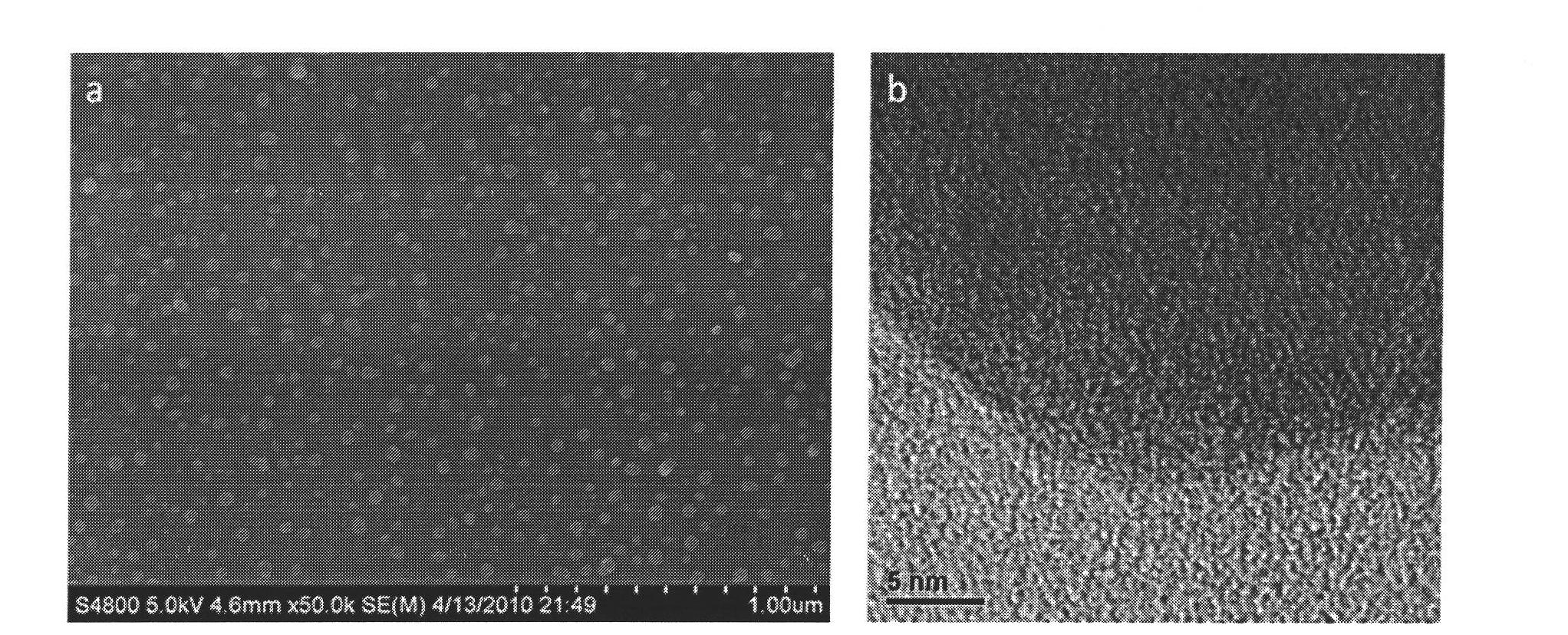

Amorphous titanium dioxide nano dot array and preparation method thereof

A technology of nano-dot array and titanium dioxide, which is applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problem of high preparation temperature, and achieve the effects of simple operation, reduced diameter and increased density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0016] 1) Polish and clean the surface of the silicon substrate to remove surface impurities;

[0017] 2) Dissolve tetrabutyl titanate, water and acetylacetone in 10ml methanol at a molar ratio of 1:1:0.3, then add 0.6g polyvinylpyrrolidone to form a titanium concentration of 0.1mol / L and a polyvinylpyrrolidone concentration of 60g / L of titanium dioxide precursor sol;

[0018] 3) The titania precursor sol was spin-coated on the silicon substrate at a speed of 7000 rpm at 5°C, and the spin coating time was 40s. The titania precursor nanodot array sol film was formed on the silicon substrate, and then the temperature was 5~℃, 10 Place for 6h under the condition of% humidity for aging;

[0019] 4) Put the aged sample into a mixed solution of water and ethanol, the volume content of water in the mixed solution is 4%, and hydrothermal treatment at 140° C. for 1 h to obtain an amorphous titanium dioxide nano-dot array on a silicon substrate.

[0020] The diameter of titanium dioxide nano-...

example 2

[0022] 1) Clean the surface of polystyrene substrate to remove surface impurities;

[0023] 2) Dissolve tetrabutyl titanate, water and acetylacetone at a molar ratio of 1:1.2:0.4 in 10ml of butanol, and then add 0.4g of polyvinylpyrrolidone to form a titanium concentration of 0.2mol / L, and the concentration of polyvinylpyrrolidone is 40g / L of titanium dioxide precursor sol;

[0024] 3) The titania precursor sol was spin-coated on the polystyrene substrate at a speed of 6000 rpm at 20°C, and the spin coating time was 40s. The titania precursor nanodot array sol film was formed on the polystyrene substrate. Place for 12h at ℃ and 95% humidity for aging;

[0025] 4) Put the aged sample into water, and hydrothermally heat it at 100°C for 12 hours to obtain a titanium dioxide nanodot array structure on a polystyrene substrate. The diameter of the titanium dioxide nanodots is 20-150nm, and the distribution density of the titanium dioxide nanodots is 4.4×10 10 cm -2 .

example 3

[0027] 1) Polish and clean the surface of the metal titanium substrate to remove surface impurities;

[0028] 2) Dissolve titanium trichloride, water and acetylacetone in 10ml ethanol at a molar ratio of 1:1.1:0.3, then add 0.3g polyvinylpyrrolidone to form a titanium concentration of 0.3mol / L and a polyvinylpyrrolidone concentration of 30g / L titanium dioxide precursor sol;

[0029] 3) The titania precursor sol was spin-coated on the titanium metal substrate at a speed of 8000 rpm at 10°C, and the spin coating time was 30s. The titania precursor nano-dot array sol film was formed on the metal titanium substrate, and then at 10°C, Place for 8 hours under 50% humidity conditions for aging;

[0030] 4) Put the aged sample into water and hydrothermally heat it at 120°C for 2h to obtain a titanium dioxide nanodot array structure on a titanium metal substrate. The diameter of the titanium dioxide nanodots is 60-250nm, and the distribution density of the titanium dioxide nanodots is 1.0 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com