Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78 results about "Isohexanes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

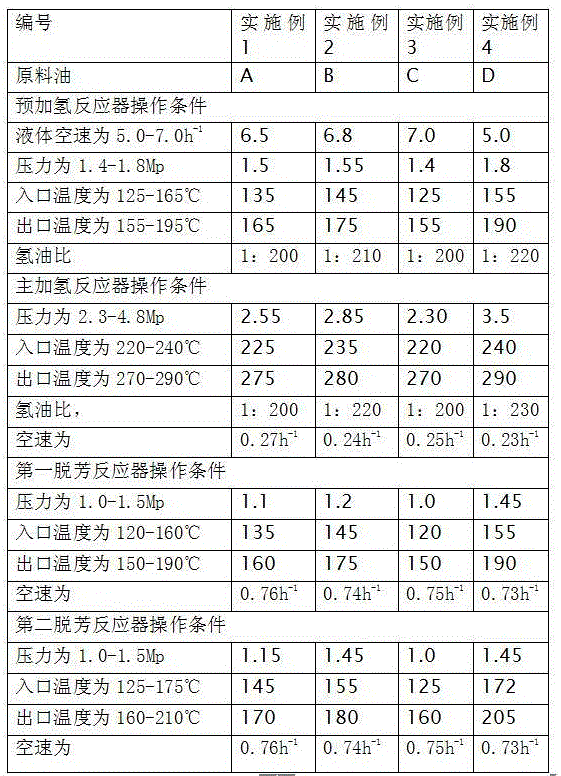

Process method for extracting normal hexane and isohexane from crude hexane

InactiveCN102351627AImprove heat transfer effectGuaranteed long-term operationDistillation purification/separationHydrocarbonsIsohexanesHydrogenation reaction

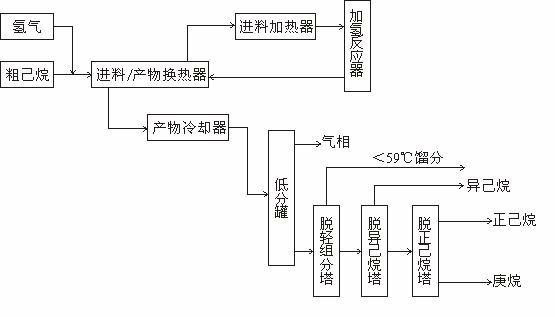

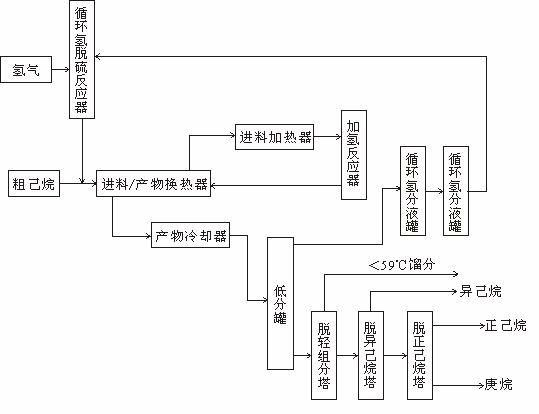

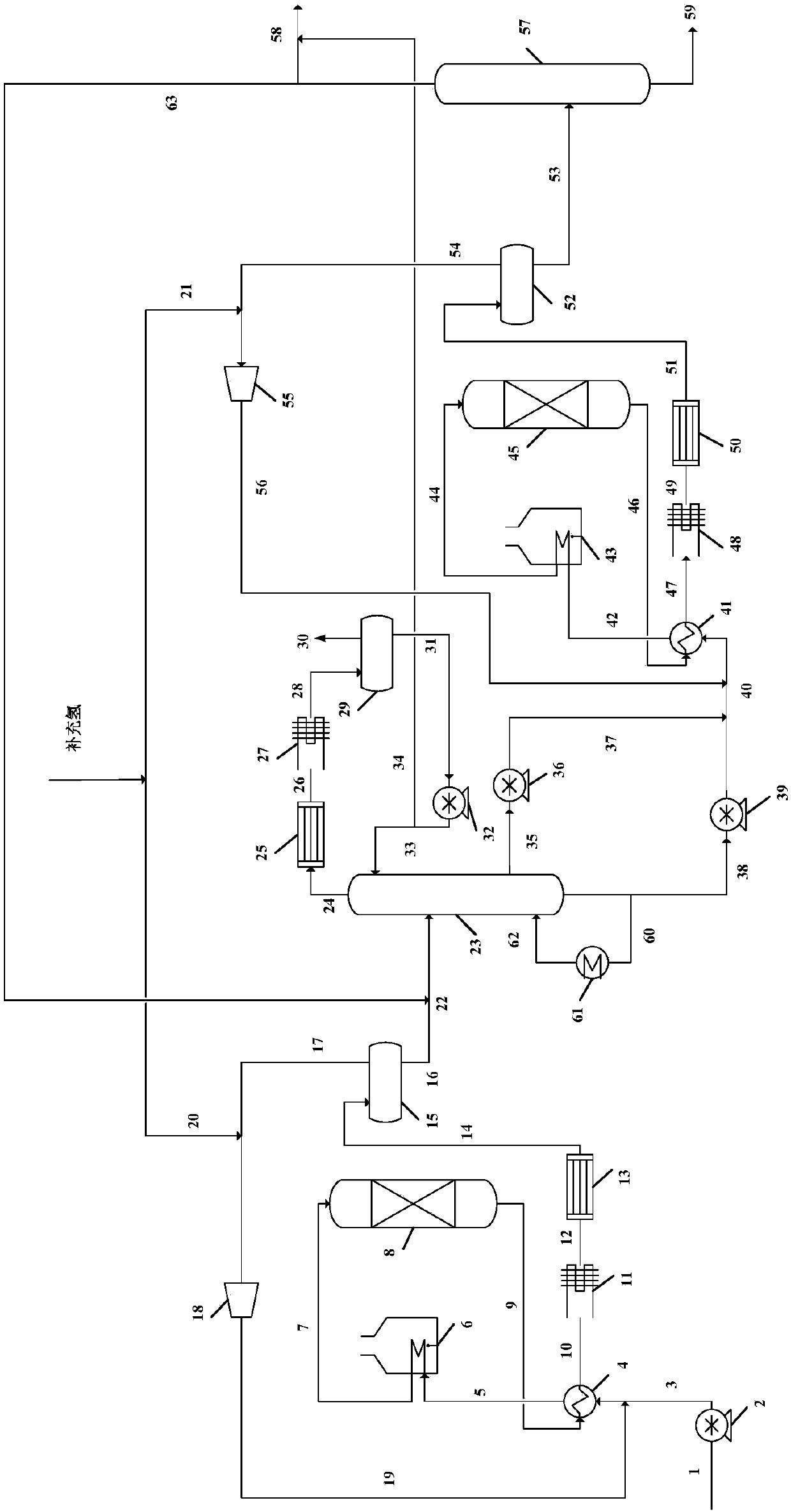

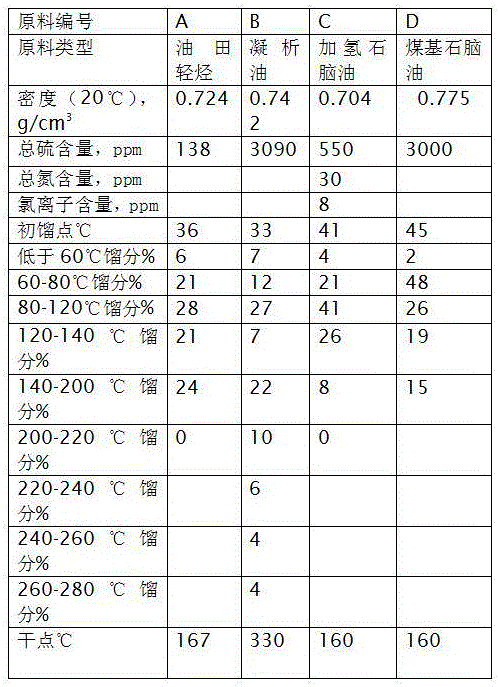

The invention discloses a process method for extracting normal hexane and isohexane from crude hexane. The process method comprises the following steps of: (1) mixing and heating raw material crude hexane and hydrogen gas and feeding into a hydrogenation reactor, and performing hydrodearomatization reaction under the action of a catalyst; (2) cooling a hydrogenation reaction product and then feeding in a low-pressure separation tank to perform gas-liquid separation, wherein gas phase is discharged from the top of the low-pressure separation tank, and oil phase at the bottom of the low-pressure separation tank is conveyed to a fractionation device to perform precise fractionation; (3) preheating the oil phase and feeding into a light component removal tower of the fractionation device to remove light components with fraction of less than 59 DEG C; (4) introducing remaining fractions of light component removal into an isohexane removal oil tower of the fractionation device to obtain high-purity isohexane; and (5) introducing the remaining fraction of isohexane removal into a normal hexane removal oil tower of the fractionation device to obtain the normal hexane. The process method has the advantages of simple and practical process, simple equipment, convenience in operation and stable and reliable product quality.

