Monomer alkane refrigerant preparation device and method

A preparation device and refrigerant technology, applied in chemical instruments and methods, hydrogenation hydrocarbon production, hydrocarbon purification/separation, etc., can solve the difficulty of separation of butene and isobutane, large investment in rectification process equipment, and reaction energy consumption High-level problems, to achieve the effect of reducing equipment investment and operation risk, flexible product adjustment, and increasing alkane yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

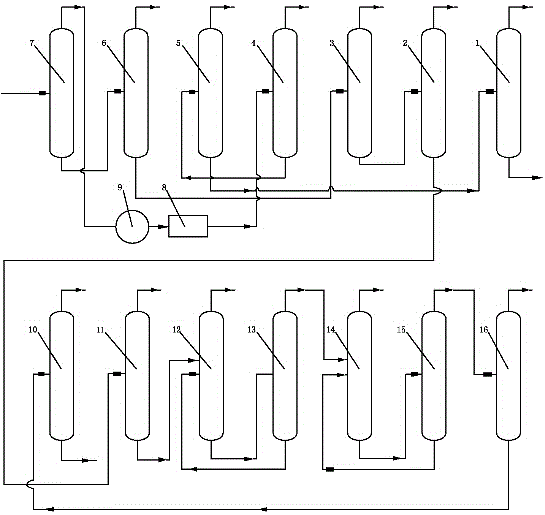

[0010] Such as figure 1 As shown, a monomer alkane refrigerant preparation device and method mainly consists of a de-n-butanizer 1, a de-cyclopentanizer 2, a de-n-pentanizer 3, a de-propanizer 4, a de-isobutanizer 5, n-isopentane separation tower 6, depropanization butane tower 7, hydrogenation reactor 8, raw material buffer tank 9, 120# tower 10, isohexane tower 11, first extractive distillation tower 12, first solvent recovery tower 13 , the second extractive distillation tower 14, the second solvent recovery tower 15 and 6# tower 16 constitute; Butane tower 5, n-isopentane separation tower 6, and depropanizer butanizer 7 are arranged horizontally from right to left. The buffer tank 9, the hydrogenation reactor 8 are connected in series with the middle part of the depropanizer 4, the bottom of the tower is connected in series with the n-isopentane separation tower 6, the bottom of the n-isopentane separation tower 6 is connected in series with the de-n-pentane tower 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com