Process method for producing hexane by using raffinate oil

A process method and raffinate oil technology, applied in chemical instruments and methods, hydrocarbon purification/separation, hydrocarbons and other directions, can solve the problem of low comprehensive utilization of raffinate oil, single hexane component, and low n-hexane yield and other problems to avoid losses and increase added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

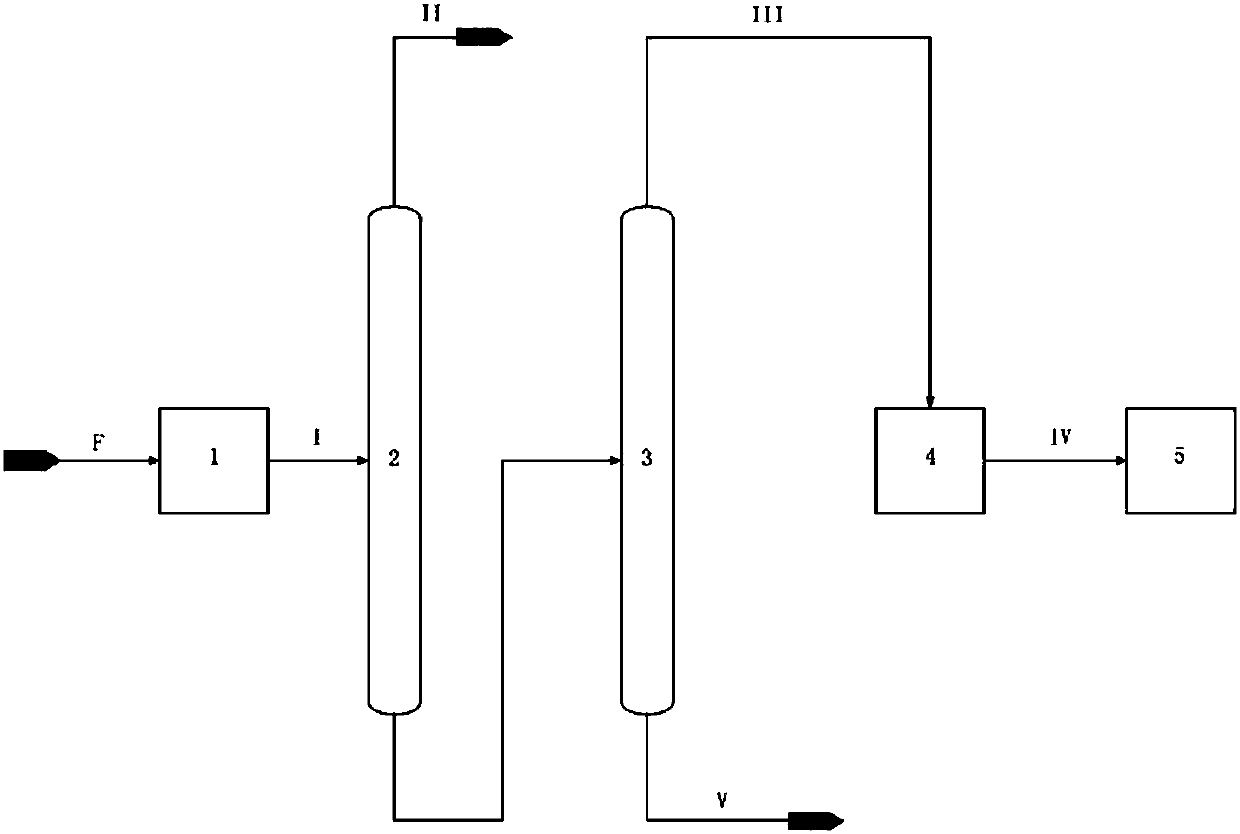

[0046] according to figure 1 Shown is a process for producing hexane by utilizing raffinate oil.

[0047] The raffinate oil F containing 20wt% isohexane, 15wt% normal hexane, 20wt% methylcyclopentane, 15wt% cyclohexane and 0.1wt% benzene is removed benzene and unsaturated hydrocarbons through a hydrogenation reactor to obtain stream I , Stream I passes through the first rectification tower and the second rectification tower in turn, and stream III containing isohexane, n-hexane, methylcyclopentane and benzene is obtained from the position above the second rectification feed, and stream III is obtained from the position below the feed The C7 and above component stream V containing cyclohexane, the C6 component in the stream V passes through the anti-isomerization reactor, and the methylcyclopentane obtained by the reaction is recycled back to the first rectification tower, and the stream III is subjected to the isomerization reaction The device obtains stream IV containing iso...

