Transfer method of ultrathin porous aluminum oxide template

A technology of porous alumina and transfer method, which is applied in the field of transfer of ultra-thin porous alumina template, which can solve the problems of limited thickness of aluminum film, uneven corrosion rate of phosphoric acid, difficulty in transfer of ultra-thin porous alumina template, etc., to achieve performance change , Easy to operate transfer processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

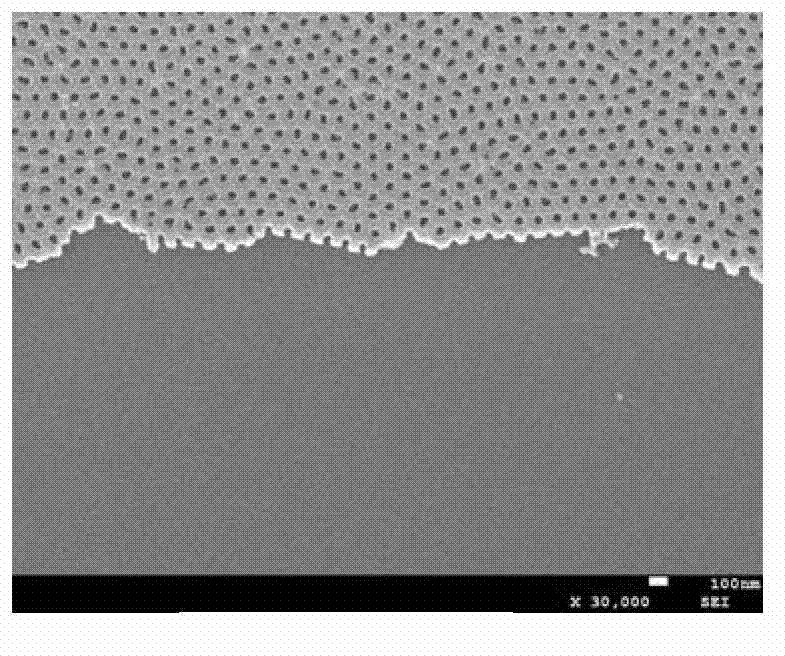

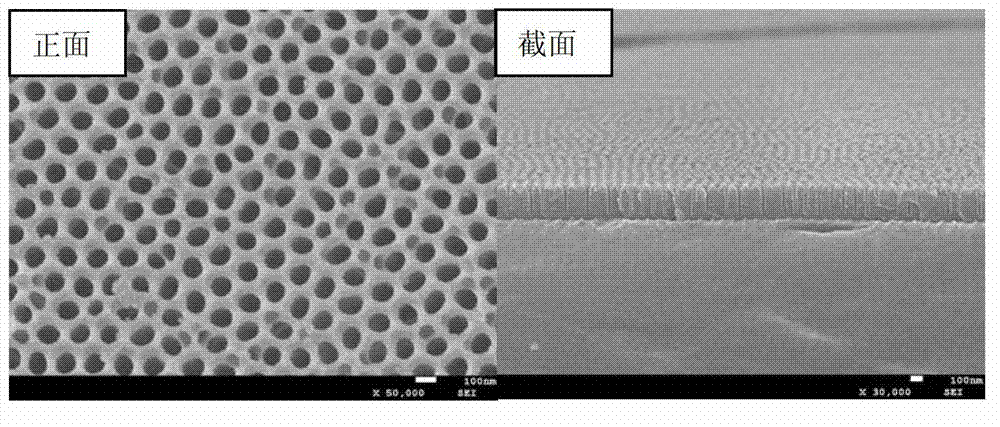

[0031] Embodiment 1, the aperture is 100 nanometers, and the preparation and transfer of the ultra-thin porous aluminum oxide template that the thickness is 200 nanometers

[0032] (1) First, pretreat the aluminum flakes, wash the high-purity aluminum flakes (99.99%) with acetone, and then place them in a mixed aqueous solution of perchloric acid and absolute ethanol with a volume ratio of 1:4, and use the graphite plate as the cathode , the aluminum sheet was used as the anode, the voltage was 10 volts, the temperature was 10° C., and the time was 180 seconds for electrolytic polishing, and then rinsed with deionized water for 1 minute.

[0033] (2) Use the aluminum sheet obtained in step (1) as the anode, the graphite plate as the cathode, and 0.3 mol / L oxalic acid as the electrolyte, the temperature of the electrolyte is 0°C, and the aluminum sheet is oxidized for the first time at a constant voltage of 60 volts. The time is 2 hours, and the electrolytic solution is stirred...

Embodiment 2

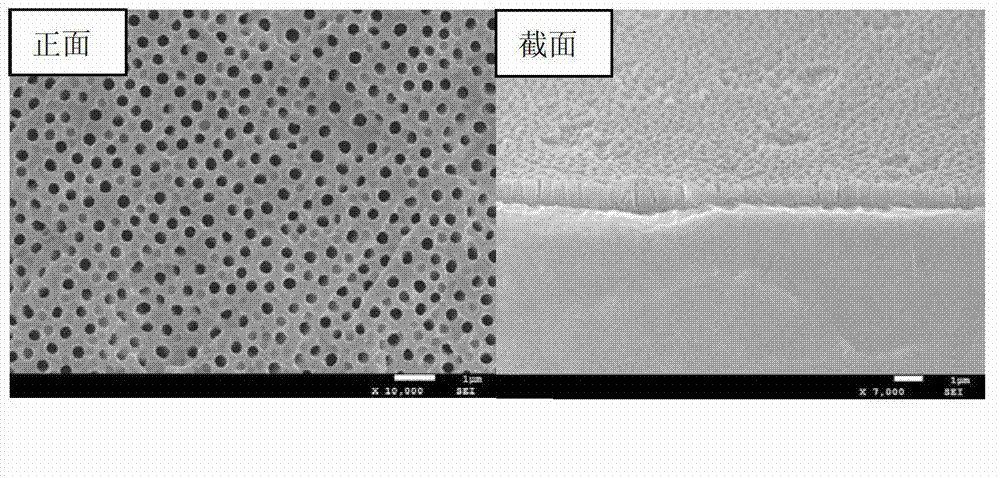

[0042] Example 2, the preparation and transfer of an ultra-thin porous alumina template with a pore size of 300 nanometers and a thickness of 600 nanometers

[0043] (1) First, pretreat the aluminum flakes, wash the high-purity aluminum flakes (99.99%) with acetone, and then place them in a mixed aqueous solution of perchloric acid and absolute ethanol with a volume ratio of 1:4, and use the graphite plate as the cathode , the aluminum sheet was used as the anode, the voltage was 10 volts, the temperature was 10° C., and the time was 180 seconds for electrolytic polishing, and then rinsed with deionized water for 1 minute.

[0044] (2) The aluminum sheet obtained in step (1) is used as the anode, the graphite plate is used as the cathode, and 0.16mol / L citric acid aqueous solution is used as the electrolyte, the temperature of the electrolyte is 10°C, and the aluminum sheet is subjected to the first Secondary oxidation, the time is 1 hour, and the electrolytic solution is stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com