Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54 results about "Glycerine acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

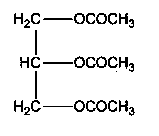

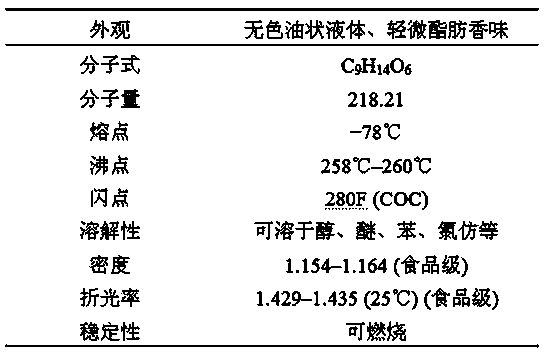

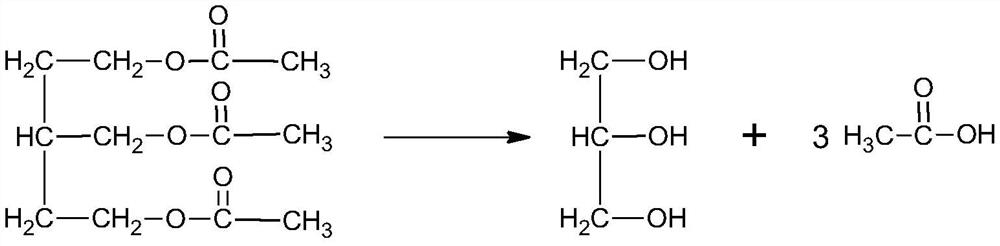

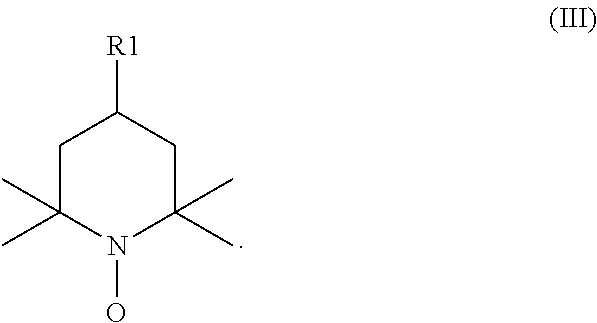

Glycerine acetate is a mixture of esters produced from the esterification of glycerol (1) with acetic acid. Multiple products can be produced from this reaction; these include the monoacetylglycerols (MAG, 2 and 3), diacetylglycerols (DAG, 4 and 5), and triacetalglycerol (TAG, triacetin, 6).

Method for producing triacetin

ActiveCN101450897AWide range of usesReduce usagePreparation by transesterificationMethyl acetateSide reaction

The invention provides a method for preparing acetin. The method comprises that: in the presence of alkali catalyst, grease reacts with acetate, and acetin and fatty acid ester are collected. The method has the advantages of: (1), producing the acetin directly by using the grease and the acetate, generating little side reaction, achieving high product quality and widely used by products; 2, avoiding using acetic acid and acid catalyst, solving the problem of serious corrosion existing in the conventional process and lowering requirements on equipment material and operation and maintenance costs; and 3, enlarging the application range of methyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

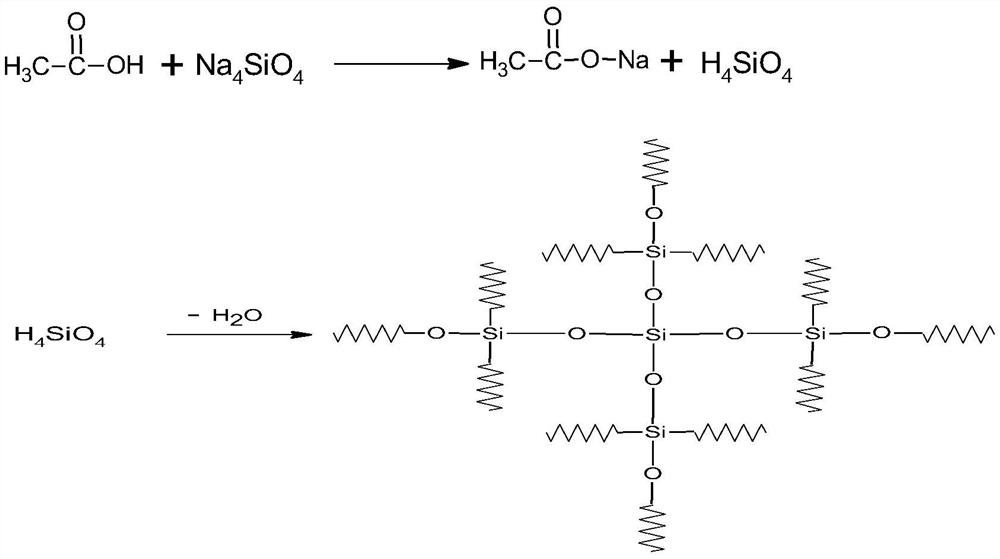

Water glass-triacetyl glycerine grouting material and preparation method thereof

ActiveCN101597497AHigh compressive strengthImprove permeabilityBuilding constructionsOrganic fertilisersGlyceryl triacetateGroundwater