Owner:洛阳金达石化有限责任公司

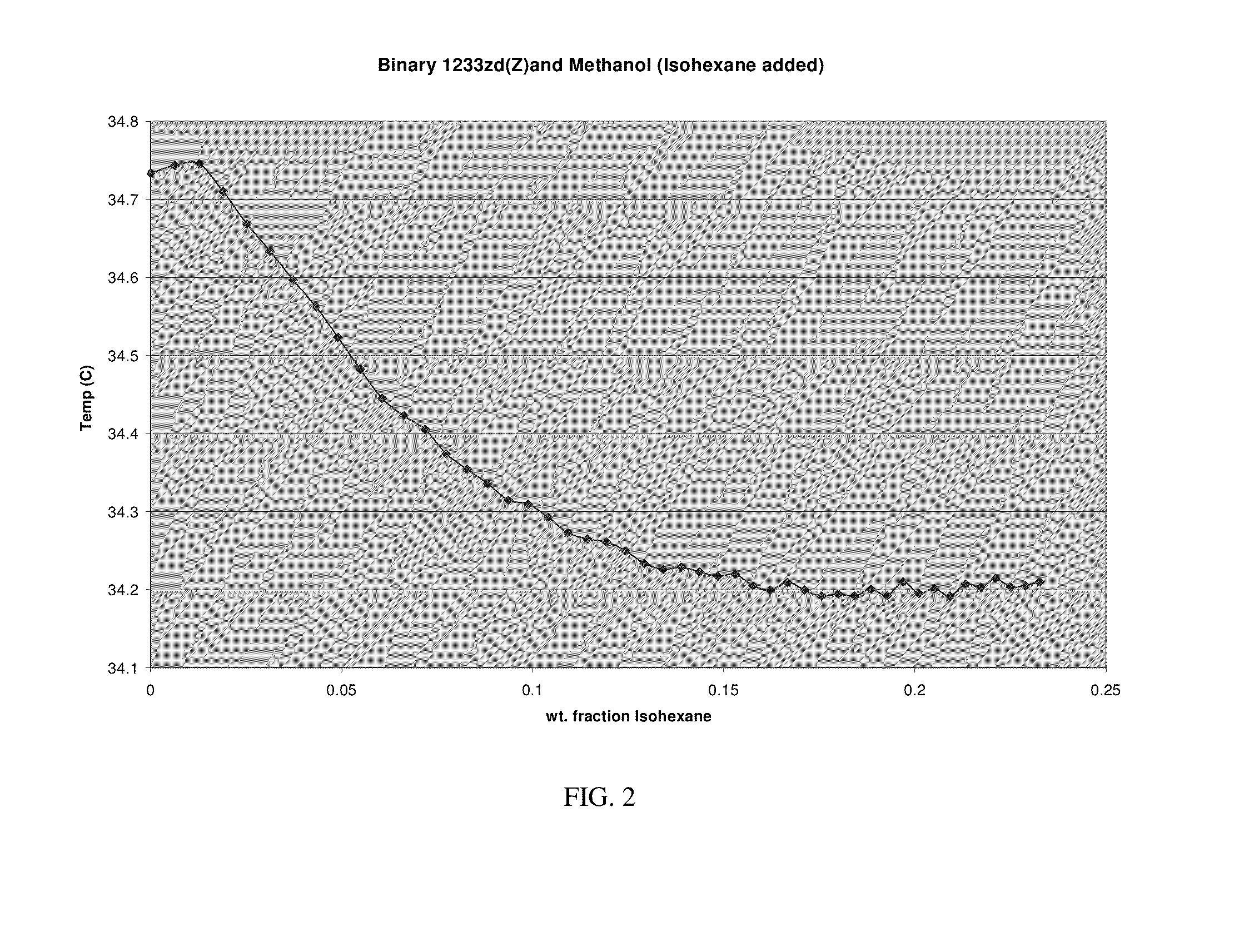

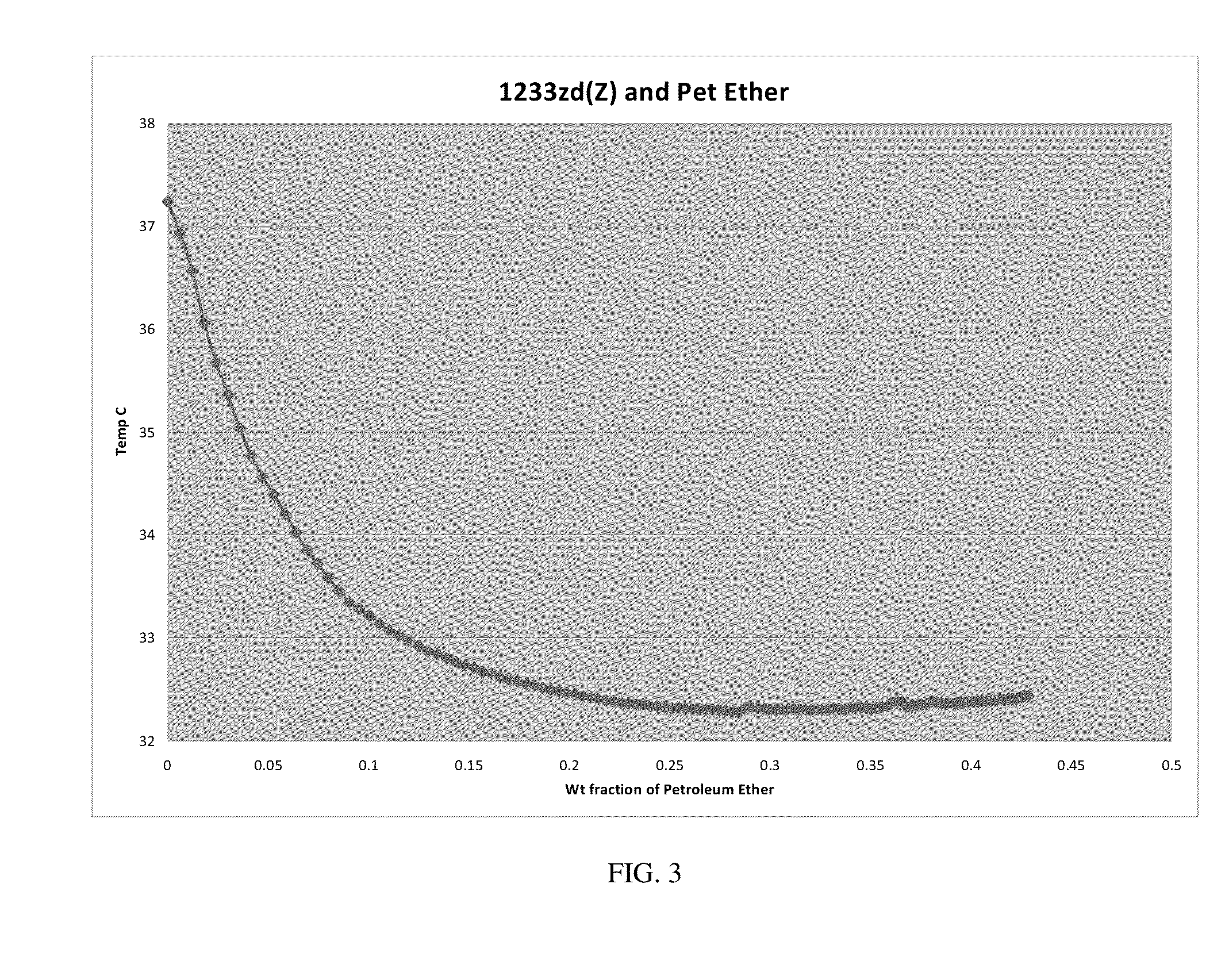

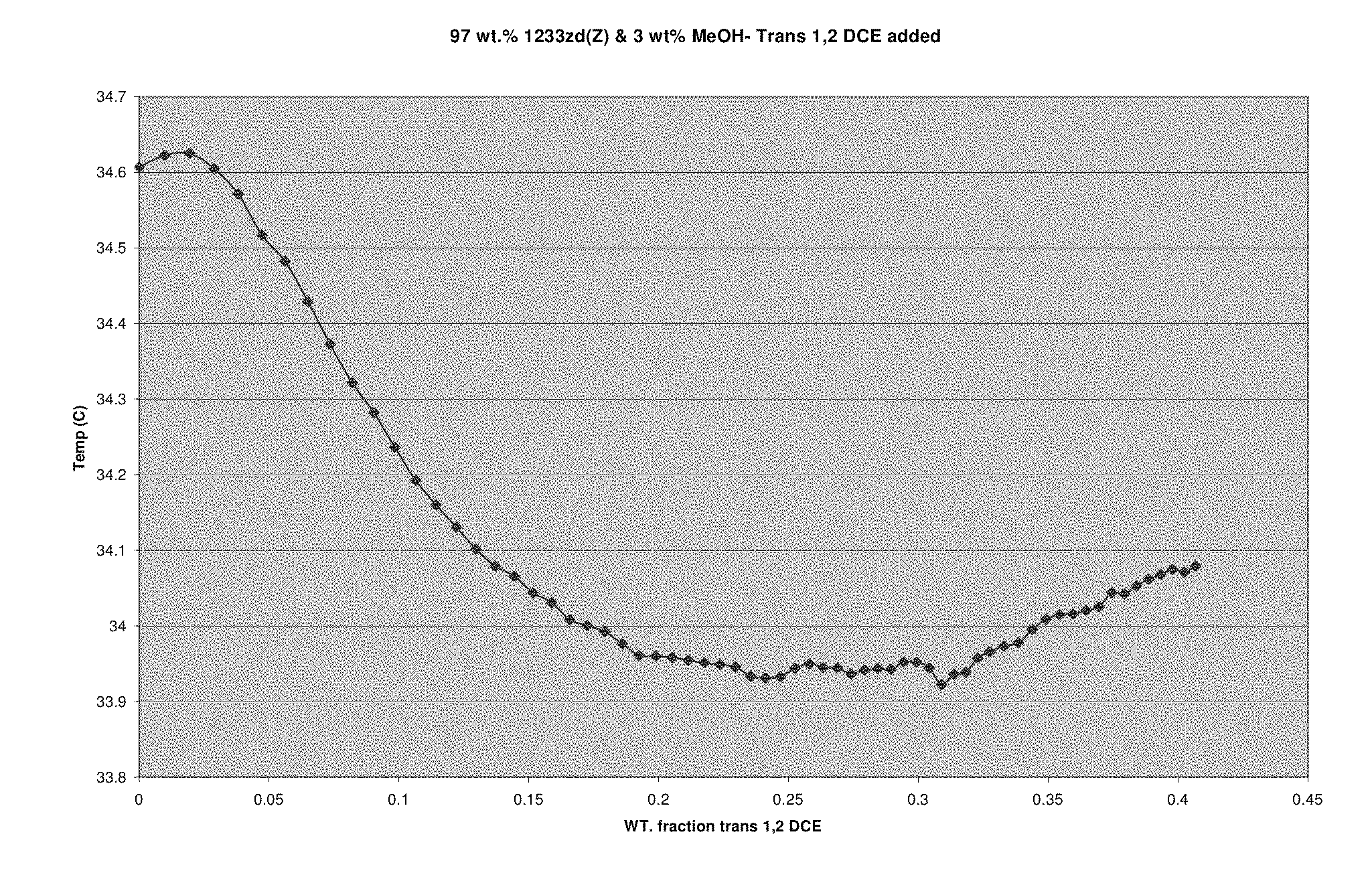

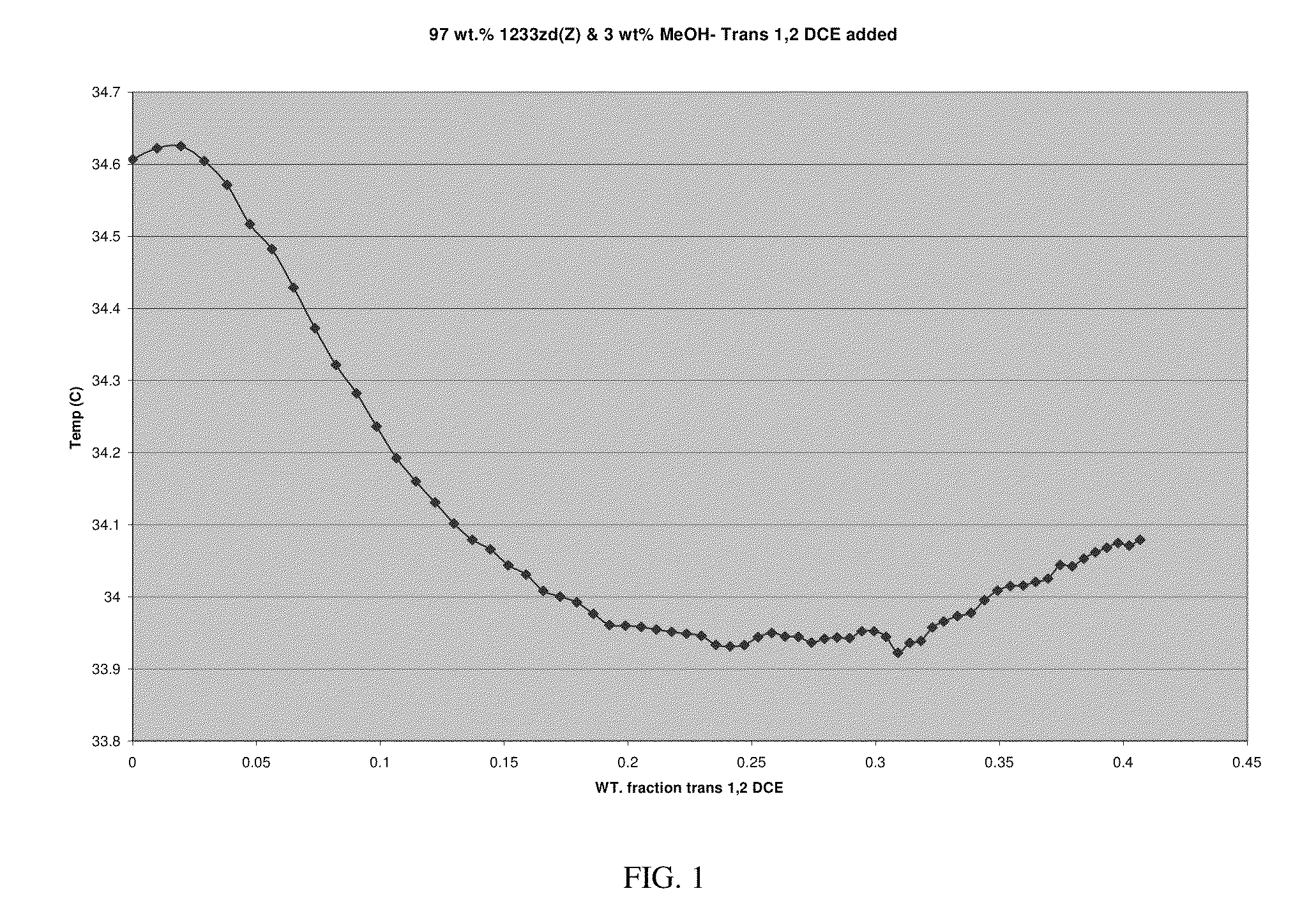

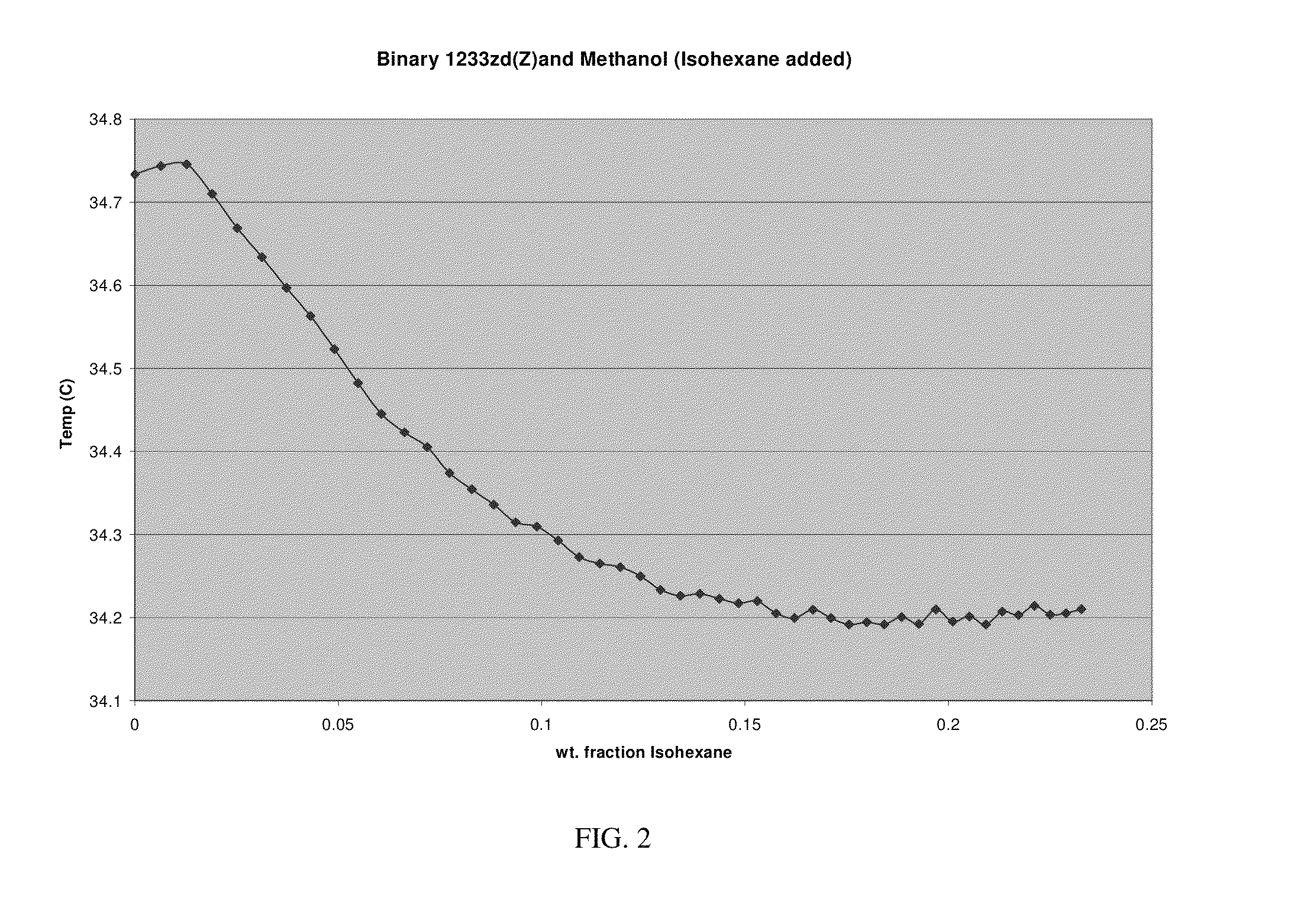

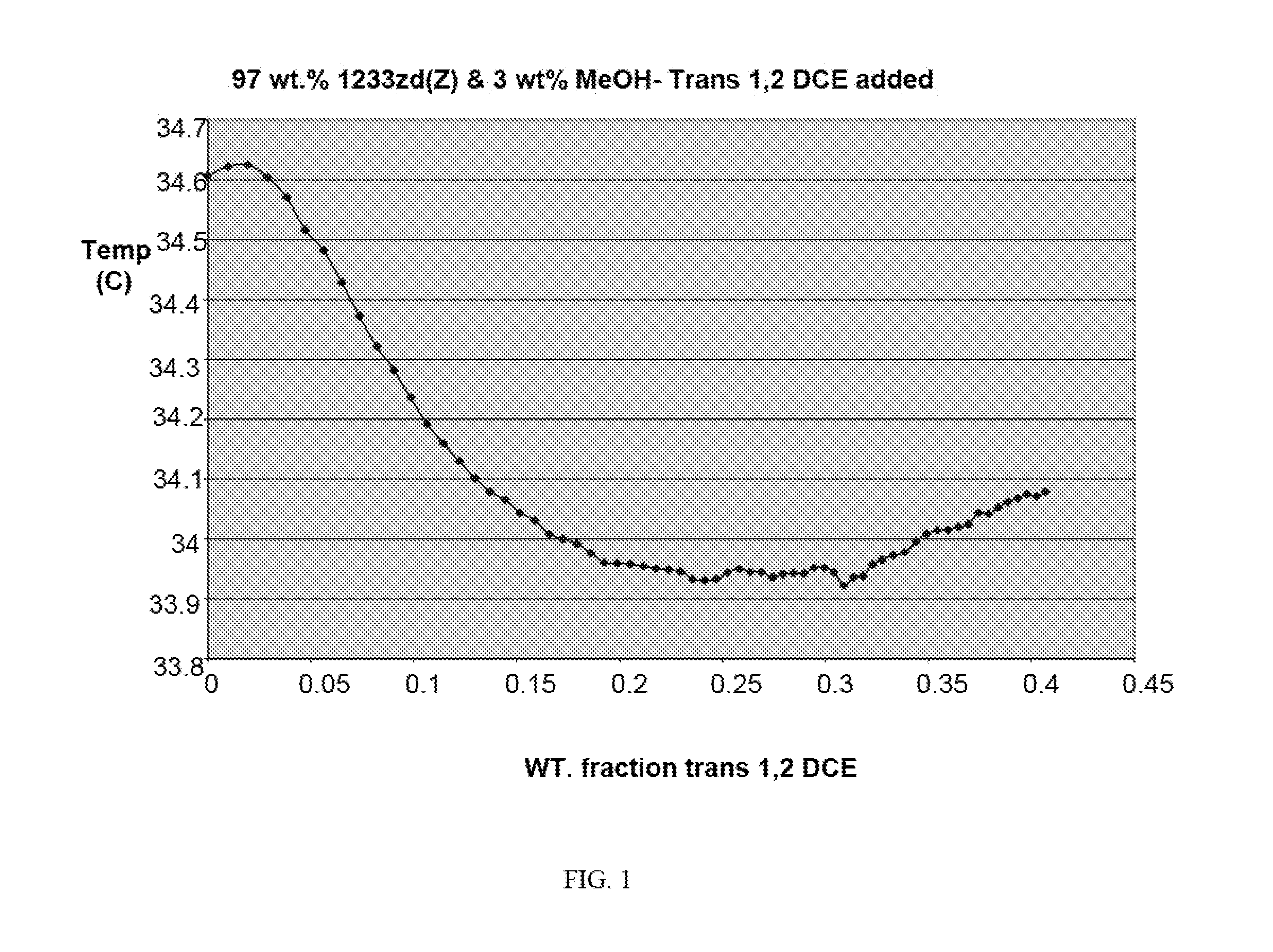

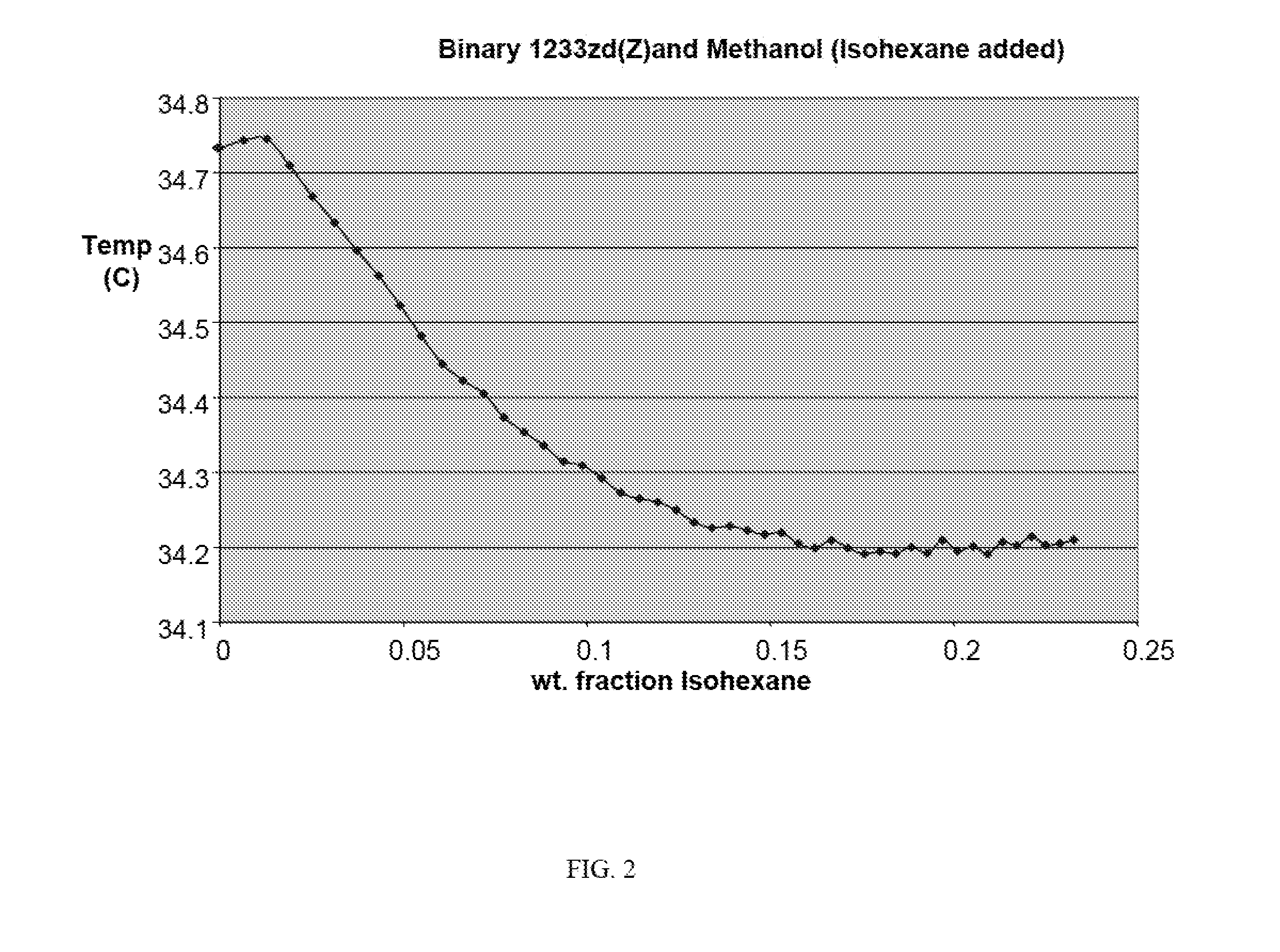

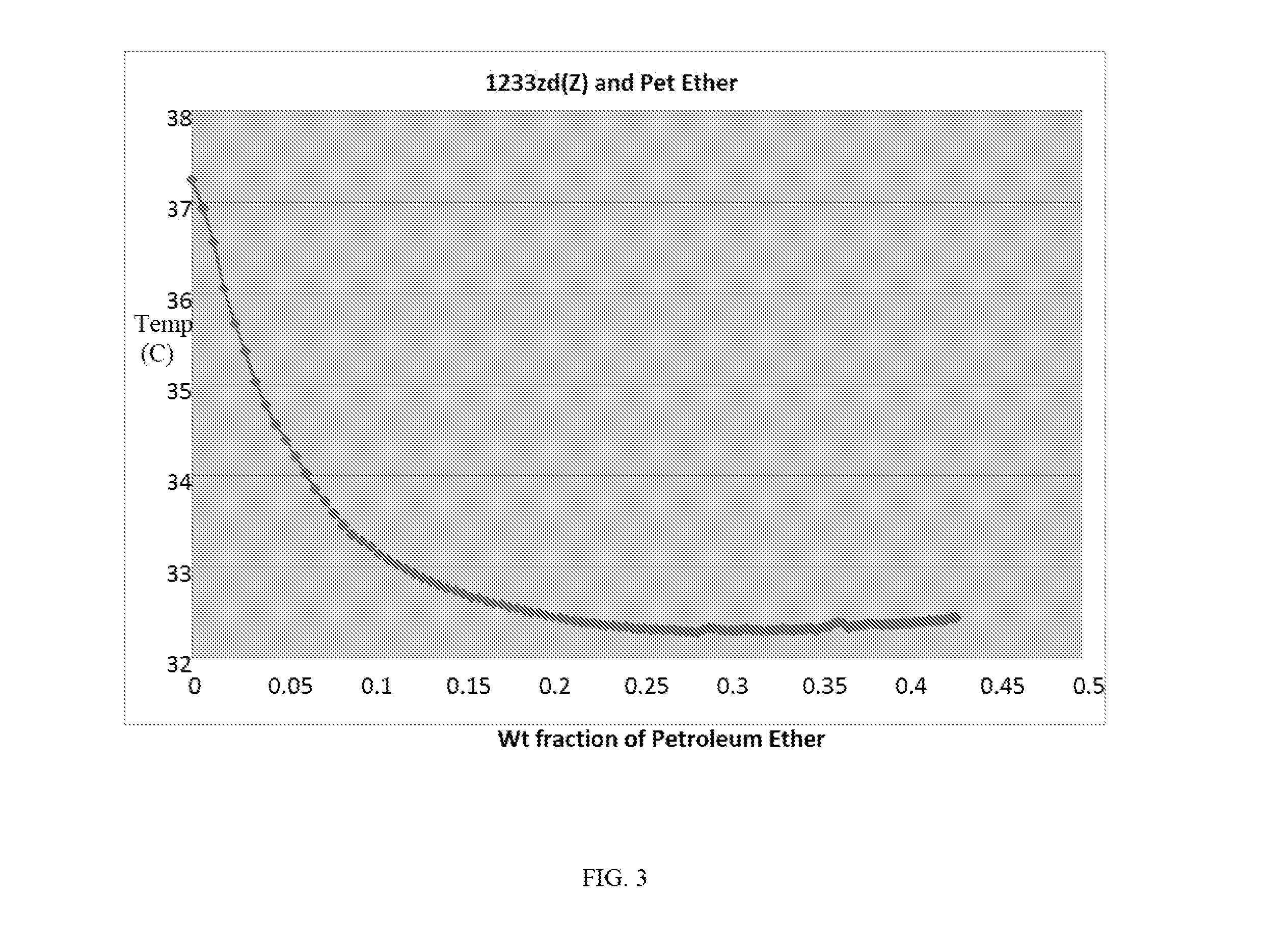

Azeotrope-like compositions comprising 1-chloro-3,3,3-trifluoropropene

The present invention relates, in part, to ternary azeotropic compositions and mixtures including chlorotrifluoropropene, methanol, and a third component selected from isohexane, trans-1,2-dichloroethylene, and petroleum ether. The present invention further relates to ternary azeotropic compositions and mixtures including chlorotrifluoropropene, cyclopentane, and a alcohol selected from methanol, ethanol, and isopropanol.

