Method for preparing high-purity beta-carotene from green tea

A carotene and green tea technology, applied in the field of extraction and purification of β-carotene, can solve the waste of biological resources and other problems, and achieve the effects of simple equipment, expanded development and utilization prospects, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

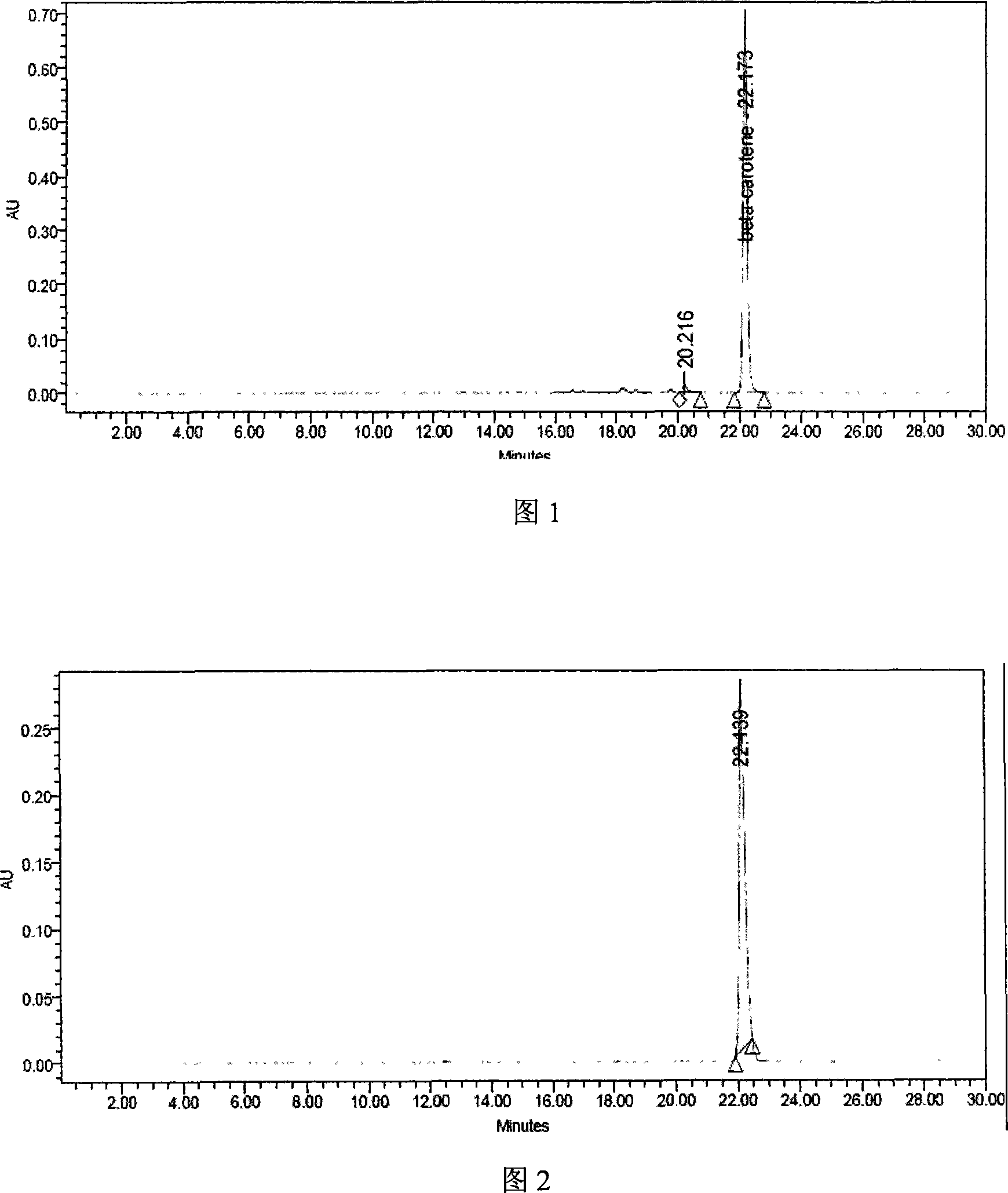

Image

Examples

Embodiment 1

[0017] (1) Take the low-grade green tea slices collected in summer from the tea production area in Hangzhou, Zhejiang, and grind them mechanically to 200 mesh at room temperature. The green tea powder was extracted with 60% aqueous ethanol (g / ml, 1:10) at 25° C. for 5.0 hours and stirred (stirring speed: 150 r / min). Let stand, filter, and dry the filter residue under reduced pressure;

[0018] (2) The filter residue in step (1) was extracted with n-hexane (g / ml, 1:12) at 28°C for 6 hours, stirred (stirring speed: 200r / min), left standing, filtered, and the filtrate was freeze-dried Concentrate to 1 / 3 of the original volume to obtain crude extract of green tea β-carotene;

[0019] (3) The green tea β-carotene crude extract obtained in step (2) is subjected to silica gel column chromatography, the eluent is ethyl acetate and n-hexane, and the elution gradient sequence is: 1.0:9.0; 2.0:8.0; 3.0:7.0; 3.5: 6.5 (ethyl acetate: n-hexane, V: V), the flow rate is 15ml / min, the efflue...

Embodiment 2

[0021] (1) Take the low-grade green tea flakes collected in autumn from the Kaihua tea production area in Zhejiang, and grind them mechanically to 300 mesh at room temperature. The green tea powder was extracted with a mixed solution containing ethanol, methanol and water (1:1:0.8) at 18° C. for 2.5 hours and stirred (stirring speed: 150 r / min). Let it stand, filter, and dry the filter residue under reduced pressure. The mass volume ratio (g / ml) of green tea powder and above-mentioned extracting solution is 1: 7.5;

[0022] (2) The filter residue in step (1) was extracted with n-hexane and acetone (1:1) at 22°C for 3 hours, stirred (stirring speed: 200r / min), allowed to stand, filtered, and the filtrate was freeze-dried and concentrated to 1 / 3 of the original volume to obtain crude extract of green tea β-carotene;

[0023] (3) Aluminum oxide column chromatography on the green tea β-carotene crude extract obtained in step (2), the eluent is chloroform and isohexane, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com