Production method for high-purity n-hexane

A production method and technology of n-hexane, which is applied in the production field of high-purity n-hexane, can solve problems such as acid corrosion and oxidation reaction, and achieve the effects of reasonable energy consumption, high product purity, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

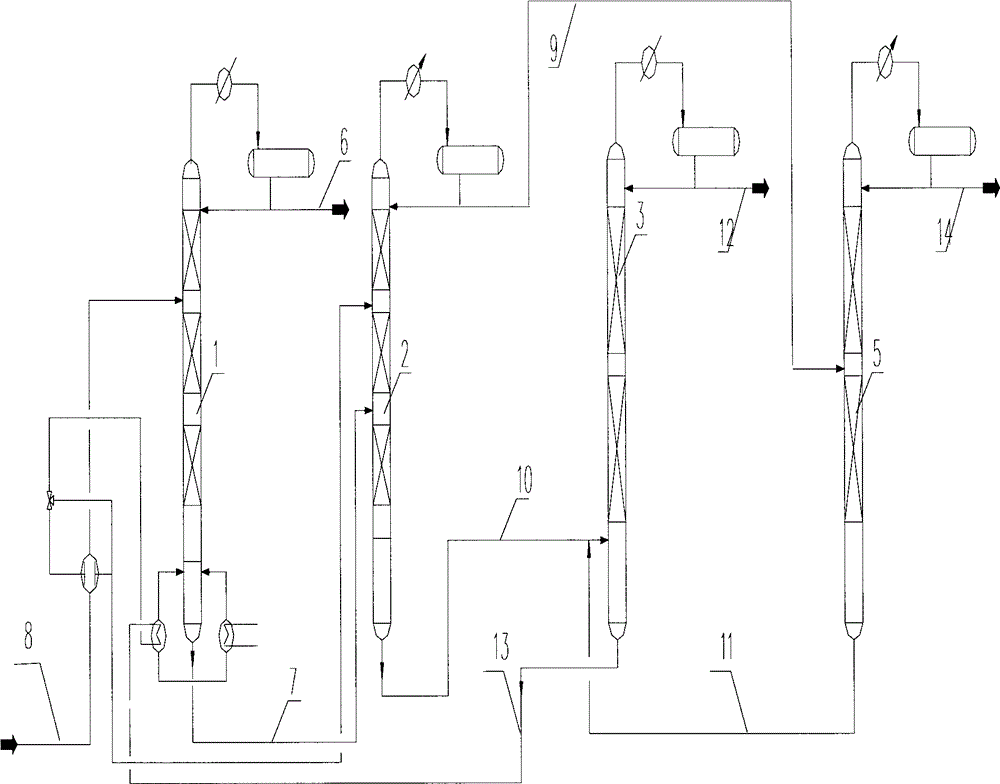

Embodiment 1

[0029]The crude hexane after reforming raffinate was hydrogenated to remove impurities and separated was used as raw material. The composition of the raw material is shown in Table 1. After rectification and separation in the deisohexane tower 1, the composition of the tower top component and the tower bottom component is shown in Table 2. The theoretical plate number of the deisohexane tower 1 is 90, the operating pressure (table) is 0.06MPa, and the tower top temperature is 79°C. The temperature at the bottom of the tower is 95°C, the light and crude n-hexane is removed and enters the middle and lower part of the extractive distillation tower 2, and the circulating solvent dioctyl phthalate enters the middle and upper part of the extractive distillation tower 2 for extractive distillation operation, and the top product Be normal hexane, the product at the bottom of the tower is a rich solvent, the composition is shown in Table 3, the number of theoretical plates of the extrac...

Embodiment 2

[0040] The crude hexane obtained by hydrogenating the reformed raffinate to remove impurities and then separated was used as the raw material, and the composition of the raw material was the same as that in Example 1. Through rectifying separation of deisohexane tower 1, the composition of tower top component and tower bottom component is shown in Table 5, and deisohexane tower 1 operating conditions: theoretical plate number 75, operating pressure (table) 0.05MPa, tower top temperature 78°C, the temperature at the bottom of the tower is 92°C, light and crude n-hexane enters the middle and lower part of the extractive distillation tower 2, and the circulating solvent (DOP) enters the middle and upper part of the extractive distillation tower 2 for extractive distillation, and the top product is Normal hexane, the product at the bottom of the tower is a rich solvent, the composition is shown in Table 6, the number of theoretical plates of the extractive distillation tower 2 is 5...

Embodiment 3

[0049] The crude hexane obtained by hydrogenating the reformed raffinate to remove impurities and then separated was used as the raw material, and the composition of the raw material was the same as that in Example 1. Through rectifying separation of deisohexane tower 1, the composition of tower top component and tower bottom component is shown in Table 8, and deisohexane tower 1 operating conditions: theoretical plate number 80, operating pressure (table) 0.1MPa, tower top temperature 87°C, the temperature at the bottom of the tower is 100°C, light and crude n-hexane is removed and enters the middle and lower part of extractive distillation tower 2, and the circulating solvent (DOP) enters the middle and upper part of extractive distillation tower 2 for extractive distillation operation, and the top product is High-purity n-hexane, the product at the bottom of the tower is a rich solvent, the composition is shown in Table 9, the number of theoretical plates of the extractive d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com