Owner:HONEYWELL INT INC

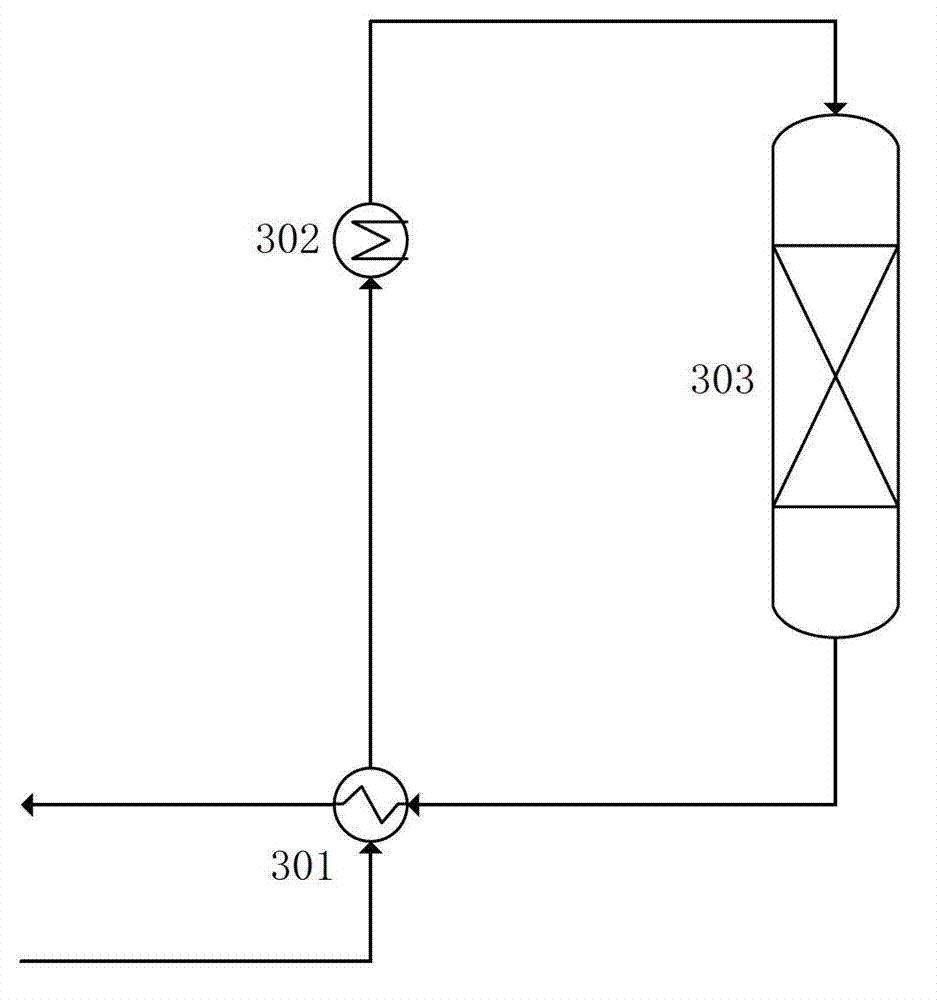

Modified 5A molecular sieve used for removing small-amount n-hexane from isohexane and regeneration method thereof

ActiveCN104888695AHigh porosityLarge adsorption capacityOther chemical processesCombustible gas purificationOxalateMolecular sieve

Disclosed is a modified 5A molecular sieve used for removing small-amount n-hexane from isohexane. The 5A molecular sieve to be modified is soaked and dealuminized through the ethanol solution of oxalic acid, and the modified 5A molecular sieve is obtained accordingly. Meanwhile, the invention discloses a regeneration method of the modified 5A molecular sieve after the n-hexane is absorbed. The modified 5A molecular sieve and method have the advantages that the modified 5A molecular sieve has larger porosity, the absorption amount of the n-hexane is increased, and more isohexane (containing small amount of n-hexane) can be treated; by means of the vapor replacement method, carbon deposition due to local excessively high temperature when the n-hexane is removed through high temperature and pressure directly is avoided.

Owner:岳阳金瀚高新技术股份有限公司

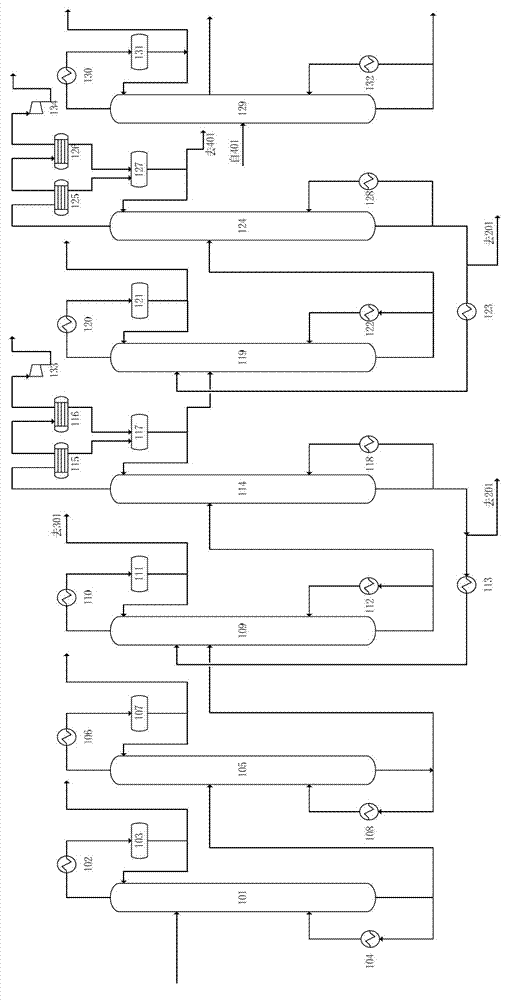

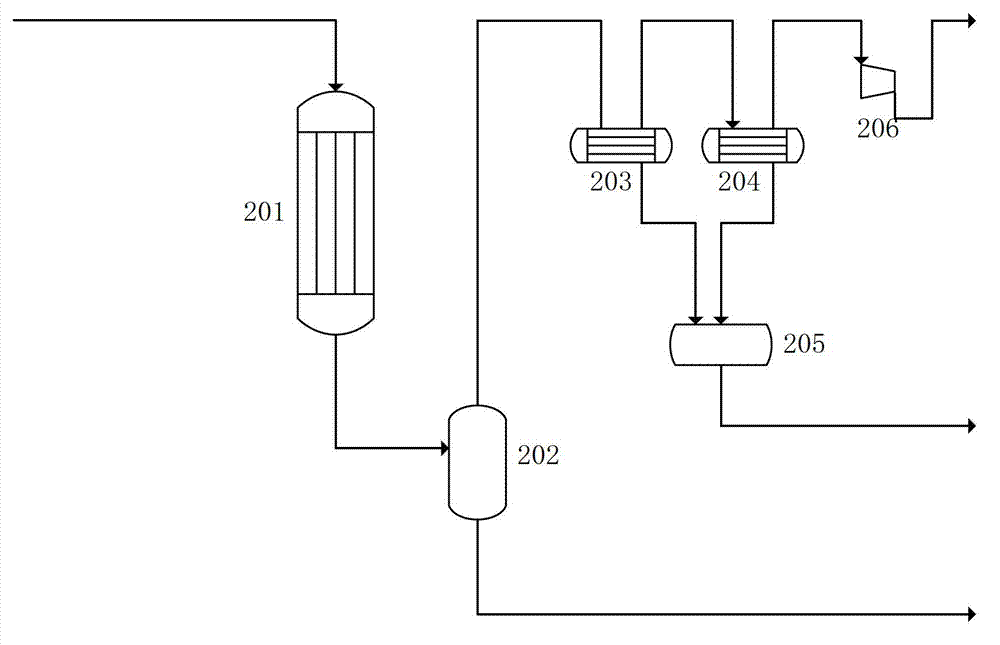

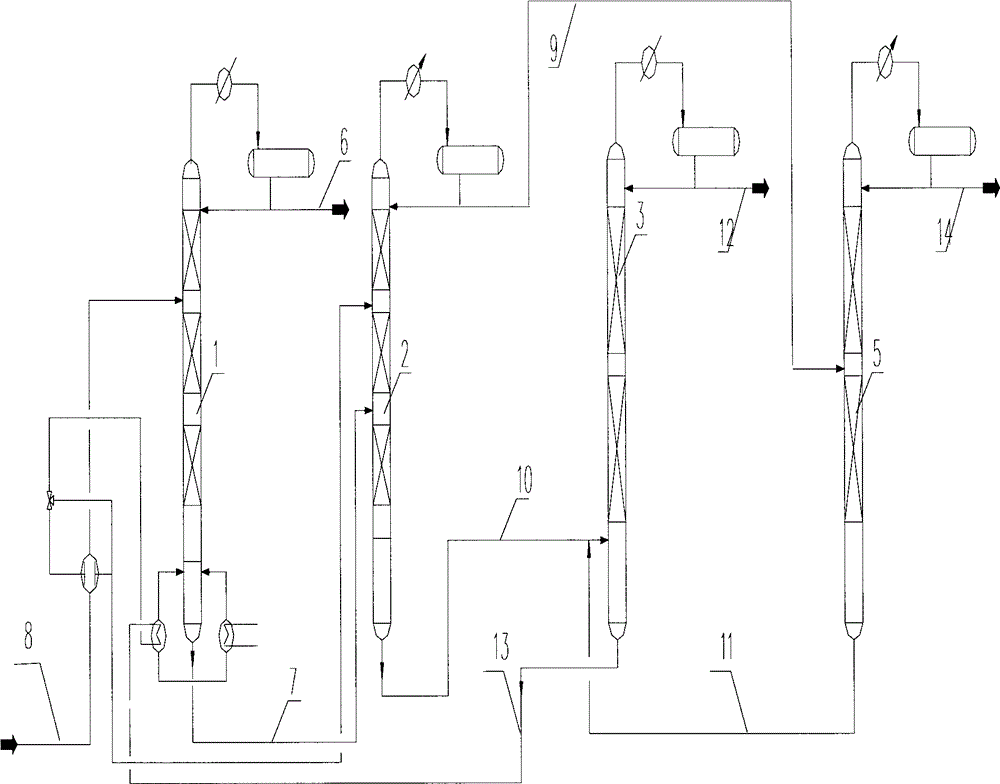

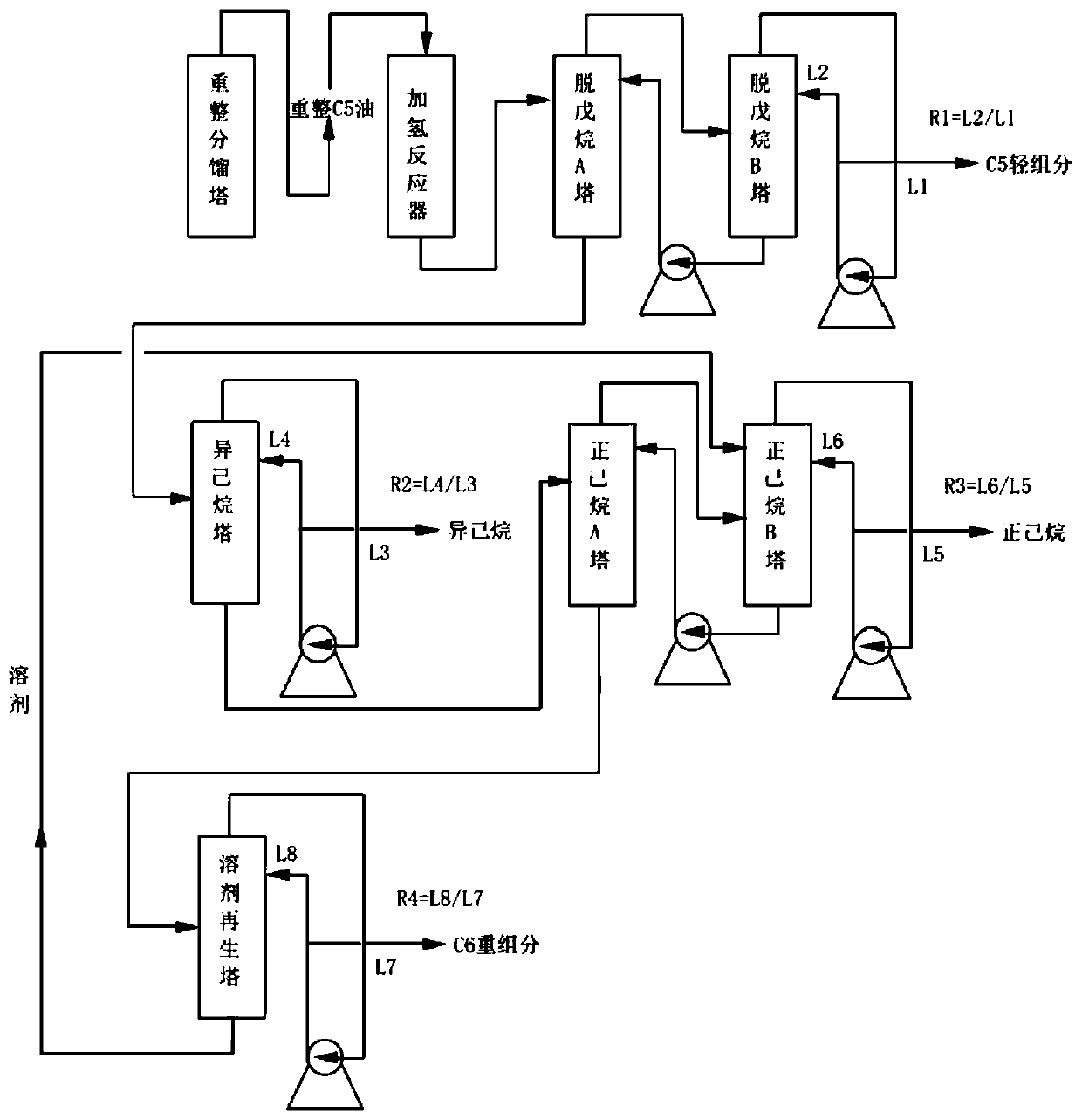

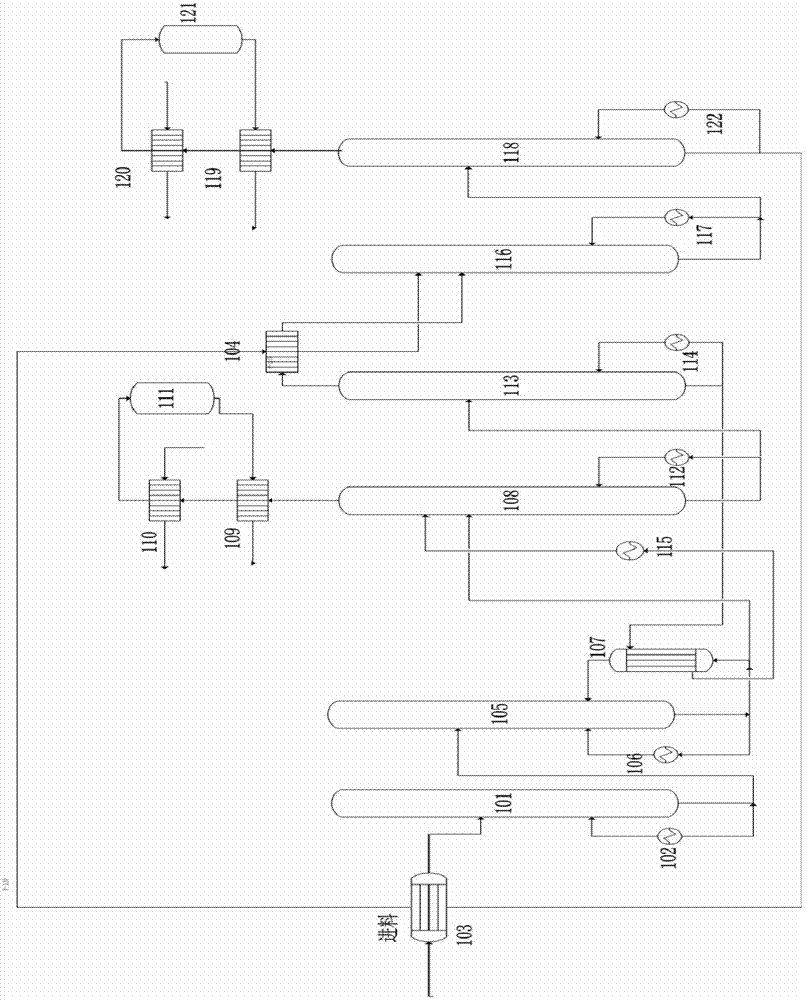

Method and device for separating n-hexane, isohexane and benzene

ActiveCN103086823ADistillation purification/separationAdsorption purification/separationExtractive distillationImpurity

The invention relates to a method and a device for separating n-hexane, isohexane and benzene. The device comprises a light component removal unit, an isohexane separation unit, an n-hexane extractive distillation unit, a first solvent recovery unit, a benzene extractive distillation unit, a second solvent recovery unit and a solvent regeneration unit. The method comprises the following steps: removing impurities with a boiling point less than the boiling point of 2-methylpentane in mixed hydrocarbon raw materials such as raffinate oil, pyrolysis gasoline or straight-run gasoline and the like from an aromatics extraction device firstly, and then separating an isohexane product; separating a n-hexane product from other materials by using an extractive distillation method; and removing n-hexane materials, and carrying out separation on the obtained product so as to obtain a benzene product. The main components of the isohexane product produced by using the technique disclosed by the invention are 2-methylpentane and 3-methylpentane, and the total mass fraction of 2-methylpentane and 3-methylpentane is not less than 95%; n-hexane meets the national standard GB16629-2008, and the mass fraction is not less than 99%; and the benzene product meets the national standard GB3405-89.

Owner:TIANJIN UNIV

Production method for high-purity n-hexane

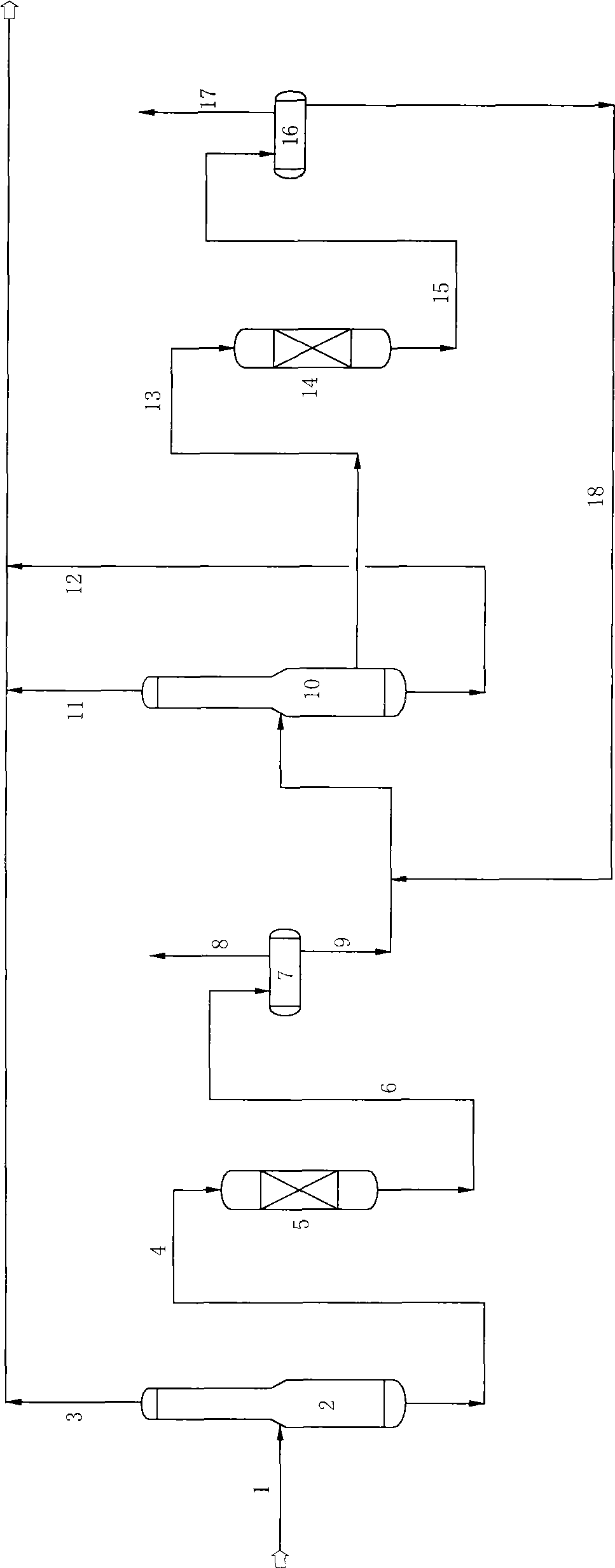

ActiveCN105085142ALower requirementImprove product qualityDistillation purification/separationIsohexanesEvaporation