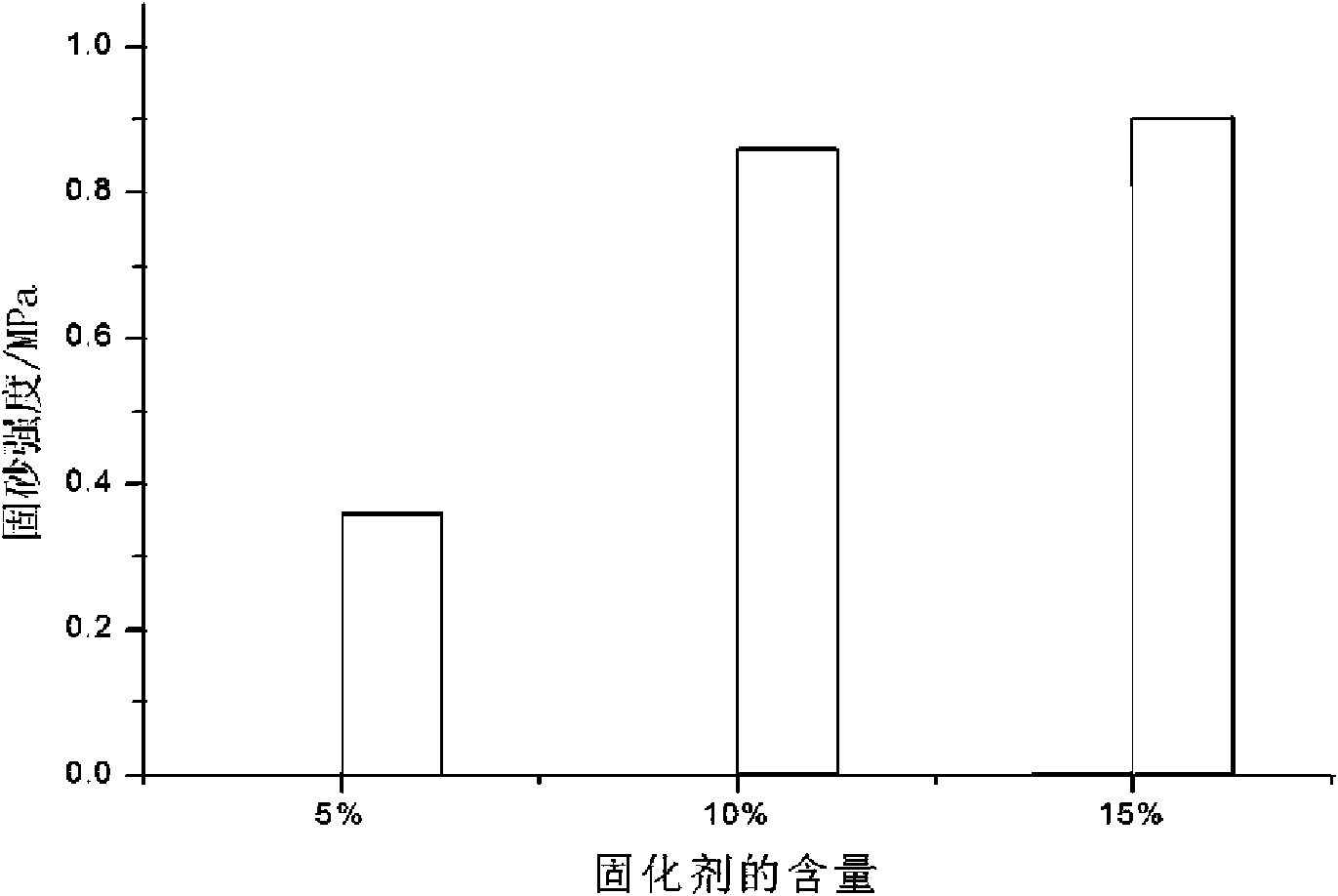

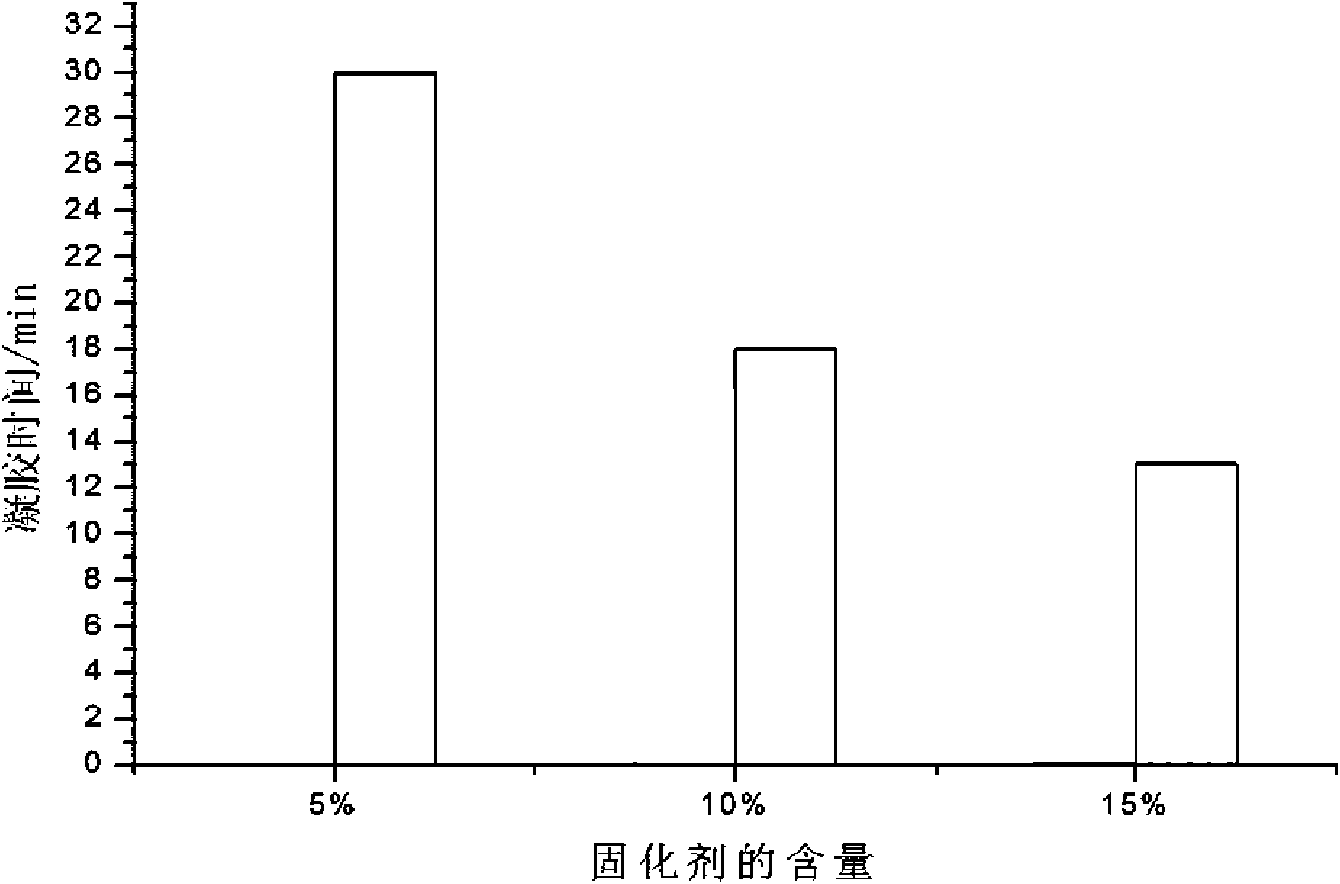

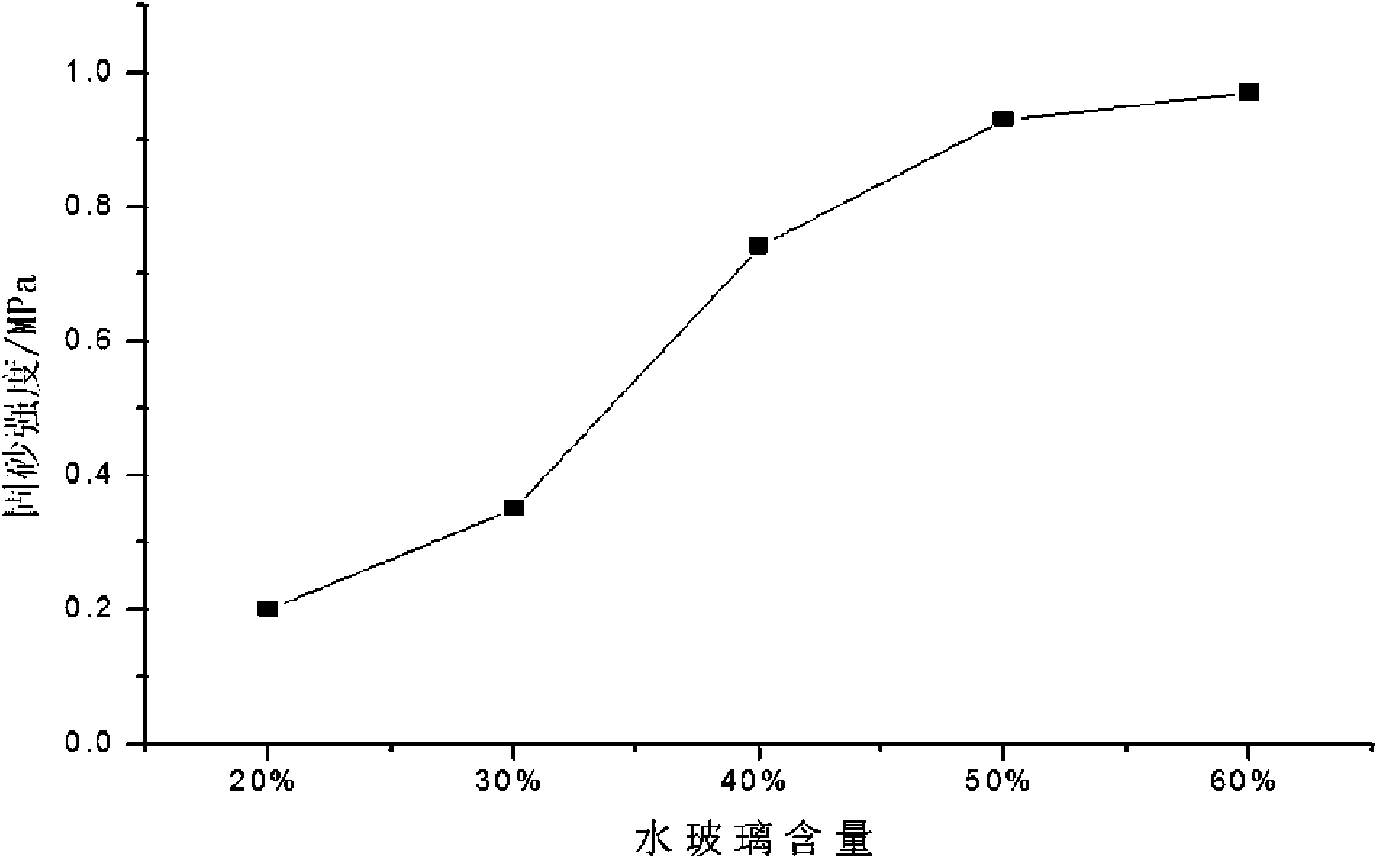

The invention discloses a water glass grouting material for reinforcing fine sand, which is prepared by taking water glass as a main material, taking a curing agent, a catalyst and a surfactant as auxiliary materials, and is prepared from the following compositions in portion by weight: 100 portions of water, 40 to 75 portions of water glass, 3 to 15 portions of curing agent, namely triacetyl glycerine, 0.05 to 0.5 portion of catalyst, and 0.5 to 2 portions of surfactant. The sand consolidation strength of the grouting material can reach 1.2MPa, the curing time is 30min or so, and the grouting material solves the technical problem that the reinforcement of the fine sand by the water glass has low strength and unsteady permeability and pollutes underground water. The permeation radius can reach 50cm when compact fine powder is grouted under the grouting pressure of between 0.3 and 0.5MPa, and the grouting material is suitable for pre-consolidating fine sand layers during the construction of underground engineering.

Owner:BEIJING MUNICIPAL ENG RES INST

Preparation method of conjugated linoleic acid glycerides

ActiveCN102584586ANo smellNo residuePreparation by transesterificationNatural resourcePotassium ethoxide

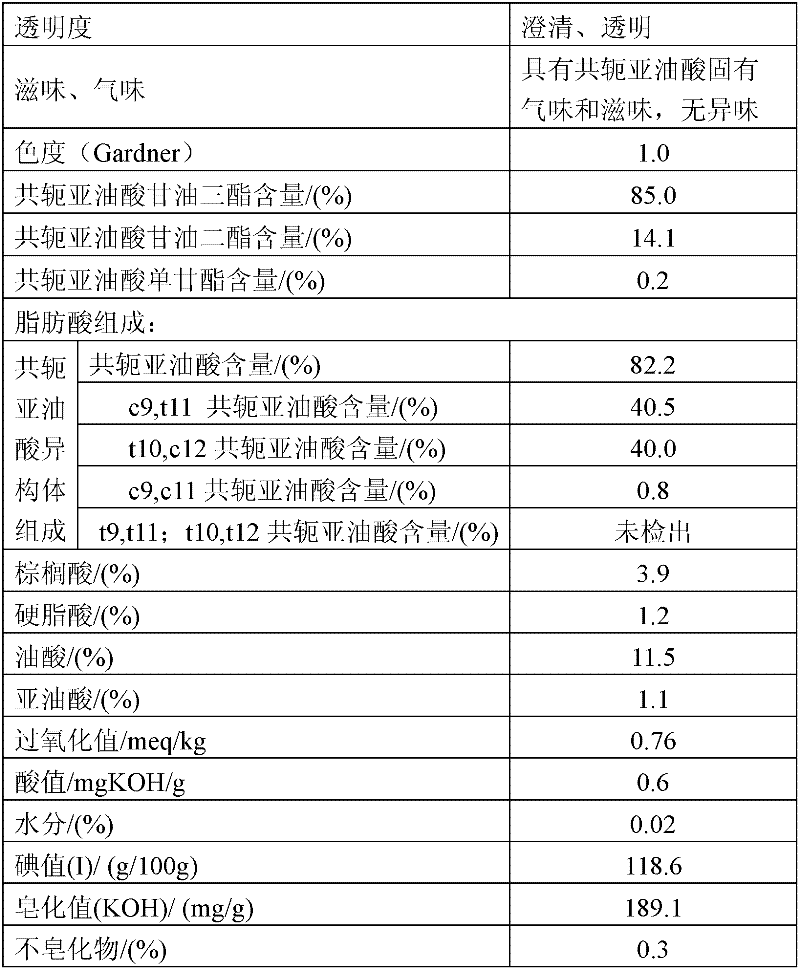

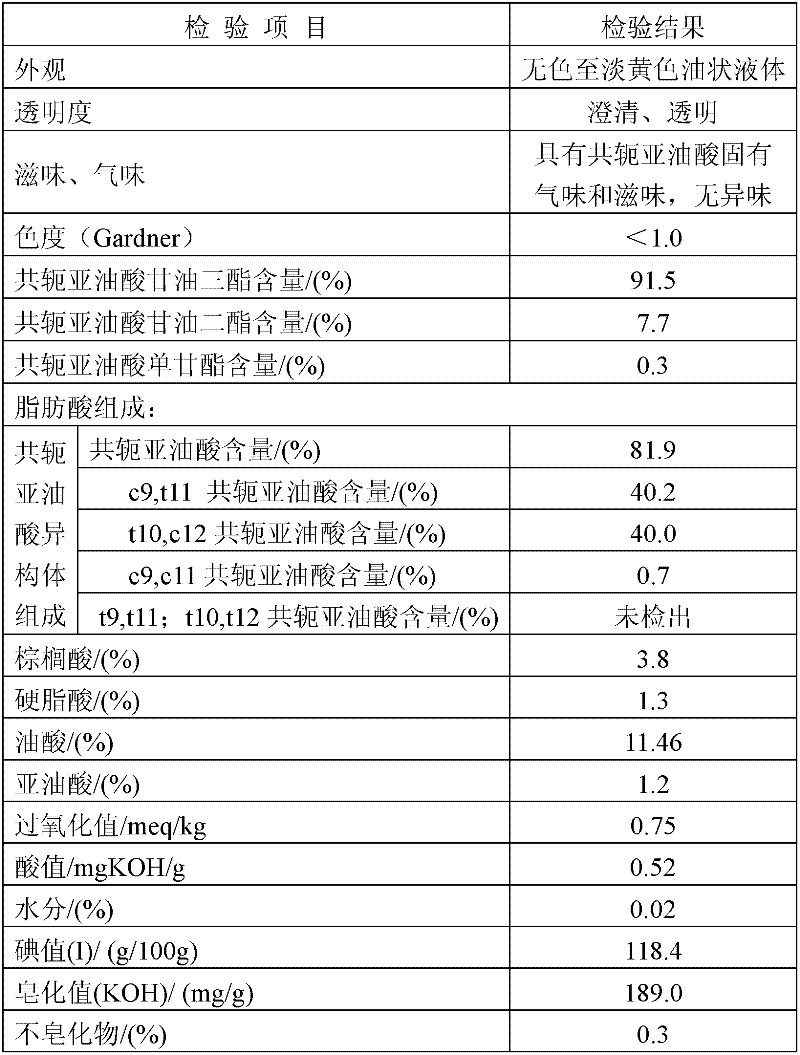

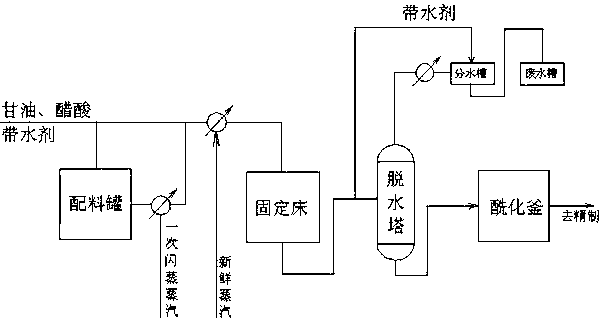

A preparation method of conjugated linoleic acid glycerides comprises the following steps: (1) C1-4 sodium alcoholate / potassium alcoholate is taken as a catalyst, linoleic acid short-chain alcohol ester is prepared to be conjugated linoleic acid short-chain alcohol ester through inversion reaction for 1-8 hours at 90-150 DEG C, and the using amount of the catalyst is 1.5-8.0% of weight of the linoleic acid short-chain alcohol ester; (2) sodium methylate / potassium methylate and sodium ethoxide / potassium ethoxide are taken as catalysts, the conjugated linoleic acid short-chain alcohol ester and acetoglyceride with mole ratio being 3:1-3.5:1 are reacted for 3-10 hours at 100 DEG C and 170 DEG C to prepare the conjugated linoleic acid glycerides, and the using amount of the catalysts is 0.8-10% of the weight of acetoglyceride. According to the preparation method, the natural resources are utilized sufficiently, an organic solvent is not needed in the main reaction; the esterification rate of conjugated oil acid is more than 99%; the reaction time is short, and the postprocessing simple; the triglyceride content of the conjugated linoleic acid glycerides is more than 90%, and the acid value of the conjugated linoleic acid glycerides is under 1.0mgKOH / g; and the conjugated linoleic acid glycerides is free from extraneous odor, good in taste and light in color, and the optimal Gar is less than or equal to 1.0.

Owner:INNOBIO CORP LTD

Fishy flavor agent for feed and preparation method of fishy flavor agent

The invention discloses a fishy flavor agent for a feed and a preparation method of the fishy flavor agent. The fishy flavor agent contains the following perfume materials in percentage by weight: 0.5-2% of glycine betaine, 1-3% of trimethylamine, 0.1-2% of 2-methyl-3-sulfydrylfuran, 0.1-1% of pyrrolidine, 0.1-1% of piperidine, 0.1-2% of phenylethylamine, 0.01-1% of 2-acetylpyridine, 0.1-1% of furanone, 1-3% of ethyl maltol, 1-3% of 2-acetylpyrazine, 1-3% of 2,3,5-trimethylpyrazine, 0.01-2% of 3-methylthiopropanal, 30-70% of fishy smell reactants and 10-60% of glycerol triacetate. The fishy flavor agent is prepared by carrying out enzymolysis on animal wastes, then adding reducing sugars to carry out Maillard reaction, and then, adding artificial synthetic essence to blend. The fishy flavor agent has the advantages that the animal wastes are reasonably utilized, the preparation process is simple, and the product is strong in fragrance, stable and easy to store.

