Thermal coupling system and method for extractive distillation of normal hexane, isohexane and benzene

A technology for extractive distillation and extractive distillation column, which is applied in the field of reducing the heat coupling system of n-hexane, isohexane and benzene extractive distillation, can solve the problems of low product purity and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

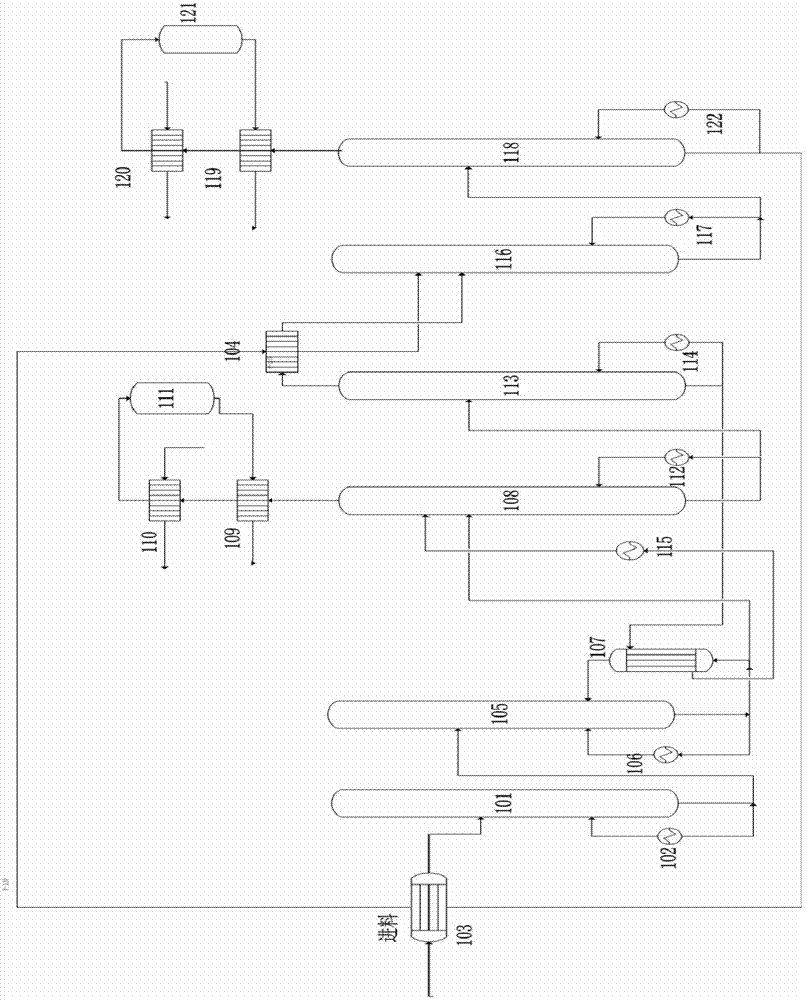

[0012] Several connections of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0013] A thermal coupling system for n-hexane, isohexane and benzene extraction and rectification system, comprising light removal tower 101, isohexane purification tower 105, n-hexane rectification tower 108, first solvent recovery tower 113, and benzene extraction and rectification tower 116 It is composed of the second solvent recovery tower 118; each tower bottom is provided with a reboiler; it is characterized in that a feed preheater 103 is provided before the light removal tower 101, and the second solvent recovery tower 118 tower kettle and the light removal tower Feed preheater 103, feed preheater 104 and benzene extractive distillation tower 116 are connected in sequence; The tower still of 113, the reboiler 107 of isohexane purification tower, the solvent cooler 115 of n-hexane rectification tower and the n-hexane rectificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com