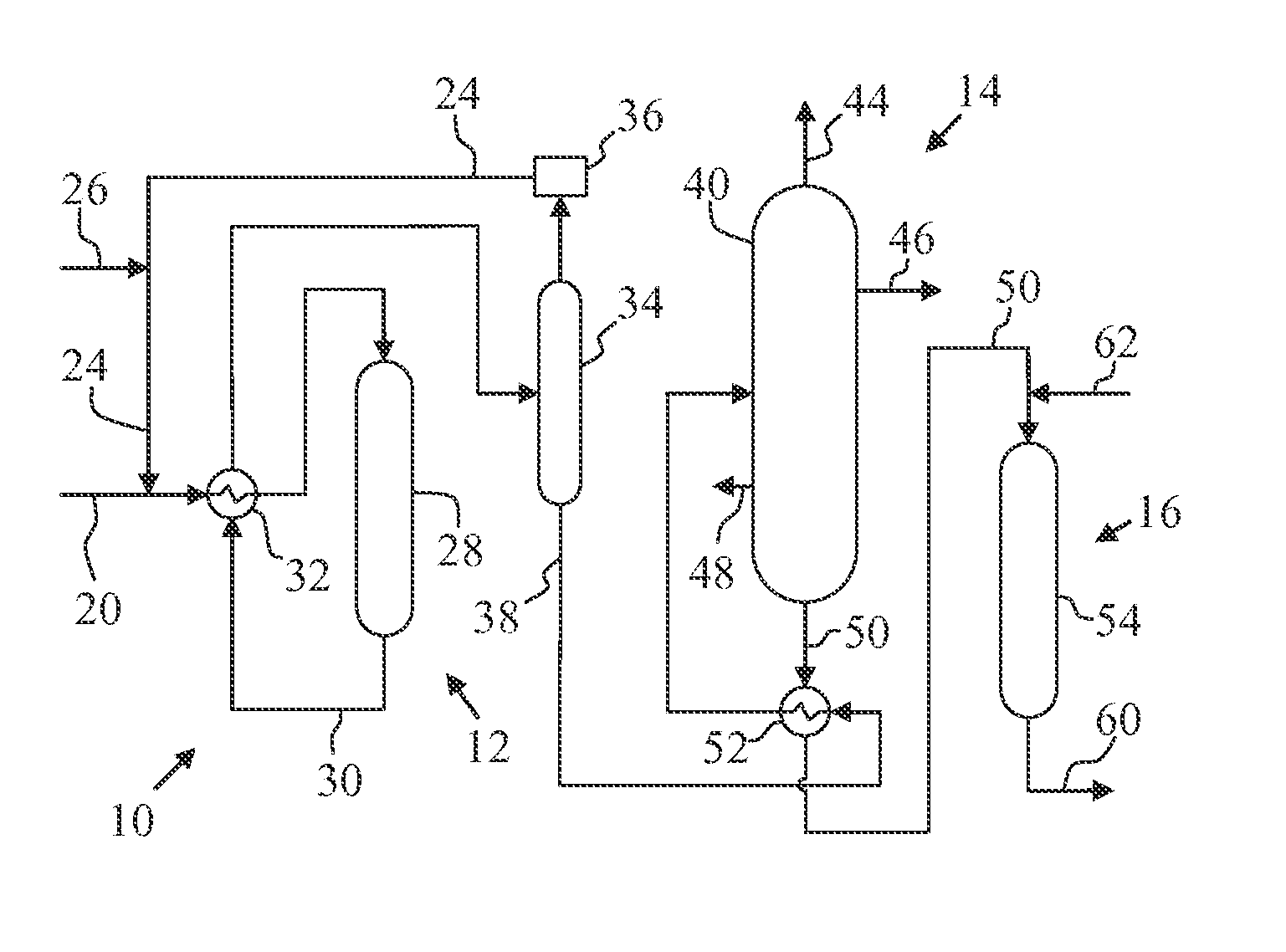

The invention discloses a production method for high-purity n-hexane. According to the method, a raw material (8) is rectified and separated in an isohexane removal tower (1), so a tower bottom component (7) of the isohexane removal tower (1) is obtained; the tower bottom component (7) of the isohexane removal tower (1) enters an extracting and rectifying tower (2) and has countercurrent contact with a circulation solvent so as to realize extraction and rectification; a tower top product (9) of the extracting and rectifying tower (2) enters an n-hexane re-evaporation tower (5); a tower top component of the n-hexane re-evaporation tower (5) is high-purity n-hexane (14), and a tower bottom component (11) of the n-hexane re-evaporation tower (5) enters a solvent recovery tower (3); a tower bottom rich solvent (10) of the extracting and rectifying tower (2) enters the solvent recovery tower (3) for solvent recovery; and a tower bottom circulation solvent (13) of the solvent recovery tower (3) returns to the extracting and rectifying tower (2) for cyclic usage. The method has the advantages of high n-hexane purity and low energy consumption.

Owner:SINOPEC GUANGZHOU ENG +1

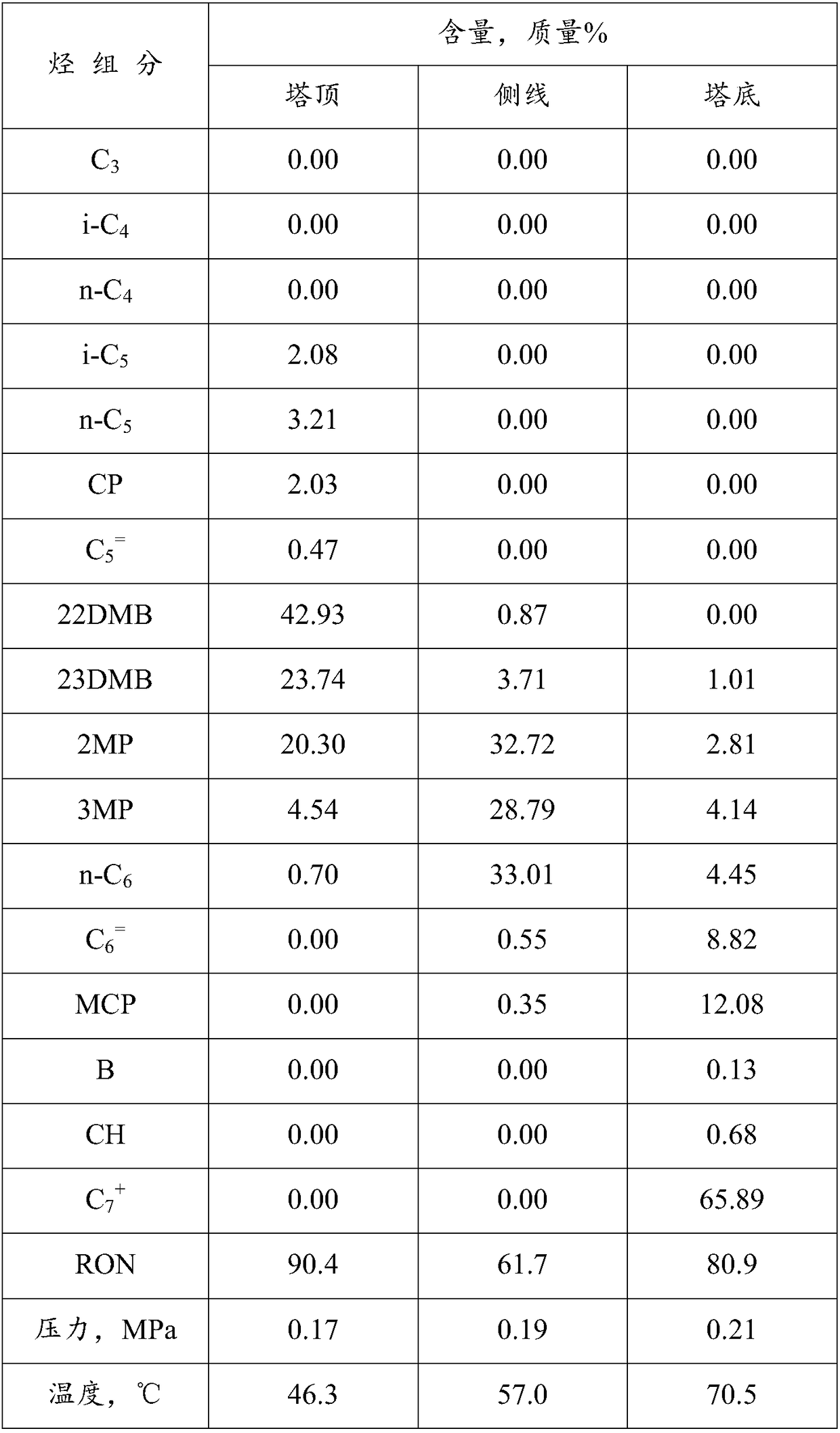

Method for producing isomerized gasoline and aromatic hydrocarbon from alkane

ActiveCN107916131AExtended service lifeReduce separation costsMolecular sieve catalystsLiquid hydrocarbon mixtures productionAlkaneIsomerization

A method for producing isomerized gasoline and aromatic hydrocarbon from alkane comprises the steps as follows: light alkane is introduced into an isomerization reaction zone for an isomerization reaction, a reaction product is subjected to gas-liquid separation, a liquid-phase product enters an isohexane removal tower, C5 alkane and dimethyl C6 alkane fractions are obtained at the tower top, n-hexane and monomethyl C6 alkane fractions are distilled from the tower side, a C7+ fraction is obtained at the tower bottom, the fractions at the tower side of the isohexane removal tower and the fraction at the tower bottom are mixed to be sent to an aromatization reaction zone for an aromatization reaction, after an aromatization reaction product is subjected to gas-liquid separation, an obtainedliquid-phase product is subjected to aromatic hydrocarbon extraction, an aromatic hydrocarbon component and non-aromatic-hydrocarbon components are obtained, and the light alkane is C5-C8 alkane. Withthe adoption of the method, the octane number of a gasoline product can be increased and the proper aromatic hydrocarbon yield can be kept.

Owner:CHINA PETROLEUM & CHEM CORP +1

Light hydrocarbon isomerization method

ActiveCN101544905AIncrease the rate of isomerizationGuaranteed isomerization rateHydrocarbon by isomerisationRefining to change hydrocarbon structural skeleton2-methylbutaneIsomerization

The invention relates to a light hydrocarbon isomerization method comprising the following steps: light hydrocarbon materials are firstly separated by a de-isopentane tower, tower top streams are extracted as isomerization products, and tower bottom streams enter a front isomerization reactor to generate isomerization reaction; liquid phase streams obtained by the gas-liquid separation of outlet streams of the front reactor are separated in a de-isohexane tower, and tower top streams and tower bottom streams of the de-isohexane tower are extracted and then mixed with the tower top streams of the de-isopentane tower and are together taken as a gasoline-stripping stabilization system of the isomerization products; siding streams of the de-isohexane tower are extracted into a rear isomerization reactor; and liquid phase streams obtained by the gas-liquid separation of reaction streams of the rear isomerization reactor completely return and are mixed with the liquid phase streams of a gas-liquid separator of the front isomerization reaction system and together taken as feeding materials of the de-isohexane tower. The method has higher normal paraffin isomerization ratio, wherein the C6 normal paraffin realizes the complete isomerization basically, thereby greatly improving the octane number of the light hydrocarbon materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gasoline additive for purifying tail gas

InactiveCN101921636AReduce harmful gas contentReduce pollutionDispersed particle separationLiquid carbonaceous fuelsIsobutanolAlternative fuels

The invention relates to an additive for gasoline, in particular to an additive for gasoline, which can purify the tail gas discharged by a vehicle using the gasoline after being added into the gasoline and can also be used for directly replacing fuel. The additive of the invention contains methanol or ethanol, isopropanol, isobutanol, xylene, toluene, hydrogenated naphtha, isobutane, methyl tertiary butyl ether, benzyl alcohol, isopropylamine, isooctane, methyl isobutyl ketone and isohexane, wherein the weight ratio of the alcohols of the methanol or the ethanol, the isopropanol and the isobutanol accounts for 47%-55%, the weight ratio of the xylene and the toluene accounts for 19%-31%, and the weight ratio of the hydrogenated naphtha, the isobutane, the methyl tertiary butyl ether, the benzyl alcohol, the isopropylamine, the isooctane, the methyl isobutyl ketone and the isohexane accounts for 16%-23%. The invention has the advantages that after the additive is used, the content of the harmful gas in the tail gas of vehicles can be lowered, and the air pollution can be reduced, thereby reducing the damage of the tail gas of vehicles to the ozonosphere in the atmosphere and reducing the conditions of causing global warming.

Owner:韩国格林替代能源开发有限会社

Use of leaching solvent in preparing edible fat and oil

InactiveCN101361533AReduce health hazardsRelieve stressFood preparationEdible oils/fats production/working-upOil and greaseIsohexanes

A leaching solvent used for preparing edible oils is characterized in that the solvent is applied to the leaching process of edible oil preparation so as to leach oil from materials. The solvent consists of the following components by weight ratio: 94 to 100 percent of isohexane, 0 to 3 percent of normal hexane and 0 to 3 percent of butane and pentane; the leaching process includes the following steps of: 1) leaching: the leaching temperature is 48 to 53 DEG C and a mass ratio between the materials and solvent is 1 / 1 to 0.8; mixed oil and leached wet meal are obtained; 2) desolventizing: the finished meal is obtained; 3) the evaporation of a first long-tube; 4) the evaporation of a second long-tube; mixed oil is obtained; and 5) steam stripping: raw oil is obtained. The solvent of the invention is mainly composed of isohexane so as to largely reduce the harm to the health of operators exposed in the manufacturing environment; the product quality can be enhanced and the protection to environment can be enhanced; the latent heat for the evaporation of isohexane is low and then the energy cost required by the solvent recycling can be effectively reduced.

Owner:中机康元粮油装备(北京)有限公司

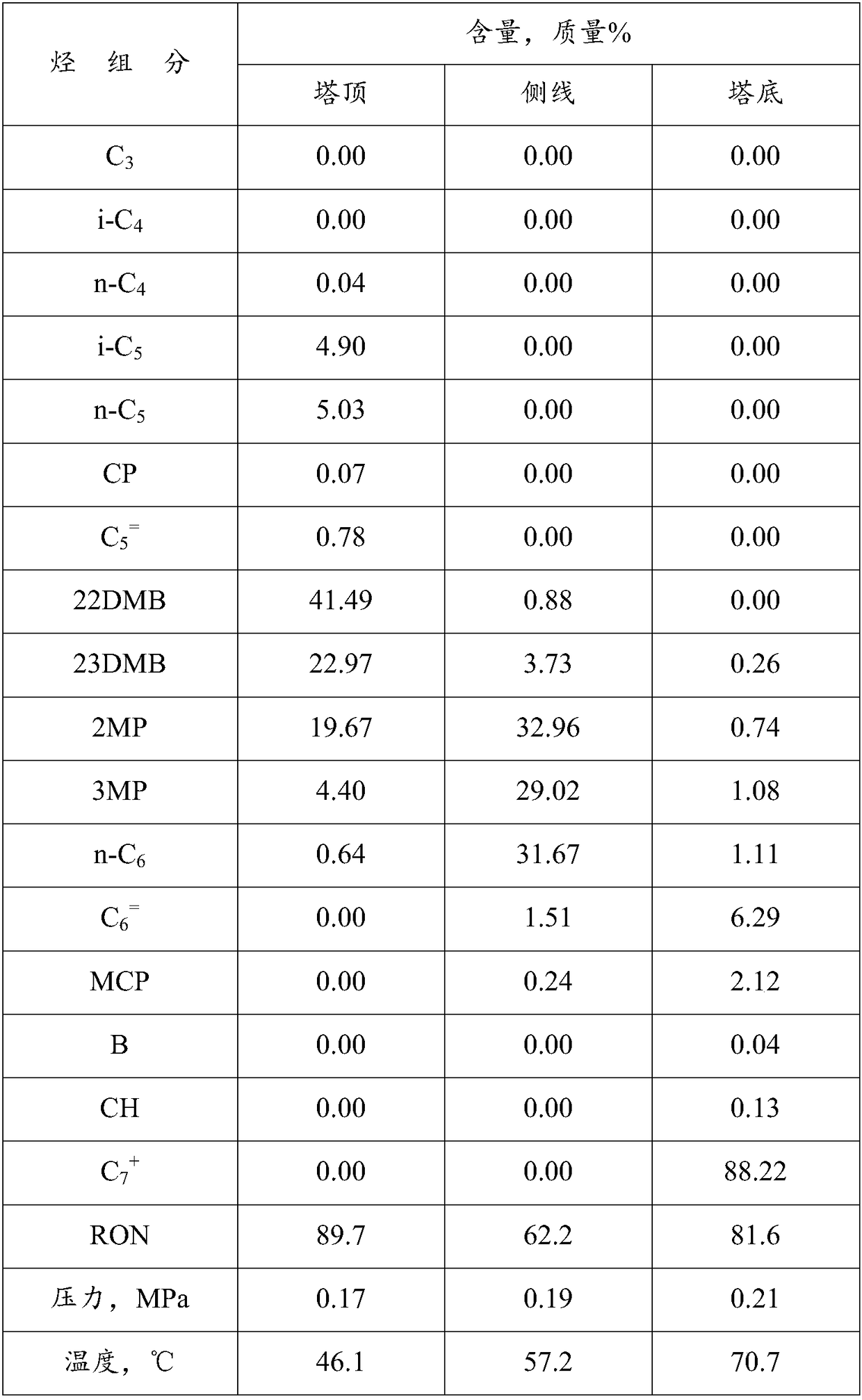

Isomerization method for light hydrocarbon

ActiveCN101497815AGuaranteed isomerization rateImprove liquid yieldRefining to change hydrocarbon structural skeletonHydrocarbon by hydrogenationAlkaneIsomerization

The invention relates to a light hydrocarbon isomerization method. Isomerization reaction is performed for light hydrocarbon raw material in an isomerization reactor at the front part, gas-liquid separation is performed for the outlet stream of the reactor at the front part, the obtained liquid phase stream is separated in an isohexane removing tower, the overhead stream mainly comprising C5 cut fraction and dimethyl C6 alkane is mixed with the bottom stream mainly comprising C7 and cut fractions more than C7 so as to be used as isomate to enter into a gasoline stabilizer, the side stream mainly comprising C6 n-alkane and monomethyl C6 alkane is led into an isomerization reactor at the rear part; after the reaction stream of the isomerization reactor at the rear part is separated, the liquid phase stream all returns and is mixed with the liquid phase stream of a gas-liquid separator of the isomerization reactor at the front part so as to be used as the feeding of the isohexane removing tower. The method has higher n-alkane isomerization ratio and greatly improves the octane number of the light hydrocarbons raw material because the C6 n-alkane basically realizes the full isomerization.