Owner:成都大帝汉克生物科技有限公司

Inner material capable of improving aroma harmony of Burley tobaccos as well as preparation method and application of inner material

ActiveCN106490667AImprove processing resistanceMask characteristic aromaTobacco preparationAcetic acidSucrose

The invention provides an inner material capable of improving the aroma harmony of Burley tobaccos. The inner material is prepared from a plurality of types of components in percentage by mass: 5%-15% of invert sugar, 5%-10% of glacial acetic acid, 1%-3% of glycerol, 1%-2% of lining undertone essence and 70%-88% of hot water at 60 DEG C, wherein the sum of all the components is 100%. The invert sugar is prepared by adding 50 parts of water into 100 parts of sucrose to prepare a saturated solution, adding citric acid which accounts for 3.0% of the weight of the sucrose and reacting at 80 DEG C-100 DEG C for 2h. According to the formula of the inner material, provided by the invention, the characteristic aroma of the Burley tobaccos is remarkably weakened and is harmonized with the aroma of flue-cured tobaccos, so that the aim of improving the aroma harmony of the Burley tobaccos is realized; and the inner material has stable physical and chemical indexes and high utilization pertinence and can be very conveniently used for a traditional cigarette material liquid applying process.

Owner:HUBEI CHINA TOBACCO IND

Process for combining glycerol triacetate through acid ion liquid catalyst

InactiveCN102675095AStrong catalytic acidityHigh yieldOrganic compound preparationCarboxylic acid esters preparationAcetic anhydridePtru catalyst

The invention relates to a process for combining glycerol triacetate through an acid ion liquid catalyst. The process includes utilizing glycerol, acetic acid, a solvent and the catalyst as raw materials to conduct esterification reaction, then adding acetic anhydride to conduct acylation reaction, separating the solvent with excess acetic acid after the acylation reaction is finished, utilizing the mixture of the solvent and the acetic acid to serve as a raw material of the next batch, separating the mixture of the ion liquid catalyst and a glycerol triacetate product in remainders in a reaction kettle, using the ion liquid catalyst in circulation mode and removing micro acetic acid in glycerol triacetate to produce food-grade glycerol triacetate. Detailed process is shown in an instruction book. The process has the advantages that the ion liquid catalyst does not corrode equipment, and side reactions such as oxidation, carbonization and polymerization caused by a liquid strong acid catalyst are basically removed. The catalyst is repeatedly used, pollution of waste water to environment is removed, and production cost is reduced. Discharge of waste sludge and alkali liquor is removed. The process is short in flow and free of pollutant discharge and achieves clean production process. The yield of the glycerol triacetate is 99%, and acidity of the glycerol triacetate is lower than 0.002%.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

A spice concoction with animal liver aroma and preparation method thereof

ActiveCN102273610ADifficult to saveEasy to storeAnimal feeding stuffAccessory food factorsFuranPyrazine

The invention discloses a perfume concoction with an animal liver fragrance and a preparation method thereof. The perfume concoction comprises: by weight, 1 to 2% of ethyl maltol, 2 to 4% of 2-methyl butyraldehyde, 0.5 to 1% of furanone, 15 to 30% of 4-methyl-5-thiazoleethanol, 0.2 to 0.4% of 2-acetylpyrazine, 1 to 2% of butyric acid, 0.5 to 1% of 2,3,5-trimethylpyrazine, 0.5 to 1% of gamma-butyrolactone, 0.3 to 0.6% of 2,3,5,6-tetramethylpyrazine, 0.2 to 0.4% of 2-acetylthiophene, 0.02 to 0.05% of 2-methyl-3-mercaptofuran, 13 to 40% of glycerol triacetate, and 30 to 50% of liver extract. Theperfume concoction realizes that a substitute of a natural liver fragrance can be utilized as a feed additive to be used in pet feed. The preparation method of the perfume concoction is simple. Perfume materials composing the perfume concoction is safe and is easy for purchase. The fragrance of the perfume concoction is pleasant, stable and true to nature. The perfume concoction is preserved easily under the condition of package encapsulation.

Owner:成都大帝汉克生物科技有限公司

Preparation process and device for glycerol triacetate

ActiveCN103965045ALow reaction temperatureHigh reactivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsO-Phosphoric AcidPtru catalyst

The invention discloses a continuous production technology and production device for producing environmental-friendly and non-toxic glycerol triacetate by catalyzing polyacid intercalated hydrotalcite. The current process of industrially producing the glycerol triacetate by mainly taking sulfuric acid, phosphoric acid and other inorganic liquid acid as catalysts through a batch still has the defects of environment pollution, unsafe production, low production efficiency and the like. According to the preparation process and device disclosed by the invention, green and high-efficiency polyacid intercalated catalysts are selected to replace the sulfuric acid and the phosphoric acid and a fixed bed process is selected for continuous production. The preparation method has the advantages of high catalytic activity as well as favorable selectivity, recycling property and environment friendliness; the production efficiency is greatly increased and the discharge of three wastes is reduced; a solid foundation is laid for green production of the glycerol triacetate and further industrial production practice application.

Owner:JIANGSU RUICHEN CHEM

Sodium silicate-bonded sand for casting and hardening method thereof

PendingCN110653330AReduce in quantityImprove densification performanceFoundry mouldsFoundry coresAluminatePhosphate

The invention discloses sodium silicate-bonded sand for casting and a hardening method thereof, and relates to the technical fields of casting modeling technology and sodium silicate modification. Thesodium silicate-bonded sand for casting comprises the following components: crude sand, sodium silicate, a hardening accelerator and / or a modifier and / or ester, wherein the hardening accelerator is one or more of salt, acid and alcohol; the modifier is one or more of phosphate, aluminate and a hydrophobic agent; and the ester comprises one or more of organic acid ester such as glyceryl diacetate,glyceryl triacetate, glyceryl acetate and the like as well as inorganic acid ester such as dimethyl carbonate, propylene carbonate, glycerol carbonate and the like. By adding the hardening accelerator and the modifier, the amount of the sodium silicate added is reduced, the hardening speed of the sodium silicate-bonded sand is accelerated, the sand mold moisture resistance is improved, and the sand mold collapsibility is improved.

Owner:陈星利

Florfenicol solution and preparation method thereof

InactiveCN102106815AImprove bioavailabilityPromote healthy growthAntibacterial agentsOrganic active ingredientsBlood concentrationEthylic acid

The invention relates to a florfenicol solution and preparation method thereof, wherein the florfenicol solution comprises the following components of: florfenicol, N, N-dimethylformamide (DMF), glycerol triacetate, tween-80 and water; the mass ratio of each component is florfenicol: DMF: glycerol triacetate: tween-80: water = (5-15): (40-60): (10-15): (1-20): 100. The preparation method of the solvent comprises the following steps of: taking 45ml of DMF, adding the DMF into the florfenicol, stirring to be dissolved; then adding glycerol triacetate, stirring to be dissolved, and then adding tween-80, stirring to be dissolved; finally adding water to 100 ml, and stirring until the solution is clear. The florfenicol solution prepared by the method can be dissolved in the water at any proportion; the florfenicol solution greatly improves the bioavailability of the products, and is featured with rapid effect, long effect and high efficiency; and the florfenicol solution can maintain long effective blood concentration in the live stock.

Owner:上海恒丰强生物技术有限公司

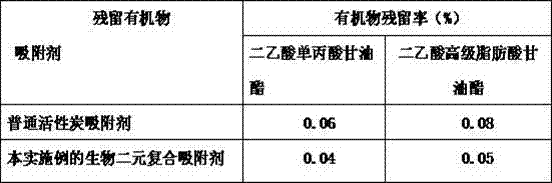

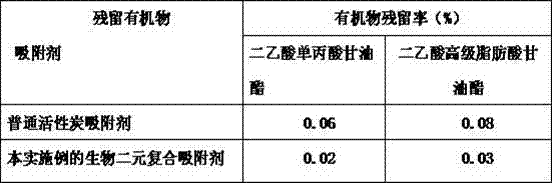

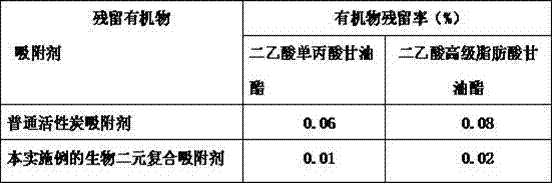

Preparation method of biological binary composite adsorbent in glycerol triacetate refinement process

InactiveCN103877945AImprove featuresIncrease contentOther chemical processesOrganic compound preparationMolecular identificationEthylic acid

The invention provides a preparation method of a biological binary composite adsorbent in a glycerol triacetate refinement process, and aims at overcoming the deficiencies of relatively poor selectivity, easiness in saturation, non-ideal subsequent refinement effect, high use cost and the like due to adoption of single active carbon as an adsorbent for removing residual organic matters in a subsequent process of glycerol triacetate in the prior art. According to the method, the surface of active carbon is grafted and coated with cyclodextrin, so that the content of oxygen-containing groups on the surface of active carbon is increased, the characteristics of active carbon are added, and active carbon can form an inclusion compound and a molecular assembly system together with a large quantity of organic and inorganic molecules under the Van der Waals' force, the hydrophobic interaction force, the effect of matching between molecules of subjective and objective bodies and the like; the enveloping effect of selective combination is commonly known as the molecular identification, and finally a high-efficiency elution effect is achieved.

