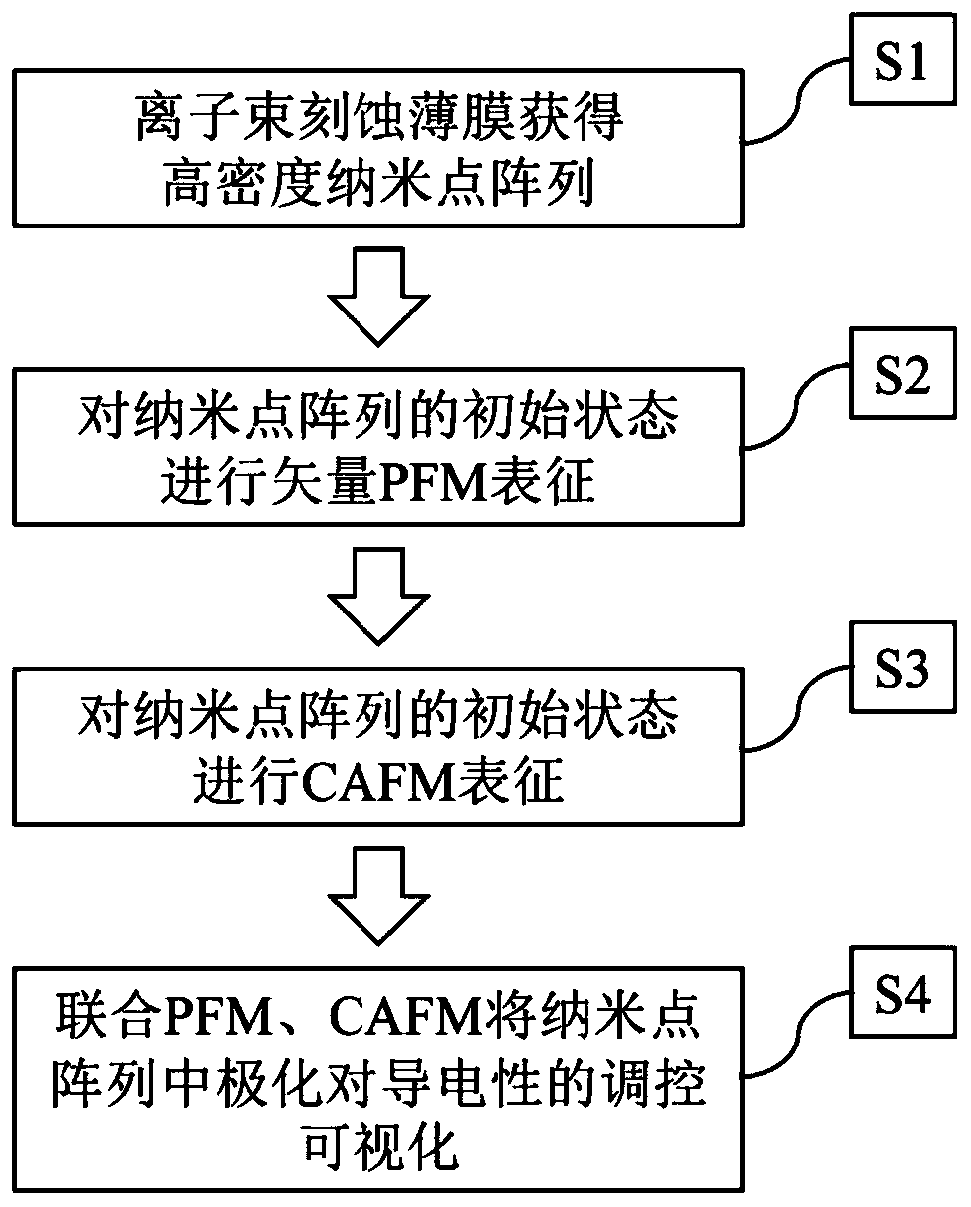

Characterization method for conductivity regulation in ferroelectric nano dot array

PendingCN110514872ALarge polarization valueAdvanced technologyMaterial nanotechnologyScanning probe microscopyMicro nanoNanodot