Owner:CHINA PETROLEUM & CHEM CORP +1

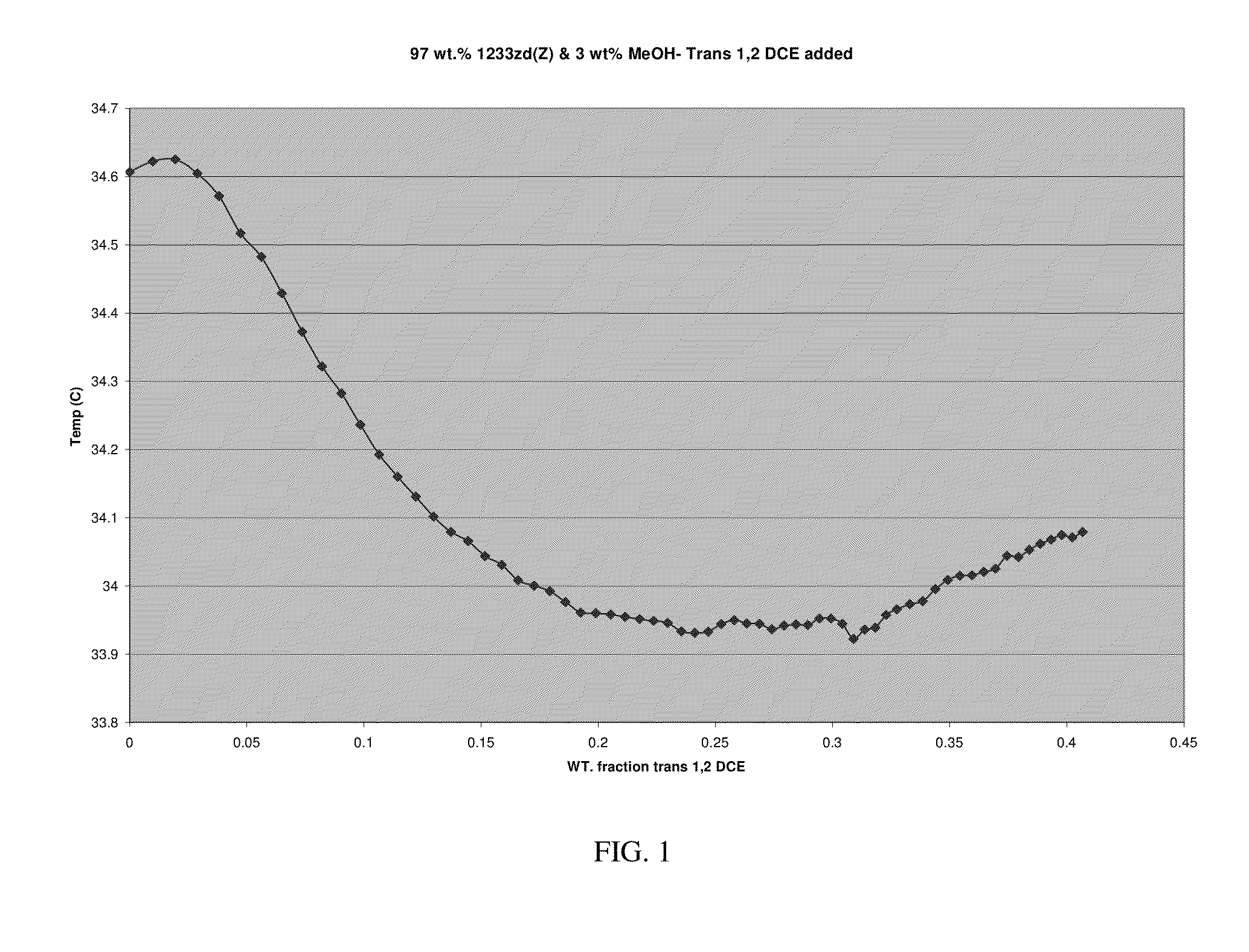

Azeotrope-like compositions comprising 1-chloro-3,3,3-trifluoropropene

The present invention relates, in part, to ternary azeotropic compositions and mixtures including chlorotrifluoropropene, methanol, and a third component selected from isohexane, trans-1,2-dichloroethylene, and petroleum ether. The present invention further relates to ternary azeotropic compositions and mixtures including chlorotrifluoropropene, cyclopentane, and a alcohol selected from methanol, ethanol, and isopropanol.

Owner:HONEYWELL INT INC

Low-carbon alcohol clean new energy fuel additive

InactiveCN108359504AControl contentFull combustion and energy savingLiquid carbonaceous fuelsFuel additivesNew energyNitromethane

The invention discloses a low-carbon alcohol clean new energy fuel additive. The low-carbon alcohol clean new energy fuel additive is compounded from methyl alcohol, butyl alcohol, isooctane, ethylcyclohexane, cyclohexane, isobutyl alcohol, petroleum ether, isohexane, methyl cyclohexane, nitromethane, ethylene glycol, liquid paraffin, methyl cyclopentane, an anti-dissolving additive, a dispersingagent, a distilling range regulator, a stabilizing agent, a compound cold starting agent and a metal surface passivator. Compared with the prior art, the low-carbon alcohol clean new energy fuel additive reduces the emission, protects the environment, improves the power, reduces the fuel consumption, clears the carbon deposit, does not need to reform an engine, is low in cost, is simple in production process, and has popularization and application values.

Owner:祝保林

Azeotrope-like compositions comprising 1-chloro-3,3,3-trifluoropropene

InactiveUS20140206589A1Number of applicationOther chemical processesDetergent mixture composition preparationAzeotropeMethanol

The present invention relates, in part, to binary azeotropic compositions and mixtures including chlorotrifluoropropene and petroleum ether and to ternary azeotropic compositions and mixtures including chlorotrifluoropropene, methanol, and a third component selected from isohexane, trans-1,2-dichloroethylene, and petroleum ether. The present invention further relates to ternary azeotropic compositions and mixtures including chlorotrifluoropropene, cyclopentane, and a alcohol selected from methanol, ethanol, and isopropanol.

Owner:HONEYWELL INT INC

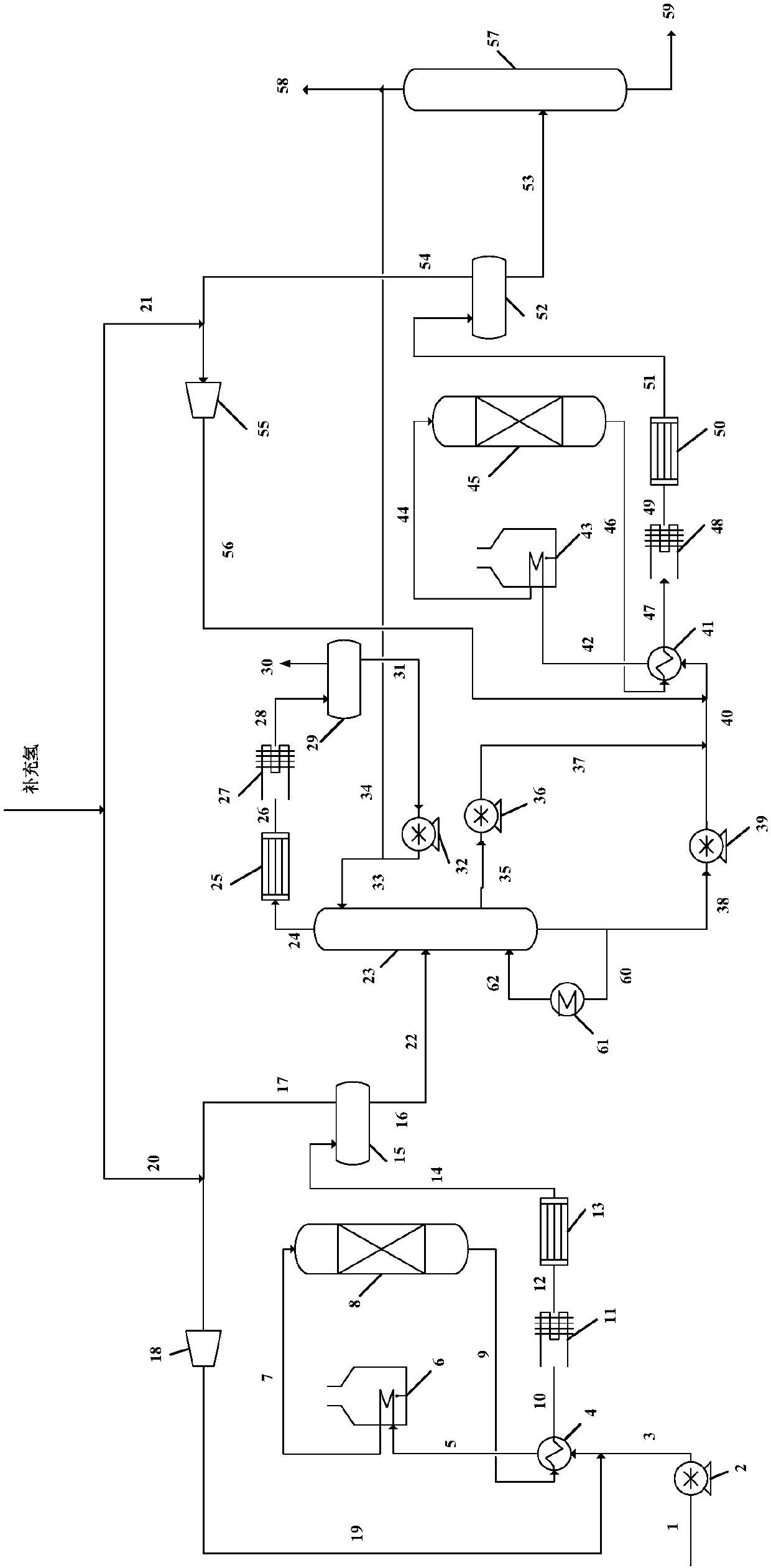

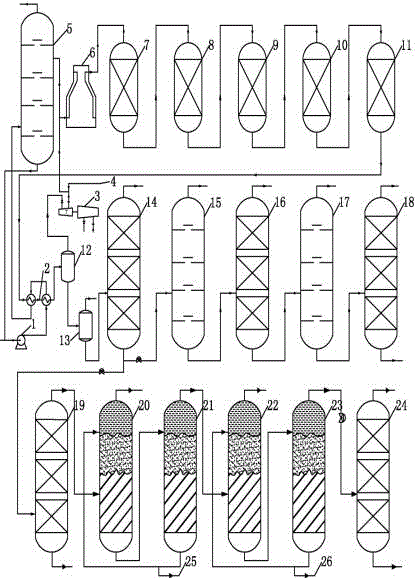

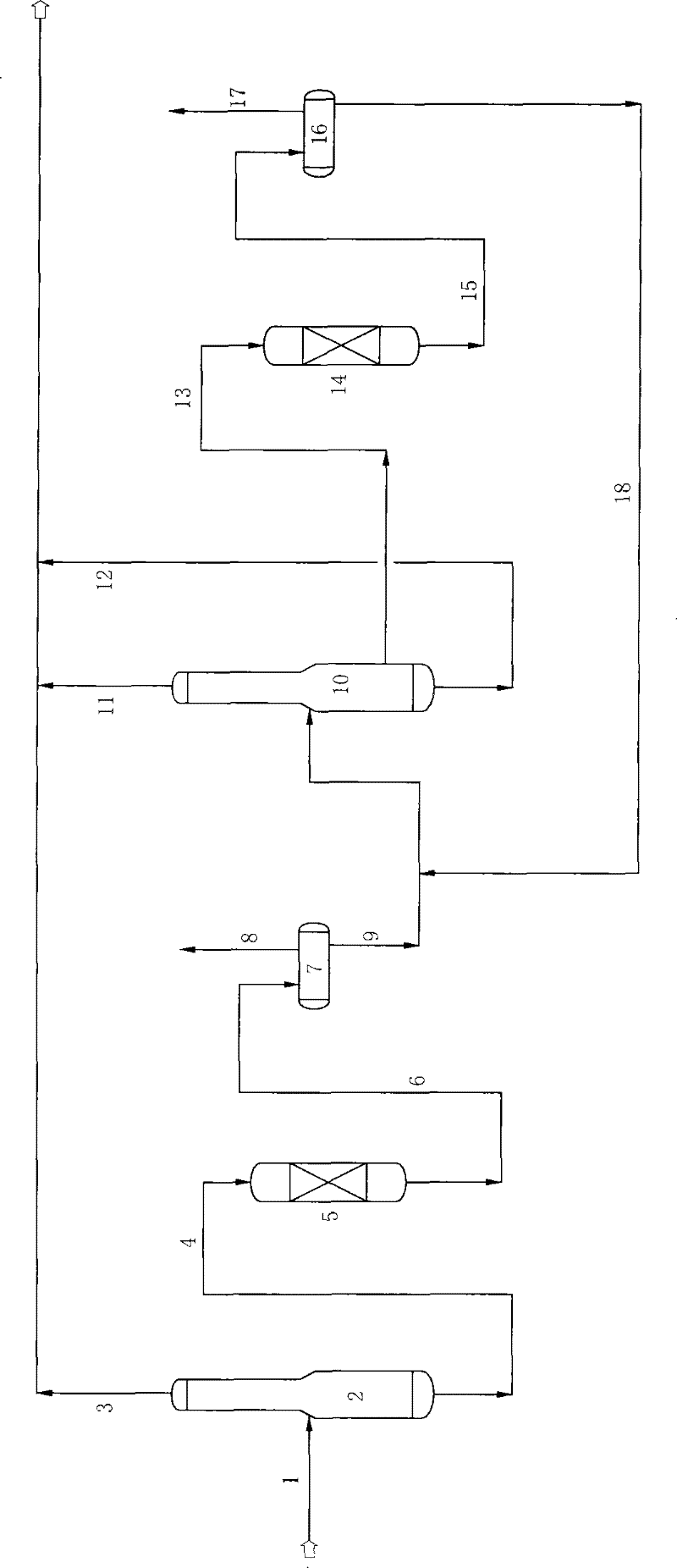

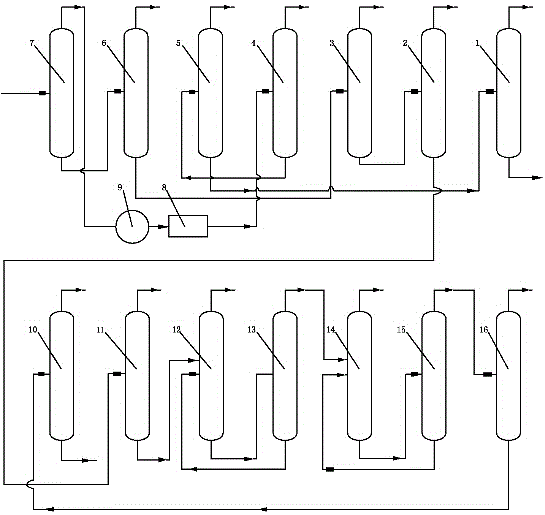

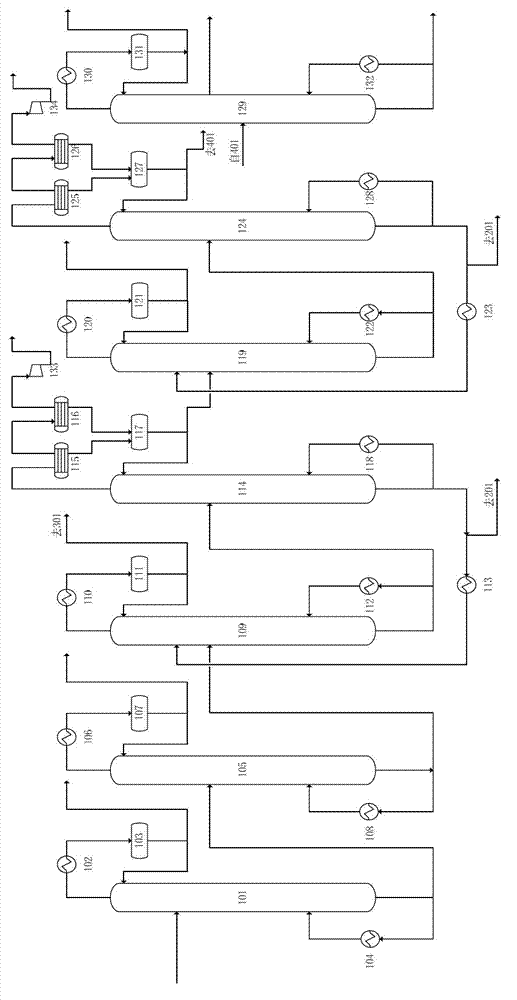

Environment-friendly solvent and partial monomer alkane production device and use method thereof

InactiveCN105950213AStrong adaptability to uncertaintyReasonable and practical designHydrocarbon by hydrogenationDistillation purification/separationAlkaneHigh pressure

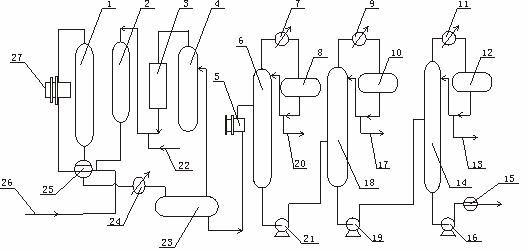

The invention provides an environment-friendly solvent and partial monomer alkane production device and a use method thereof. The invention adopts the technical scheme that the environment-friendly solvent and partial monomer alkane production device mainly comprises a feed pump (1), a heat exchanger unit (2), a circulating hydrogen compressor (3), a new hydrogen line (4), a light hydrocarbon removal tower (5), a heating furnace (6), a pre-hydrogenating reactor (7), a main hydrogenating reactor (8), an absorption reactor (9), a first dearomatization reactor (10), a second dearomatization reactor (11), a high-pressure separator (12), a low-pressure separator (13), a pentane rectifying tower (14), a hexane rectifying tower (15), a heptane rectifying tower I (16), a heptane rectifying tower II (17), a hydrogenation tail oil rectifying tower (18), an isohexane rectifying tower (19), an N-hexane extraction and rectification tower (20), a first extraction solvent recovery tower (21), a methyl cyclopentane rectifying tower (22), a second extraction solvent recovery tower (23), a benzene rectifying tower (24), a first extraction solvent regeneration evaporator (25) and a second extraction solvent regeneration evaporator (26). The environment-friendly solvent and partial monomer alkane production device provided by the invention is reasonable and practical in design and better in economic benefits.

Owner:DONGYING JUNYUAN PETROLEUM TECH DEV CO LTD

Methods and apparatuses for forming low-aromatic high-octane product streams

Methods and apparatuses for forming low-aromatic high-octane product streams and methods for processing hydrocarbons are provided. In an embodiment, a method for forming a low-aromatic high-octane product stream includes deisohexanizing or deisoheptanizing a hydrocarbon stream and forming a cycloalkane-rich stream. Further, the method includes isomerizing the cycloalkane-rich stream at equilibrium conditions favoring formation of cyclopentanes over cyclohexanes.

Owner:UOP LLC

Process for decreasing coking of convection sections of cracking furnaces

ActiveCN104593039AAvoid cokingImprove technical effectThermal non-catalytic crackingN octaneQuenching

The invention relates to a process for decreasing coking of convection sections of cracking furnaces and is mainly used for solving the problem that the high polymers carried by the diluted steam cannot be removed in the prior art. The process for decreasing coking of the convection sections of cracking furnaces comprises the following steps: cracking gas generated by a cracking furnace enters a bath tower after undergoing quenching and oil washing; the process water of the bath tower enters a process water stripping tower; the water of the process water stripping tower enters a process water extraction tower to contact an extraction agent; the water of the process water extraction tower enters a diluted steam generator to generate diluted steam; and the diluted steam enters the cracking furnace. The extraction agent is selected from at least one of n-pentane, n-hexane, n-heptane, n-octane, n-nonane, isopentane, isohexane, cyclopentane, cyclohexane, benzene, methylbenzene and xylene. According to the technical scheme, the process has the effect of preferably solving the problem and can be used for the convection sections of cracking furnaces.