Owner:云南省玉溪市溶剂厂有限公司

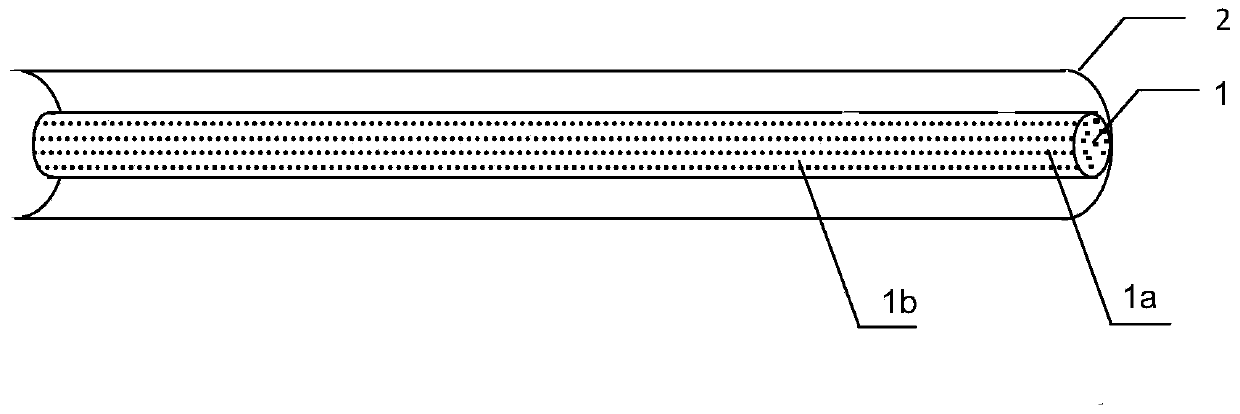

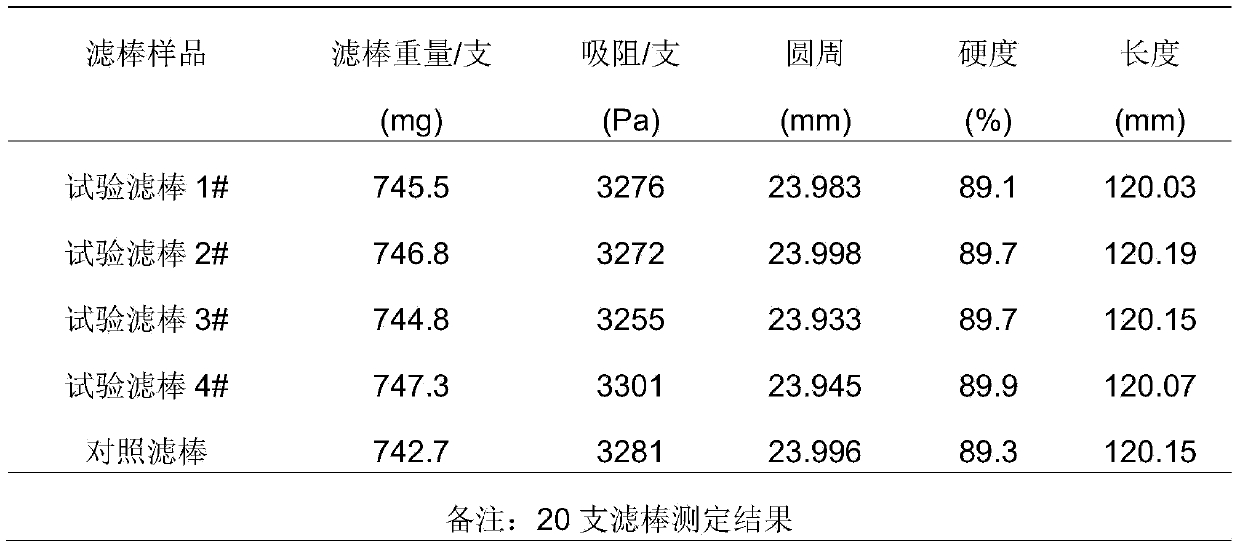

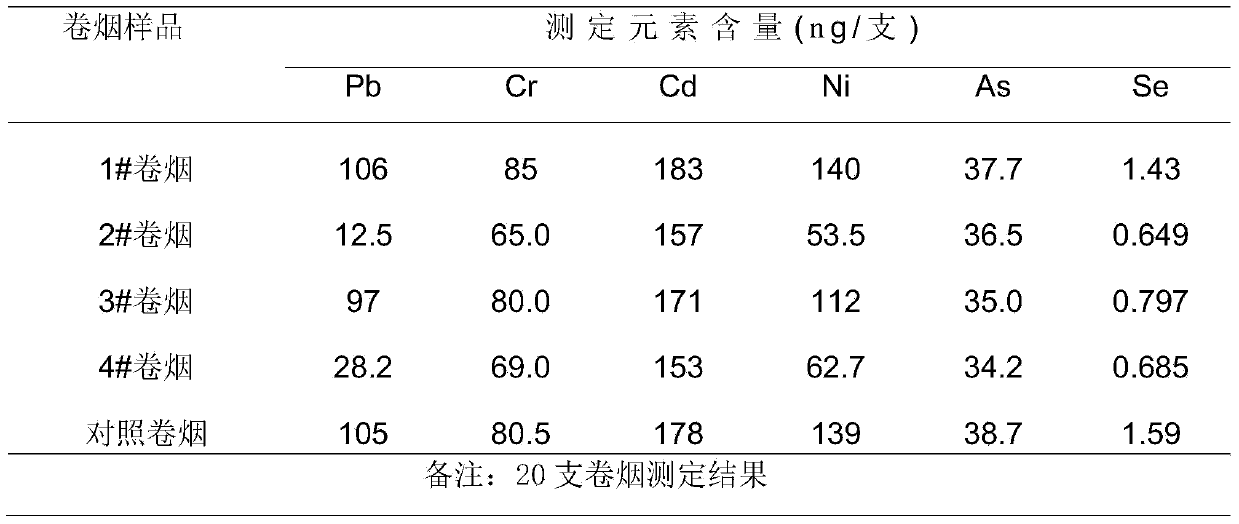

Cigarette filter rod loaded with nano chitosan and preparation method thereof

The invention discloses a cigarette filter rod loaded with nano chitosan. The cigarette filter rod is characterized in that the cigarette filter rod can effectively reduce the content of lead, cadmium, nickel, arsenic, chromium, selenium and other heavy metal in the smoke of a cigarette, and the reducing effect on the three kinds of heavy metal of the lead, the nickel and the selenium is especially obvious. A preparation method of the cigarette filter rod loaded with the nano chitosan is characterized in that firstly, the nano chitosan is scattered into filter rod plasticizer glycerol triacetate, nano chitosan / glycerol triacetate dispersion liquid is formed, and then in the forming process of the filter rod, the dispersion liquid is used as filter plasticizer to be sprayed on a cellulose acetate tow to form the filter rod. The nano chitosan carried by the glycerol triacetate is evenly sprayed on the cellulose acetate tow.

Owner:CHINA TOBACCO GUANGXI IND

Method for preparing cigarette filter with controllable adsorption performance

ActiveCN103190701AControl adsorptionReduce colorTobacco smoke filtersActivated charcoal powderActivated carbon

The invention provides a method for preparing a cigarette filter with a controllable adsorption performance. The research and the application of existing cigarette additives mainly focus on the harm reduction function or the flavoring function, the single function can be implemented easily, and related technologies are mature, however, the research of the two fields tend to extremalization, and certain defects exist. The method comprises the steps of adding 5-20 parts of nano-sized activated carbon powder into 100 parts of glycerol triacetate, and mixing uniformly; preparing materials; and uniformly adding the glycerol triacetate containing activated carbon and the like into tows. According to the method for preparing the cigarette filter, the activated carbon does not react with the glycerol triacetate, the activated carbon is just uniformly dispersed inside the glycerol triacetate, and the effect of the glycerol triacetate serving as a plasticizer is not changed, so that the cigarette filter in which the glycerol triacetate containing the activated carbon is added is high in adsorption performance.

Owner:ENDIAN SCI & TECH DEV OF YUNNAN

Ibuprofen nanoemulsion and preparation method thereof

InactiveCN102091033AImprove bioavailabilityQuick-actingOrganic active ingredientsAntipyreticGlycerolBioavailability

The invention relates to ibuprofen nanoemulsion and a preparation method thereof. The ibuprofen nanoemulsion comprises ibuprofen, glycerol triacetate, Tween-80 and water in a mass ratio of (1-5):(5-15):(10-20):(20-100). The preparation method of the solvent comprises: adding ibuprofen into 10 milliliters of glycerol triacetate, and stirring to dissolve ibuprofen; adding Tween-80, and stirring for 2 minutes to dissolve the Tween-80; and adding water till the total volume is 100 milliliters, and stirring till the solution is clear. The ibuprofen nanoemulsion prepared by the method can dissolve in water according to any ratio, so the biological utilization rate of the product is improved greatly; and the ibuprofen nanoemulsion has the characteristic of instant, long and high effectiveness, and can keep an effective blood medicine concentration for a long time in the bodies of livestock.

Owner:上海恒丰强生物技术有限公司

Organic/inorganic composition for consolidating quicksand and preparation method thereof

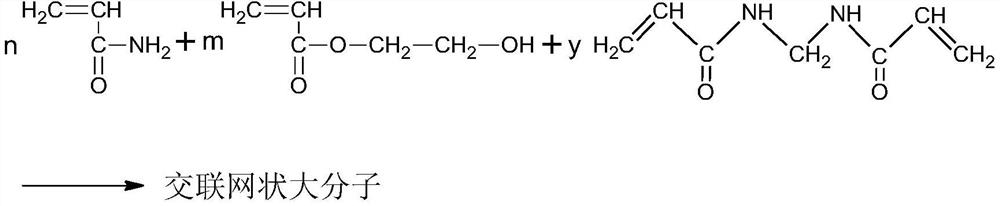

InactiveCN112920806AReduce decreaseAdd lessOther chemical processesBuilding constructionsPolymer scienceMeth-

The invention relates to an organic / inorganic composition for consolidating quicksand and a preparation method thereof. The organic / inorganic composition comprises the following components: a component A, which comprises hydroxyethyl acrylate, acrylamide, N,N-methylene bisacrylamide, triethanolamine, glycerol triacetate and water; and a component B, which comprises water glass, an initiator, water and an emulsifier. The preparation method comprises the following steps: preparation of a composition A: dissolving acrylamide and N,N-methylene bisacrylamide into water, adding hydroxyethyl acrylate, triethanolamine and glycerol triacetate into the water after acrylamide and N,N-methylene bisacrylamide are completely dissolved, and uniformly stirring to obtain the composition A; preparation of the composition B: dissolving an initiator and an emulsifier in water to form a mixture dissolving solution, and adding the mixture dissolving solution into water glass to obtain the composition B; and mixing the composition A and the composition B through a grouting machine at the temperature of 10-25 DEG C and then injecting into quicksand. The mixture solution is forcibly diffused, permeated, reacted and solidified, and then the quicksand can be consolidated. The composition is nontoxic or is low in toxicity.