The invention discloses a characterization method for conductivity regulation in a ferroelectric nano dot array, and belongs to the technical field of nano ferroelectric material preparation and micro-nano characterization. A ferroelectric film is etched by an ion beam to obtain a high-density nano dot array; a domain structure of a ferroelectric topological domain is obtained by means of vector piezoelectric power microscopy characterization; a conductive atomic force microscope is used for observing conductive channels in the nanodots, that the conductive area in a single nanodot is dozens of nanometers according to a two-dimensional current image, and the conductive channels have the characteristic similar to metal conductivity; and a piezoelectric force microscope and a conductive atomic force microscope are combined to obtain regulation of polarization on conductivity. The method can be used for developing a nonvolatile and high-density ferroelectric random access memory; the central domain structure of the nanodot provides a scheme for researching the ferroelectric topological domain and a topological material; and the conductivity of the nanodots can be regulated through polarization inversion, regulation control can be visualized through the provided characterization method, and the visibility and reliability of data are improved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

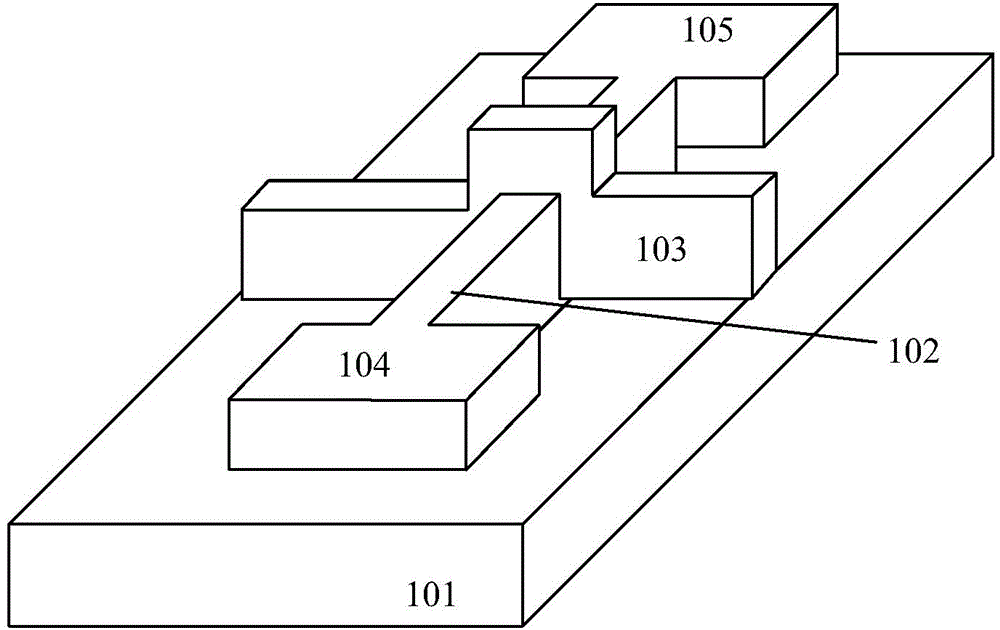

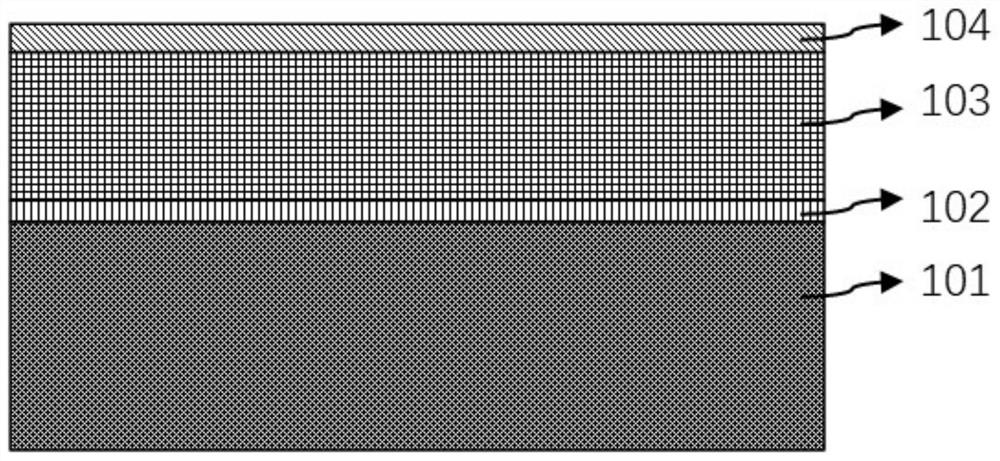

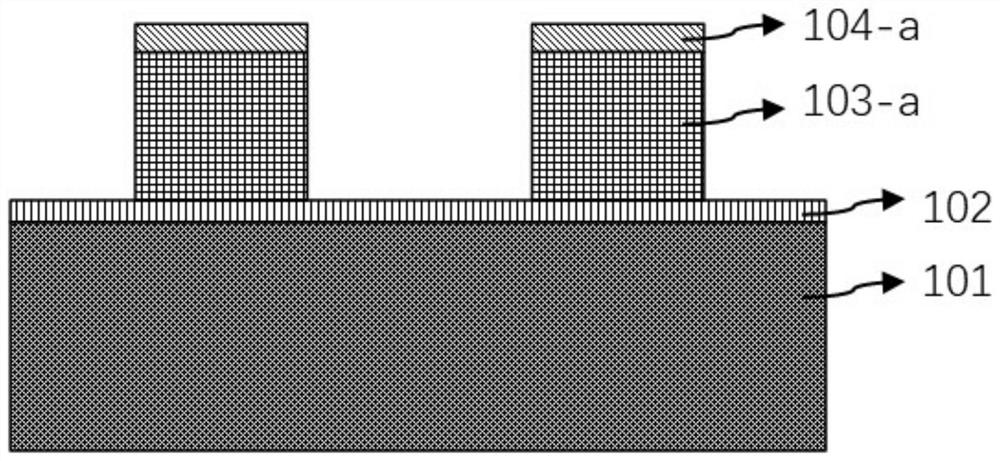

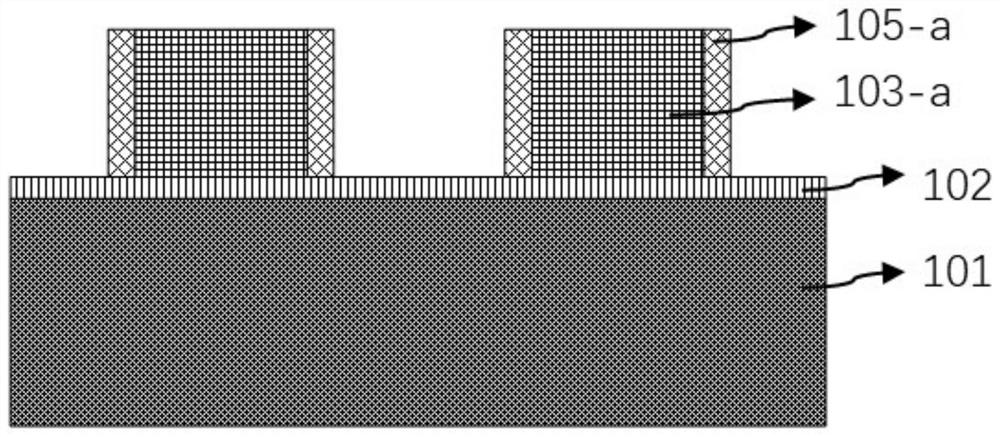

Method for manufacturing transistor based on embedded-type metal nano point and manufactured product

ActiveCN105225954ASmall feature sizeReduce power consumptionSemiconductor/solid-state device manufacturingSemiconductor devicesNanodot arraySemiconductor

The present invention discloses a method for manufacturing a transistor based on embedded-type metal nano points and a manufactured product. Through this method, trenches with metal nano points can be manufactured, and transistors without semiconductors can thus be obtained. The method comprises forming fin-type structures on a substrate; filling gaps among the fin-type structures with a gap filler; exposing top parts of the fin-type structures; forming a metal nano point array on top parts of the gap filler and the fin-type structures; and removing the gap filler and the metal nano points on the gap filler, so as to form the structure of the metal nano points only disposed on the fin-type structures.

