Process method for extracting normal hexane and isohexane from crude hexane

A process method and technology of crude hexane, which is applied in the field of petrochemical separation, can solve the problems of difficulty in obtaining high-purity n-hexane products, high energy consumption of precision rectification, and high production costs, and achieves remarkable benzene removal effect and simple production process , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

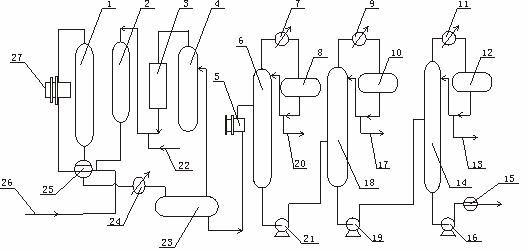

[0024] The technical solution of the present invention will be further described in detail through the drawings and examples below, however, the present invention is not limited to these examples.

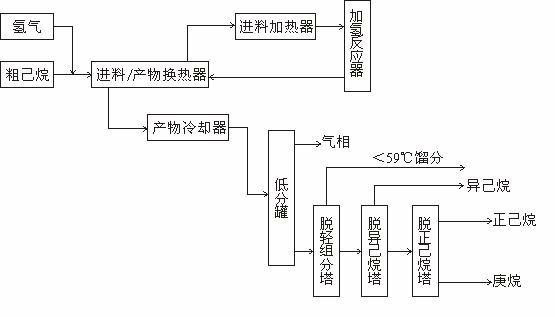

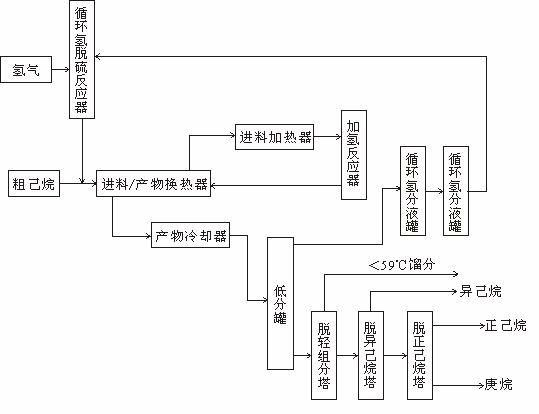

[0025] Such as figure 1 Shown, the present invention extracts the processing method of normal hexane, isohexane by crude hexane, and its concrete processing steps are:

[0026] (1) The catalyst loaded in the hydrogenation reactor is an active metal nickel-based catalyst with a spherical appearance, a diameter of 2.5~4.5mm, and a bulk density of 0.6±0.02 g / cm 3 , the specific surface area is not less than 100m 2 / g, the radial compressive strength is not more than 40N / grain; the raw material crude hexane is mixed with hydrogen, heated to 130-170°C by the feed / product heat exchanger and feed heater, and then enters the hydrogenation reactor. Hydrodearomatization reaction is carried out under the influence of hydrogenation reaction. The operating conditions of hydrogenation reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com