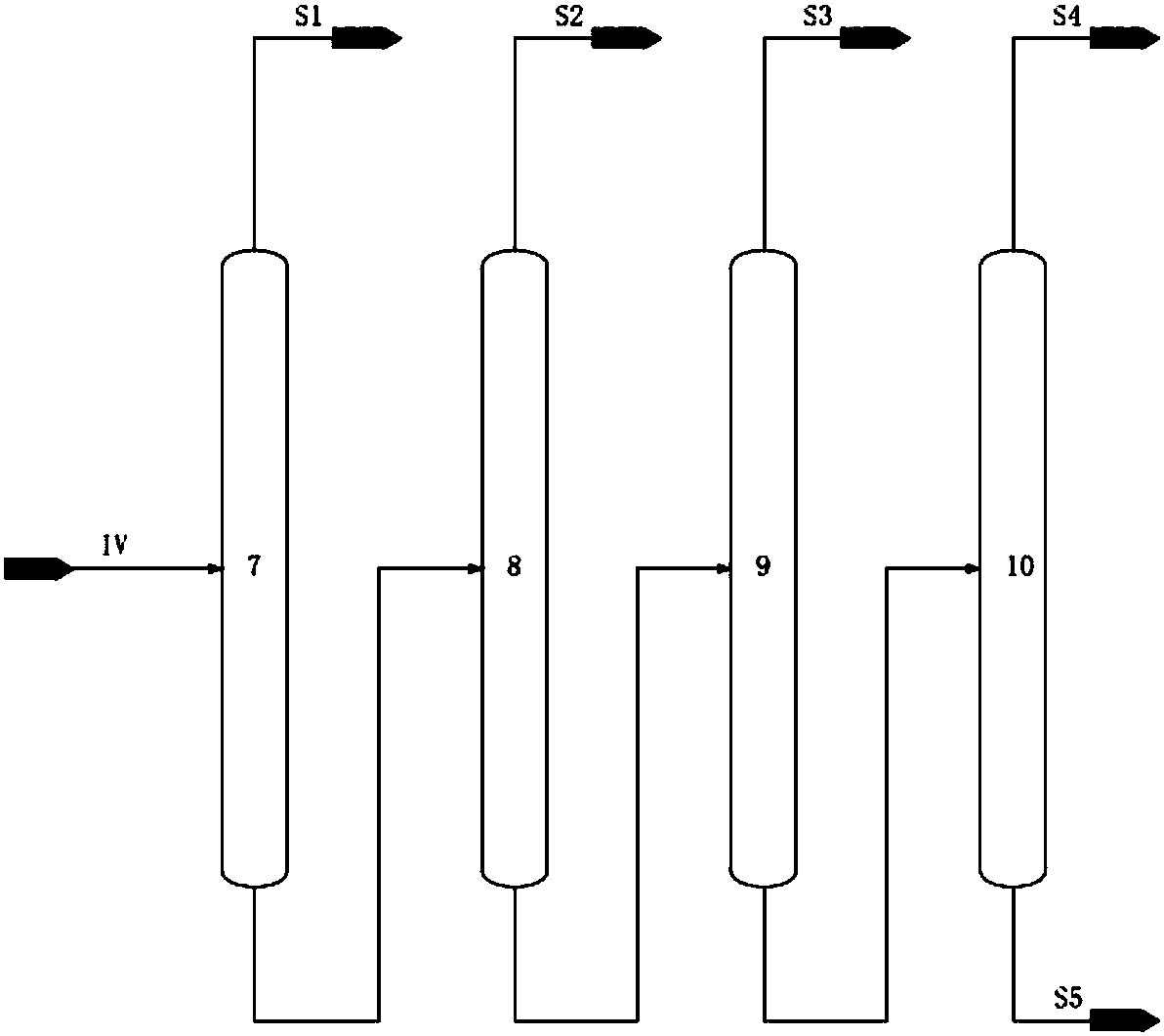

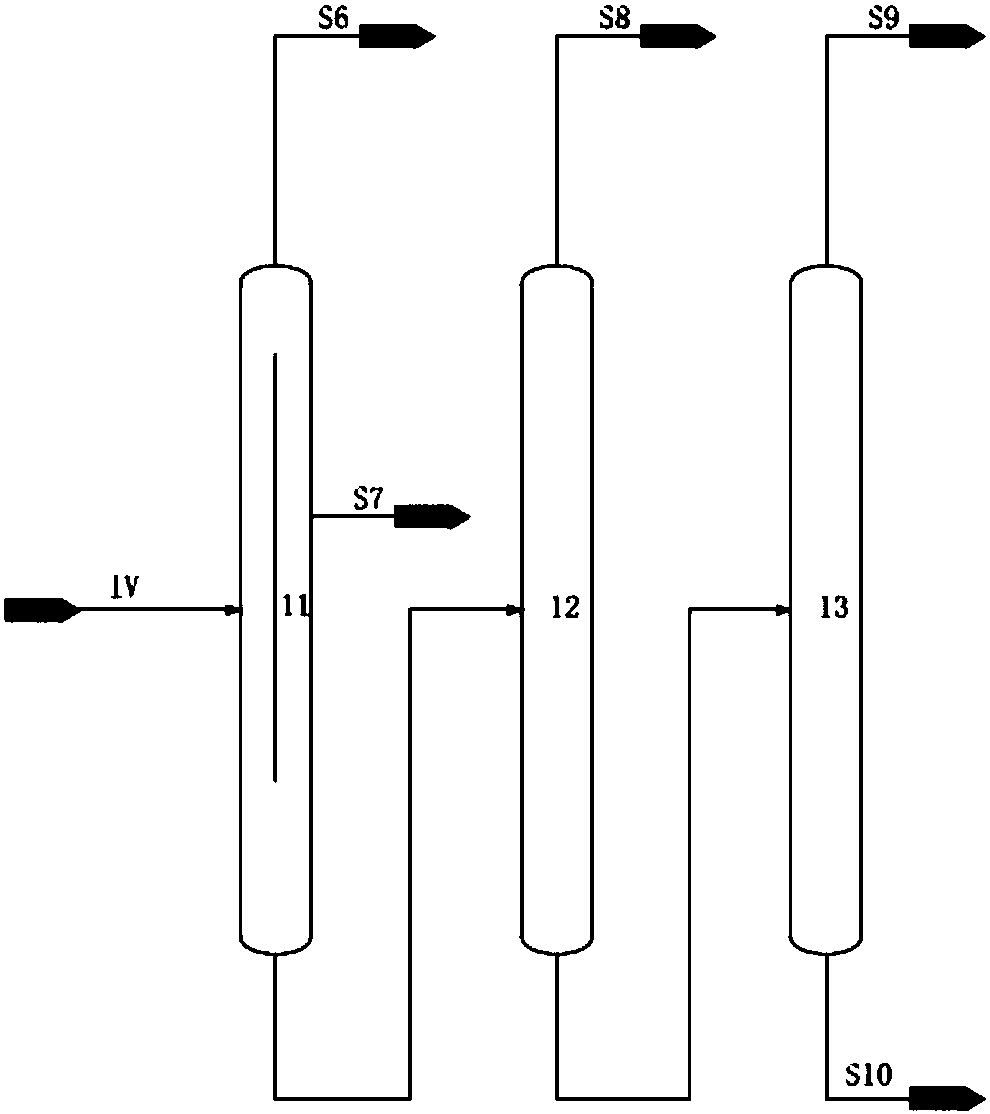

Embodiment 2

[0053] Implementation is similar to Example 1. The raffinate oil F containing 20wt% isohexane, 15wt% normal hexane, 20wt% methylcyclopentane, 15wt% cyclohexane and 0.1wt% benzene is removed benzene and unsaturated hydrocarbons through a hydrogenation reactor to obtain stream I , Stream I passes through the first rectification tower and the second rectification tower in turn, and stream III containing isohexane, n-hexane, methylcyclopentane and benzene is obtained from the position above the second rectification feed, and stream III is obtained from the position below the feed The C7 and above component stream V containing cyclohexane, the C6 component in the stream V passes through the anti-isomerization reactor, and the methylcyclopentane obtained by the reaction is recycled back to the first rectification tower, and the stream III is subjected to the isomerization reaction The device obtains stream IV containing isohexane, n-hexane, methylcyclopentane, and cyclohexane, and s...

Embodiment 3

[0061] Implementation is similar to Example 1. The raffinate oil F containing 20wt% isohexane, 15wt% normal hexane, 20wt% methylcyclopentane, 15wt% cyclohexane and 0.1wt% benzene is removed benzene and unsaturated hydrocarbons through a hydrogenation reactor to obtain stream I , Stream I passes through the first rectification tower and the second rectification tower in turn, and stream III containing isohexane, n-hexane, methylcyclopentane and benzene is obtained from the position above the second rectification feed, and stream III is obtained from the position below the feed The C7 and above component stream V containing cyclohexane, the C6 component in the stream V passes through the anti-isomerization reactor, and the methylcyclopentane obtained by the reaction is recycled back to the first rectification tower, and the stream III is subjected to the isomerization reaction The device obtains stream IV containing isohexane, n-hexane, methylcyclopentane, and cyclohexane, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com