Owner:SEMICON MFG INT (SHANGHAI) CORP

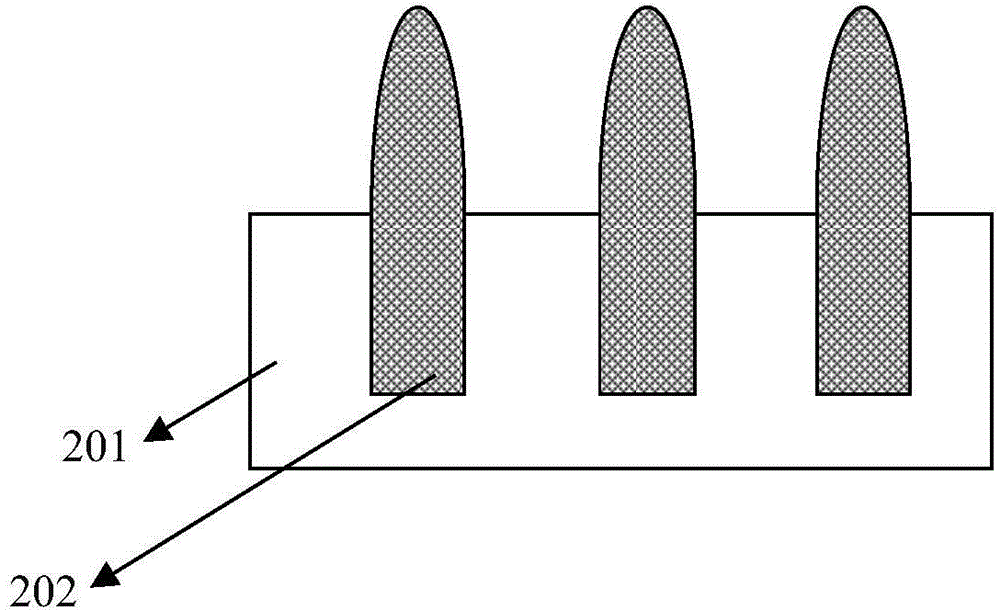

Preparation method of small-size density-controllable silicon nanodot array

InactiveCN102569033AUniform size distributionGood size controlSemiconductor/solid-state device manufacturingNanodotSilicon dioxide

The invention discloses a preparation method of a small-size density-controllable silicon nanodot array, relating to a preparation method of the silicon nanodot array. The preparation method comprises the following steps of: depositing an aluminum film on a substrate, then annealing and anodizing the aluminum film; removing silica dots on the surfaces of the formed anodized aluminum film and the silicon substrate, namely, forming a silicon nanodot array with larger size on the surface of a sample; and deoxidizing the sample to obtain the large-area, uniform, small-size density-controllable silicon nanodot array without an insulated barrier layer. The prepared silicon nanodots are uniform in size distribution and controllable in size and density; and no insulated layer exists between the silicon nanodots and the substrate, so that preparation of electric / photoelectric components is facilitated; meanwhile, the preparation method disclosed by the invention is simple in process conditions and free of complex equipment and has favorable application prospect in large-scale industrial production.

Owner:XIAMEN UNIV

Method for preparing density-adjustable TiO2 nanorod array

InactiveCN101973582BChange densityControlled surface wettabilityNanostructure manufactureTitanium dioxideVolumetric Mass DensityNanodot array

The invention discloses a method for preparing a density-adjustable TiO2 nanorod array. The diameter of TiO2 nanorods is 10-200 nm, and the density distribution range of the TiO2 nanorods is 9.4*10<2> / cm<-2> to 8.3*10<13> / m<-2>. The preparation method comprises the following steps of: (1) dissolving tetrabutyl titanate, water and acetylacetone into alcohol, and adding polyvinylpyrrolidone to formtitanium dioxide precursor sol; (2) quickly spin-coating the titanium dioxide precursor sol on a substrate to form a titanium dioxide precursor nano lattice array sol film on the substrate, and putting the substrate into a muffle furnace for thermal treatment; and (3) putting the thermally treated substrate into a titanate and acid mixed water solution for hydro-thermal treatment to obtain the TiO2 nanorod array on the substrate. The preparation method is simple, and the surface wettability, the photocatalytic property and the photoelectric properties of the prepared TiO2 nanorod array can becontrolled according to different diameters and densities.

Owner:ZHEJIANG UNIV

Preparation method of vertical nanowire array

PendingCN113173557AHigh purityNo damageDecorative surface effectsSolid-state devicesSilicon nanowiresSilicon oxide

The invention relates to a preparation method of a vertical nanowire array, which comprises the following steps of: forming a nanoscale two-layer side wall cross array by adopting a two-time self-aligned side wall transfer technology, forming a silicon nitride nano dot array by utilizing the selection ratio of silicon oxide to silicon nitride and reactive ion etching (RIE) of the height difference of the cross position of the secondary side wall array, preparing a silicon nitride dot matrix array, etching substrate silicon by taking the silicon nitride dot matrix array as a mask to form a vertical nanowire array, and finally corroding residual silicon nitride and silicon oxide by using an acid solution to prepare the high-purity, damage-free, orderly and vertically arranged silicon nanowires.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