Owner:山西凝固力新型材料股份有限公司

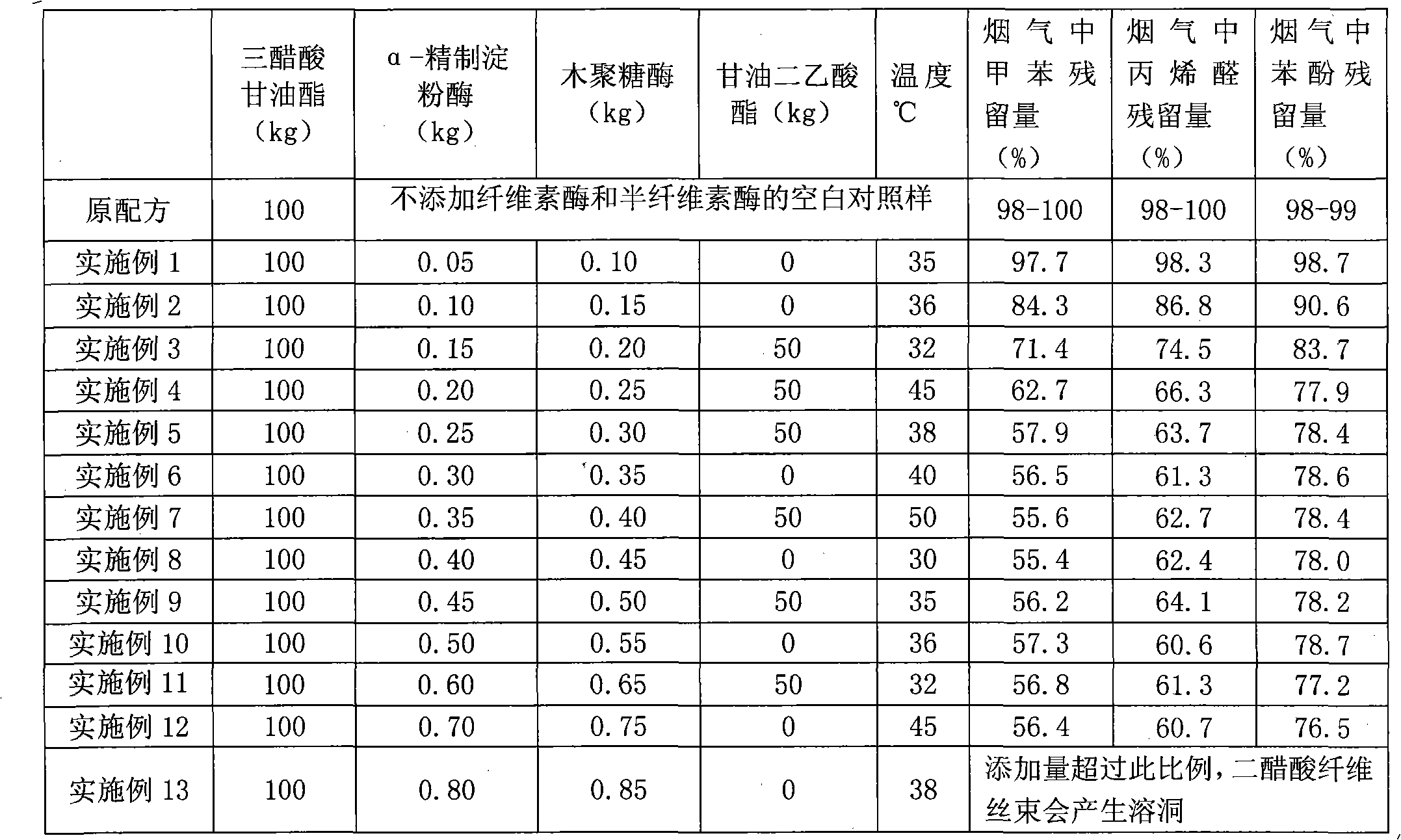

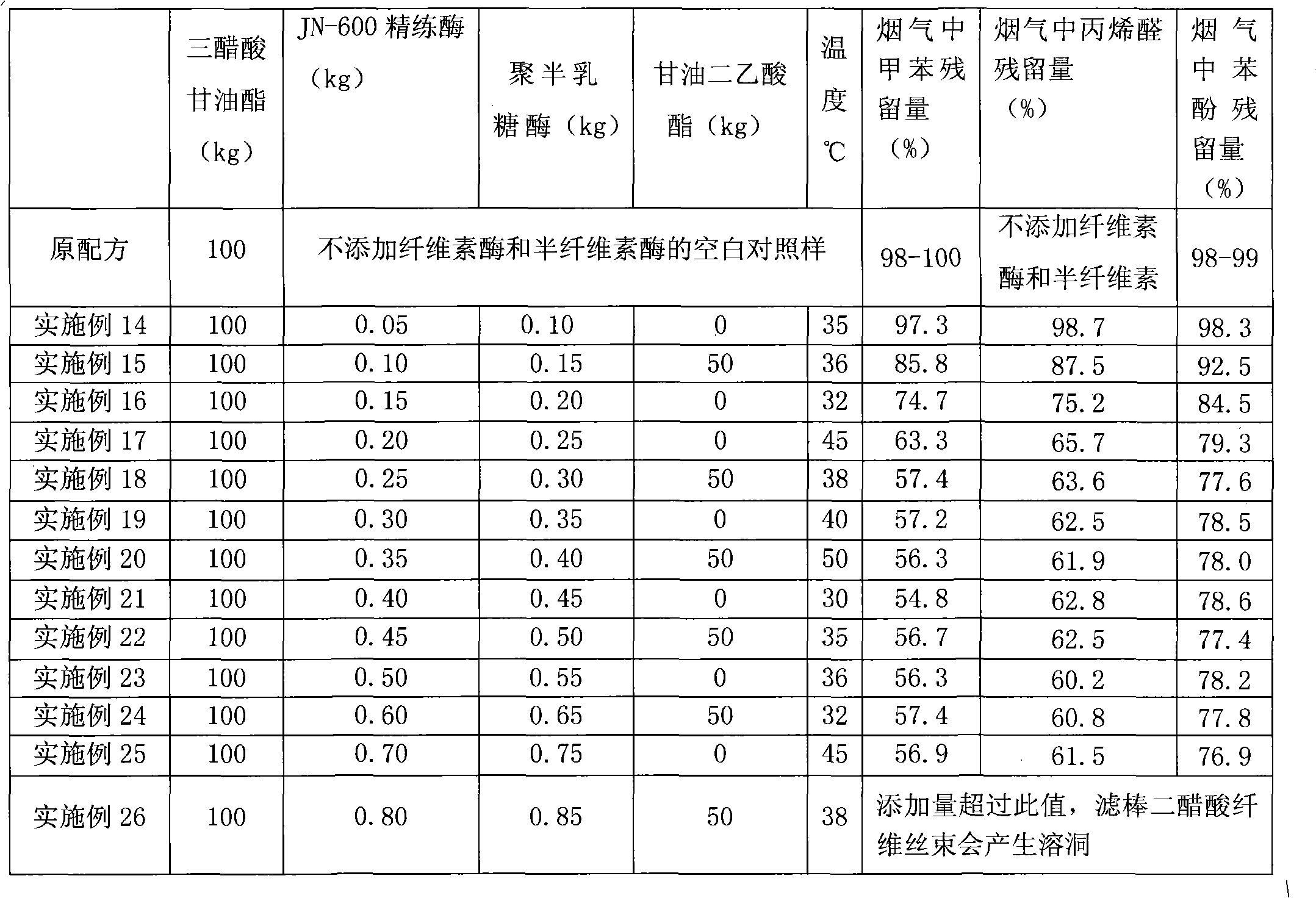

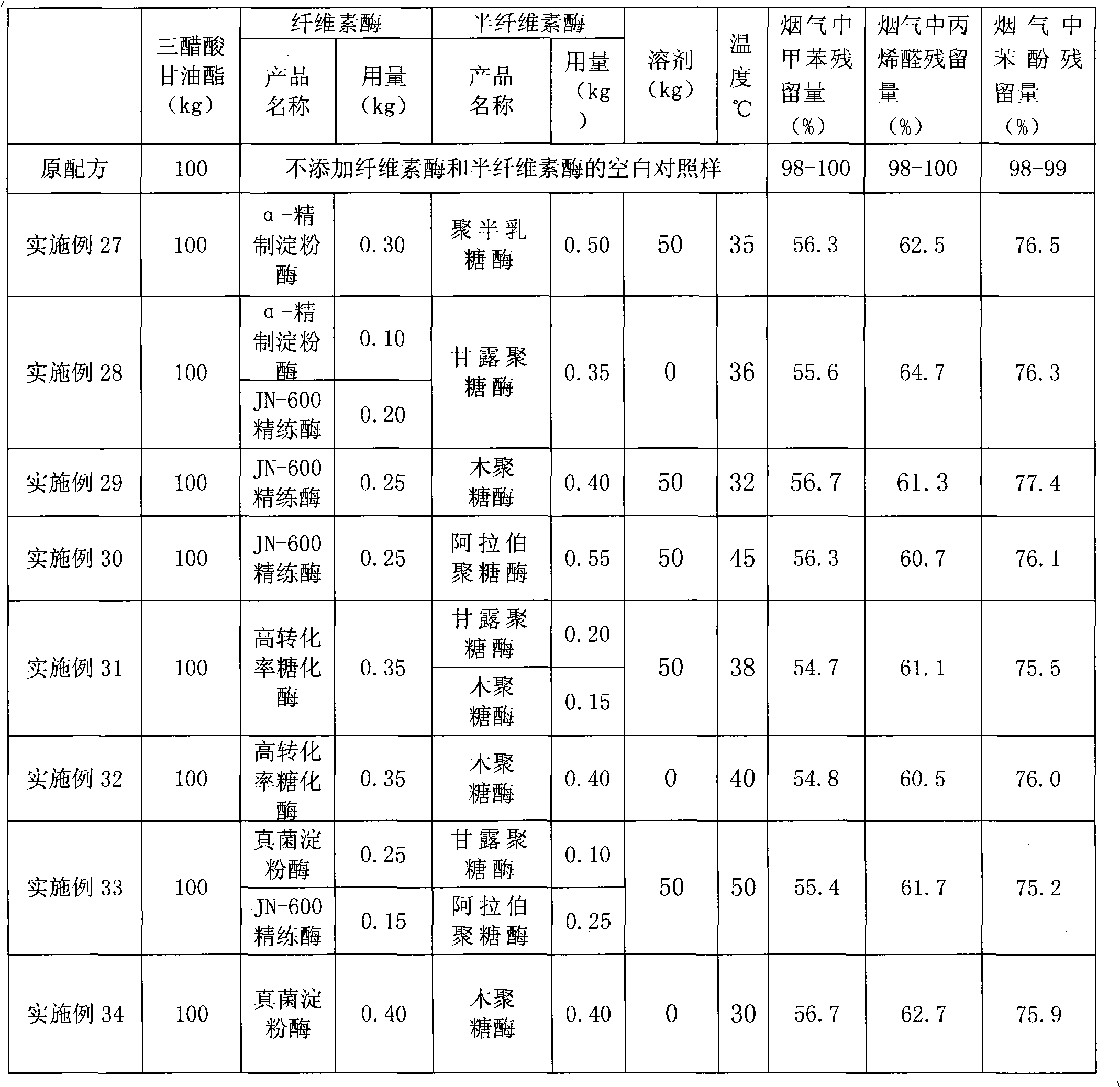

Production method of plasticiser capable of improving cigarette filter stick filtering effectiveness and suction quality

ActiveCN101486802BWon't change propertiesEnsure food safety and hygieneTobacco smoke filtersBenzenePlasticizer

The invention discloses a method for producing a plasticizer which can improve the filtration efficiency and the pumping quality of a cigarette filter rod; the plasticizer which is produced by the method can cause the cigarette filter rod to enhance the capacity to filter harmful substances, so the harmful components of aldehyde, benzene, and phenol in the cigarette mainstream smoke are significantly reduced, and the pumping quality of the cigarette is improved. The purpose is achieved by the following technical proposal: A. glyceryl triacetate is heated; when the temperature reaches 30-50 DEG C, cellulase and hemicellulase are added into the glyceryl triacetate; in accordance with the part by weight, the cellulase / glyceryl triacetate is less than 0.008, and the hemicellulase / glyceryl triacetate is less than 0.0085; B. the temperature is maintained at 30-50 DEG C, and then stirring is carried out to the mixture until the cellulase and hemicellulase are completely dissolved; and C. thestirring is stopped; and after the bubbles are completely dispersed, when the mixture has no small particles and other fine impurities by observation, the dissolution is completed, and then heat preservation is stopped, and finally the mixture is cooled to room temperature.

Owner:云南省玉溪市溶剂厂有限公司

Glycerol acetate plasticizer for PVC (Polyvinyl Chloride) sheet and method of preparing glycerol acetate plasticizer

The invention relates to a glycerol acetate plasticizer for a PVC (Polyvinyl Chloride) sheet and a method of preparing the glycerol acetate plasticizer. The glycerol acetate plasticizer is prepared from the following components in parts by weight: 100 parts of PVC, 2 parts of an organic tin stabilizer, 40 parts of a glycerol acetate plasticizer, 5 parts of epoxidized soybean oil, 0.4 parts of an internal lubricant and 0.2 parts of an external lubricant, wherein the glycerol acetate plasticizer is a mixture of glycerol triacetate and o-phenyl and p-phenyl plasticizers; 40 parts by weight of the glycerol acetate plasticizer include 20 to 30 parts by weight of the glycerol triacetate and 10 to 20 parts by weight of the o-phenyl and p-phenyl plasticizers. The method of preparing the glycerol acetate plasticizer comprises the four steps of charging, stirring, mixing and sheeting. The glycerol acetate plasticizer for the PVC sheet and the method of preparing the glycerol acetate plasticizer have the advantages that the prepared composite plasticizer is environmentally-friendly and low in toxicity, and a prepared PVC sheet is high in quality, good in elastic performance and resistant to high temperature; moreover, the method is simple, and the process conditions are stable and easy to control, and the process flow is simple and environmentally-friendly, and industrial production is facilitated.

Owner:JIANGSU RUICHEN CHEM

Method for preparing cement grinding aid from leachate

InactiveCN112745051ALow costReduce the amount addedTreatment involving filtrationMultistage water/sewage treatmentEthylic acidPropanediol

The invention belongs to the technical field of cement grinding aid preparation, and particularly relates to a method for preparing a cement grinding aid from a leachate. The method comprises the following steps: S1, adding activated carbon into the landfill leachate, adsorbing peculiar smell in the landfill leachate, decolorizing at the same time, and filtering the activated carbon through a filter screen after no peculiar smell exists in the landfill leachate; S2, adding a treating agent into the landfill leachate, stirring to form a flocculation precipitate, and filtering the flocculation precipitate; S3, adjusting the pH value of the landfill leachate to 9-11 to obtain a modified landfill leachate; and S4, adding the modified landfill leachate, triethanolamine, glycerol triacetate, propylene glycol, triisopropanolamine, sodium silicate and molasses into water, and stirring and mixing to obtain the cement grinding aid. The landfill leachate is used as a main raw material to replace heavy alcohol in the cement grinding aid, and the addition amount of the heavy alcohol is reduced, so that the cost of the cement grinding aid is greatly reduced.

Owner:江苏仁爱建材科技开发有限公司

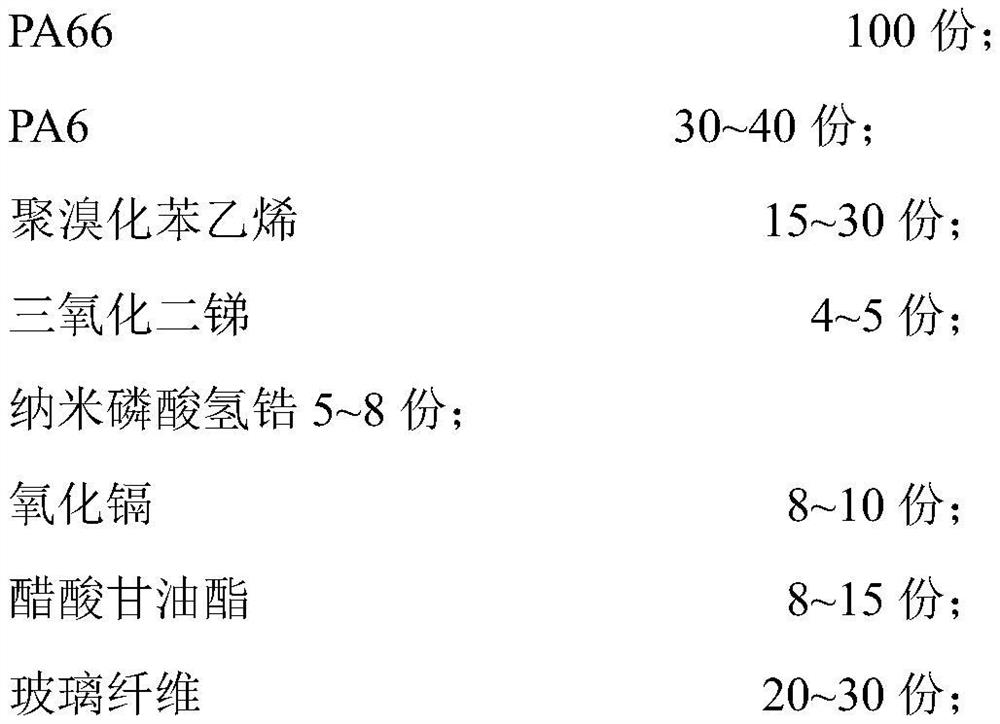

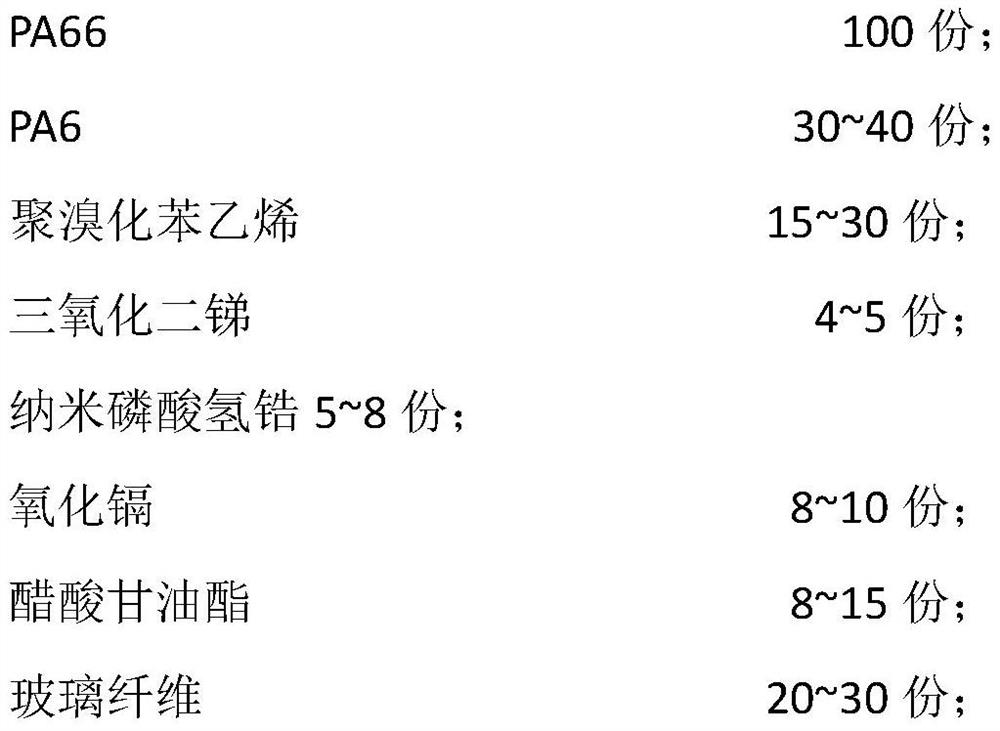

Halogen-containing flame-retardant nylon material with ultrahigh fluidity and high CTI and preparation method thereof

