Preparation process and device for glycerol triacetate

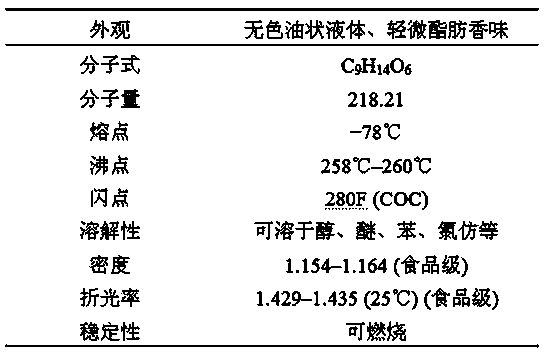

A technology for the preparation of glycerol triacetate, which is applied to the preparation of carboxylic acid esters, the preparation of organic compounds, metal/metal oxide/metal hydroxide catalysts, etc., and can solve the problems of large environmental pollution and strong corrosion of equipment , to achieve high catalytic activity, lower reaction temperature and good reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

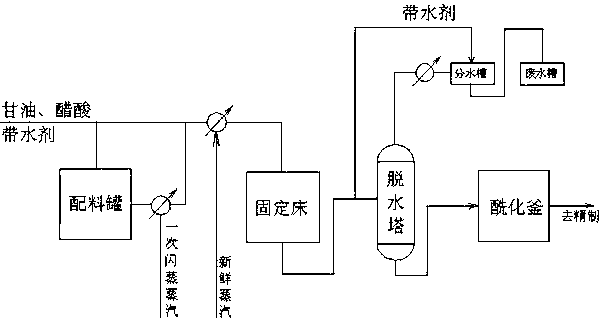

Method used

Image

Examples

Embodiment 1

[0042] Heat glycerin, acetic acid, and water-containing agent to 125°C~135°C, then put the materials into the batching tank at a rate of 300 Kg / h of glycerin, 1000 Kg / h of acetic acid, and 100 Kg / h of water-containing agent, mix well and then circulate The pump is continuously pumped into the fixed bed reactor loaded with 200 Kg of nitrate intercalated magnesium aluminum hydrotalcite catalyst to carry out the esterification reaction; the temperature of the fixed bed reactor is controlled between 130°C and 135°C, and the pressure is controlled at 0.28MPa; The residence time of the material in the fixed-bed reactor is controlled at 24 hours. The material after the esterification reaction enters the dehydration tower for distillation and dehydration. The temperature at the top of the dehydration tower is controlled at 86°C. The raw material is sent to the acylation kettle for acylation reaction at 160°C~180°C, the time is controlled within 1~2h, after the acylation is completed, i...

Embodiment 2

[0045] Heat glycerin, acetic acid, and water-carrying agent through two pipelines to 125°C~135°C, and then put the materials into the batching tank at a rate of 300KG / h glycerin, 1000KG / h acetic acid, and 100KG / h water-carrying agent, mix them evenly and pass through The circulating pump is continuously pumped into the fixed-bed reactor loaded with nitrate-intercalated magnesium-aluminum hydrotalcite catalyst for esterification reaction; the temperature of the fixed-bed reactor is controlled between 120°C and 130°C, and the pressure is controlled at 0.20MPa; The residence time in the fixed-bed reactor is controlled at 20 hours. The material after the esterification reaction enters the dehydration tower for distillation and dehydration. The temperature at the top of the dehydration tower is controlled at 80°C. It is sent to the acylation tank for acylation operation, after the acylation is completed, it is subjected to deacidification, dehydration and other refining processes, a...

Embodiment 3

[0048] Heat glycerin, acetic acid, and water-carrying agent through two pipelines to 125°C~135°C, then put the materials into the batching tank at a rate of 300KG / h glycerin, 900KG / h acetic acid, and 100KG / h water-carrying agent, mix them evenly and pass through The circulating pump is continuously injected into the fixed-bed reactor loaded with multi-acid intercalated hydrotalcite catalyst for esterification reaction; the temperature of the fixed-bed reactor is controlled between 120°C and 130°C, and the pressure is controlled at 0.20MPa; The residence time in the bed reactor is controlled at 20h. The material after the esterification reaction enters the dehydration tower for distillation and dehydration. The temperature at the top of the dehydration tower is controlled at 80°C. Put it into the acylation tank for acylation operation, after the acylation is completed, it will carry out deacidification, dehydration and other refining processes, and finally obtain the finished pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com