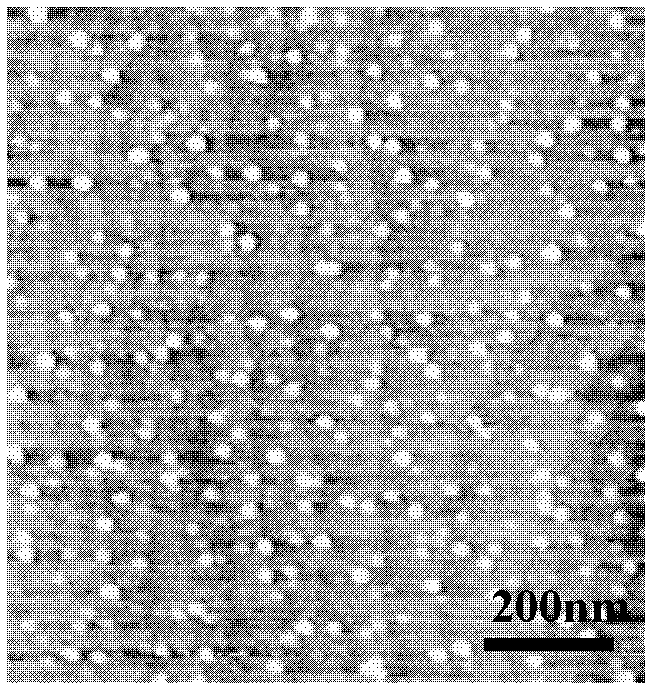

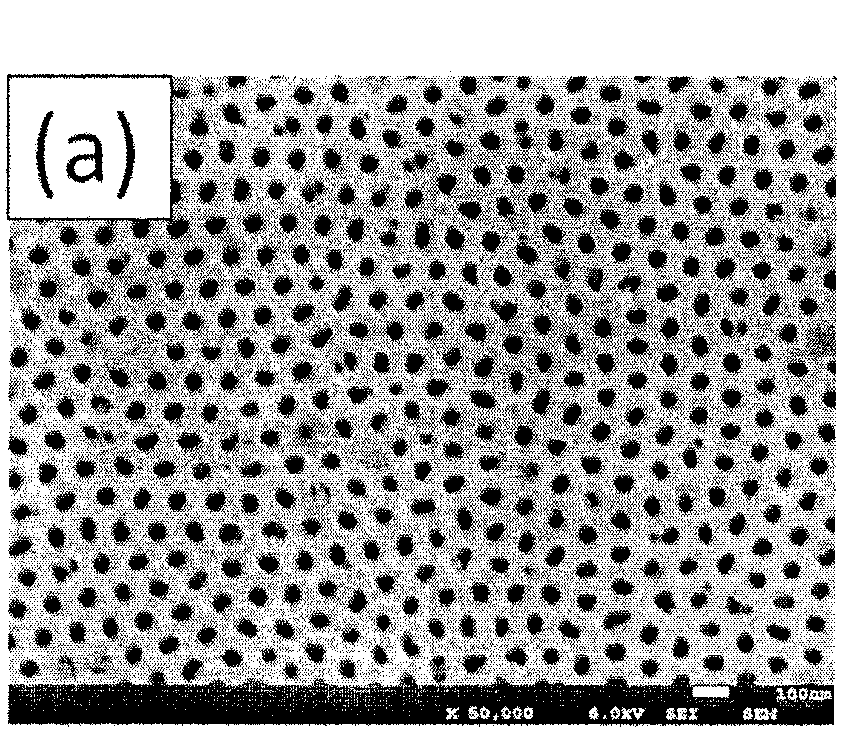

Preparation method of oxide dilute magnetic semiconductor nanodot array with high saturation magnetization

InactiveCN105463380BHigh saturation magnetizationGood size controlVacuum evaporation coatingSputtering coatingPoint densityMagnetic semiconductor

The invention discloses a preparing method for high-saturation-magnetization (In1-xFex)2O3 oxide diluted magnetic semiconductor nanometer point arrays. A prepared bi-pass porous ultra-thin anodised aluminum template is transferred to an Al2O3(0001) substrate, the large-area (In1-xFex)2O3 nanometer point arrays highly orderly grow on the substrate covered with the template through a pulsed laser deposition method, and finally the template is removed. Obtained (In1-xFex)2O3 nanometer points with the room-temperature ferromagnetism are 30-100 nm in diameter, 20-40 nm in height, 65-150 nm in distance and 176 Gb / in2-33 Gb / in2 in point density, a sample represents the ferromagnetism at the temperature of 300 K, and under the condition that the saturation magnetization ratios of the nanometer point arrays are the same, prepared films with the same thickness are greatly improved.

