Method for preparing nano dot array of controllable unit size using nano ball template

A technology of nano-dot array and unit size, applied in the field of nano-dot array

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

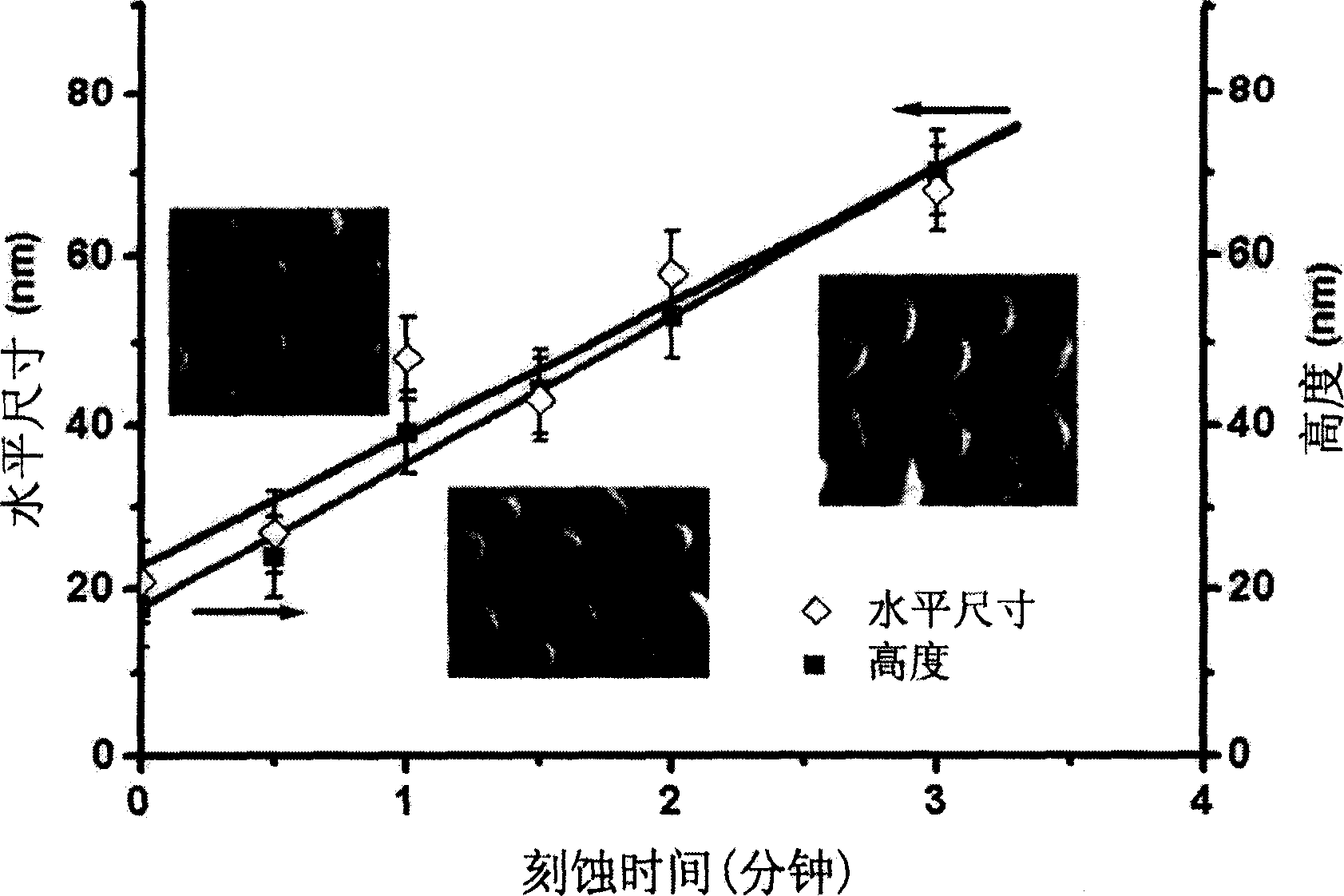

[0022] Controllable expansion of deposition channels in single-layer and double-layer polystyrene nanosphere templates (sphere diameter 200 nm) was performed by oxygen plasma etching. Then, a layer of metal aluminum is evaporated on the template, and polystyrene spheres are dissolved in toluene solvent to obtain a regularly arranged array of nano-dots.

[0023] The effect of plasma etching on the expansion of deposition channels in the template and the preparation of nanodot arrays can be characterized by scanning electron microscopy (SEM). The high-density polystyrene template can be seen from the SEM photo before the plasma etching process figure 1 In (a), it can be seen that the original deposition channel in the template is blocked due to the obvious deformation of the polystyrene sphere with a diameter of 200 nm, thus making the template unusable. figure 1 (b) shows the effect of assembling polystyrene spheres with a diameter of 440nm into a template. It can be seen that...

Embodiment 2

[0030] The implementation process is similar to that of Example 1, except that the spheres used for the template are changed to other diameters: 0.01-10 μm.

Embodiment 3

[0032] The implementation process is similar to Example 1, except that the balls used as the template are changed into nano (micro) balls of other materials, such as polybutadiene, polyisoprene, SiO 2 , Ag, Au, Co, FePt, etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com