The invention relates to an ultrahigh-fluidity high-CTI halogen-containing flame-retardant nylon material and a preparation method thereof. The ultrahigh-fluidity high-CTI halogen-containing flame-retardant nylon material is prepared from, by weight, 100 parts of PA66, 30-40 parts of PA6, 15-30 parts of polybrominated styrene, 4-5 parts of antimony trioxide, 5-8 parts of nano zirconium hydrogen phosphate, 8-10 parts of cadmium oxide, 8-15 parts of glycerol acetate and 20-30 parts of glass fibers; the preparation method comprises the following steps: weighing the PA66, the PA6, the polybrominated styrene, the antimony trioxide, the zirconium hydrogen phosphate and the cadmium oxide according to the weight ratio, mixing by a high-speed mixer, and adding from a main feeding hole of a double-screw extruder; weighing glass fibers and adding the glass fibers from a fifth section of the double-screw extruder; weighing glycerol acetate, and pumping the glycerol acetate from the seventh section of the double-screw extruder; and finally, extruding and granulating the components by a twin-screw extruder to prepare the halogen-containing flame-retardant nylon material with ultrahigh flowability and high CTI. The halogen-containing flame-retardant nylon material disclosed by the invention has excellent flowing capacity and tracking resistance.

Owner:上海日之升科技有限公司

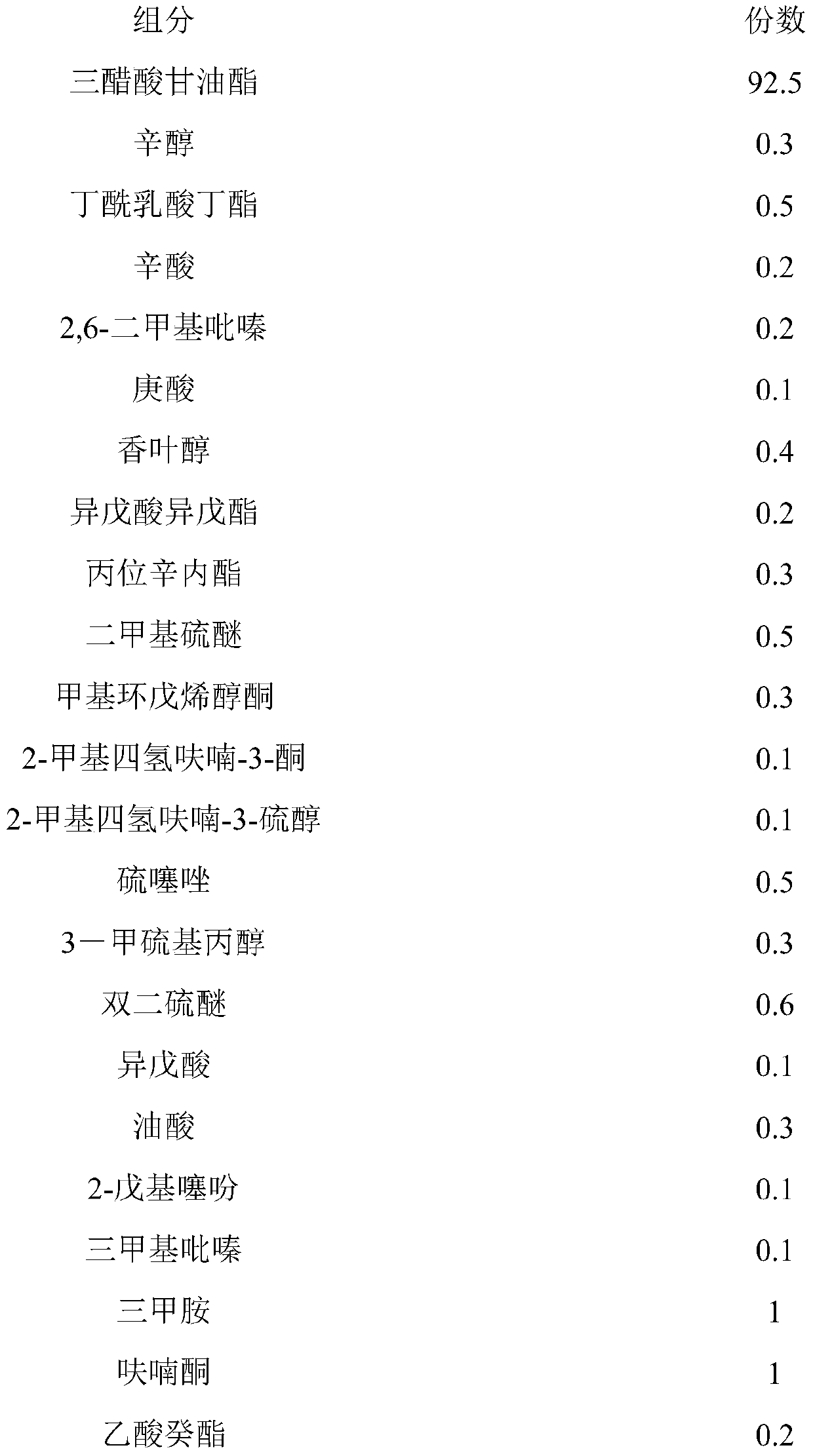

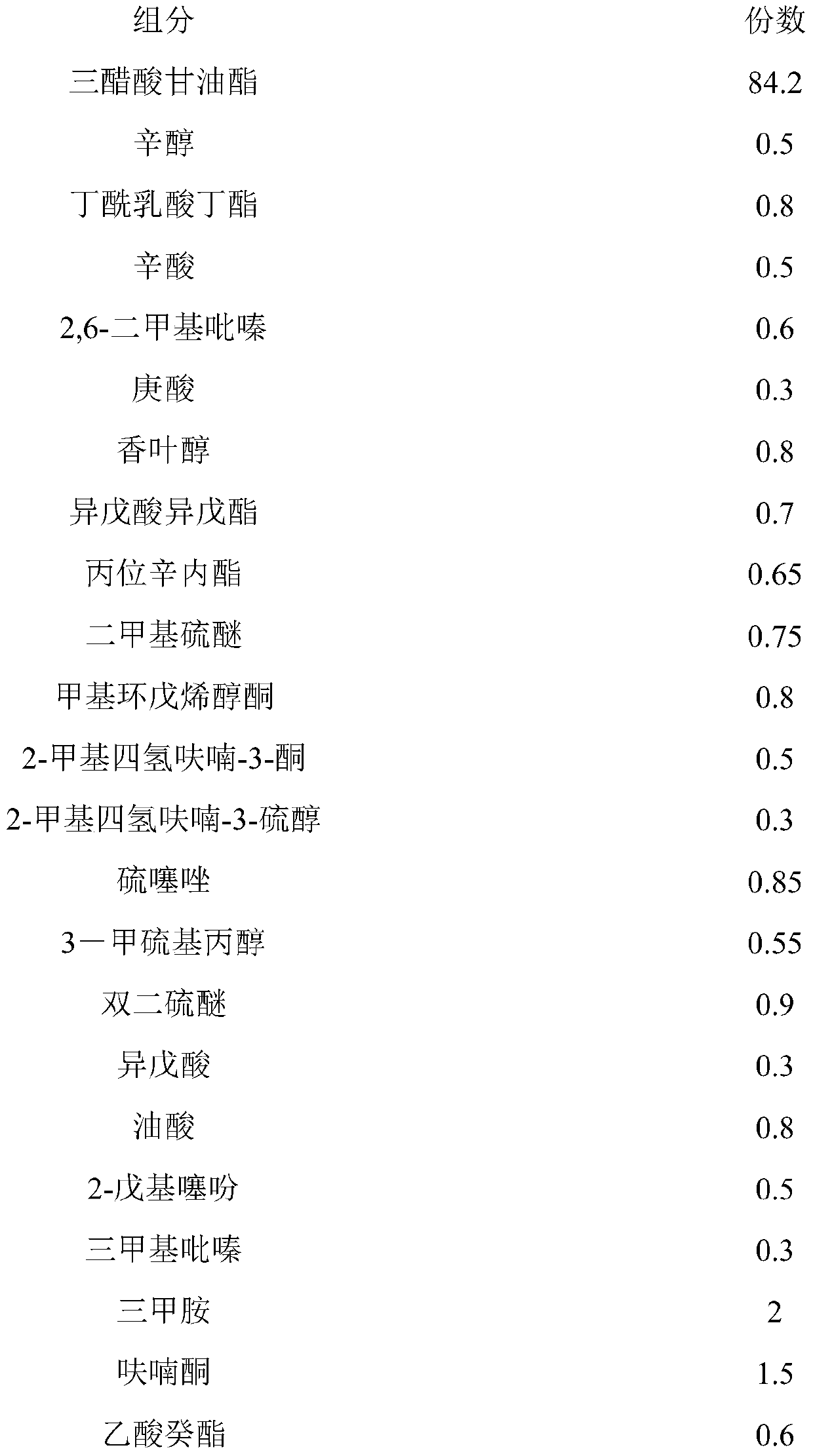

Salmon essence and preparation method and application thereof

The invention discloses a salmon essence and a preparation method and application thereof. The salmon essence comprises the following components: glycerol triacetate, octanol, butyl butyryl lactate, caprylic acid, 2,6-dimethylpyrazine, heptanoic acid, geraniol, isoamyl isovalerate, gamma-octanoic lactone, dimethyl sulfide, methyl cyclopentenolone, 2-methyltetrahydrofuran-3-one, 2-methyltetrahydrofuran-3-mercaptan, 4-methyl-5-beta-hydroxyethyl thiazole, 3-methylthiopropanol, thienyl disulfide, isovaleric acid, oleic acid, 2-pentylthiophene, trimethyl pyrazine, trimethylamine, furanone, decyl acetate and methyl furoate. The salmon essence disclosed by the invention is soft and vivid in fragrance, fresh in taste, lasting in fragrance retention and low in cost.

Owner:GUANGZHOU HUABAO FOOD CO LTD

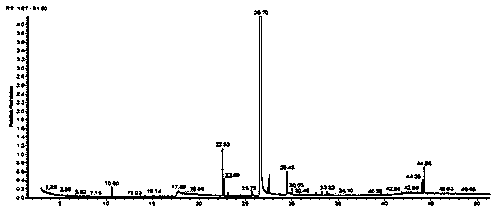

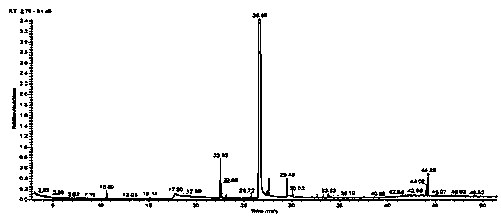

Determination method for content of glycerol monoacetate and glycerol diacetate in glycerol triacetate for cigarettes

ActiveCN107941981AAccurately analyze test resultsAchieving Simultaneous DetectionComponent separationN dimethylformamideGas chromatography–mass spectrometry

The invention provides a determination method for the content of glycerol monoacetate and glycerol diacetate in glycerol triacetate for cigarettes. The determination method comprises the following steps: (1) preparing an internal standard solution; (2) preparing a standard working solution; (3) determining by gas chromatography-mass spectrometry; (4) calculating a determination result of a sample.Aiming at the glycerol triacetate, the invention provides the determination method for analyzing the content of the glycerol monoacetate and the glycerol diacetate in the glycerol triacetate througha chromatographic column with a large pore diameter, a thick liquid film and a high column capacity by taking analytically pure anhydrous N,N-dimethylformamide as a solvent and directly diluting and feeding; the determination method has the advantages of convenience for operation, rapidness and the like.