Owner:山西师范大学

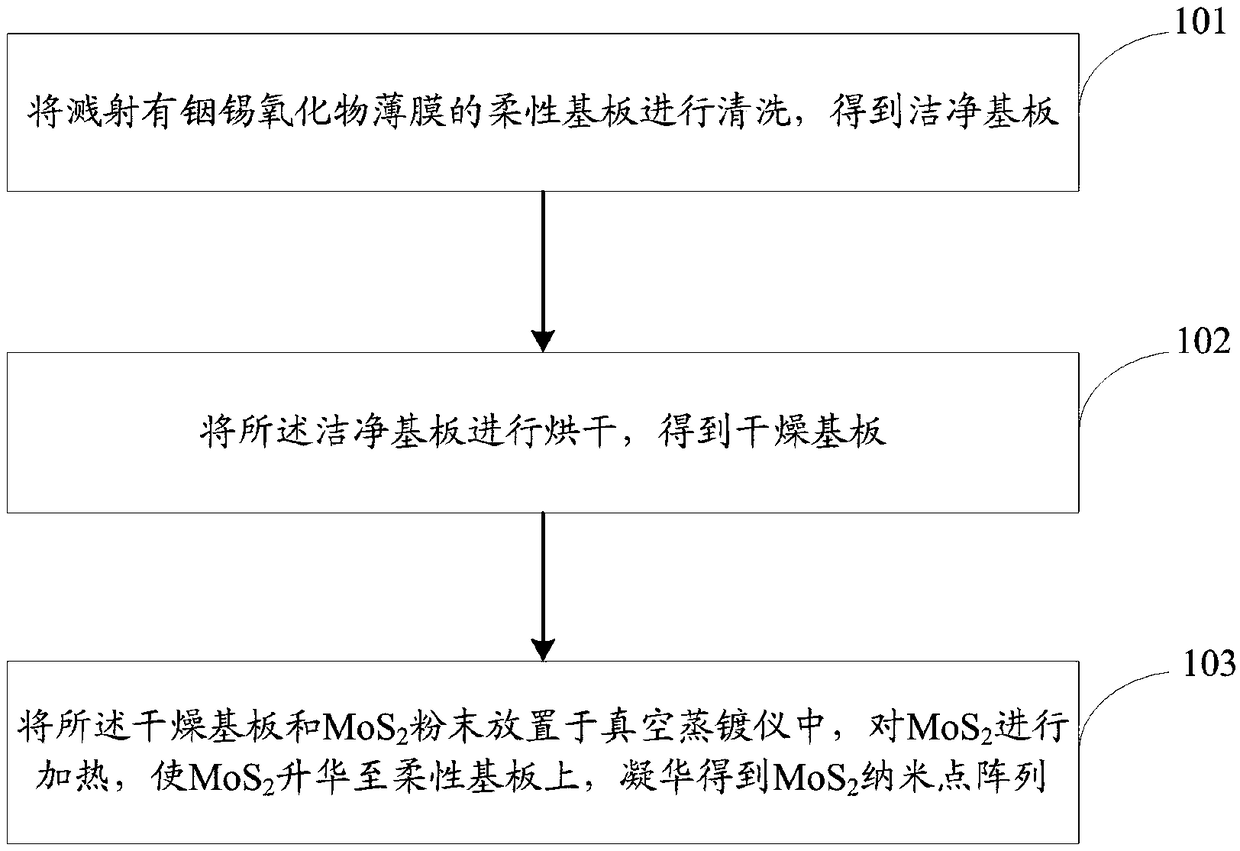

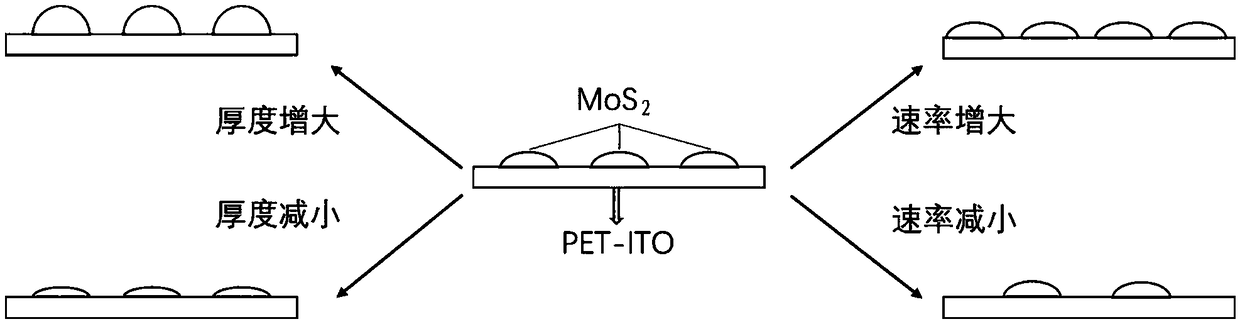

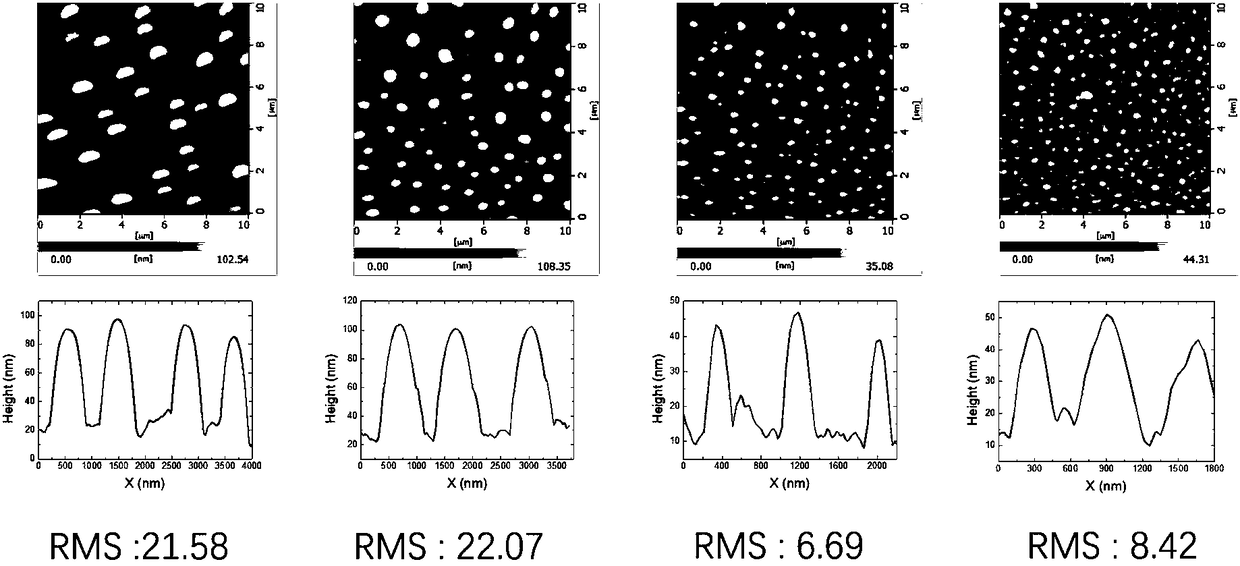

Preparation method and system of molybdenum disulfide (MoS2) nanodot array based on flexible substrate

InactiveCN108914061AQuality improvementVacuum evaporation coatingSputtering coatingSputteringIndium tin oxide

The invention discloses a preparation method and system of a molybdenum disulfide (MoS2) nanodot array based on a flexible substrate. The preparation method includes: cleaning the flexible substrate sputtered with an indium tin oxide film to obtain a clean substrate; drying the clean substrate to obtain a dry substrate; placing the dry and clean flexible substrate and MoS2 powder in a vacuum evaporator, heating and sublimating the MoS2 powder to condense the MoS2 powder on the dry and clean flexible substrate to obtain the MoS2 nanodot array. The preparation method or system of the MoS2 nano-dot array based on the flexible substrate directly uses the high vacuum evaporator to heat and evaporate the MoS2 powder onto the flexible substrate. A series of nano-dot arrays with controllable sizesand quantities can be prepared, and the finished product has high quality, and can be directly applied to the preparation of other flexible devices.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com