Method for preparing water glass self-hardening sand curing agent from glycerol diacetate

A technology of glycerol diacetate and water glass, applied in chemical instruments and methods, chemical/physical processes, mixers with rotary stirring devices, etc., can solve the effect of uniformity, affect the stirring efficiency, and is not conducive to ensuring the quality of the curing agent And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

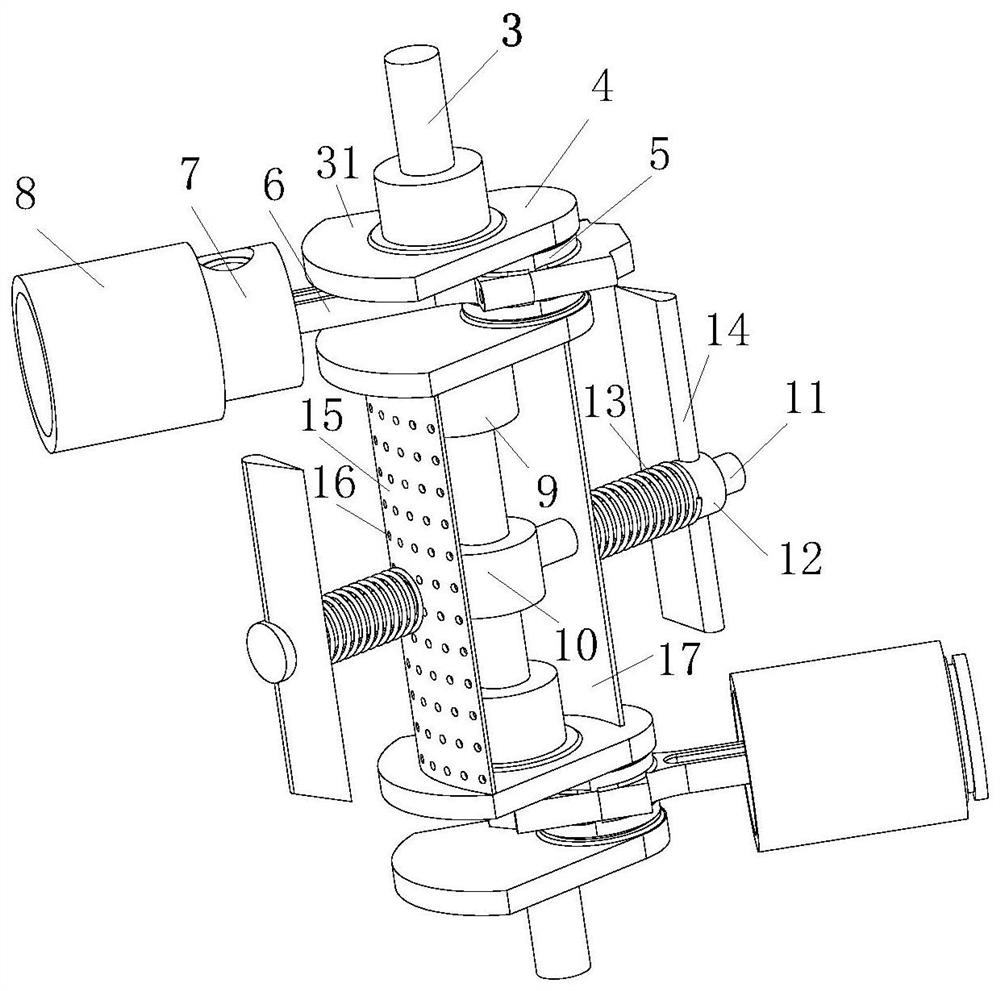

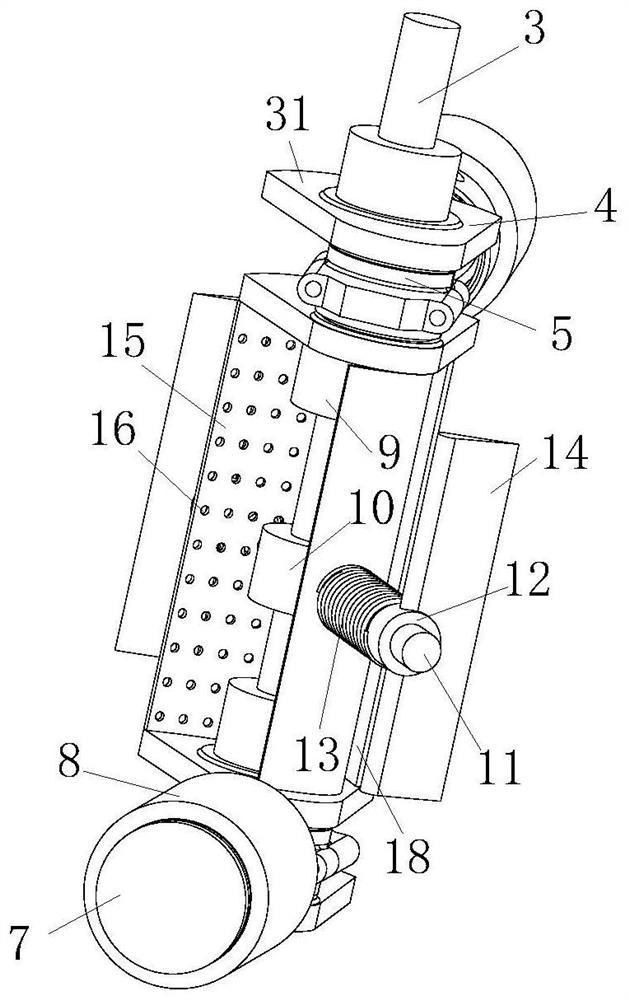

[0037] As an embodiment of the present invention, another communication passage 20 connecting the installation groove 19 and the inner cavity of the tank body 1 is provided in the inner wall of the tank body 1 below the installation groove 19, and the communication passages on both sides of the installation groove 19 20 are all provided with one-way valves 21 with the same flow direction. Through the setting of the one-way valve 21, the material can be sucked in through one communication channel 20 when the piston 7 is pulled out, and then the material can be discharged through another communication channel 20 when the piston 7 is compressed, thus realizing the forced circulation mixing between the upper and lower layers of materials , to avoid delamination that affects the overall stirring effect; at the same time, compared with the use of the water pump in the prior art, the application can realize the circulation of the material in the tank 1 only through the setting of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com