Owner:HUBEI CHINA TOBACCO IND

Method for preparing water glass self-hardening sand curing agent from glycerol diacetate

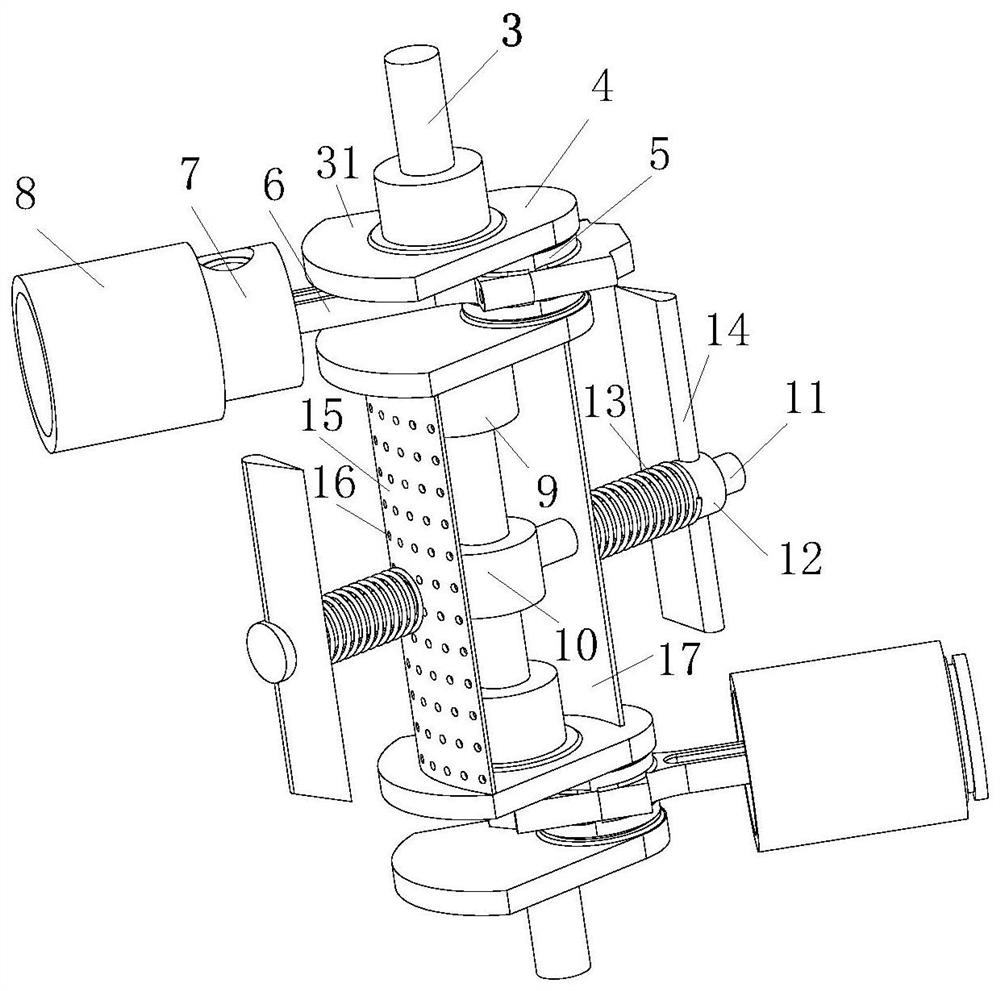

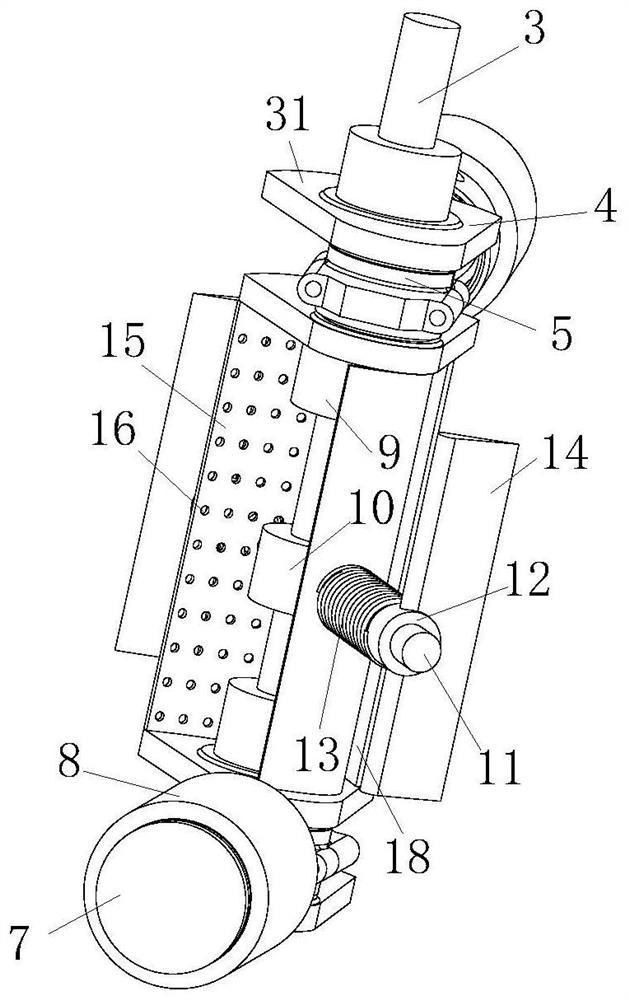

PendingCN113069953AImprove uniformityWell mixedShaking/oscillating/vibrating mixersFlow mixersHydraulic cylinderGlycerol

The invention belongs to the technical field of curing agents, and particularly relates to a method for preparing a water glass self-hardening sand curing agent from glycerol diacetate. A stirring tank used in the method comprises a tank body, a feeding hole in the upper portion of the tank body and a discharging hole in the lower portion of the tank body, wherein a motor is fixedly arranged in the middle of the upper end of the tank body, the output end of the motor is in transmission connection with a first rotating shaft, the first rotating shaft penetrates through the upper end of the tank body, extends into the inner cavity of the tank body and is rotationally connected with the bottom of the inner cavity of the tank body, and a plurality of groups of crankshafts are arranged on the first rotating shaft at intervals. Through the arrangement of the crankshaft, the connecting rod and the hydraulic cylinder, materials flowing in a rotating mode in the tank body can be disturbed, impact dispersion is achieved, the stirring effect is improved, the materials on the inner layer and the outer layer of the tank body are moved to the inner side, and mixing of the materials on the inner layer and the outer layer is accelerated, so that the materials are mixed more sufficiently and are better in uniformity.

Owner:安徽艾蒂贝生物股份有限公司

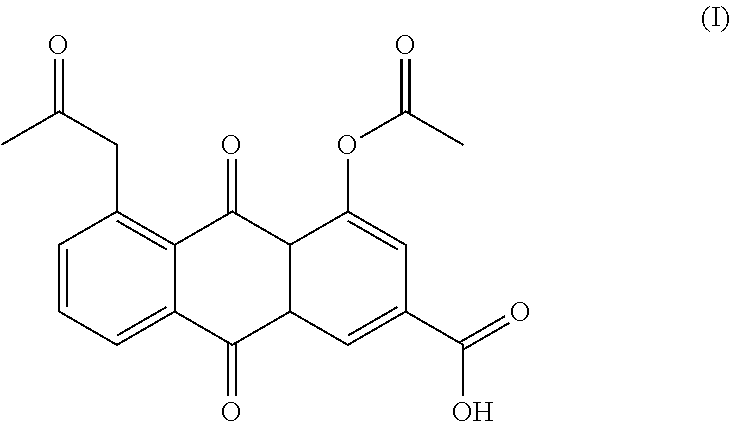

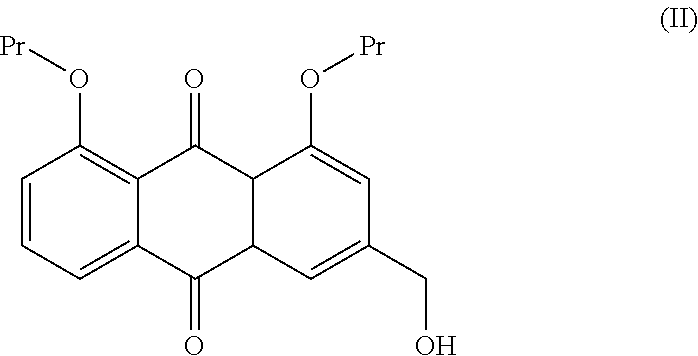

Process for the preparation of diacerin

InactiveUS20110015269A1High purityGood yieldOrganic active ingredientsBiocideOrganic chemistryDiacerein

Owner:LAB CHIM INTERNAZ

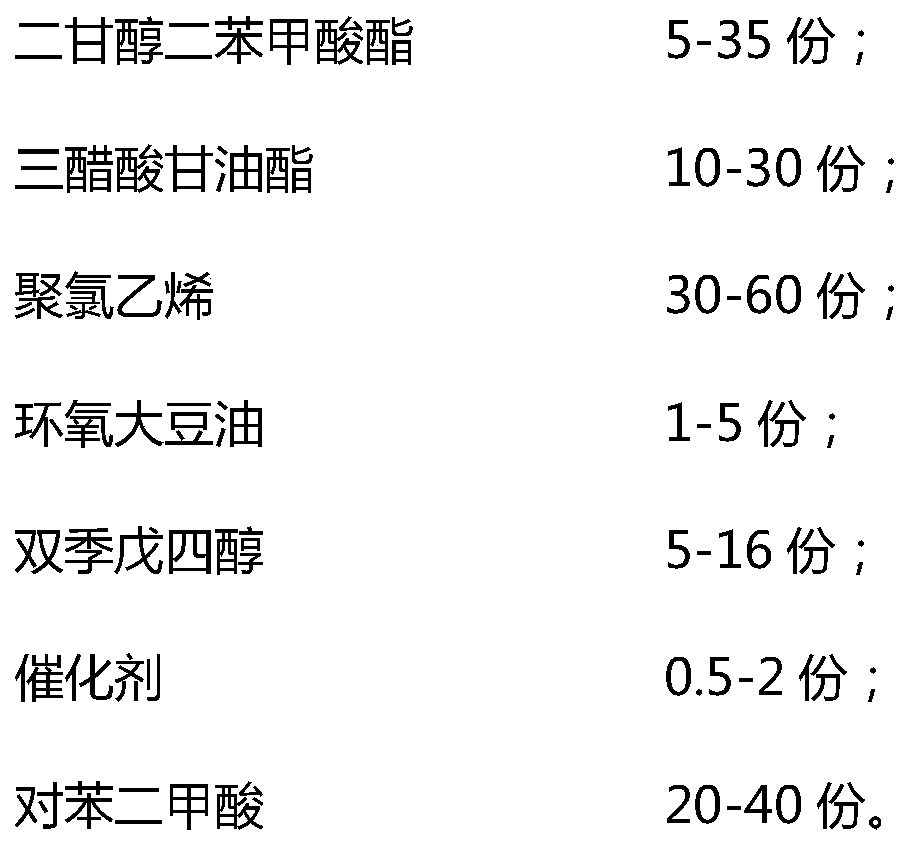

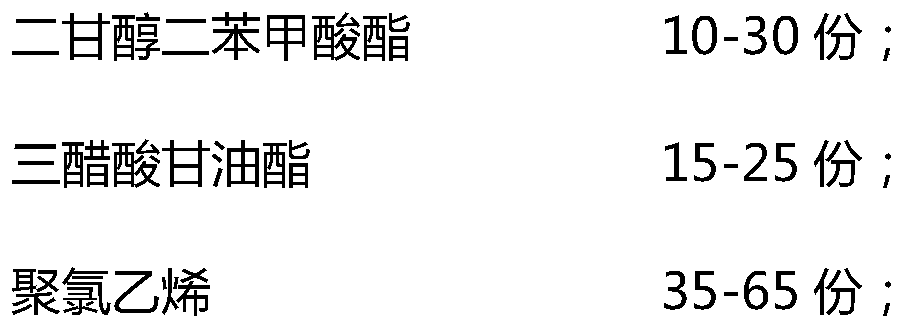

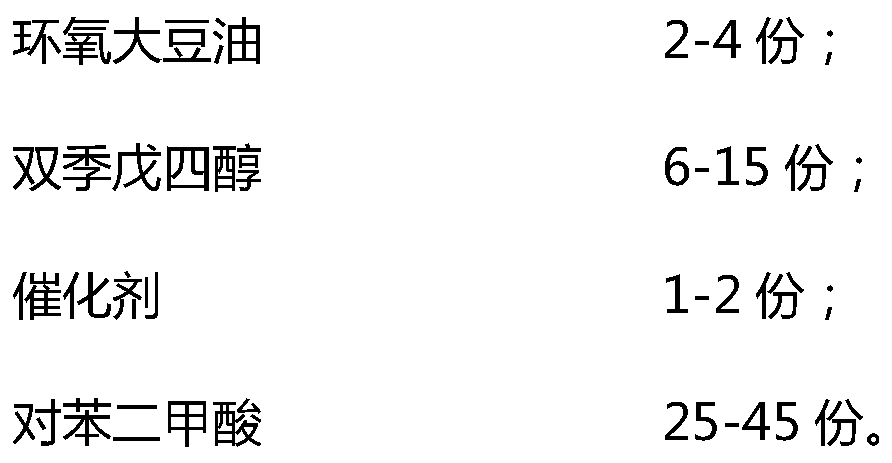

A kind of preparation method of PVC plasticizer

The invention discloses a method for preparing a PVC plasticizer. The method comprises the following steps: (1) firstly, diethylene glycol dibenzoate, dipentaerythritol, a catalyst and terephthalic acid are mixed and uniformly stirred at normal pressure under nitrogen protection condition, and then glycerol triacetate, polyvinyl chloride and the epoxidized soybean oil are continuously stirred under the protection of nitrogen at normal temperature to obtain a mixture; (2) the mixture obtained in the step (1) is mixed to obtain a mixed material; and (3) the mixed material obtained in the step (2) is cooled to room temperature to obtain a finished product. The plasticizer controls the ratio of various components in the preparation process to make the prepared PVC plasticizer have excellent impact resistance, weather resistance and insulation, can be widely used in medical equipment, food packaging, toys, artificial leather and the like, greatly reduces the loss and pollution in the processing of the products, and reduces the cost of the product.

