Method for producing isomerized gasoline and aromatic hydrocarbon from alkane

A technology of isomerization and alkanes, applied in chemical instruments and methods, production of liquid hydrocarbon mixtures, petroleum industry, etc., to achieve the effect of reducing separation costs and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

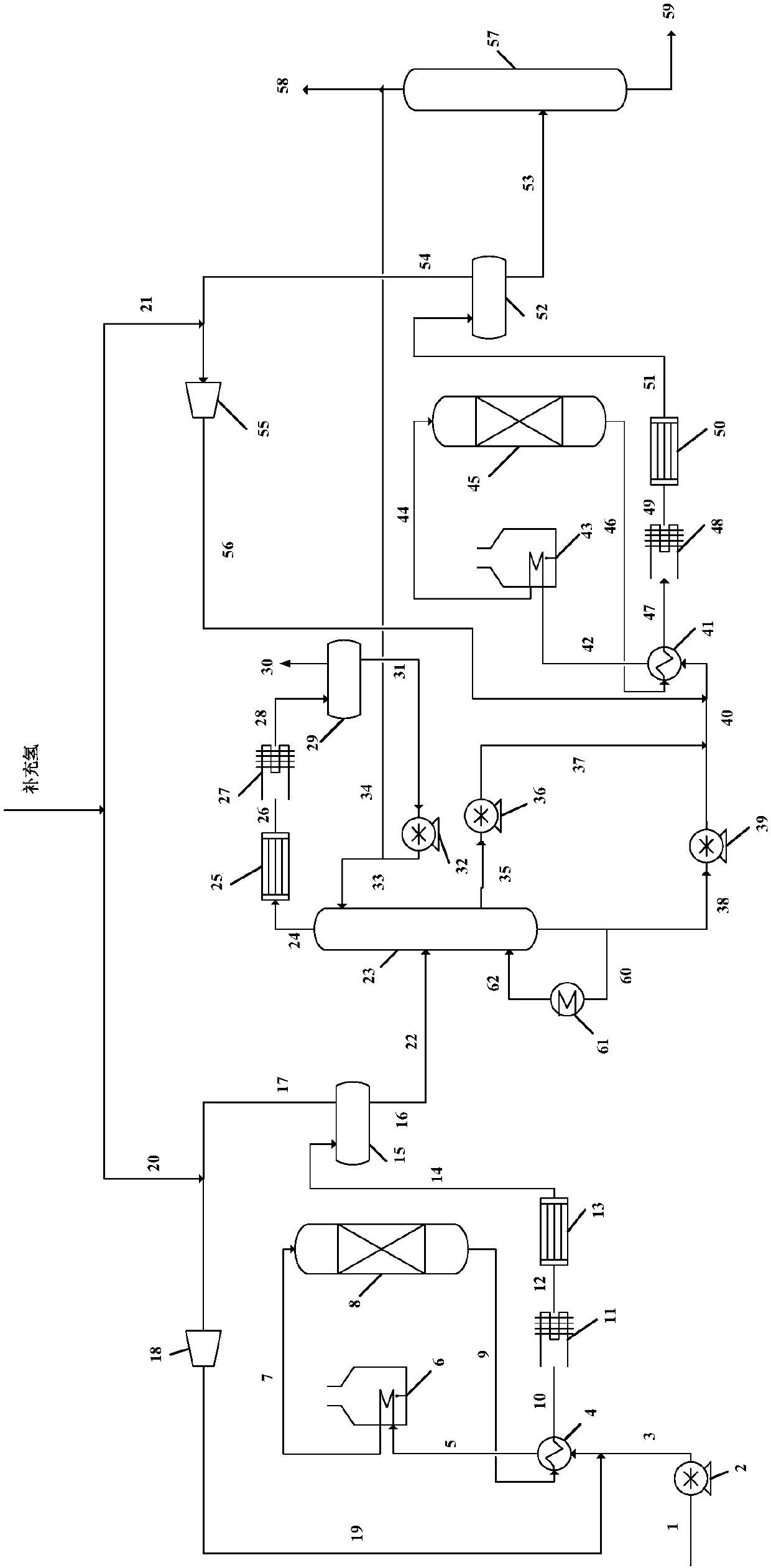

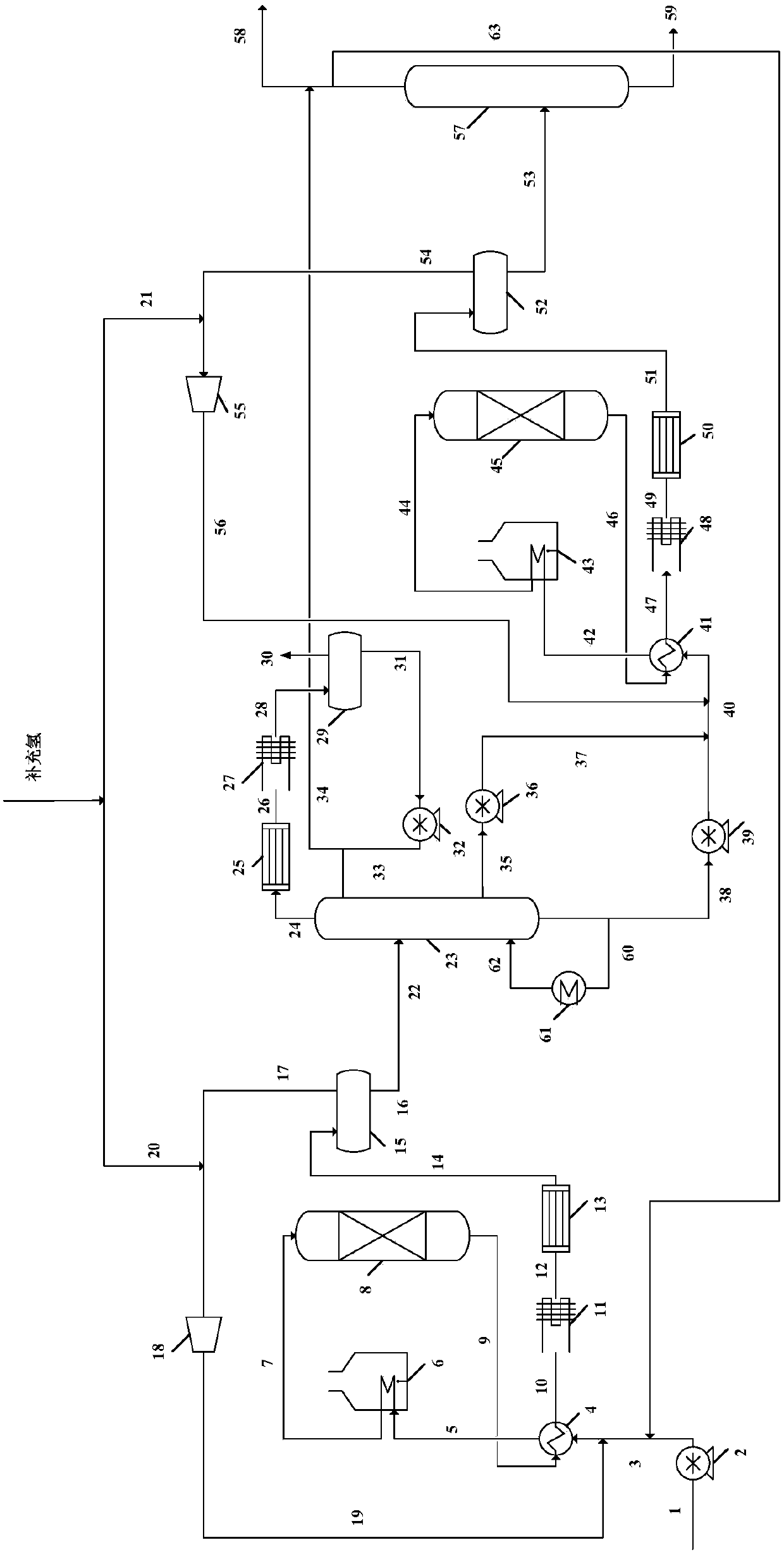

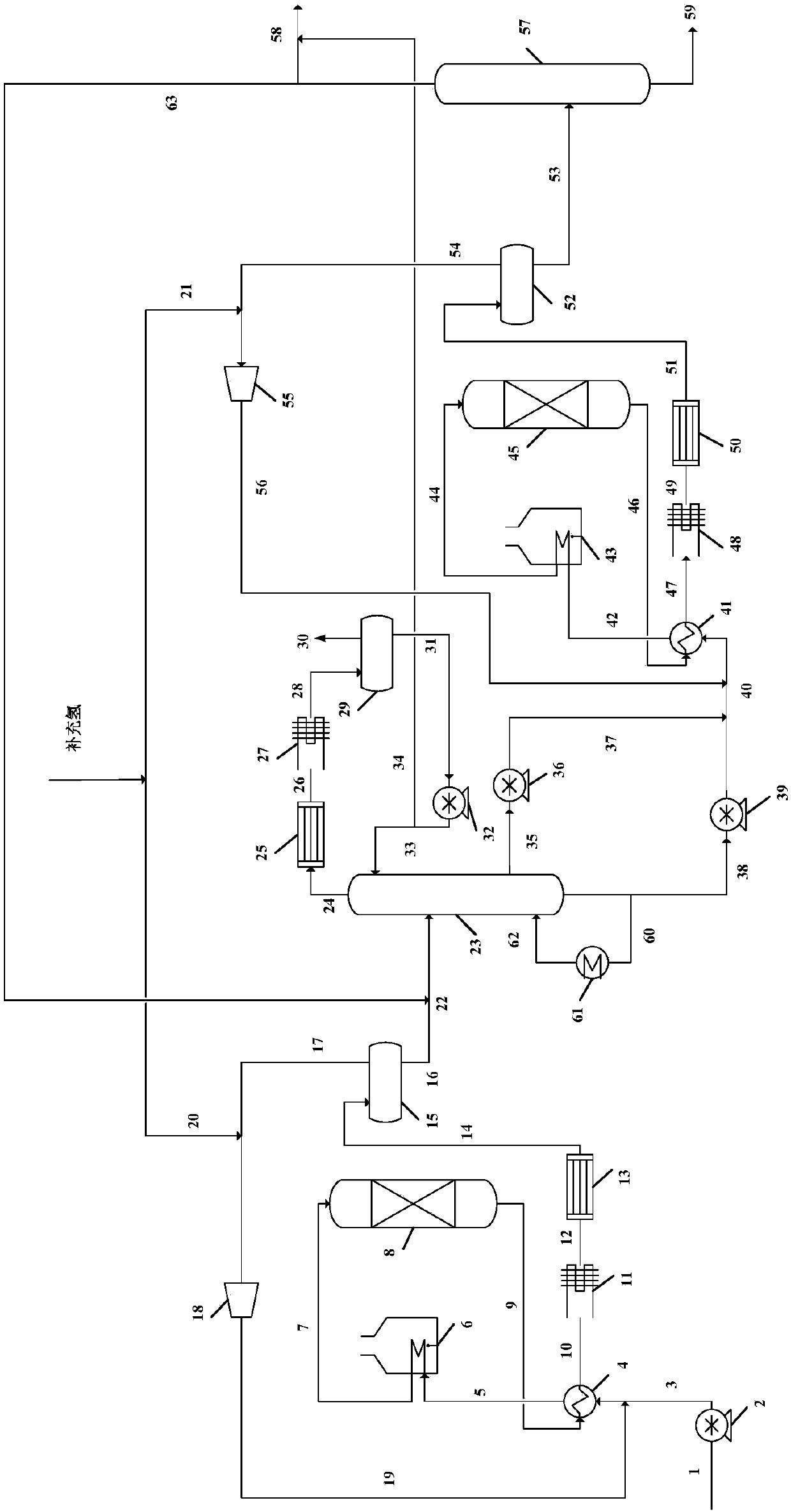

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of zeolite provided by the invention comprises the following steps:

[0032] (1) Mix the directing agent, inorganic base, aluminum source, silicon source and water to obtain a reaction mixture gel. In the reaction mixture gel, the molar ratio of each substance is (2.0-4.0) inorganic base: Al 2 o 3 : (5~20) SiO 2 : (60~300)H 2 O; the composition of the directing agent is (5~10)K 2 O: Al 2 o 3 : (26~40) SiO 2 : (300~600)H 2 O, the inorganic base is selected from potassium hydroxide or a mixture of potassium hydroxide and sodium hydroxide,

