A kind of preparation method of PVC plasticizer

A technology of catalyst and glycerol triacetate, which is applied in the field of plasticizing processing, can solve the problems of plasticizers that have not achieved electrical insulation performance, cannot meet market demand, and poor durability of plasticizers, and achieve improved impact resistance and weather resistance Good effect of improving and plasticizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 A kind of PVC plasticizer and preparation method thereof

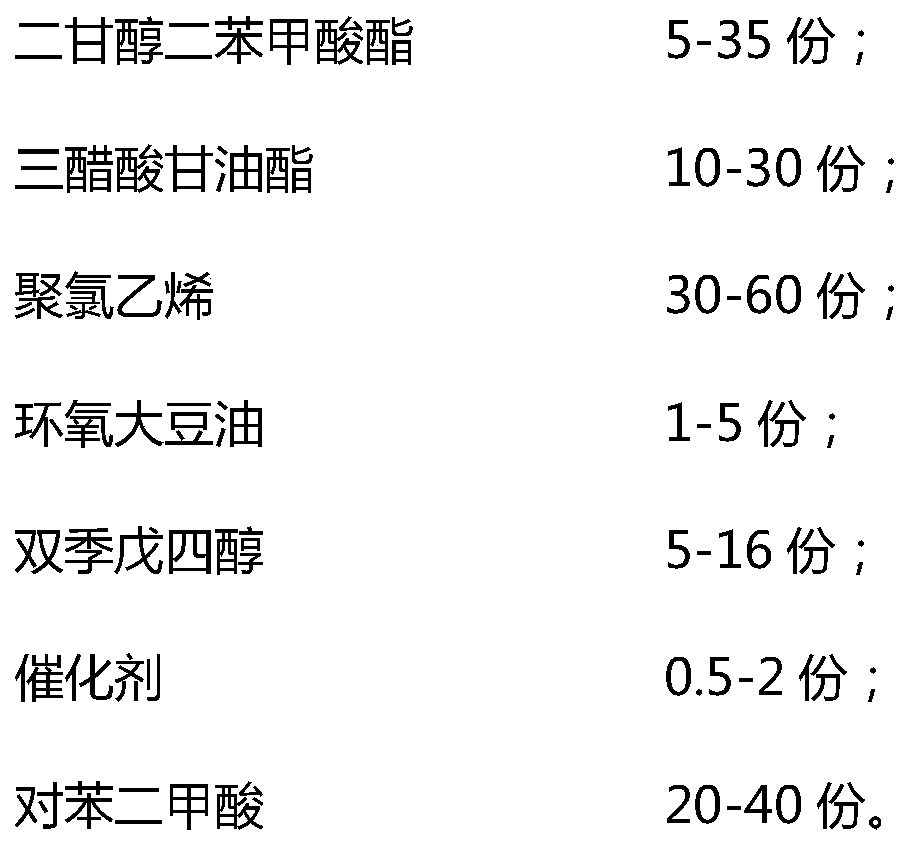

[0044] formula:

[0045] components content Diethylene glycol dibenzoate 10 copies Triacetin 30 copies PVC 35 copies Epoxidized soybean oil 2 copies Dipentaerythritol 5 copies Dibutyltin silicate 0.5 parts Tetra-n-butyl titanate 0.5 parts Terephthalic acid 20 copies

[0046] Preparation:

[0047](1) Diethylene glycol dibenzoate, dipentaerythritol, catalyst and terephthalic acid are mixed and added in the mixer and stirred evenly under normal pressure under the condition of nitrogen protection, the stirring speed is 40r / min, and the stirring time is 20min, Then add glyceryl triacetate, polyvinyl chloride and epoxidized soybean oil into the mixer and continue stirring at room temperature under nitrogen protection, the stirring speed is 40r / min, and the stirring time is 30min, so that the materials are mixed to obtain a mixture;

...