Owner:SINOPEC SHANGHAI ENG +1

Method for preparing high-purity beta-carotene from green tea

InactiveCN101182303AHigh extraction rateHigh purityOrganic chemistryPlant ingredientsFraction CollectorBeta-Carotene

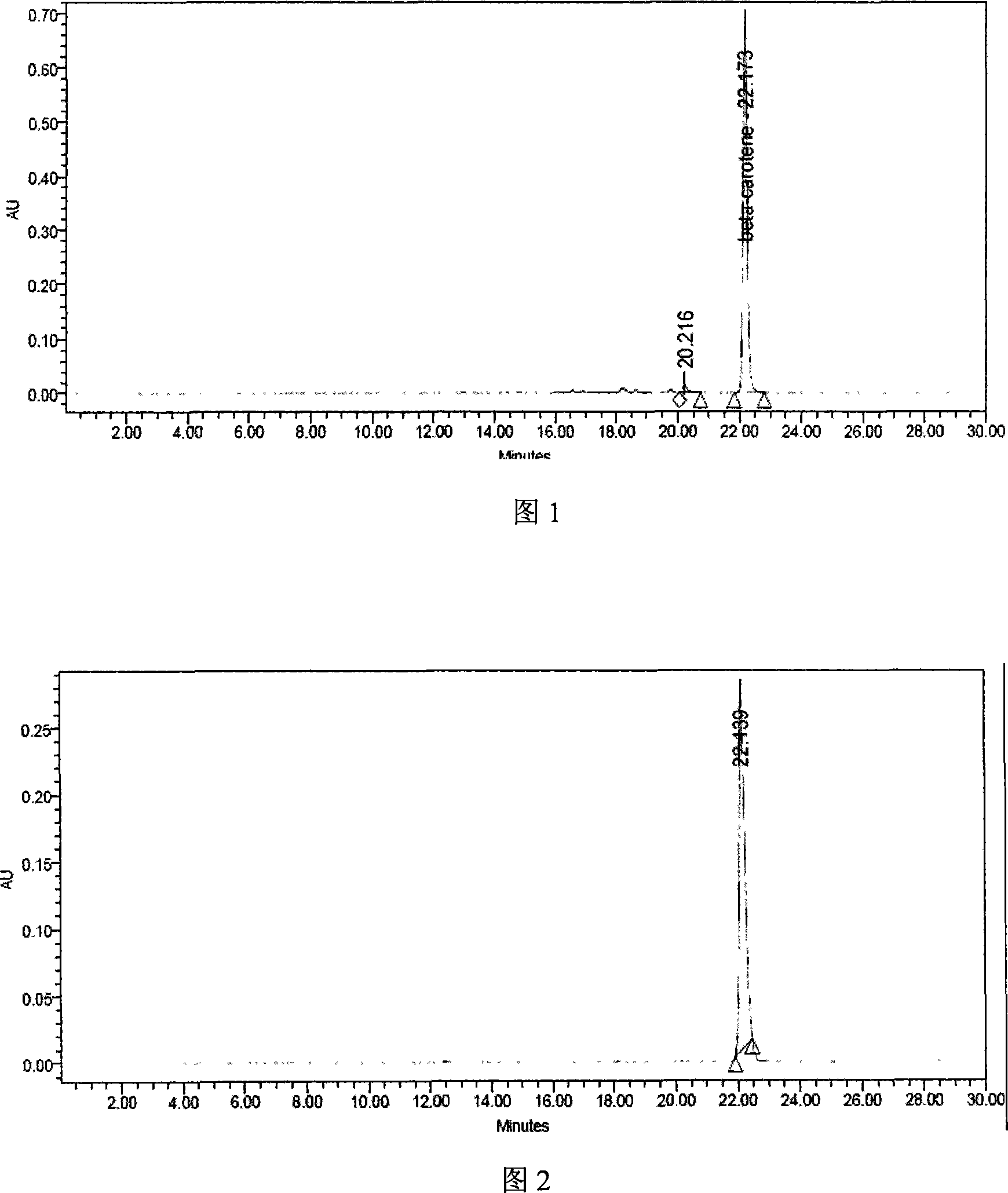

A method for preparing high-purity β-carotene from green tea. The main contents are as follows: first extract the pulverized green tea powder with a mixture of methanol, ethanol and H2O or at least one of them, and dry the extracted tea dregs under reduced pressure, and then extract them with ethyl acetate, acetone, n-hexane, isohexane, One or more of dichloromethane and trichloromethane are used as the extracting solution to extract the crude extract of green tea β-carotene. After the crude extract is concentrated, it is subjected to gradient elution chromatography on silica gel or alumina column chromatography. The eluents are two of ethyl acetate, acetone, n-hexane, isohexane, cyclohexane, dichloromethane and chloroform. The effluent is collected in parts and vacuum freeze-dried to obtain high-purity green tea β-carotene. The invention is suitable for common green tea, especially low-grade green tea as raw material, and has the characteristics of simple technological process and required equipment, high extraction rate and high purity of β-carotene in tea leaves.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

Processes for the isomerization of paraffins of 5 and 6 carbon atoms with methylcyclopentane recovery

InactiveCN101171212AReduced Membrane Surface AreaHigh economic feasibilityHydrocarbon by isomerisationRefining to change hydrocarbon structural skeletonMethylcyclopentaneBoiling point

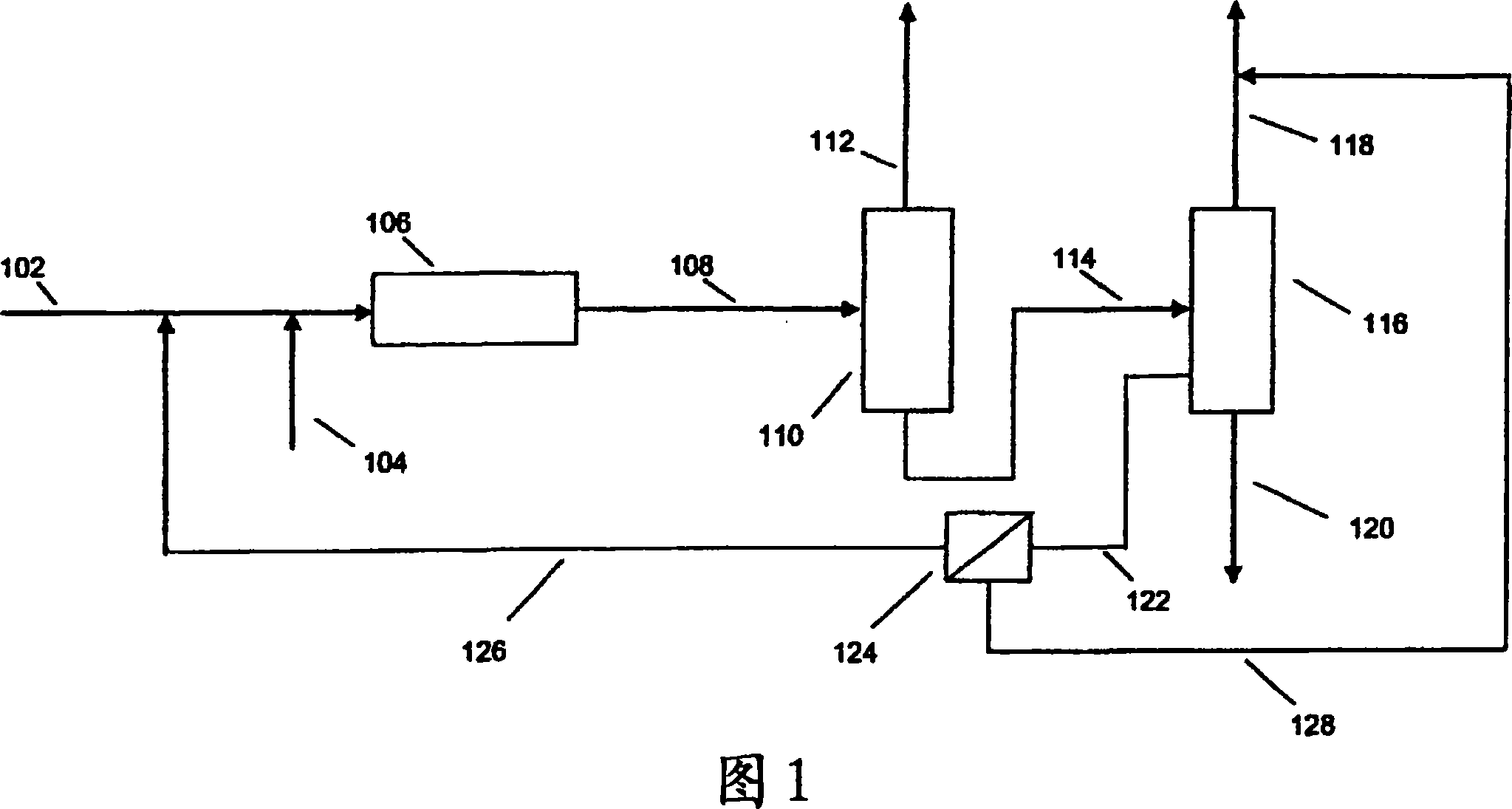

In an isomerization process where the isomerization effluent (108) is fractionated in a deisohexanizer (116) to provide an overhead (118) containing dimethylbutanes and a higher boiling fraction (122) containing normal hexane, the higher boiling is contacted with a selectively permeable membrane (124) to provide a retentate containing methylcyclopentane (128). If desired, the normal hexane-containing permeate can be recycled for isomerization. The preferred membranes are sieving membranes having a C6 Permeate Flow Index of at least 0.01 and a C6 Permeate Flow Ratio of at least 1.25:1.

Owner:UOP LLC

Benzene-free low-toxicity industrial oil cleaning agent and preparation method thereof

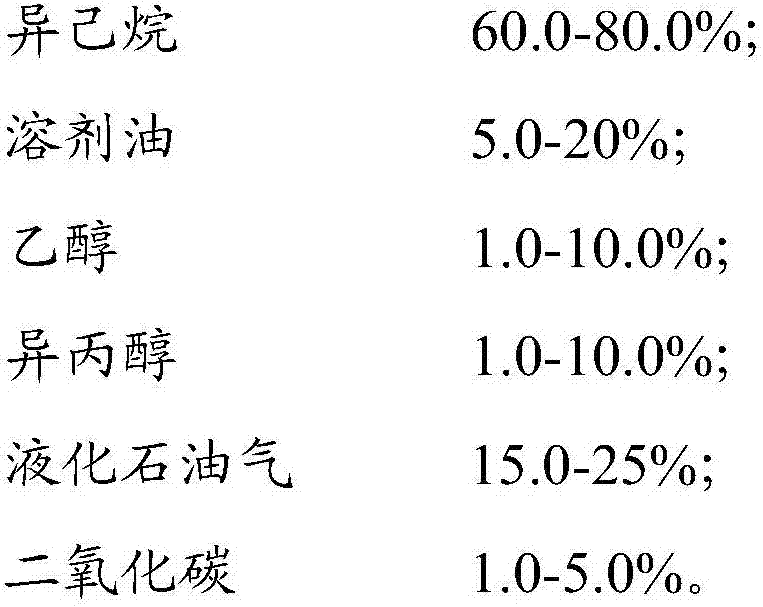

InactiveCN106987463AEasy to cleanVolatile fastOrganic non-surface-active detergent compositionsInorganic non-surface-active detergent compositionsAlkaneSolvent

The invention relates to a benzene-free low-toxicity industrial oil cleaning agent and a preparation method thereof. The industrial oil cleaning agent is prepared from the following components in percentage by weight: 60.0-80.0% of isohexane, 5.0-20% of solvent oil, 1.0-10.0% of ethyl alcohol, 1.0-10.0% of isopropyl alcohol, 15.0-25% of liquefied petroleum gas and 1.0-5.0% of carbon dioxide. The adopted solvent is alcohol solvent and an alkane solvent, does not contain benzene and chlorine solvents, is low in toxicity and environment-friendly, and the industrial oil cleaning agent is high in cleaning force, fast in volatilization and free of a residue and a traditional industrial oil cleaning agent can be replaced.

Owner:广东莱雅新化工科技有限公司

Light hydrocarbon isomerization method

ActiveCN101544905BIncrease the rate of isomerizationGuaranteed isomerization rateHydrocarbon by isomerisationRefining to change hydrocarbon structural skeleton2-methylbutaneIsomerization

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for extracting oil in spent bleaching clay by ultrasonic assisted isohexane

InactiveCN105296166AHigh oil extraction rateIncrease industry profitsFatty oils/acids recovery from wasteFatty substance recoveryCavitationUltrasonic assisted

The invention provides a method for extracting oil in spent bleaching clay by ultrasonic assisted isohexane. Under the oscillation and cavitation action of ultrasonic waves, oil adsorbed in the spent bleaching clay is fully extracted in the isohexane, thus fulfilling the aim of increasing the oil extraction rate. The method comprises the following steps: dispersing the spent bleaching clay into the isohexane, uniformly mixing, extracting the oil adsorbed in the spent bleaching clay into the isohexane under the synergistic action of ultrasonic treatment, heating and stirring, performing washing and centrifugal solid-liquid separation on an oil-removed bleaching clay system obtained by filtration, and drying and grinding obtained solid products, thus obtaining regenerated bleaching clay. According to the method, the oil in the oil spent bleaching clay can be extracted to the maximum extent, so that the extraction time is shortened, and the maximum oil extraction rate is 97 percent; meanwhile, after being regenerated, the spent bleaching clay can be used for brickmaking by filling and repeatedly used, so that the aim of recycling economy is fulfilled. The method has an important significance for oil and fat refining.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

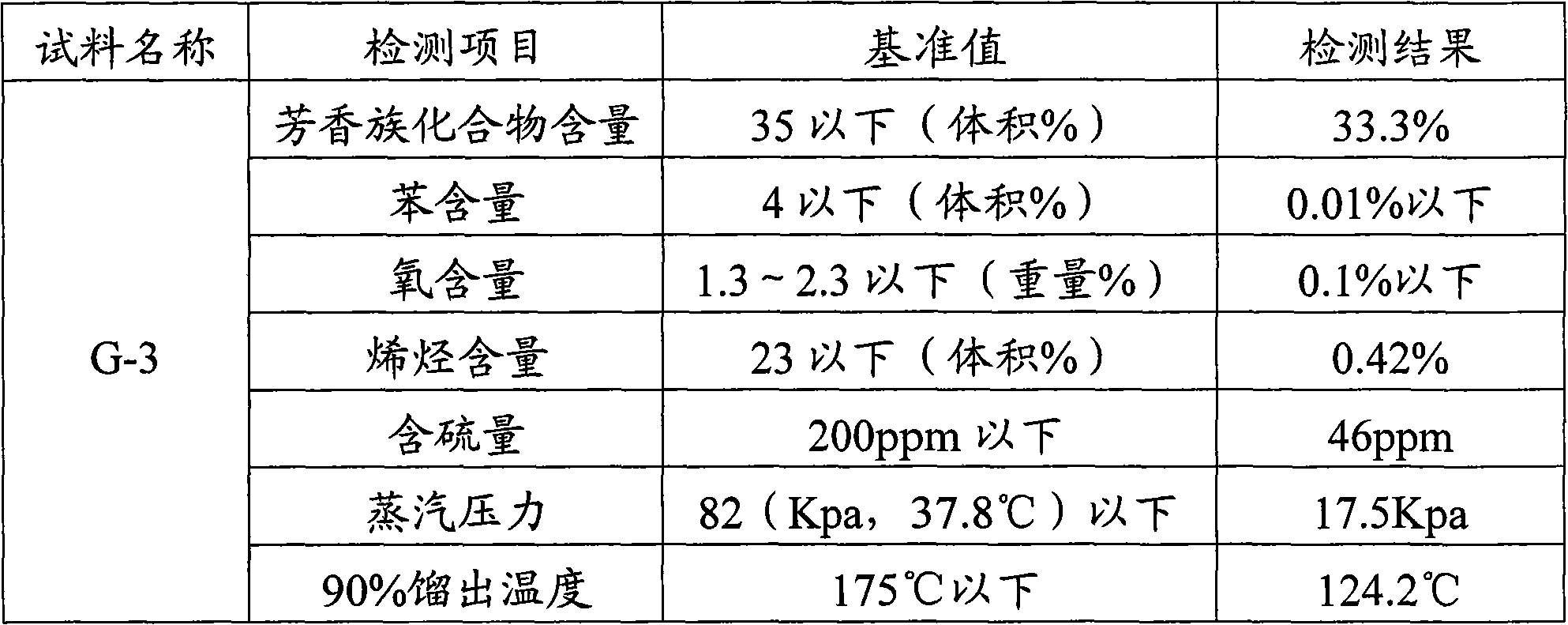

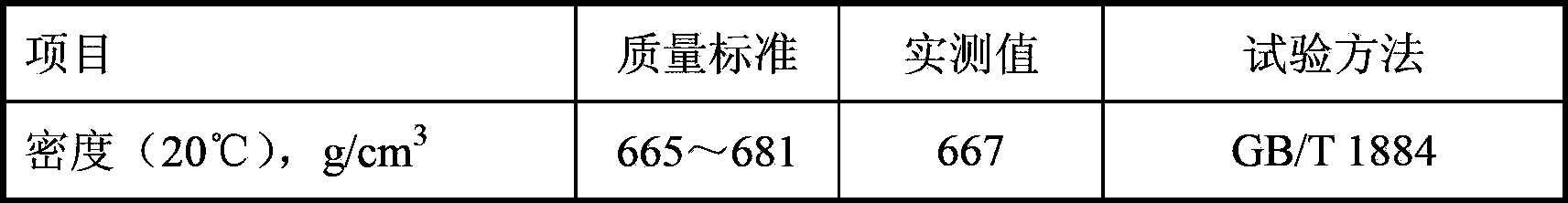

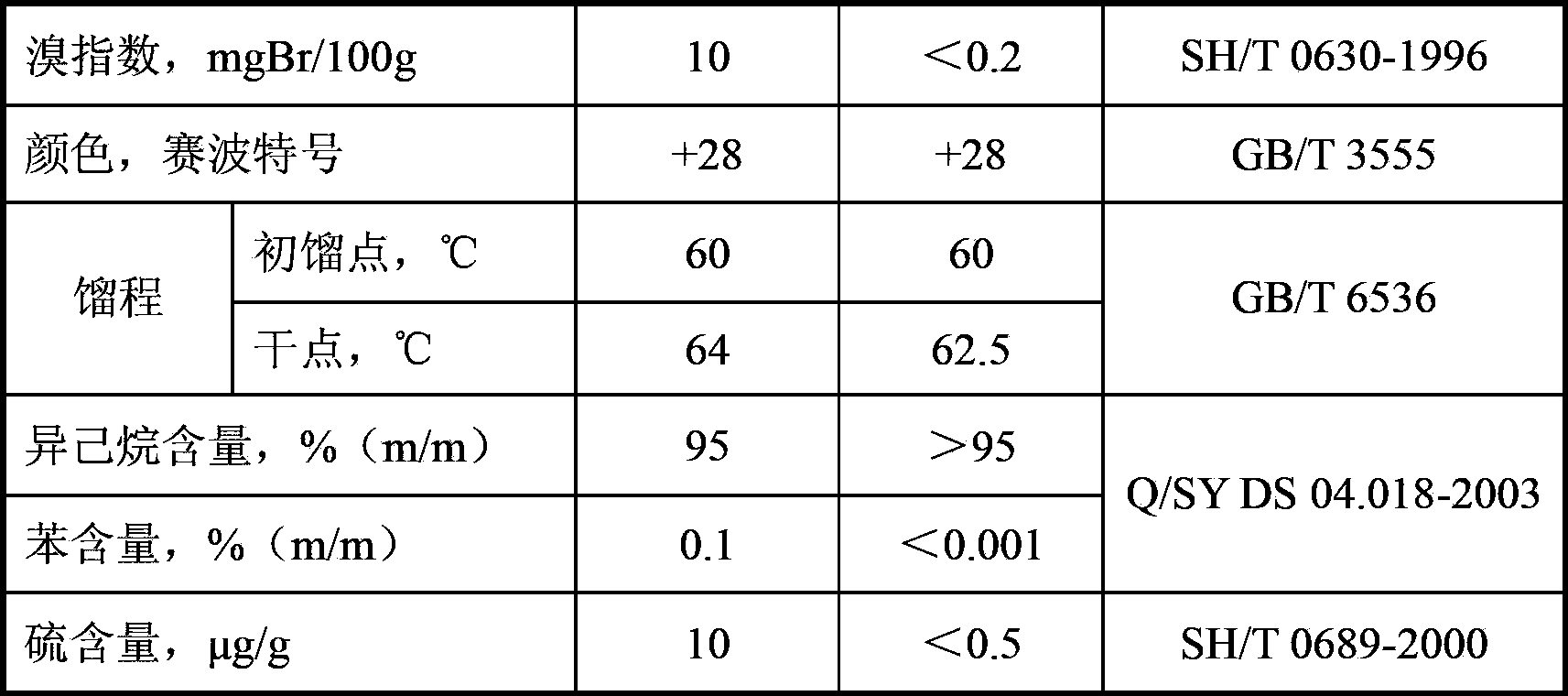

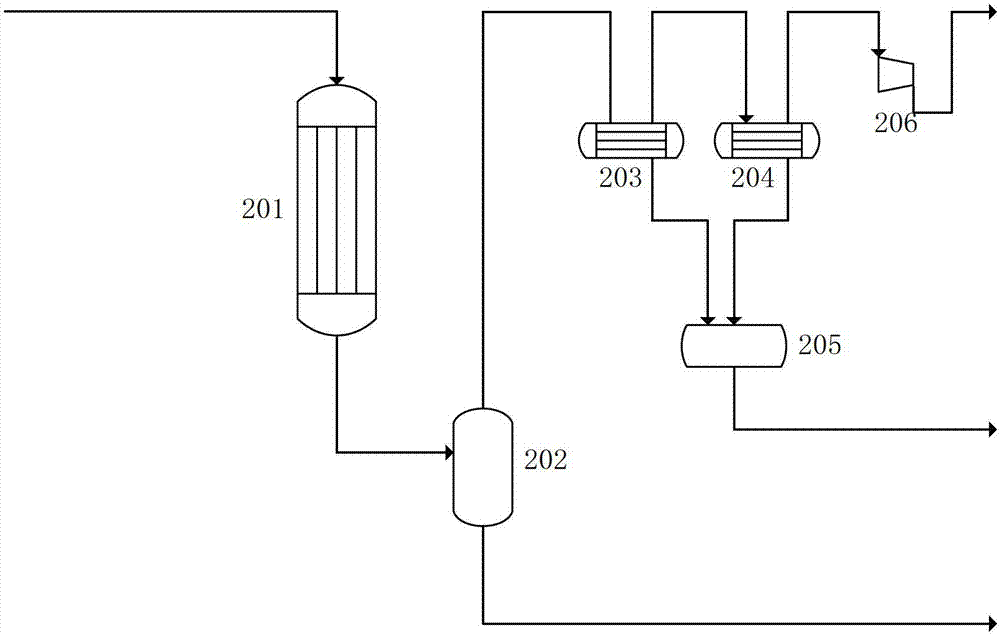

Method for preparing high-purity isohexane solvent oil

ActiveCN103833499AHigh activityReduced need for post-refiningDistillation purification/separationTreatment with hydrotreatment processesAir velocityDistillation

The invention relates to a method for preparing high-purity isohexane solvent oil. The method comprises the following steps: carrying out hydrofining on reformed raffinate oil, and adopting a nickel catalyst, wherein the process conditions are as follows: the pressure is 0.2-2.0Mpa; the temperature is 80-220 DEG C; the air velocity is 2.0-4.0h<-1>; and the hydrogen oil ratio is 40-200v / v; cutting off the fraction over 65 DEG C from the hydrofined reformed raffinate oil on a true boiling point distillation apparatus; repeating the steps and collecting the fraction which is not greater than 65 DEG C for three times; cutting the collected fraction which is not greater than 65 DEG C on the true boiling point distillation apparatus again; and collecting products of different temperature segments of tower distillate products by a plurality of small bottles, wherein 0.5 DEG C is taken as a distillation segment, thus obtaining the isohexane product of which the purity is 95.323% between 59.5 DEG C and 62 DEG C. By adopting the method, the reformed raffinate oil is taken as a raw material, aromatic hydrocarbon and olefins are removed by adopting a high-activity nickel catalyst in a hydrofining manner, and the isohexane product of which the purity is not smaller than 95% is obtained on the true boiling point distillation apparatus by cutting and fractionation twice.