[0033] (2) Perform static hydrothermal crystallization of the above reaction mixture gel at 100-200°C for 10-120 hours, during which there is at least one intermittent stirring time, the intermittent stirring time is 0.1-3.0 hours, and the solid after the crystallization reaction Wash and dry.

[0034] The step (1) of the above method is the preparation of the reactant gel. During the preparation process...

example 1

[0054] Prepare Pt-Cl / Al according to CN104549376A example 1 method 2 o 3 low temperature isomerization catalyst.

[0055] (1) Preparation of alumina carrier

[0056] Take 100 grams of aluminum hydroxide powder (SB, produced by Condea, Germany, with an alumina content of 85% by mass) and an appropriate amount of deionized water to make the liquid / solid mass ratio 1:1.6, and add 2 mL of it under stirring with a volume ratio of 1: 1 of dilute nitric acid, extrusion molding, drying at 120°C for 2 hours, and calcining at 550°C for 4 hours to obtain γ-alumina carrier.

[0057] (2) Impregnated platinum

[0058] The gamma-alumina carrier prepared in step (1) is impregnated with a mixture of chloroplatinic acid, hydrochloric acid and trichloroacetic acid prepared in a predetermined amount, and the amount of platinum contained in the mixture should make the prepared catalyst reach the required The platinum content, the amount of hydrochloric acid and trichloroacetic acid are respect...

example 2

[0062] According to CN99105790.2 example 1 method to prepare zeolite type isomerization catalyst.

[0063] (1) Preparation of composite carrier

[0064] Take 100 grams of sodium mordenite with a silica / alumina molar ratio of 11.3 and 800 milliliters of 1 mol / liter NH 4 Exchange the Cl solution at 90-95°C for 3 hours, filter, wash the obtained solid with deionized water, dry at 120°C for 3 hours, repeat the operation twice, then exchange it with 800 ml of 1 mol / L hydrochloric acid at 90-95°C for 3 hours, and filter , washed with deionized water until the filtrate was neutral, and roasted at 600°C for 4 hours to prepare a hydrogen-type mordenite with a sodium content of 0.03% by mass and a silica / alumina molar ratio of 23.5.

[0065] Take 100 g of sodium Beta zeolite with a silica / alumina molar ratio of 28.6, and prepare hydrogen Beta zeolite with a sodium content of 0.03% by mass according to the above-mentioned ammonium exchange method.

[0066] Mix the above-mentioned hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com