Embodiment 2

[0050] Embodiment 2 A kind of PVC plasticizer and preparation method thereof

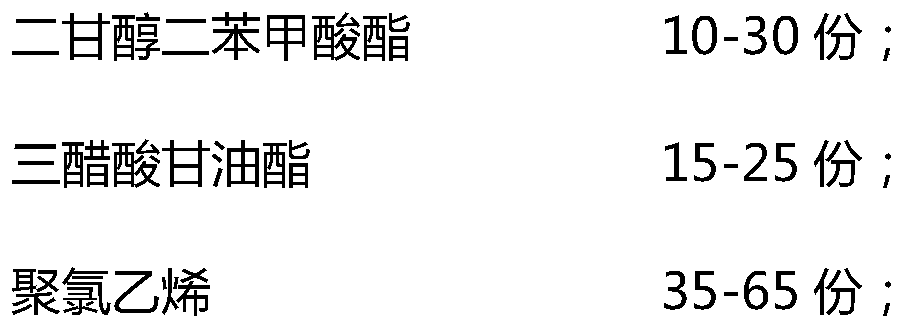

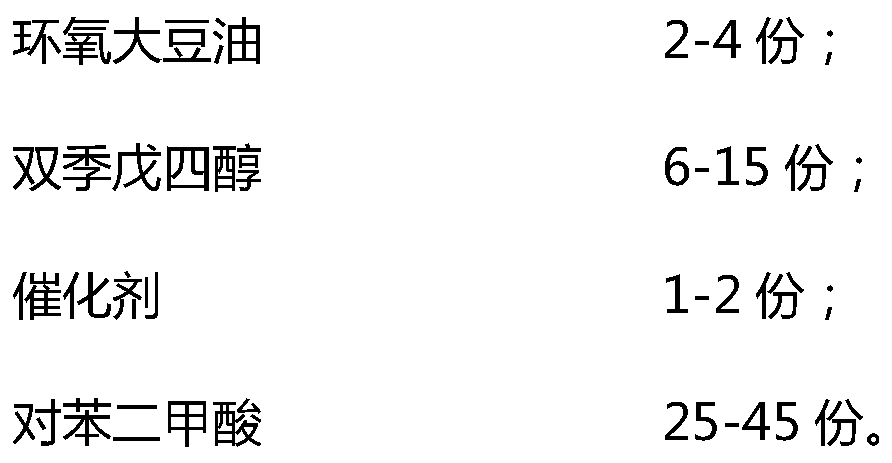

[0051] formula:

[0052]

[0053]

[0054] Preparation:

[0055] (1) Diethylene glycol dibenzoate, dipentaerythritol, catalyst and terephthalic acid are mixed and added in the mixer and stirred evenly under normal pressure under the condition of nitrogen protection, the stirring speed is 50r / min, and the stirring time is 20min, Then add glycerol triacetate, polyvinyl chloride and epoxidized soybean oil into the mixer and continue stirring at room temperature under nitrogen protection, the stirring speed is 50r / min, and the stirring time is 40min, so that the materials are mixed to obtain a mixture;

[0056] (2) Put the mixture obtained in step (1) into a kneader for mixing, the pre-mixing temperature is 165°C, the mixing time is 18min, the post-mixing temperature is 155°C, and the mixing time is 25min, to obtain mixing materials;

[0057] (3) Cool the mixed material obtained in step (2) to ...

Embodiment 3

[0058] Embodiment 3 A kind of PVC plasticizer and preparation method thereof

[0059] formula:

[0060] components content Diethylene glycol dibenzoate 20 copies Triacetin 25 copies PVC 40 copies Epoxidized soybean oil 4 parts Dipentaerythritol 8 servings Dibutyltin silicate 1 copy Tetra-n-butyl titanate 1 copy Terephthalic acid 30 copies

[0061] Preparation:

[0062] (1) Diethylene glycol dibenzoate, dipentaerythritol, catalyst and terephthalic acid are mixed and added in the mixer and stirred evenly under normal pressure under the condition of nitrogen protection, the stirring speed is 60r / min, and the stirring time is 20min, Then add glycerol triacetate, polyvinyl chloride and epoxidized soybean oil into the mixer and continue stirring at room temperature under nitrogen protection, the stirring speed is 50r / min, and the stirring time is 40min, so that the materials are mixed to obtain a mixture;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com