Owner:PETROCHINA CO LTD

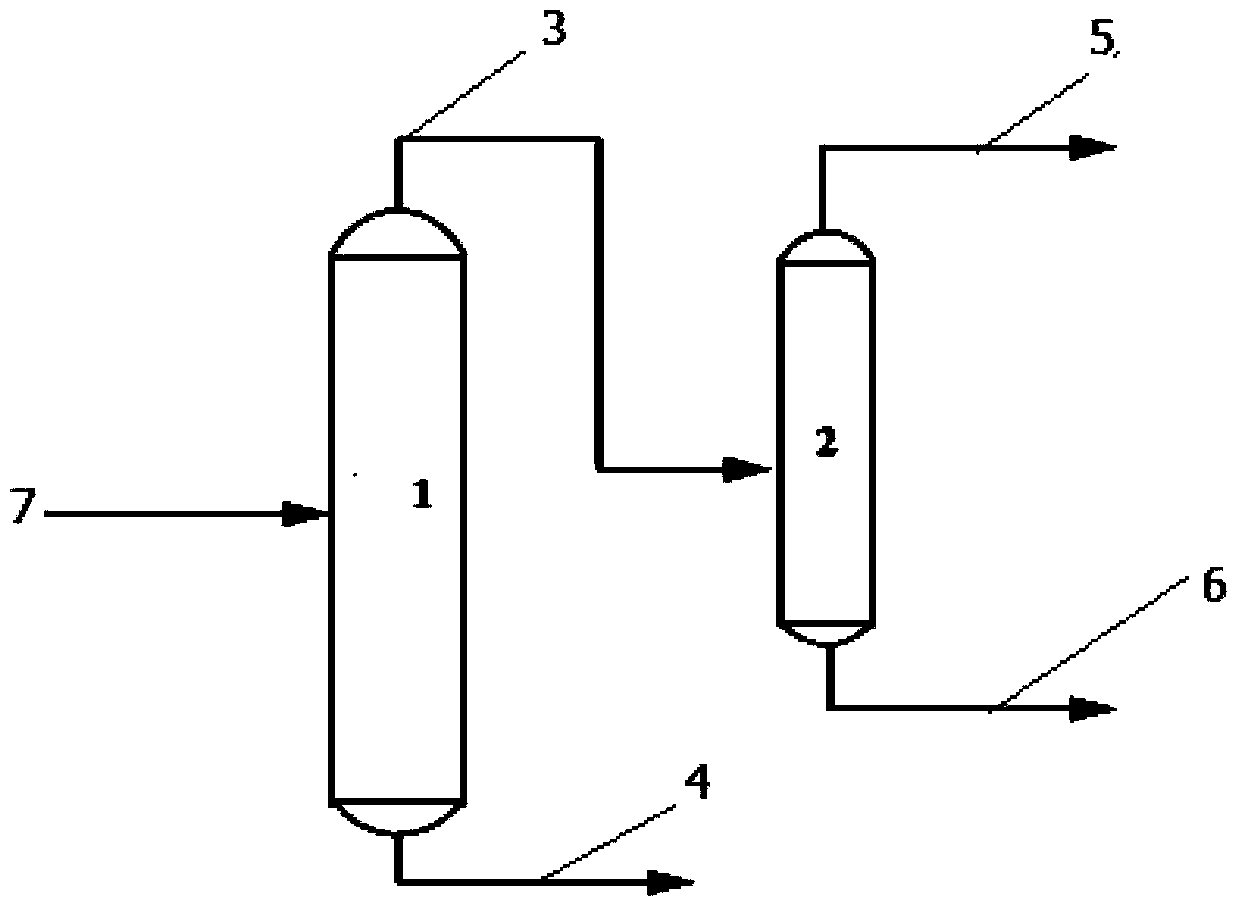

Preparation method of high purity n-hexane

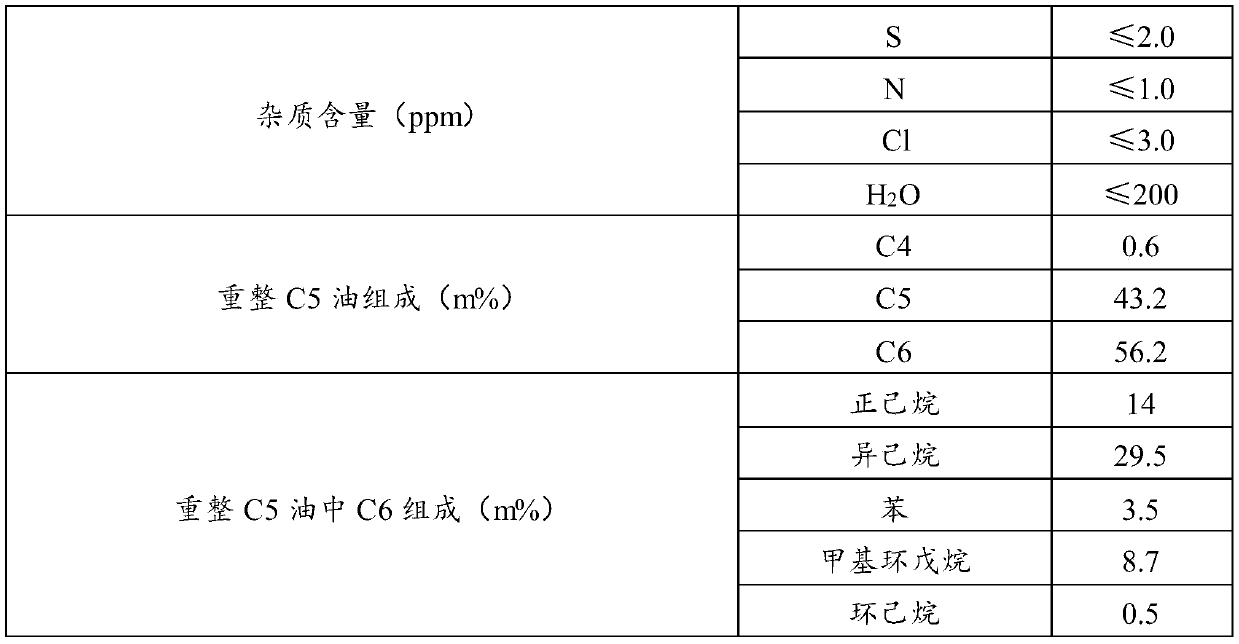

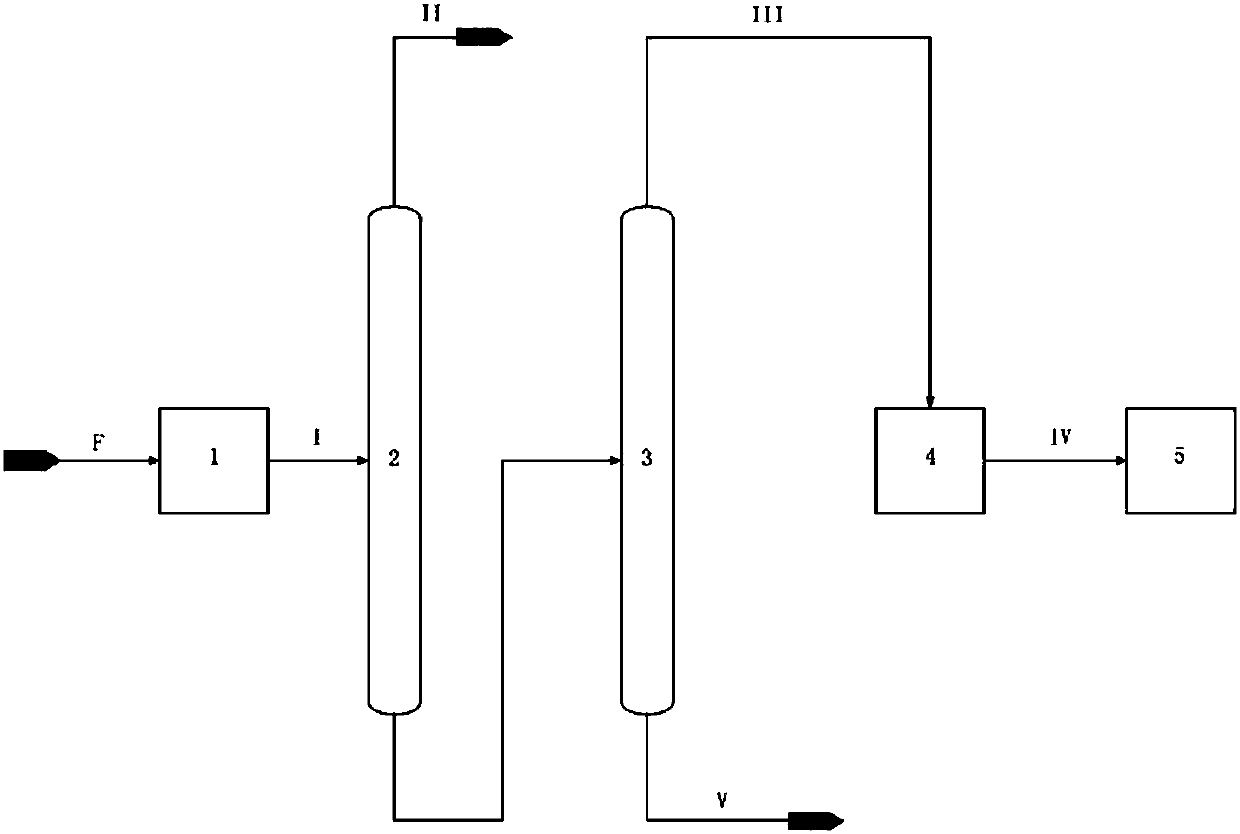

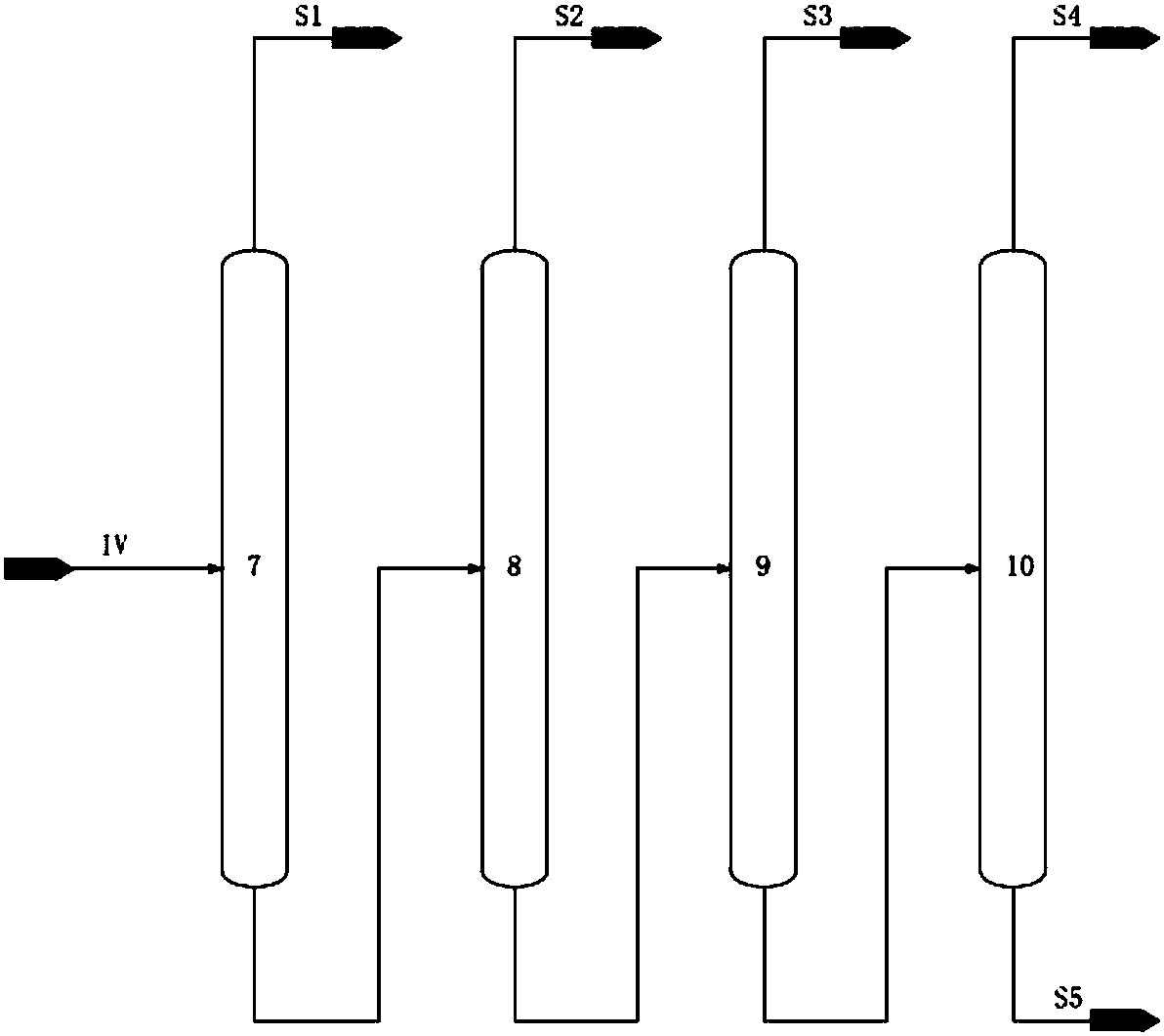

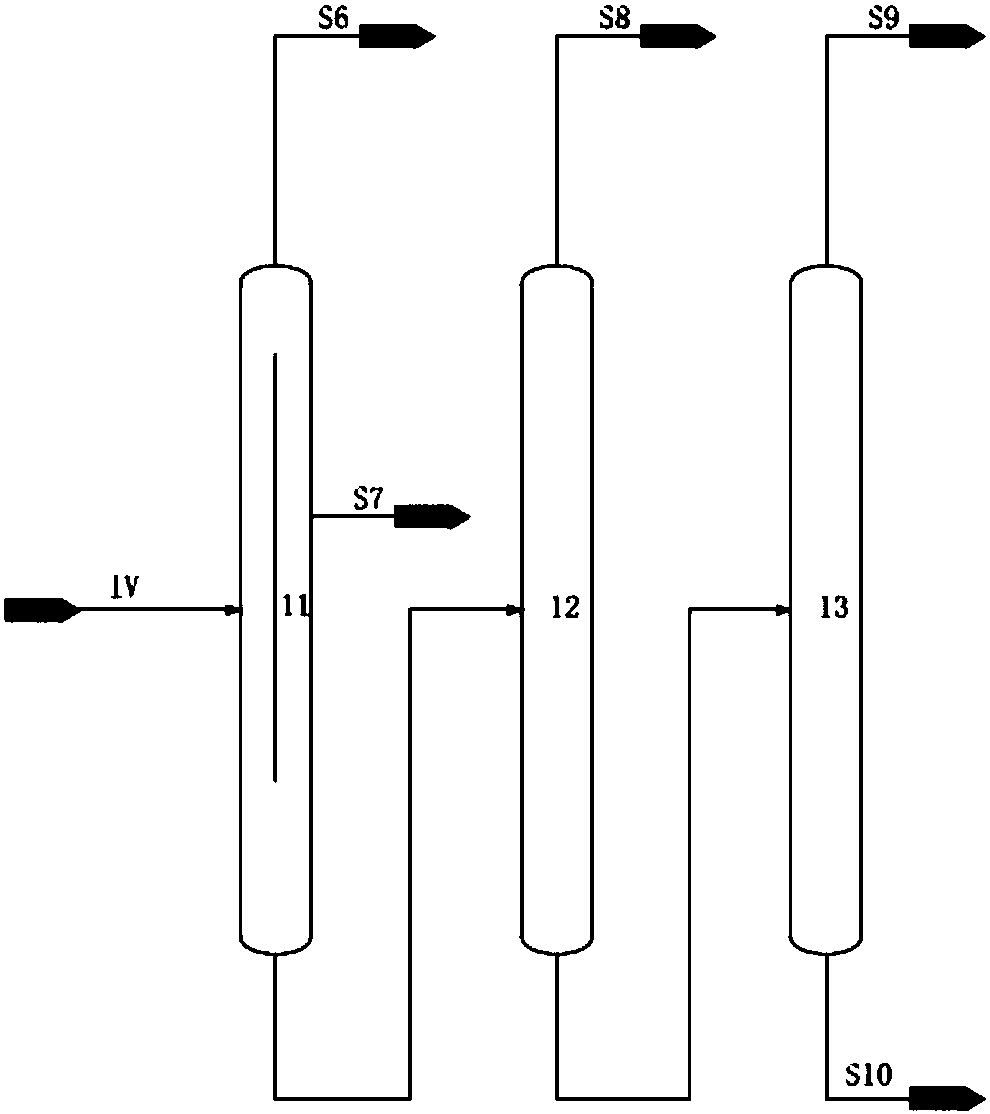

ActiveCN110229042AEasy to prepareSimple processDistillation purification/separationHydrocarbonsLiquid productIsohexanes

The invention provides a preparation method of high purity n-hexane. The method includes the steps of: a) subjecting reformate C5 oil and hydrogen to hydrogenation reaction under the action of a hydrogenation catalyst, and conducting C5 light component separation on a reaction liquid product to obtain a remaining heavy component; b) subjecting the remaining heavy component to isohexane separationto obtain a isohexane removed heavy component; and c) conducting n-hexane separation on the isohexane removed heavy component obtained in step b), thus obtaining high purity n-hexane. Compared with the prior art, the preparation method provided by the invention takes reformate C5 oil as the raw material, and adopts a specific process to prepare the high purity n-hexane. The preparation method provided by the invention has the advantages of simple process, low cost, no pollution, and long-term stable operation. The prepared high purity n-hexane has purity of 99% or above, and the product quality is stable.

Owner:SHANDONG JINGBO PETROCHEM

Process method for producing hexane by using raffinate oil

ActiveCN109704906AAvoid lostIncrease added valueHydrocarbon by isomerisationHydrocarbon by hydrogenationBenzeneIsohexanes

The invention relates to a process method for producing hexane by using raffinate oil, benzene and unsaturated hydrocarbons in the raffinate oil F are removed through a hydrogenation reactor so as toobtain a material flow I; the material flow I passes through a first rectifying tower and a second rectifying tower in sequence, a material flow III containing isohexane, n-hexane, methylcyclopentaneand benzene is obtained from a position above the feeding of the second rectifying tower so as to obtain a cyclohexane-containing C7 and above material flow V, the C6 component in the material flow Vis subjected to reaction in a trans-isomerization reactor, the obtained methylcyclopentane is recycled back to the first rectifying tower, the material flow III is subjected to isomerization reactionand separating to obtain the isohexane, the n-hexane, the methylcyclopentane and cyclohexane, wherein methylcyclopentane is circulated to the isomerization reactor. The method effectively solves the problem that the existing raffinate oil is low in comprehensive utilization rate, the n-hexane yield is low, the cyclohexane yield is low, hexane component is single, and added value of the product islow, and can be applied to industrial continuous production.

