Method for preparing high-purity isohexane solvent oil

A technology of isohexane and solvent oil, which is applied in the field of preparation of high-purity isohexane solvent oil, can solve the problem of small supply and achieve high activity, remarkable effect and excellent product properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

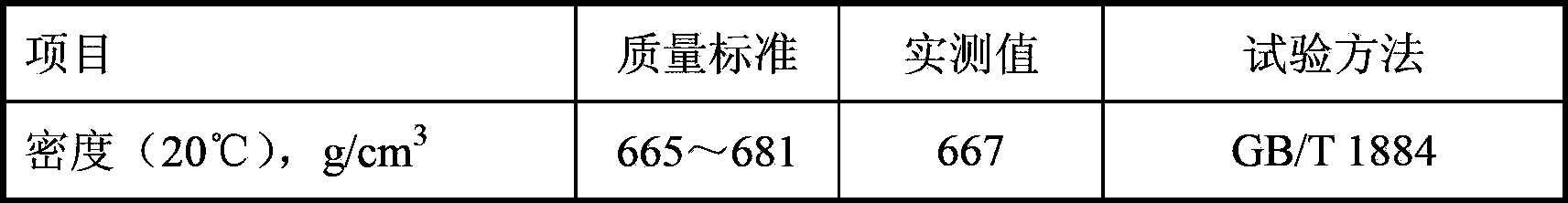

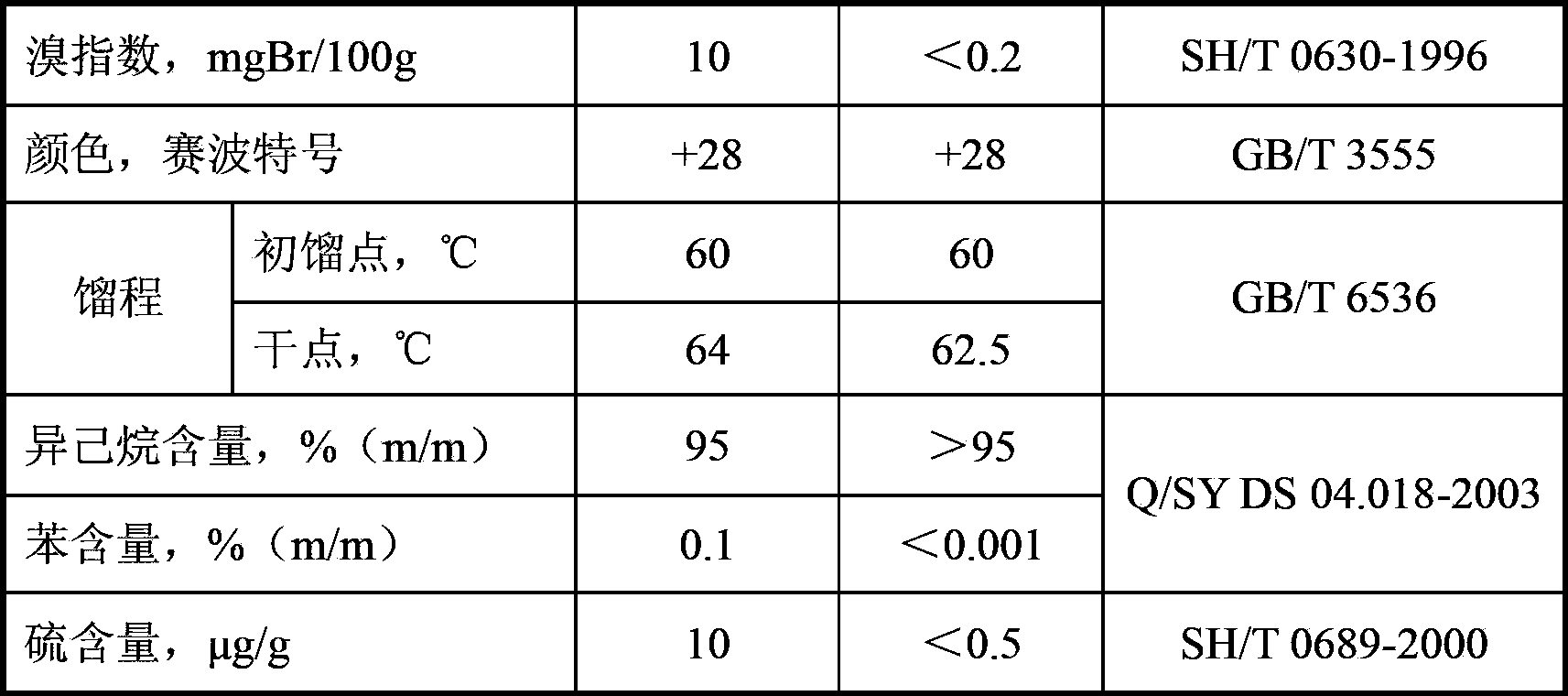

Examples

Embodiment Construction

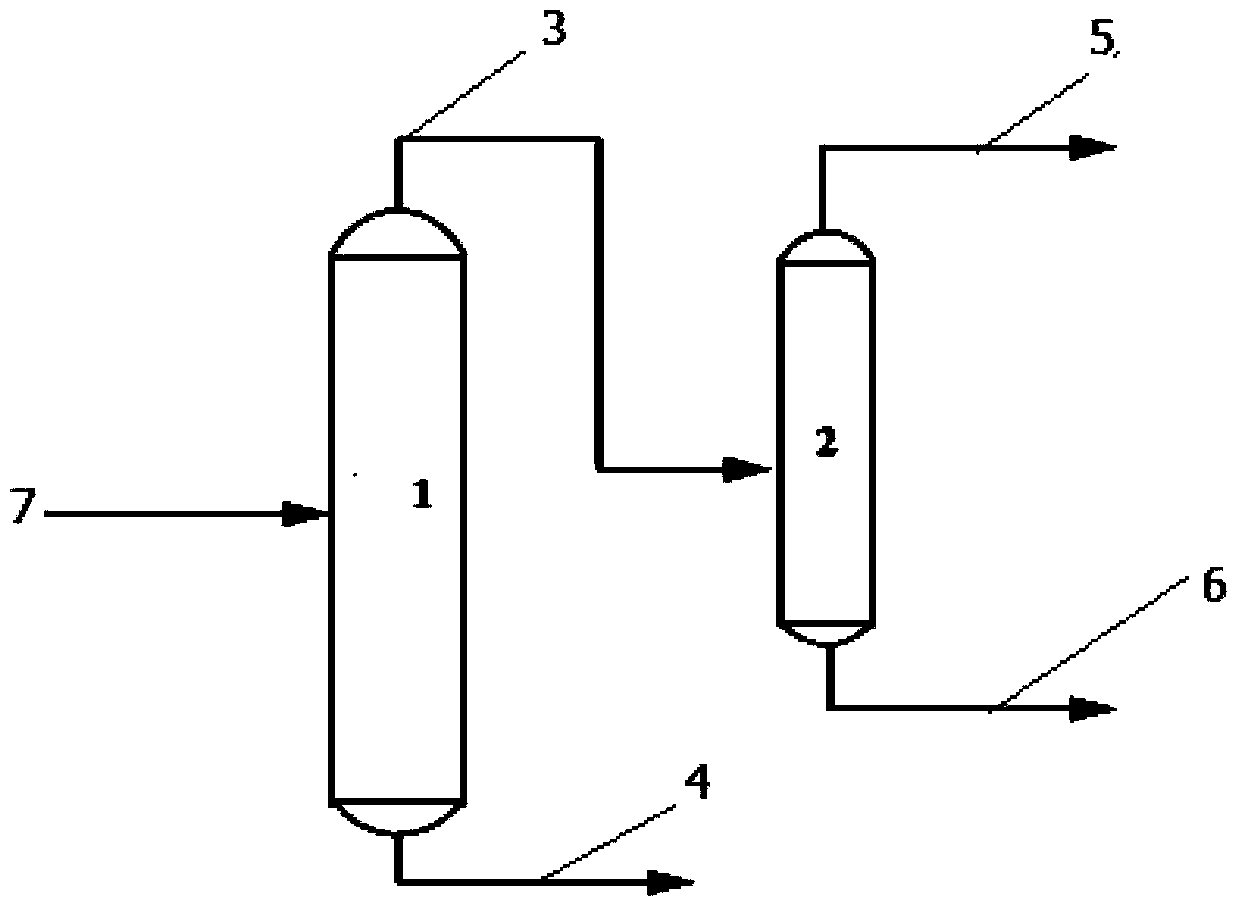

[0020] A preparation method for high-purity isohexane solvent oil, characterized in that:

[0021] (1), preparation of nickel-based catalyst

[0022] Add squash powder, nitric acid, phosphoric acid, and water to aluminum hydroxide dry powder for kneading, extrude into strips, dry at 120°C for 2 hours, and roast at 550°C for 4 hours to obtain a catalyst carrier; prepare a solution containing nickel and auxiliary metals, etc. The catalyst was impregnated on the alumina support, dried at 120°C for 2 hours, and calcined at 500°C for 4 hours.

[0023] The active metal content of the catalyst is 25m%~50m% in terms of NiO, the preferred metal content is 30m%~35m%, the shape is a clover strip Ф1.3×3~8mm, and the bulk density is 0.9~1.1g / ml. The surface area is 120~160cm 2 / g, strength ≥ 220N / cm.

[0024] (2) Hydrofining of reformed raffinate to remove sulfur, olefins and aromatics

[0025] The isohexane content in the reformed raffinate is 18%-35%, the distillation range is ≤130°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com