Environment-friendly solvent and partial monomer alkane production device and use method thereof

An environmentally friendly solvent and production device technology, used in hydrocarbon oil treatment products, chemical instruments and methods, catalysts, etc., can solve the problems of increased consumption of extractants, increased energy consumption and cost, and achieve less three waste emissions and reasonable design. Practical, uncertain effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

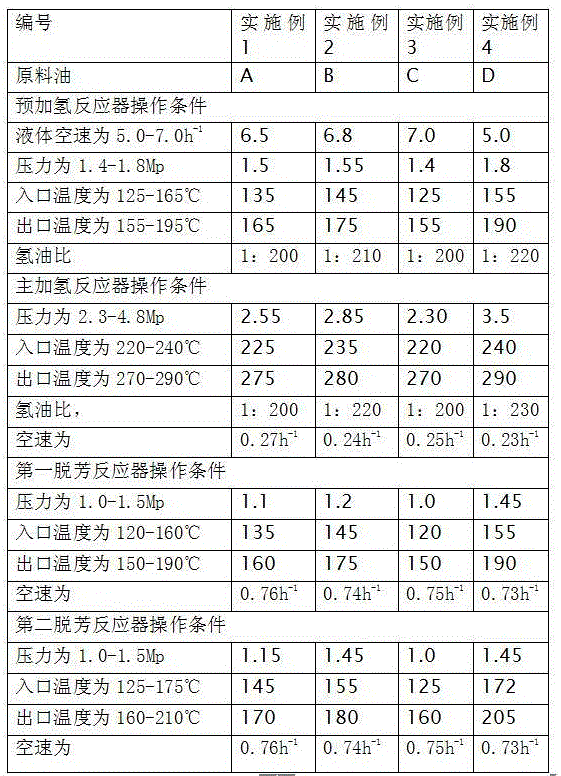

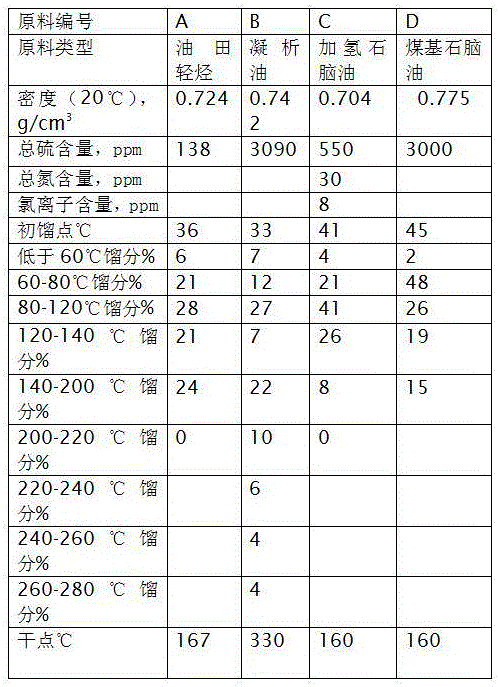

Embodiment 1

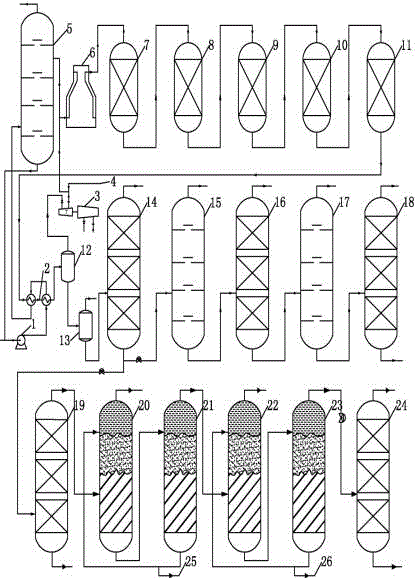

[0018] Example 1 (see image 3 )

[0019] The raw material A is pumped into the heat exchanger group for heat exchange and then enters the light hydrocarbon removal tower, and is heated to 135°C by the heating furnace to enter the reaction unit for deep hydrodesulfurization reaction, denitrogenation, dechlorination reaction and dearomatization saturation reaction; the reaction product enters The gas-liquid separation of the high-pressure separator, the obtained hydrogen-rich gas is the circulating hydrogen, and the obtained liquid phase fraction enters the rectification system through the low-pressure separator, and the solvent oil products of each fraction are separated. Through the rectification unit, the pentane foaming agent product and 30-60 ℃ petroleum ether product are rectified in the pentane rectification tower; the 6# plant extract with hexane as the main component is rectified in the hexane rectification tower Solvent and petroleum ether products at 60-90°C; in the...

Embodiment 2

[0020] Example 2 (see image 3 )

[0021] The raw material B is pumped into the heat exchanger group to exchange heat and then enters the light hydrocarbon removal tower, and the temperature is raised to 145°C through the heating furnace to enter the reaction unit for deep hydrodesulfurization reaction, denitrogenation, dechlorination reaction and dearomatization saturation reaction; the reaction product enters The gas-liquid separation of the high-pressure separator, the obtained hydrogen-rich gas is the circulating hydrogen, and the obtained liquid phase fraction enters the rectification system through the low-pressure separator, and the solvent oil products of each fraction are separated. Through the rectification unit, the pentane foaming agent product and 30-60 ℃ petroleum ether product are rectified in the pentane rectification tower; the 6# plant extract with hexane as the main component is rectified in the hexane rectification tower Solvent and petroleum ether product...

Embodiment 4

[0024] Embodiment 4 (see image 3 )

[0025] The raw material D is pumped into the heat exchanger group for heat exchange and directly mixed with hydrogen without going through the light hydrocarbon removal tower, and the temperature is raised to 155°C through the heating furnace to enter the reaction unit for deep hydrodesulfurization reaction, denitrogenation, dechlorination reaction and dearomatization saturation Reaction: The reaction product enters the high-pressure separator for gas-liquid separation, and the obtained hydrogen-rich gas is recycled hydrogen. The obtained liquid phase fraction enters the rectification system through the low-pressure separator, and the solvent oil products of each fraction are separated. Through the rectification unit, the pentane foaming agent product and 30-60 ℃ petroleum ether product are rectified in the pentane rectification tower; the 6# plant extract with hexane as the main component is rectified in the hexane rectification tower So...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com