Owner:CHINA PETROLEUM & CHEM CORP +1

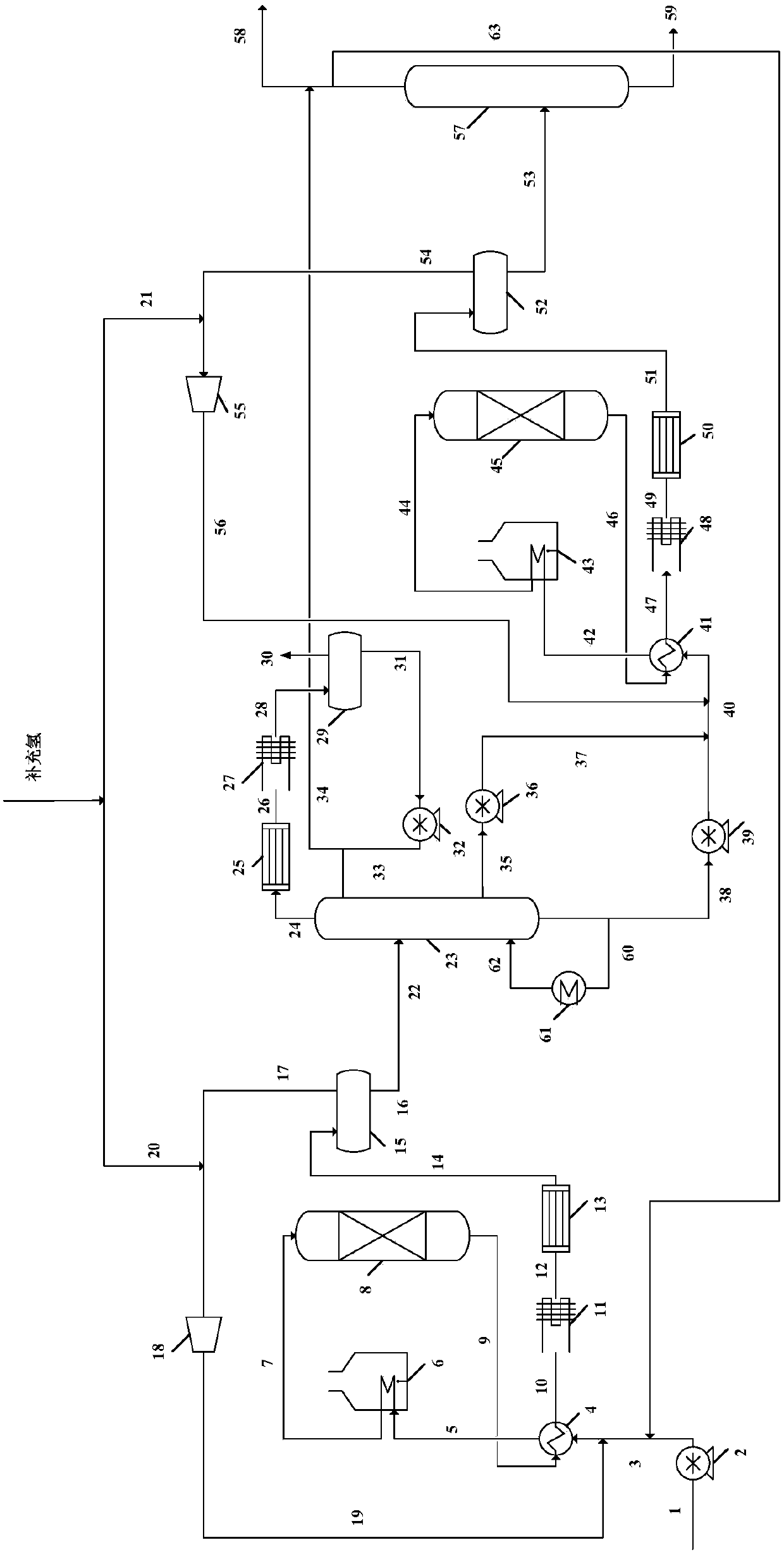

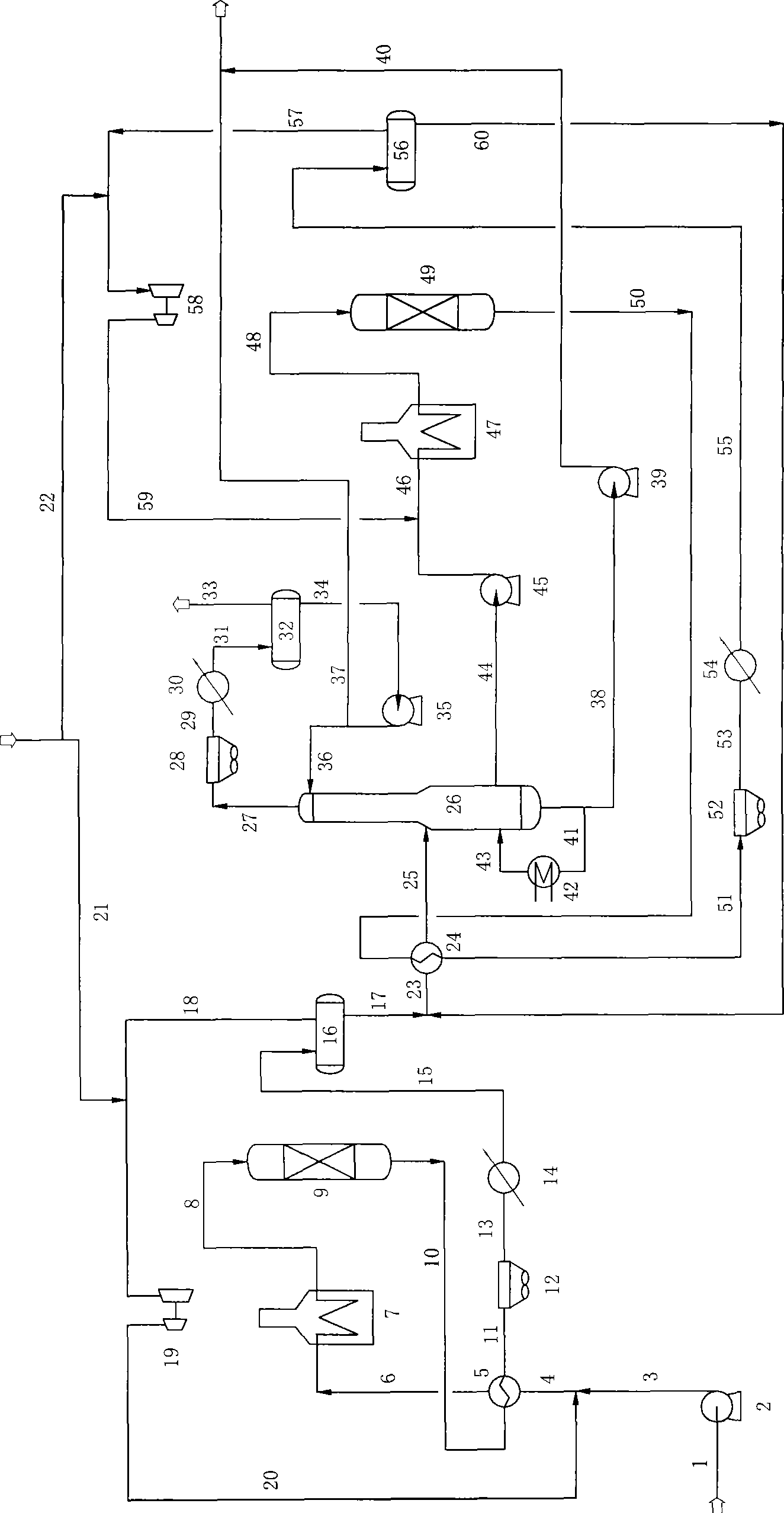

Monomer alkane refrigerant preparation device and method

ActiveCN105130733AHigh purityHigh yieldHydrocarbon by hydrogenationHydrocarbon purification/separationAlkaneSolvent

The invention provides a monomer alkane refrigerant preparation device. The technical scheme thereof is that the device mainly comprises an n-butane removal tower (1), a cyclopentane removal tower (2), an n-pentane removal tower (3), a propane removal tower (4), an iso-butane removal tower (5), an ortho-iso-pentane knockout tower (6), a propane-butane removal tower (7), a hydrogenation reactor (8), a material buffer tank (9), a No. 120 tower (10), an isohexane tower (11), a first extraction rectification column (12), a first solvent recovery tower (13), a second extraction rectification column (14), a second solvent recovery tower (15) and a No. 6 tower (16). The monomer alkane refrigerant preparation device has the beneficial effects that the whole device is low in energy consumption, less in three-waste discharge and flexible in product adaptation, so that equipment investment and operation risk are greatly reduced, and the convert ratio can reach 99.99 percent, and obtained propane, iso-butane and pentane products are high in purity and are ideal environment-friendly hydrocarbon refrigerants at present.

Owner:DONGYING JUNYUAN PETROLEUM TECH DEV CO LTD

Method for extracting garlic essential oil by using isohexane with assistance of ultrasonic waves

InactiveCN108424812AReduce energy consumptionImprove oil yieldEssential-oils/perfumesIsohexanesEvaporation

The invention discloses a method for extracting garlic essential oil by using isohexane with the assistance of ultrasonic waves. The method comprises the steps of crushing garlic, carrying out enzymolysis, carrying out ultrasonic extraction, carrying out steam distillation, carrying out extraction by using isohexane, carrying out dehydration treatment, and carrying out separation and evaporation to obtain garlic essential oil. The method has the advantages of low energy consumption and high oil yield, the isohexane is used as an extraction solvent and is safe and easy to recover, and the method is more suitable for industrial production.

Owner:广东润华药业有限公司

Defogging detergent

InactiveCN103834501AFast evaporationEasy to useOther chemical processesOrganic non-surface-active detergent compositionsIsohexanesHazardous substance

The invention relates to the technical field of a detergent, and particularly relates to a defogging detergent which consists of the following raw materials in percentage by weight: 25-35 percent of isohexane, 15-25 percent of neo-hexane and 45-60 percent of hexamethyldisiloxane. Compared with the existing detergent, the defogging detergent disclosed by the invention can be used for cleaning oil dirt and fingerprints and replacing the detergents added with harmful substances, such as whellote gas n-hexane, acetone and the like; a product cleaned by the defogging detergent is free of white points, watermarks and fog, smooth, easy to wipe, clean and bright; and moreover, the detergent is high in volatilization speed, environment-friendly, safe and odorless.

Owner:广东剑鑫科技股份有限公司

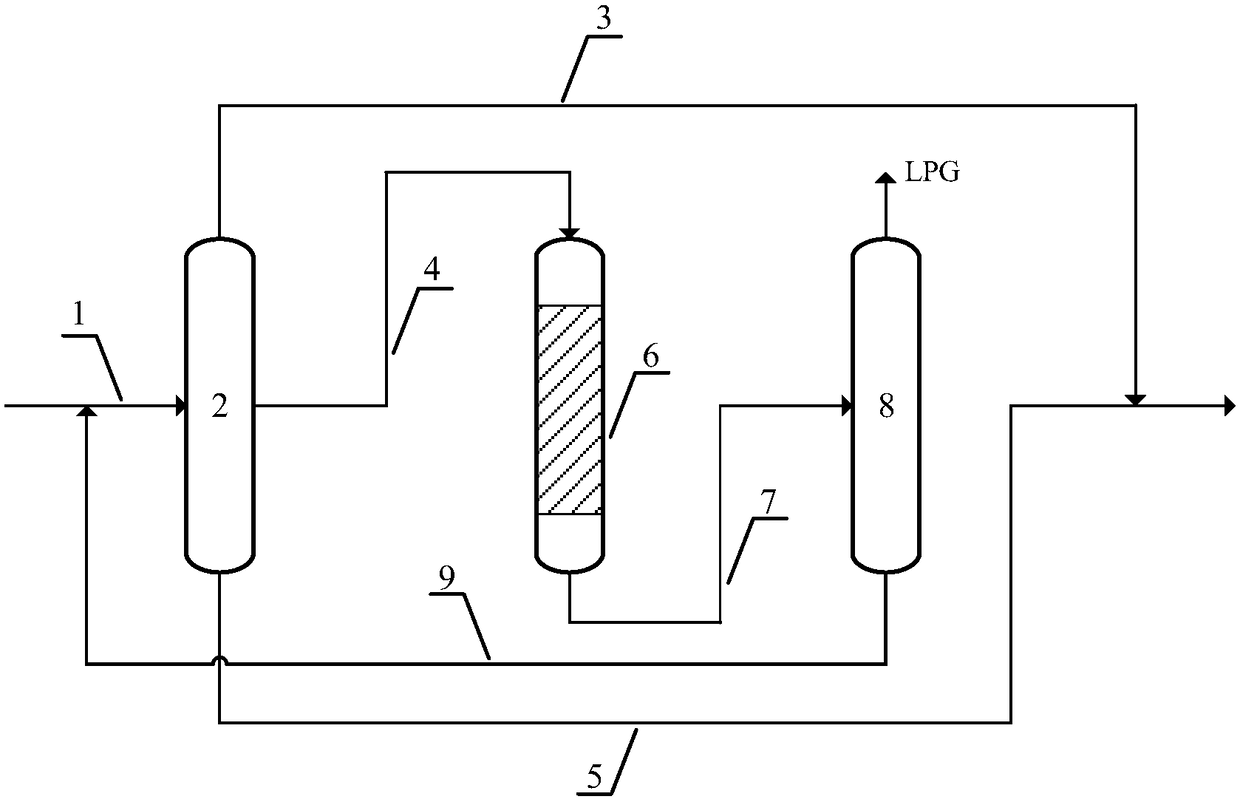

Method for producing high-octane-number gasoline from aromatic hydrocarbon raffinate oil

ActiveCN108624355ABoost octaneTreatment with hydrotreatment processesHydrocarbon oils treatment productsIsomerizationIsohexanes

The invention relates to a method for producing high-octane-number gasoline from aromatic hydrocarbon raffinate oil. The method comprises that aromatic hydrocarbon raffinate oil is fed into an isohexane removing tower (2), C7<+>-rich tower bottom components are discharged from the tower bottom, dimethylbutane-rich tower top components are discharged from the tower top, side stream components richin monomethylpentane and n-hexane are discharged from the side stream, the side stream components contact an isomerization catalyst, and an isomerization reaction is performed at a temperature of 120-280 DEG C under a pressure of 1.0-3.5 MPa according to a hydrogen / hydrocarbon molar ratio of 0.1-6.0. According to the present invention, with the method, the low-octane-number component is subjectedto the isomerization reaction so as to effectively improve the octane number of the aromatic hydrocarbon raffinate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and device for separating n-hexane, isohexane and benzene

ActiveCN103086823BDistillation purification/separationAdsorption purification/separationIsohexanesExtractive distillation

The invention relates to a method and a device for separating n-hexane, isohexane and benzene. The device comprises a light component removal unit, an isohexane separation unit, an n-hexane extractive distillation unit, a first solvent recovery unit, a benzene extractive distillation unit, a second solvent recovery unit and a solvent regeneration unit. The method comprises the following steps: removing impurities with a boiling point less than the boiling point of 2-methylpentane in mixed hydrocarbon raw materials such as raffinate oil, pyrolysis gasoline or straight-run gasoline and the like from an aromatics extraction device firstly, and then separating an isohexane product; separating a n-hexane product from other materials by using an extractive distillation method; and removing n-hexane materials, and carrying out separation on the obtained product so as to obtain a benzene product. The main components of the isohexane product produced by using the technique disclosed by the invention are 2-methylpentane and 3-methylpentane, and the total mass fraction of 2-methylpentane and 3-methylpentane is not less than 95%; n-hexane meets the national standard GB16629-2008, and the mass fraction is not less than 99%; and the benzene product meets the national standard GB3405-89.

Owner:TIANJIN UNIV

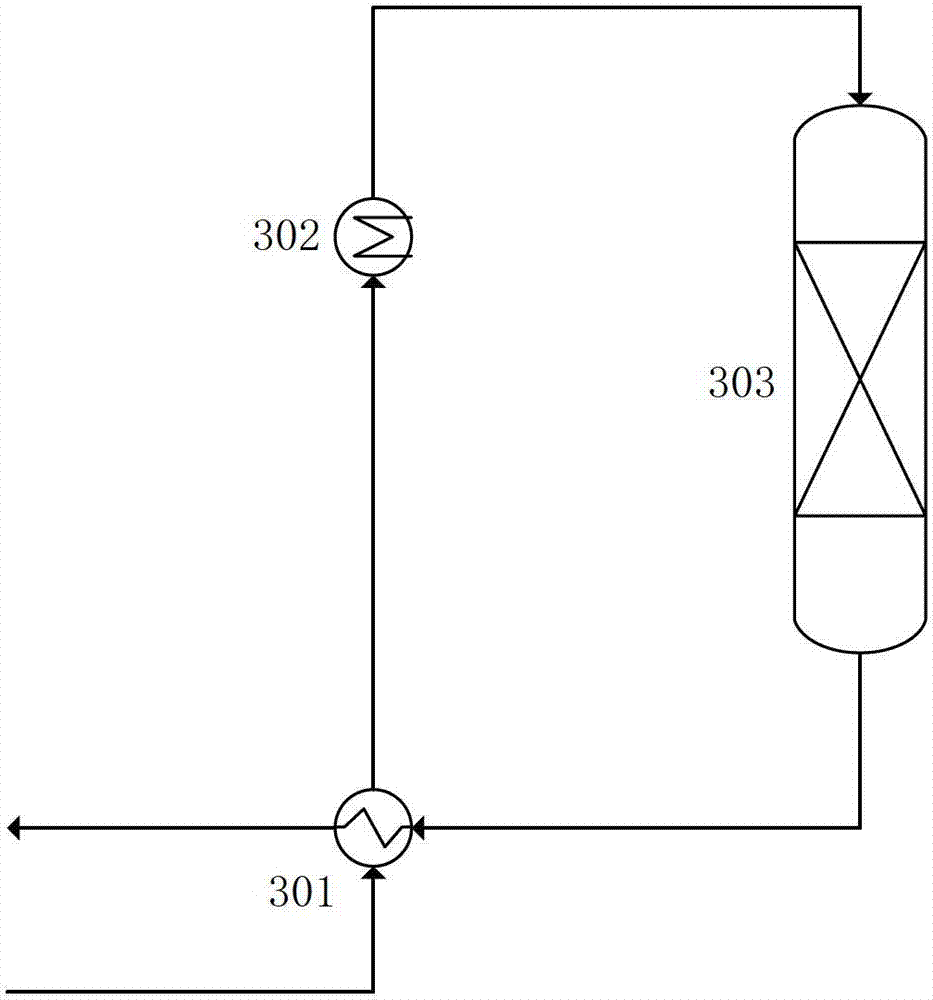

Thermal coupling system and method for extractive distillation of normal hexane, isohexane and benzene

ActiveCN103113179ALow costTake advantage ofDistillation purification/separationBulk chemical productionIsohexanesPlate heat exchanger

The invention relates to a thermal coupling method for extractive distillation of normal hexane, isohexane and benzene. A rectifying tower consists of a dehydrating tower, an isohexane tower, a normal hexane extractive distillation tower, a first solvent recovery tower, a benzene extractive distillation tower and a second solvent recovery tower. Residue of the second solvent recovery tower respectively exchange heat with fed materials of the dehydrating tower and the benzene extractive distillation tower. Residue of the first solvent recovery tower is a heating medium of a reboiler of the isohexane tower, and products at the tops of the normal hexane extractive distillation tower and the benzene extractive distillation tower enter an argil adsorbent bed via two plate heat exchangers which are of all-welded type, so that all counter-current operation is realized. One of the plate heat exchanger uses the material discharged from the argil adsorbent bed as a heating medium, and all stream heats are adequately utilized. According to the invention, the power energy of the rectifying unit is greatly reduced, the production cost of the normal hexane is lowered, and the market competitiveness is improved.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com