Owner:JIANGSU RUICHEN CHEM

Perfume concoction with animal liver fragrance and preparation method thereof

ActiveCN102273610BDifficult to saveEasy to storeAnimal feeding stuffAccessory food factorsFuranAnimal science

The invention discloses a perfume concoction with an animal liver fragrance and a preparation method thereof. The perfume concoction comprises: by weight, 1 to 2% of ethyl maltol, 2 to 4% of 2-methyl butyraldehyde, 0.5 to 1% of furanone, 15 to 30% of 4-methyl-5-thiazoleethanol, 0.2 to 0.4% of 2-acetylpyrazine, 1 to 2% of butyric acid, 0.5 to 1% of 2,3,5-trimethylpyrazine, 0.5 to 1% of gamma-butyrolactone, 0.3 to 0.6% of 2,3,5,6-tetramethylpyrazine, 0.2 to 0.4% of 2-acetylthiophene, 0.02 to 0.05% of 2-methyl-3-mercaptofuran, 13 to 40% of glycerol triacetate, and 30 to 50% of liver extract. Theperfume concoction realizes that a substitute of a natural liver fragrance can be utilized as a feed additive to be used in pet feed. The preparation method of the perfume concoction is simple. Perfume materials composing the perfume concoction is safe and is easy for purchase. The fragrance of the perfume concoction is pleasant, stable and true to nature. The perfume concoction is preserved easily under the condition of package encapsulation.

Owner:成都大帝汉克生物科技有限公司

Chitosan solution resistant to irradiation degradation and irradiation sterilization method thereof

The invention relates to chitosan, in particular to a chitosan solution resistant to irradiation degradation and an irradiation sterilization method thereof, and belongs to the technical field of biological material processing. The invention discloses a chitosan solution resistant to irradiation degradation, and the solution is characterized in that the solution comprises the following components in percentage by mass: 0.5%-2% of chitosan, 0.25%-1% of glacial acetic acid, 4%-6% of glycerol, 3%-4% of n-butyl alcohol, 0.6%-1% of propylene glycol, and the balance of water. The glycerol, the n-butyl alcohol and the propylene glycol are added into the chitosan solution, so the degradation of chitosan in the irradiation process of the chitosan solution can be reduced, the stability of the chitosan solution is improved, and the film-forming and bacterium-blocking effects of the chitosan solution are improved.

Owner:GUANGZHOU RAINHOME PHARM&TECH CO LTD

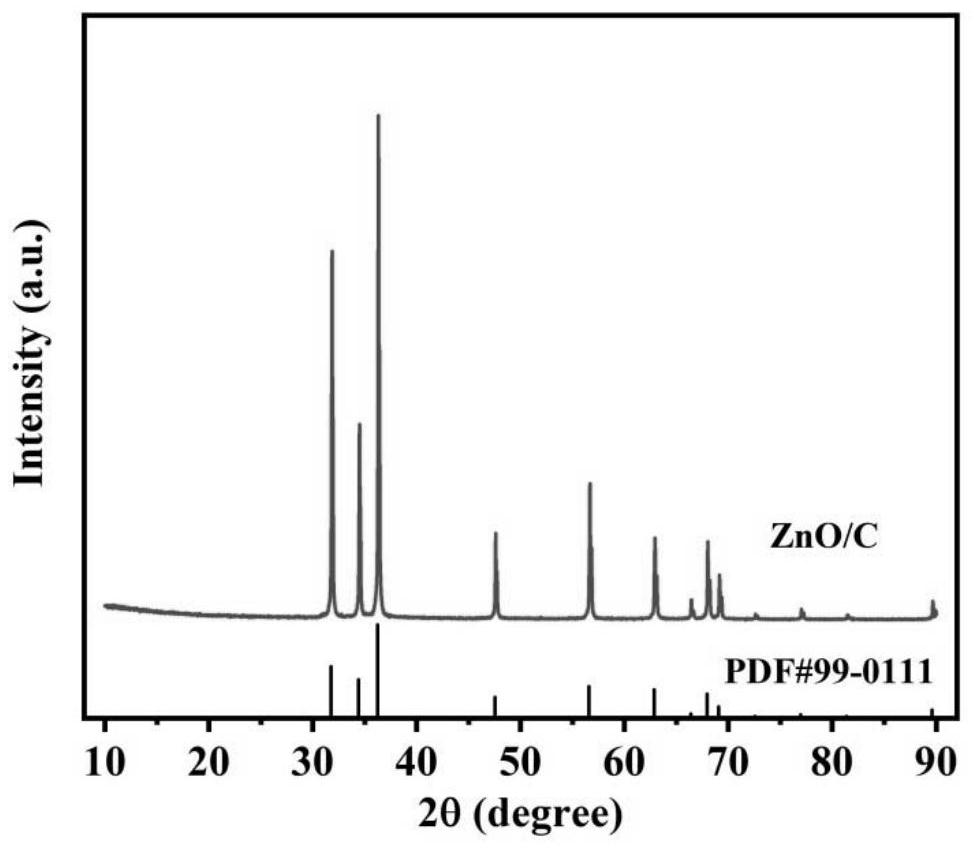

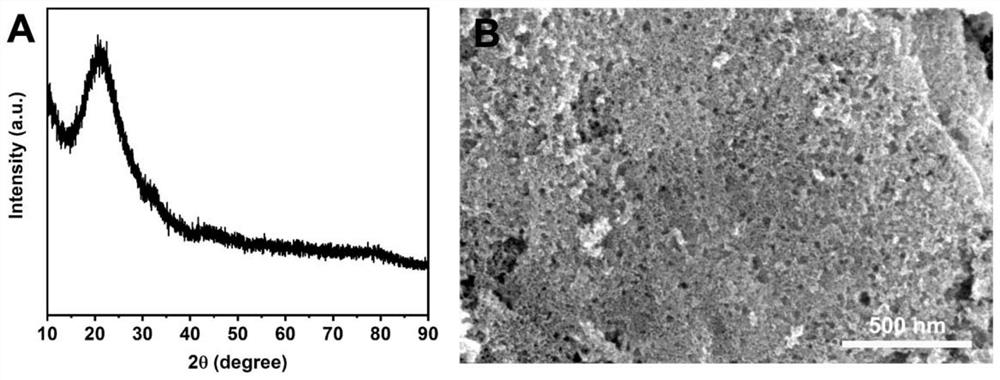

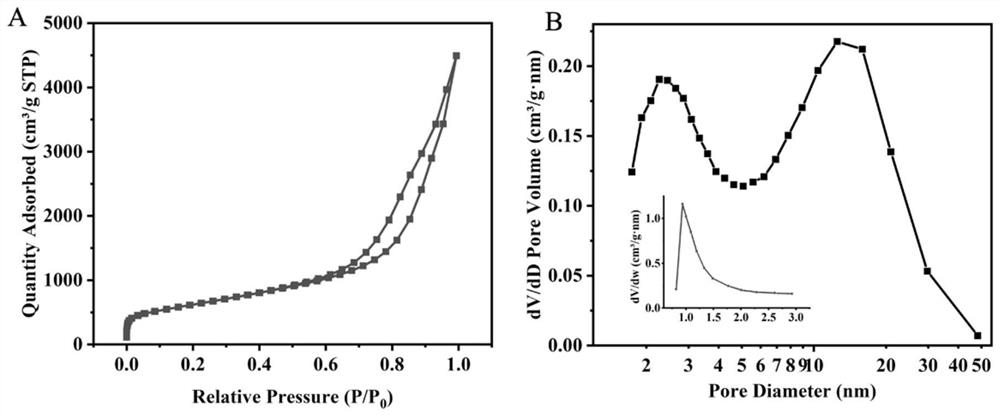

Simple preparation method of honeycomb porous carbon with high specific surface area

ActiveCN111994897ARegular Chemical Structural PropertiesRealize large-scale production applicationsCarbon preparation/purificationPorous carbonEthylic acid

The invention relates to a simple preparation method of honeycomb porous carbon with a high specific surface area. The preparation method comprises the following steps: mixing zinc acetate with glycerol for reaction to obtain an organic complex containing glycerol acetate and zinc glyceroxide; and calcining and cracking the organic complex precipitate containing glycerol acetate and glycerozinc athigh temperature to remove the soft template glycerol acetate, cleaning with dilute acid to remove zinc oxide, and collecting to obtain the honeycomb porous carbon. The method is novel in thought andsimple and convenient to operate, the preparation of the honeycomb porous carbon with the high specific surface area is controllably prepared by an in-situ dual-template strategy through a simple one-step method, and the obtained porous carbon is high in specific surface area and relatively uniform in pore structure.

Owner:XUCHANG UNIV

Ageing resistant furan resin sealing gasket and production method thereof

The invention discloses an ageing resistant furan resin sealing gasket and a production method thereof. The sealing gasket is produced from chlorohydrin rubber, ethylene propylene diene monomer and a modifier, wherein aluminum dihydrogen phosphate added in the invention has high fracture, compression and hydration resistance, and various ageing and wear resistant materials added in the modifier enhance the integral performances of the sealing gasket. A condensation polymerization reaction of active hydrogen, a hydroxymethyl group and a hydroxymethyl group on molecules of furan resin added in the invention and a polymerization reaction of opened double bonds on a furan nucleus are carried out under the catalysis of p-toluenesulfonic acid, methyl sulfate and glyceryl triacetate to form tridimensional network structured solid resin in order to realize hardening molding; and 3-(phenylamino)propyltrimethoxysilane, sulfobutyl ether-beta-cyclodextrin and diethylene glycol diacetate added in the invention reinforce the bonding property between particles and the furan resin, and rock wool, porous aluminum titanate, zircon, cement cinder and other reinforcing agents added in the invention improve the heat ageing cracking resistance, so the casting efficiency is improved, and the casting cost is reduced.

Owner:CHANGZHOU YINGSHUN ELECTRONICS

Method for producing triacetin

ActiveCN101450897BWide range of usesReduce usagePreparation by transesterificationMethyl acetateSide reaction

The invention provides a method for preparing acetin. The method comprises that: in the presence of alkali catalyst, grease reacts with acetate, and acetin and fatty acid ester are collected. The method has the advantages of: (1), producing the acetin directly by using the grease and the acetate, generating little side reaction, achieving high product quality and widely used by products; 2, avoiding using acetic acid and acid catalyst, solving the problem of serious corrosion existing in the conventional process and lowering requirements on equipment material and operation and maintenance costs; and 3, enlarging the application range of methyl acetate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of energy-saving and environment-friendly furan resin casting alcohol-based curing agent

The invention discloses an energy-saving and environment-friendly furan resin casting alcohol-based curing agent which is different from a sulfonic acid curing agent, and methanol, sulfuric acid, propylene carbonate and glycerol acetate are adopted in the preparation process. Higher environmental protection standards can be reached in actual production and application, the curing effect of the furan resin casting adhesive is better, the amount of waste water is reduced, and the body health of workers is effectively protected. The curing agent well solves the problems that an existing sulfonic acid curing agent is long in preparation time, a large amount of waste water is generated, benzene substance residues exist, and the production efficiency and the environment-friendly requirement are not ideal.

Owner:江苏华岗材料科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com